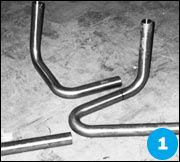

300 CNC-B Tube Bender Applications

The 300 CNC-B bender is extreme workhorse in the automotive, pipe and tube fabricating industries, i.e., for hydraulic lines.

FEATURES OF THE 300 CNC-B TUBE BENDER

- Simple input of machine parameters, DOB, DBB, POB (PLC-FX3U

series Mitsubishi) - Memory capacity: Unlimited

- Operational modes: jog, step and auto

- Self diagnosis: displays of fault source and remedies

- Identification of single bend from multi-bend part.

- Self option carriage use

- Safety auto prevention from bending operation when

last end section is too short - Speed levels of DOB, DBB, and POB: 16 variable settings

- Repeatability precision: DOB/POB: 0.1deg; DBB: 0.1mm

- Resolution: DOB/POB: 0.1deg; DBB: 0.1mm

- Parameter preset resolution: DOB/POB: 0.1deg; DBB: 0.1mm

- Northman Directional Valves

- Preset of processing, i.e., with mandrel or without mandrel,

auto mandrel lubrication, speed levels of DOB, DBB, and

POB / Servo System – Series A, National (Japan)

STANDARD

- Pressure Die Holder

- Wiper Die Holder

- Overhead Tie Bar (Eliminates Die Deflection)

- Pressure Die Assist

- Servo Carriage Boost

- Panasonic Servo Motors

- Mandrel Lubricator

- Mandrel Extractor

- Mandrel Early Out Programmable

- BendPro G2 Control

- Clockwise Rotation

ADDITIONAL SPECIFICATIONS FOR THE 300 CNC-B

- Capacity: 4.25″ OD x .200 Wall

- Maximum Feeding: 33ft/min

- Maximum POB: 20 r/min

- Standard Maximum Radius: 14 inch

- Maximum Bend Angle: 190 degrees

- Operating Pressure: 2000 psi

- Reservoir Capacity: 175 US gallons

- Approximate Weight: 14500 lbs

- Approximate Dimensions: 20′ L x 5′ W x 6′ H

- Voltage: 220 volt/440/3 Phase 60 Hz, 50 Hz optional

- Bend angle accuracy +/-: 0.1 degree

- Bend arm speed: 2rpm

- Maximum tube length over mandrel: 9 1/2 ft

- Motor: 30HP