Understanding CNC Tube Bender Investment Decisions

CNC tube bender cost ranges from $10,000 for entry-level Chinese models to over $100,000 for industrial-grade systems. Here’s what you need to know:

Quick Price Breakdown:

– Entry-level: $10,000-$18,000 (basic automation)

– Mid-range: $20,000-$32,000 (higher capacity)

– High-capacity: $35,000-$49,000 (advanced features)

– Custom/Industrial: $100,000+ (specialized applications)

– Used/Rebuilt: $8,500-$75,000 (varies by condition)

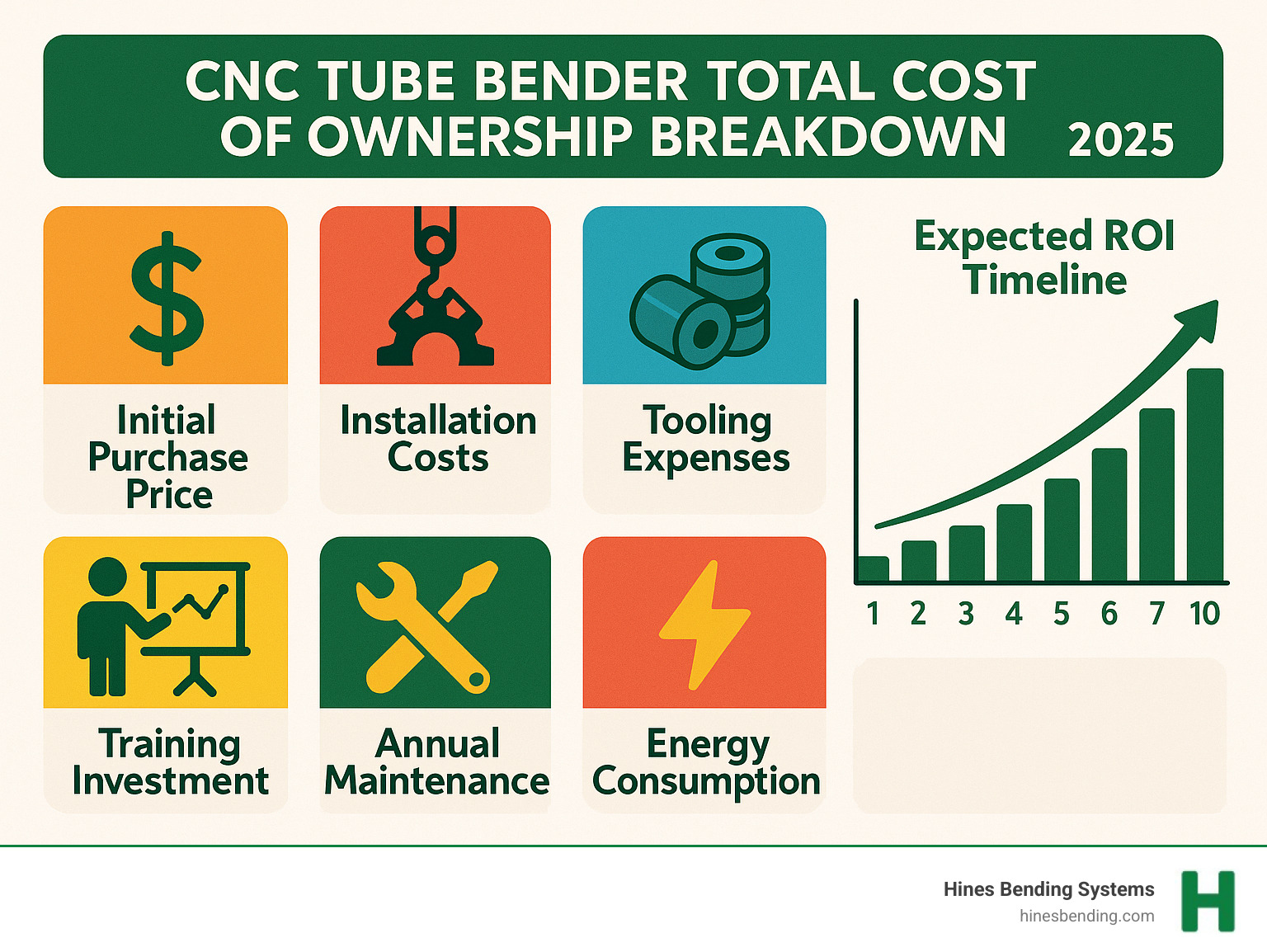

Manufacturing operations managers face a complex buying decision when investing in CNC tube bending equipment. The initial purchase price is just one piece of the puzzle.

Total ownership costs include tooling, training, maintenance, and energy consumption. Shipping alone can add several thousand dollars to your budget.

The right machine depends on your tube diameter requirements, production volume, and precision needs. All-electric systems offer better repeatability but cost more upfront. Hydraulic models provide more power for heavy-duty applications.

Smart buyers consider the complete lifecycle cost – not just the sticker price. A quality machine from an experienced manufacturer can deliver decades of reliable service with proper support.

Quick cnc tube bender cost definitions:

– automatic pipe bending machine

– industrial pipe benders

– pipe bending machines

Price Range Overview – From Hobby to Heavy-Duty

The cnc tube bender cost landscape tells a fascinating story about what you’re really buying. After decades of installing more bending machines worldwide than anyone else, we at Hines Bending Systems have seen how price differences reflect genuine value – not just fancy marketing.

Entry-level machines in the $10,000-$18,000 range might seem like bargains at first glance. These basic units handle simple tube diameters with limited automation. But here’s the catch – that attractive FOB price tag doesn’t include shipping costs that can easily add several thousand dollars. More importantly, you’re often on your own when it comes to installation support and ongoing technical help.

The mid-range sweet spot sits between $20,000-$32,000, where you start seeing real capability improvements. These systems feature servo-electric drives and can tackle more complex bending sequences. Most fabrication shops find their perfect match in this range because the machines offer genuine productivity gains without breaking the budget.

When you step up to high-capacity benders ($35,000-$49,000), you’re entering serious manufacturing territory. These workhorses handle larger tube diameters – think 76mm to 90mm – and come loaded with advanced automation features. Multi-axis control systems and mandrel support become standard equipment, not expensive add-ons.

At the top end, custom industrial solutions start around $100,000 and can reach $349,900 for specialized applications. These aren’t just machines – they’re precision manufacturing systems built for aerospace, energy, and other demanding industries where “close enough” isn’t good enough.

For simpler needs, manual and hydraulic tube benders without CNC control offer entry points as low as $475 for basic models and $945 for hydraulic versions with cylinders included.

| Price Range | New | Used | Rebuilt |

|---|---|---|---|

| Entry-level | $10K-$18K | $6K-$12K | $8K-$15K |

| Mid-range | $20K-$32K | $12K-$20K | $16K-$25K |

| High-capacity | $35K-$49K | $20K-$35K | $28K-$40K |

| Custom/Industrial | $100K+ | $45K-$75K | $65K-$85K |

Example Market Listings

The global marketplace reveals striking price variations that go far beyond simple feature comparisons. Scientific research on global machine pricing shows manufacturers offering 290 different CNC pipe bending machine models with FOB prices spanning $10,000 to $43,000 per piece.

What the listings don’t tell you is the real story. Those minimum order quantities of “1 piece” come with lead times during peak season of 12+ months. Shipping costs get quoted separately, and you’ll quickly find that “FOB” means you’re handling everything from port pickup to final installation.

The price differential between overseas and domestic machines reflects more than manufacturing costs. When you invest in quality equipment from an experienced manufacturer like Hines Bending Systems, you’re buying decades of engineering expertise, comprehensive training programs, and a support network that keeps your production running smoothly.

That’s why major organizations like NASA trust Hines Bending Systems for their critical applications. The initial cnc tube bender cost becomes secondary when you need machines that deliver consistent results year after year.

Factors That Drive CNC Tube Bender Cost

When our clients at Hines Bending Systems ask about CNC tube bender cost, we always start with the same question: “What are you trying to bend?” The answer reveals everything about what drives pricing in this industry.

Tube diameter capacity sits at the heart of every pricing decision. Think of it this way – bending a drinking straw requires different forces than bending a garden hose. Machines designed for 32mm tubes live in a completely different world than those tackling 90mm pipes. The bigger the tube, the more robust everything needs to be.

Drive technology creates another major cost fork in the road. All-electric servo systems deliver incredible precision – we’re talking repeatability that makes hydraulic systems look clunky by comparison. They also sip electricity instead of guzzling it. But hydraulic drives still rule when raw power matters most for heavy-duty applications.

The number of axes determines how complex your bends can be. Basic 3-axis systems handle most jobs beautifully, but when you need those intricate multi-plane bends, 5-axis machines become essential. Each additional axis means more servo motors, more encoders, and more sophisticated control systems.

Mandrel support separates amateur-hour bending from professional results. Without internal mandrels, thin-wall tubes collapse or distort during bending. With them, you get clean, consistent bends that meet aerospace standards. That’s why NASA trusts Hines Bending Systems – they know quality when they see it.

Automation level ranges from basic CNC control to fully robotic cells. Higher automation costs more upfront but can run multiple shifts with minimal supervision. We’ve installed systems that practically run themselves once properly set up.

Country of manufacture affects both initial price and long-term value. While some overseas machines offer lower sticker prices, the total cost of ownership tells a different story. At Hines, we’ve built our reputation on machines that deliver decades of reliable service with proper support.

CNC Tube Bender Cost & Machine Size

The relationship between machine size and CNC tube bender cost isn’t linear – it’s exponential. A machine handling 90mm tubes doesn’t just cost twice as much as a 32mm unit. It might cost four times as much, and here’s why.

Smaller machines designed for 32mm tubes are nimble performers. They feature lighter frame construction, modest power requirements around 12-20 kW, and blazing-fast bending speeds up to 147 degrees per second. Their compact footprint makes them perfect for shops with limited space.

But step up to 90mm capacity, and everything changes dramatically. These machines demand massive frame structures to maintain rigidity under enormous bending forces. Power consumption jumps to 49 kW – over four times the electrical demand. Bending speeds slow to a more controlled 35 degrees per second, but the precision remains absolute.

The physics are unforgiving. Bending forces don’t scale proportionally with tube diameter – they explode exponentially. This explains why high-capacity machines require disproportionately heavier construction and sophisticated control systems.

Frame rigidity becomes absolutely critical as diameter increases. Any flex in the machine translates directly to inconsistent bends. That’s why our largest machines feature construction that would make a bridge engineer proud.

More info about CNC Tube Bending Machines Near Me

CNC Tube Bender Cost & Automation Features

Advanced automation features can double or triple your CNC tube bender cost, but they often pay for themselves through dramatically improved productivity. We’ve seen shops transform their operations with the right automation choices.

Multi-stack tooling might sound technical, but it’s a game-changer for busy shops. Imagine swapping dies in under 5 minutes instead of 30. Quick-change systems eliminate the setup bottleneck that kills productivity between jobs. The feature costs more upfront but delivers returns through improved machine utilization.

Right/left bending capability turns your machine into a productivity powerhouse. Twin-head configurations produce matching components simultaneously, effectively doubling throughput for symmetric parts. It’s like having two machines in the space of one.

Robotic loading systems represent the ultimate in automation. Yes, they add $50,000 to $100,000 to your machine cost. But they also enable lights-out operation across multiple shifts. We’ve installed robotic cells that run 20 hours a day with minimal supervision.

Simulation software prevents expensive mistakes before they happen. Advanced systems import CAD files directly and simulate the complete bending sequence, catching potential collisions or tooling conflicts in the virtual world. It’s much cheaper to fix problems on screen than on the shop floor.

Servo-electric technology delivers positioning accuracy within 0.1mm while consuming far less energy than hydraulic alternatives. The technology premium pays dividends through reduced scrap rates and lower operating costs. When you’re bending expensive aerospace tubing, precision isn’t optional.

Remote diagnostics keep your machine running when problems arise. Our technicians can access machine controls via internet connection, often resolving issues without expensive service calls. It’s like having a Hines expert on call 24/7.

More info about Advantages of CNC Tube Bending Machine for Sale

New, Used, and Rebuilt Options Compared

When evaluating CNC tube bender cost options, many buyers consider alternatives to new equipment purchases. The decision between new, used, and rebuilt machines involves careful consideration of your long-term production needs and support requirements.

New machines from Hines Bending Systems provide the ultimate peace of mind. You get complete warranty coverage, the latest control technology, and full manufacturer support from the world’s leading bending machine company. While new equipment commands premium pricing, our clients consistently find that the investment pays dividends through superior reliability and productivity.

The delivery timeline for new equipment can extend beyond 12 months during peak demand periods, but this reflects the careful engineering and quality construction that goes into every Hines machine. When you’re supplying agencies like NASA, you can’t compromise on quality or delivery promises.

Used machines present an attractive price point, with CNC tube bender cost ranging from $8,500 to $75,000 depending on age and condition. However, buyers must steer significant risks around parts availability, remaining service life, and technical support. Machines from quality manufacturers like Hines retain their value better because they’re built to last decades, not years.

The depreciation curve tells an interesting story. Quality machines lose 20-30% of their value in the first year, then hold their worth remarkably well. This reflects the robust construction and ongoing support that serious manufacturers provide their clients.

Rebuilt machines offer compelling middle-ground options. Professional rebuilds include complete mechanical inspections, worn component replacement, and often controller upgrades that bring older machines up to modern standards. The rebuild scope can be extensive – essentially creating a like-new machine at a fraction of new equipment cost.

At Hines Bending, we understand that not every application requires our latest technology. Sometimes a properly rebuilt machine provides exactly the capabilities you need while preserving working capital for other investments.

Financing and leasing options make new equipment more accessible than many buyers realize. These arrangements preserve cash flow while providing access to the latest technology and full warranty protection. The tax advantages often make the total cost of ownership very attractive compared to used alternatives.

Where to Find Value Deals

Smart buyers know that finding quality used equipment requires expertise and patience. The bending machine market has its own rhythms and reliable sources for good deals.

Auction houses can offer opportunities, but they require deep technical knowledge to evaluate what you’re really buying. Without understanding the specific wear patterns and maintenance history of tube bending equipment, auction purchases become expensive gambles.

Certified rebuilders provide professionally restored machines with meaningful warranties. These specialists understand the equipment intimately and can often upgrade older machines with modern control systems. The key is working with rebuilders who have genuine expertise in tube bending technology.

Trade-in credits represent one of the best paths to equipment upgrades. At Hines Bending Systems, we work closely with clients who are expanding their capabilities or updating their production lines. Our trade-in programs apply real value toward new equipment purchases while ensuring your old machine finds a good home.

The most valuable deals often come from working directly with experienced manufacturers. Companies like Hines occasionally have demonstration machines or trade-ins that have been thoroughly inspected and updated. These machines combine cost savings with the confidence that comes from manufacturer backing.

The secret to finding genuine value is partnering with people who understand both the equipment and your production requirements. Generic machine dealers can’t provide the application expertise that comes from decades of solving complex bending challenges.

More info about Used CNC Bending Machines for Sale

Ownership Costs Beyond the Sticker Price

Here’s what catches many buyers off guard: the CNC tube bender cost on the invoice is just the beginning of your investment story. At Hines Bending Systems, we’ve guided thousands of clients through this journey, and we always emphasize the importance of understanding your complete ownership picture.

Tooling sets often surprise new buyers with their cost and complexity. A single tooling package for one tube diameter can easily run $5,000 to $15,000. If you’re bending multiple sizes and radii – which most shops do – you’ll need an extensive tooling library. The good news? Quality tooling from experienced manufacturers like Hines lasts for years and delivers consistent results.

Think of preventive maintenance as insurance for your production schedule. Annual maintenance contracts typically cost 8-12% of your machine’s value, but they prevent the kind of catastrophic failures that can shut down your operation for weeks. We’ve seen shops save tens of thousands by catching problems early through regular maintenance.

Spare parts inventory represents another balancing act. You need critical components on hand to prevent costly downtime, but you don’t want to tie up excessive capital in parts that might never be needed. Working with a manufacturer who maintains extensive parts inventory and fast shipping helps minimize your on-site storage requirements.

Energy consumption varies dramatically between machine types. Hydraulic systems might consume 40-60 kW continuously, while modern all-electric machines use just 4-6 kW for equivalent work. Over ten years, this difference can add up to substantial savings – sometimes enough to justify the higher initial cost of electric technology.

Operator training pays dividends far beyond its initial cost. Comprehensive training programs run $2,000 to $5,000 per operator, but trained operators produce less scrap, work more efficiently, and catch problems before they become expensive failures. At Hines, we’ve seen properly trained operators achieve productivity levels that quickly recover the training investment.

Software updates keep your machine current with the latest features and security patches. Some manufacturers bundle these into service contracts, while others charge separately. Budget around $1,000 to $3,000 annually for software maintenance – it’s a small price for staying current with technology advances.

The biggest hidden cost? Production downtime risk. When a critical machine fails during an important production run, you’re looking at thousands of dollars per hour in lost output, plus potential penalties for late deliveries. This is why choosing equipment from established manufacturers with responsive service networks is so crucial.

Maximizing ROI on a CNC Tube Bender

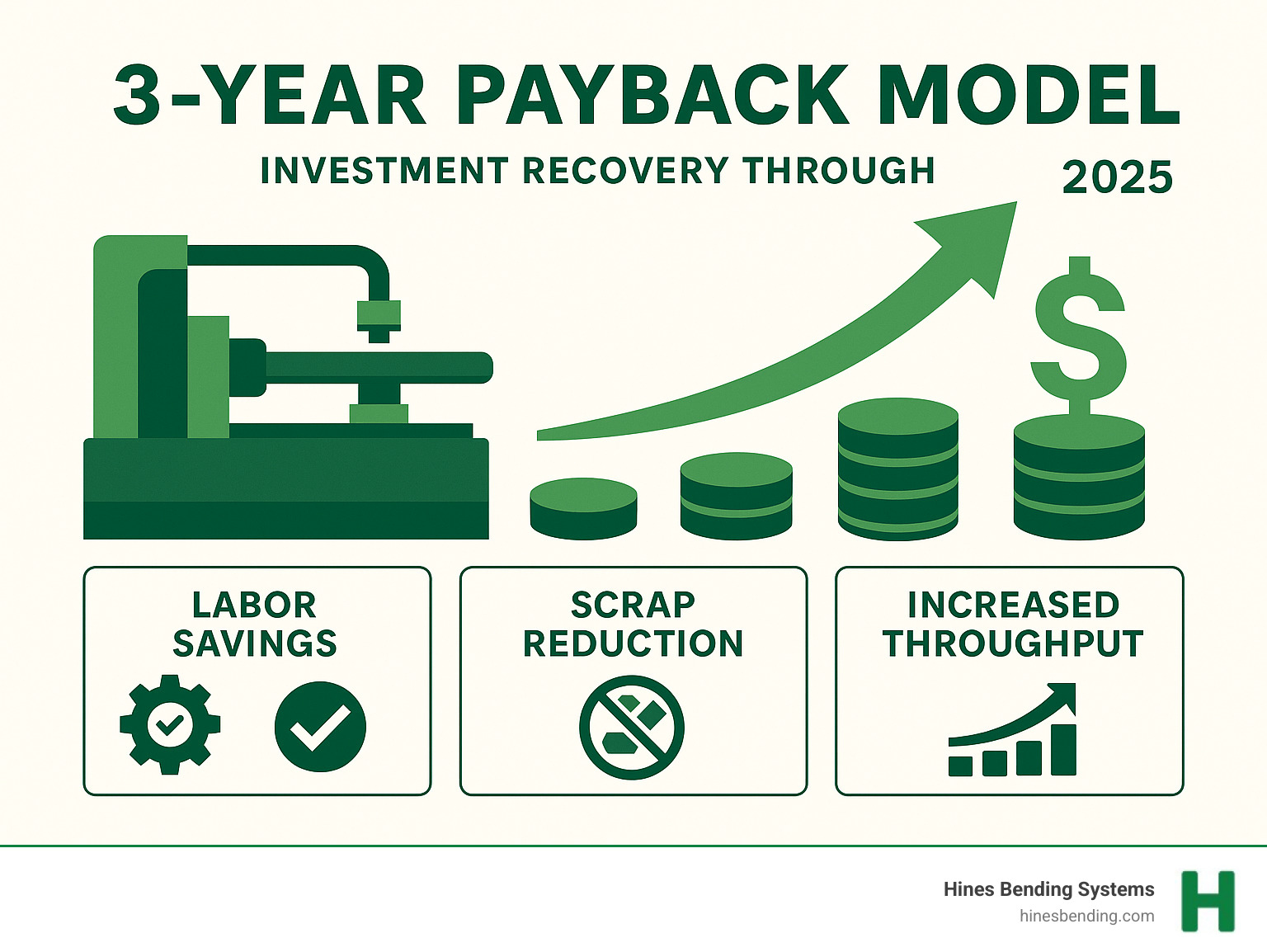

The most successful CNC installations we’ve seen at Hines don’t just replace manual processes – they transform entire operations. Smart buyers focus on multiple revenue streams to maximize their return on investment.

Cycle-time savings deliver immediate, measurable benefits. CNC automation typically reduces complex bending sequences from hours to minutes. We’ve documented cases where shops achieved 60-80% cycle time reductions compared to manual methods. That’s not just faster production – it’s the ability to take on more work with the same resources.

Scrap reduction might seem less dramatic than speed improvements, but it directly impacts your bottom line. CNC precision and repeatability virtually eliminate the setup-related scrap that plagues manual operations. When you’re working with expensive materials, this alone can justify the equipment investment.

Multi-shift utilization transforms your equipment from a day-shift tool into a 24-hour profit center. Modern CNC systems can run lights-out with minimal supervision, effectively tripling your production capacity without proportional increases in labor costs. This is where the real magic happens for return on investment.

Quick changeovers open up new market opportunities. Advanced tooling systems complete setup changes in minutes rather than hours, making small-batch production economically viable. Suddenly, you can compete for jobs that were previously unprofitable due to setup time.

Labor efficiency multiplies your skilled operators’ impact. Instead of manually operating equipment, they can program and monitor multiple CNC machines simultaneously. This shift from manual labor to skilled supervision often doubles or triples operator productivity.

Quality consistency builds customer confidence and reduces inspection costs. When every part meets specifications without variation, you spend less time on quality control and more time on productive work. Happy customers also mean repeat business and referrals.

Most well-planned CNC installations achieve payback within 18 to 36 months through these combined benefits. The key is working with experienced partners who understand how to optimize your specific application. At Hines Bending Systems, we’ve installed more bending machines worldwide than any other manufacturer, giving us unique insight into what makes installations successful.

Frequently Asked Questions about CNC Tube Bender Cost

What is the average cnc tube bender cost for a 2-inch capacity shop?

When you’re looking at CNC tube bender cost for 2-inch (roughly 50mm) tube capacity, you’re entering serious fabrication territory. Most quality machines in this range run $25,000-$45,000, depending on how sophisticated you need to get.

This isn’t just about tube diameter – it’s about the precision and automation required to handle this size effectively. You’ll typically get servo control across 3-5 axes, mandrel bending capability for clean results, and programmable sequences that remember your most complex jobs.

A basic 3-axis setup might start around $25,000, but don’t be surprised if a fully automated system with robotic loading pushes past $75,000. The real question isn’t just what you can afford upfront – it’s what features will actually pay for themselves through improved productivity.

At Hines Bending Systems, we’ve installed more tube benders worldwide than anyone else. This experience helps us match the right machine to your specific needs without paying for bells and whistles you’ll never use. Our NASA-level quality standards ensure you’re getting equipment that will serve your shop for decades.

How much can I save by buying a rebuilt unit instead of new?

Here’s where things get interesting. A quality rebuilt machine typically costs 40-60% of new equipment pricing. That $50,000 new machine might be available rebuilt for $20,000-$30,000 – real money in anybody’s book.

But savings come with trade-offs you need to understand. You’re looking at older technology, shorter warranty coverage (usually 90 days to a year), and the reality that parts might be harder to find down the road. The service history is often unknown, which can be concerning for critical production equipment.

The key word here is quality rebuilds. The best rebuilders completely tear down the machine, replace worn components, and update control systems. They document everything and stand behind their work with meaningful warranties.

At Hines Bending Systems, our rebuilding process meets the same exacting standards as our new machines. We know these machines inside and out – we built them. When we rebuild equipment, it performs like new because we understand every component and how they work together. Plus, you get the same expert support that has made us the worldwide leader in bending solutions.

Which hidden fees should I budget for (shipping, install, training)?

Nobody likes surprises, especially expensive ones. The smart approach is budgeting an extra 25-35% of your machine cost for the essentials that get you up and running.

Shipping costs vary wildly based on where you are and how big your machine is. Domestic shipping typically runs $2,000-$8,000, while international shipping can hit $5,000-$15,000. Oversized machines requiring special permits cost even more.

Installation expenses add up quickly. You’re looking at $2,000-$5,000 for electrical connections, another $1,000-$3,000 for compressed air systems, and potentially $1,000-$5,000 for foundation work. Don’t forget rigging and positioning costs of $1,500-$4,000.

Training investment is absolutely critical. Basic operator training runs $2,000-$3,000, while advanced programming courses cost $3,000-$5,000. Maintenance training adds another $2,000-$4,000, but prevents costly mistakes and downtime.

Then there are the smaller items that add up: permits and inspections ($500-$2,000), your initial tooling package ($5,000-$15,000), spare parts starter kit ($2,000-$5,000), and software licenses ($1,000-$3,000).

Working with experienced manufacturers like Hines Bending Systems eliminates most surprises. We provide detailed cost breakdowns upfront and can coordinate your entire installation process. Our decades of experience mean we know exactly what’s needed to get your operation running smoothly from day one. When you’re working with the company that’s installed more bending machines than anyone else worldwide, you can trust the process will go right.

Conclusion

Making the right CNC tube bender cost decision means looking at the complete picture – not just the initial price tag. Whether you’re considering a $10,000 entry-level machine or a $100,000+ industrial system, the real value comes from finding equipment that perfectly matches your needs and delivers reliable performance for years to come.

That’s where Hines Bending Systems makes all the difference. We’re the global leader in tube bending technology, with more installations worldwide than any other manufacturer. This isn’t just a claim – it’s the result of decades spent perfecting our craft and building relationships with customers who demand the absolute best.

Our experience runs deeper than anyone else in the industry. We’ve worked with companies ranging from small fabrication shops to NASA and other demanding government agencies. When the space program needs precision bending equipment, they turn to us. That same level of expertise and quality goes into every machine we build, regardless of size or application.

What really sets us apart is our commitment to custom solutions. We don’t believe in forcing customers into pre-built packages that might not fit their needs. Instead, our team works closely with you to understand your specific requirements, production goals, and budget constraints. Then we design the optimal bending solution that delivers exactly what you need.

This NASA-level quality approach means you get equipment that performs reliably under the most demanding conditions. Our machines handle everything from prototype work to high-volume production, always delivering the precision and consistency that builds successful businesses.

The tube bending industry has plenty of suppliers, but nobody has more expertise and experience than our team. We’ve seen every type of application, solved countless challenging problems, and helped thousands of companies improve their operations through better bending technology.

When you’re ready to invest in CNC tube bending equipment, don’t settle for generic solutions or untested suppliers. Work with the industry leader who has the proven track record and deep knowledge to ensure your success from day one.