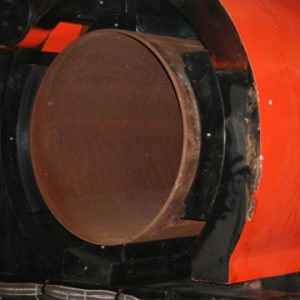

In any economy or budget, this machine will keep you bending for years with every feature you will need to do the jobs that come your way.

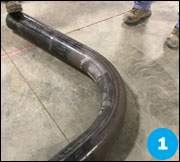

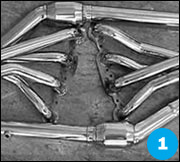

100 CNC-B Tube Bender Applications

The 100 CNC-B bender is employed extensively in the food and beverage, fuel lines and appliance industries. NASA uses a CNC tube bender at its White Sands training facility.

FEATURES OF THE 100 CNC-B TUBE BENDER

- Simple input of machine parameters, DOB, DBB, POB (PLC-FX3U

series Mitsubishi) - Memory capacity: Unlimited

- Operational modes: jog, step and auto

- Self diagnosis: displays of fault source and remedies

- Identification of single bend from multi-bend part.

- Self option carriage use

- Safety auto prevention from bending operation when

last end section is too short - Speed levels of DOB, DBB, and POB: 16 variable settings

- Repeatability precision: DOB/POB: 0.1deg; DBB: 0.1mm

- Resolution: DOB/POB: 0.1deg; DBB: 0.1mm

- Parameter preset resolution: DOB/POB: 0.1deg; DBB: 0.1mm

- Northman Directional Valves

- Preset of processing, i.e., with mandrel or without mandrel,

auto mandrel lubrication, speed levels of DOB, DBB, and

POB / Servo System – Series A, National (Japan)

STANDARD

- Pressure Die Holder

- Wiper Die Holder

- Overhead Tie Bar (Eliminates Die Deflection)

- Pressure Die Assist

- Servo Carriage Boost

- Panasonic Servo Motors

- Mandrel Lubricator

- Mandrel Extractor

- Mandrel Early Out Programmable

- BendPro G2 Control

- Clockwise Rotation

ADDITIONAL SPECIFICATIONS FOR THE 100 CNC-B

- Capacity: 1.375″ OD x .120 Wall

- Maximum Feeding: 160ft/min

- Maximum POB: 50r/min

- Standard Maximum Radius: 5 inch

- Maximum Bend Angle: 190 degrees

- Operating Pressure: 1200psi

- Reservoir Capacity: 80 U.S. Gallons

- Approximate Weight: 5500lbs

- Approximate Dimensions: 10′ L x 3′ W x 4.5′ H

- Voltage: 220 volt/3 Phase/60Hz; 50Hz Optional

- Bend angle accuracy +/-: 0.1 degree

- Bend arm speed: 10rpm

- Maximum tube length over mandrel: 6 ft

- Motor: 5HP

![tube-bender-100-CNCB-3-axis-machine[1]](https://hinesbending.com/wp-content/uploads/2018/03/tube-bender-100-CNCB-3-axis-machine1.jpg)