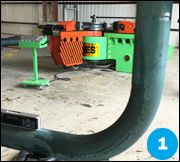

Undoubtedly, the 1200 NC bender is a giant in the manufacturing world for the most difficult of jobs for heavy wall pipe bending.

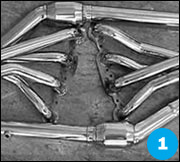

1200 NC Tube Bender Applications

The 1200 NC bender is used largely for pre-insulated piping systems.

If you need a machine or tooling quote, click here.

Return to home page to see additional tube benders.

FEATURES OF THE 1200 NC TUBE BENDER

- Hydraulic Manifolds Interchangeable (Parker, Vickers, etc.)

- Solid Machined Steel Bend Arms

- Easy Touch Screen Operation

- Includes All Die Holders

- Operator Safety Features

- Manifold Style Hydraulic and High Pressure Filter

STANDARD

- Wiper Die Holder

- Overhead Tie Bar (Eliminates Die Deflection)

- Pressure Die Assist

- Pressure Die Assist Rear Support Roller

- Mandrel Rod SAE Thread Supplied (1)

- Mandrel Lubricator

- Mandrel Extractor

- Mandrel Early Out Programmable

- PLC Controller – Mitsubishi FX3U

- Memory Capacity: 100 job storage, 6 bends per part

- Touch Screen (Proface America)

- Tube Piece Counter

- Clockwise Rotation

- Dual Stage Pump Hydraulic System

ADDITIONAL SPECIFICATIONS FOR THE 1200 NC

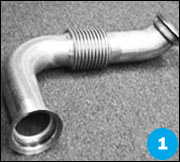

- Capacity: 12” O.D. x .625 Wall

- Standard Maximum Radius: 26 inch

- Maximum Bend Angle: 190 degrees

- Bend Angle Accuracy (+ / -): 0.25 degree

- Bend Arm Speed: 0.4 RPM

- Maximum Tube Length Over Mandrel: 24 feet

- Motor: 130 HP

- Operating Pressure: 2500 psi

- Reservoir Capacity: 450 U.S. Gallons

- Approximate Weight: 200000lbs

- Approximate Dimensions: 36’ L x 19’ W x 9’ H

- Voltage: 440/480/3 Phase/60Hz