Tube + Pipe Bender Training

Need to efficiently operate your tube and pipe bender?

You’ve come to the right place. We believe that training and continuing education is absolutely vital to your success. Not only will your engineering and production become more efficient, but your company will be producing exceptionally high quality bends immediately with our guidance. If you are an expert or have a lot, some, a little or no bending experience whatsoever, Hines Bending’s comprehensive course will thoroughly train your and or your staff on your machine, maintenance, bending, tooling and trouble shooting. We teach state-of-the-art techniques that will give your company the production levels you are seeking. By the end of the day, you will be bending parts and acquired some major tricks of the trade.

Hines Bending Systems offers several levels of training:

- Fee-based. If you need us to travel to you, we can travel to your production site. We are happy to provide a cost estimate if you require on site training.

Please contact us for training and seminar availability.

Helping Startup Companies get into the Tube and Pipe Bender Industry

Over the years we have helped companies enter the tube and pipe industry using the most econmical path. We consistently offer the most popular and affordable tube and pipe benders in the industry – semi-automatic NC and fully automated CNC tube & pipe benders.

All of tube and pipe benders have proven to be simple, strong and reliable. We help you choose the correct machine and associated tooling. Importantly, in less than a day’s of training, you will be efficiently producing parts.

Bending 101

Below are two important tabs – Operator Setup and Pipe Distortions. Access Operator Setup for guidance on dies and clamps. Access Pipe Distortions to find solutions for various results on pipe and tube materials.

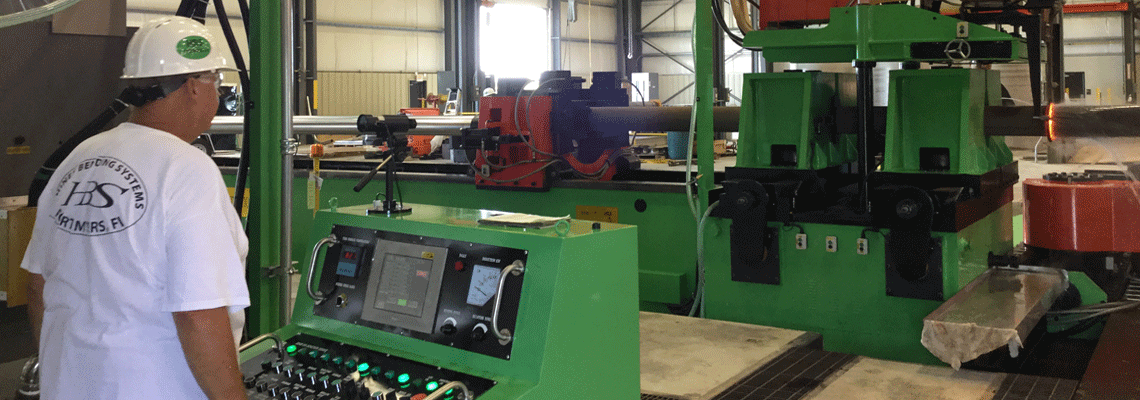

HINES BENDING’S PRESIDENT AND CEO JIM HYNES INSTRUCTS A TRAINEE ON WHAT TO LOOK FOR IN A QUALITY BEND.

INSTALLING A WIPER DIE.

DETERMINING UP TO TANGENT AND PARALLEL WITH TUBE GROVE, I.E., DETERMINING “TRUE.”

APPLYING PRESSURE TO ENSURE THE BEND DIE IS LOCKED TIGHTLY INTO PLACE.

LOWERING THE BEND DIE ONTO the MACHINE MAKING SURE THE DIE IS ALIGNED, SETTING LEVEL AND TRUE TO THE MACHINE.

CHECKING PRESSURE GUAGE.

LEARNING TO INSTALL A MANDREL.