SINCE 1975

We Build & Install the Best Benders in the World!

With the most bender installations and the most expertise & experience in the industry, Hines can provide the best solution. Get in contact with us today to find out why the U.S. Government, NASA, and other major companies trust Hines to supply their bending machines.

Featured Projects

Precision bending solutions for America's most critical missions

NASA Space Exploration - Advanced Aerospace Equipment

Hines Bending Systems provides mission-critical tube and pipe bending equipment to NASA for aerospace applications. Our precision CNC bending machines meet the exacting standards required for space exploration programs. Trusted by the world's leading space agency for reliability and precision.

Eastern Shipbuilding - Military & Emergency Vessels

Hines Bending Systems supplies tube and pipe bending equipment to Eastern Shipbuilding for U.S. Navy vessels and the FDNY Marine Division fireboat. Our equipment helps build the vessels that protect America's waterways and serve our nation's heroes.

Newly developed accessory for HBS Induction Benders

HBS revolutionizes pipe bending with interchangeable bend arms—allowing you to handle everything from small to large OD pipes on a single induction bender. Say goodbye to turning away jobs and hello to expanded capabilities without the cost of multiple machines.

Cost-Effective Expansion

Eliminate the need for separate machines. One investment covers your entire range of pipe sizes.

Versatile Production

Accept both small and large OD projects without limitation. Expand your product line instantly.

Quick Changeover

Swap bend arms efficiently to move between different pipe sizes and maximize machine utilization.

Proven Technology

Field-tested design delivering reliable performance across multiple diameter ranges.

Precision-engineered small arm for compact pipe sizes

Side-by-side view of interchangeable arm system

Complete system showing versatility in action

Enhanced small arm configuration for specialized applications

Example Configuration

Ready to Expand Your Capabilities?

Discover how HBS interchangeable bend arms can transform your pipe bending operation. Our team is ready to discuss your specific requirements and show you how this proven technology can add new revenue streams to your business.

Why Choose Us?

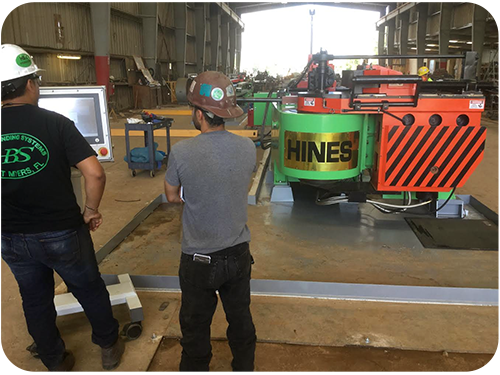

Nobody has installed benders for more companies around the world than Hines.

Our newest machines are at the cutting edge of induction and automatic bending capabilities.

Since 1975, we have been a leader in the bending machine industry, with worldwide installation and training. There is a reason Hines has been trusted with providing the United States Military and other amazing customers with their bending solutions for decades.

Our customers leverage the fact that we build the best benders, have the most bender installations, and have the most bending expertise and experience to find the best bending solution for them

If you are interested in learning more about how we can provide you with the most optimal bending solutions, give us a call.

Worldwide Bending Machine Sales & Installation

If you need more information about which tube bender, pipe bender, or induction bender is the best choice for your production needs, then call us. We can also connect you to one of our financing partners.

As an existing customer, you can trade in your Hines machine and upgrade to a newer model or a different type of bender. We’ll give you an estimate on the trade-in value and arrange for the old machine to be shipped back when you take delivery of a new bender. If you are a caller from outside of the United States, feel free to use our toll free number.

Most Popular Bender Categories

Interested in investing in a pipe or tube bender?

You probably have questions that should be satisfactorily answered before making your investment in one of these valuable machines. Fill out the contact form or call us to learn more and get a free quote for your new bending machine!

We can train your employees to use our bending machines.

Hines Bending Systems offers warranties on all of our products.