Why CNC Tube Bending and Notching Changes Everything

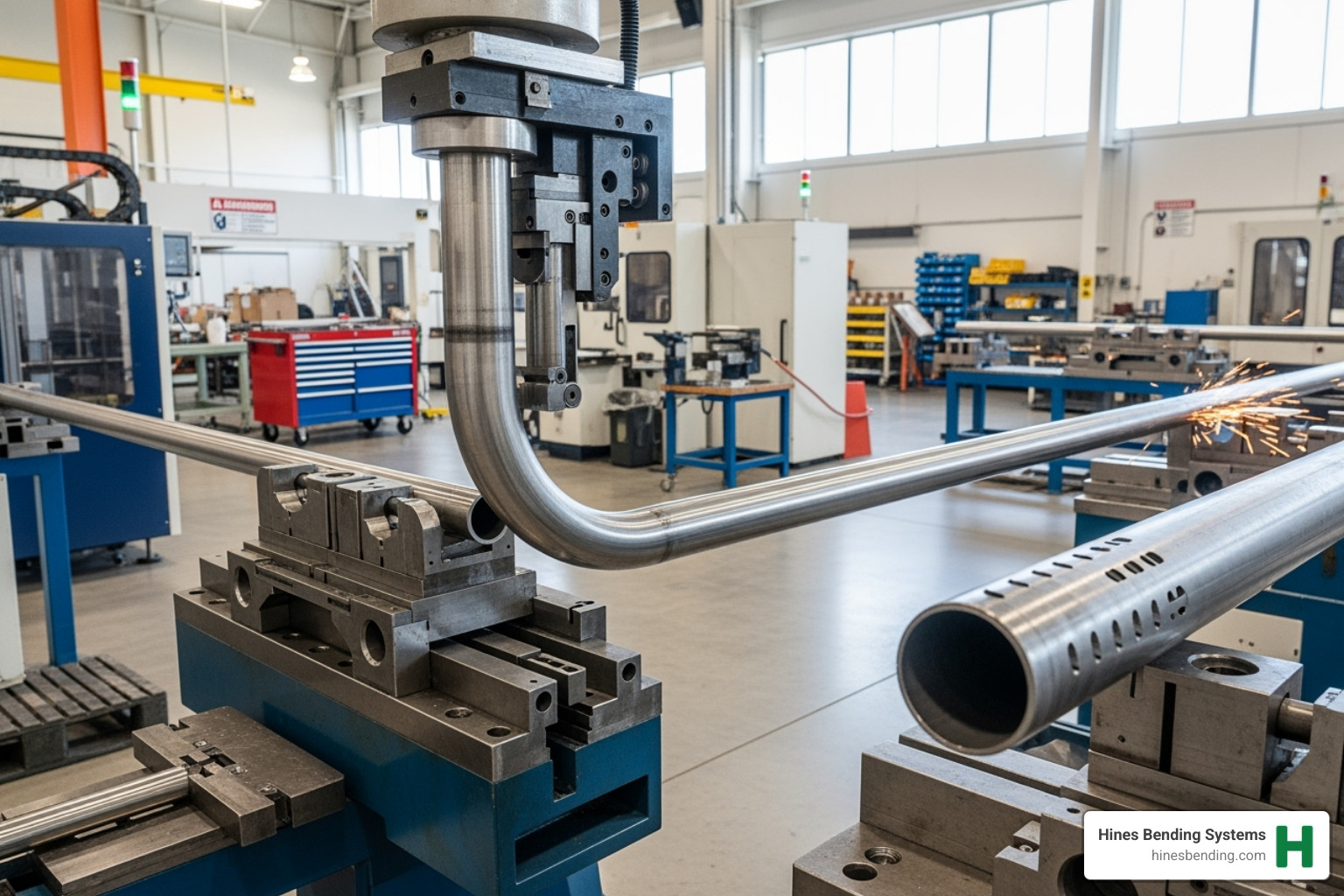

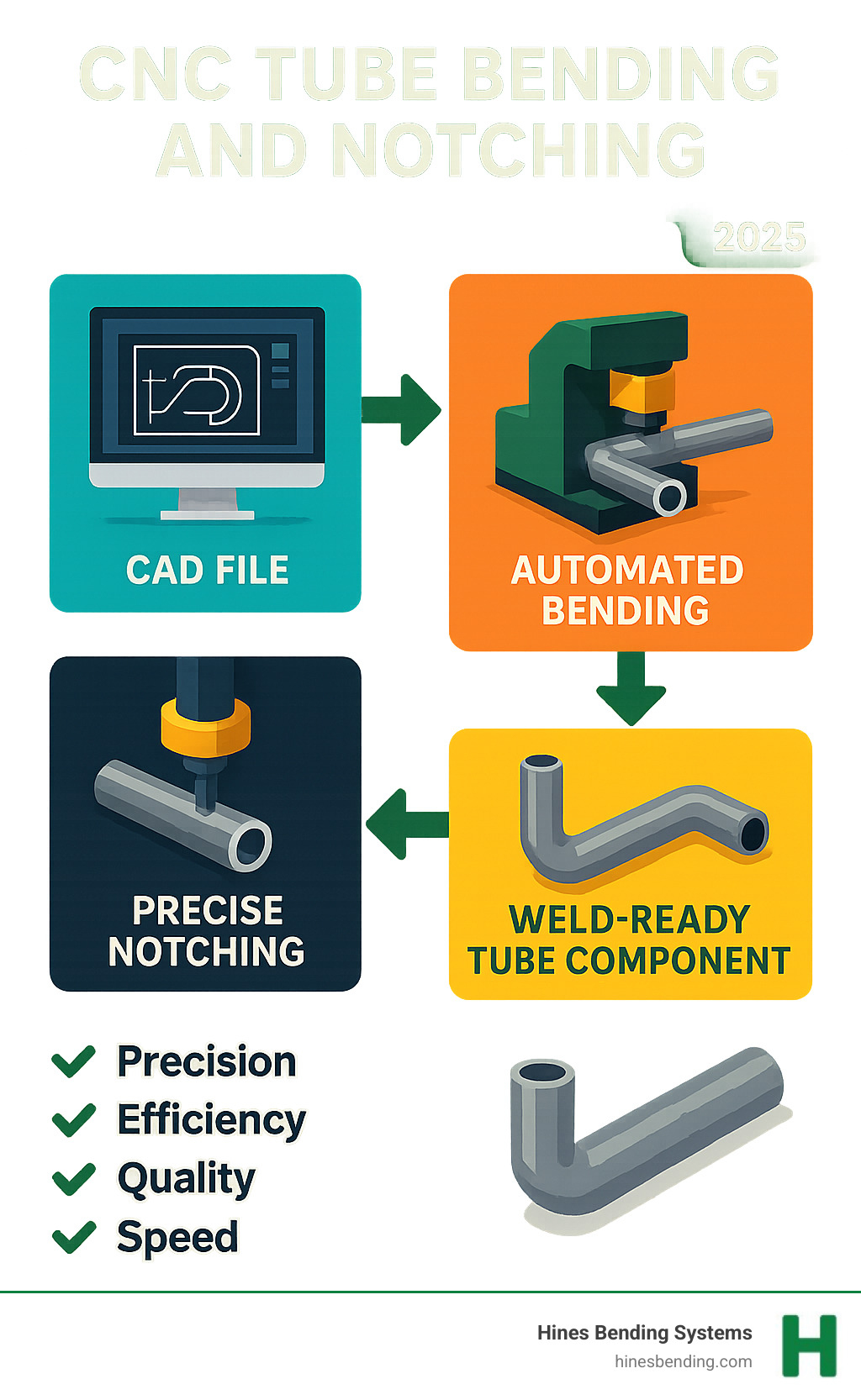

CNC tube bending and notching represents the fusion of two critical fabrication processes that transform how manufacturers create precision tube assemblies. This integrated approach combines computer-controlled bending with precise cutting techniques to produce weld-ready components that fit together perfectly.

Key Benefits of CNC Tube Bending and Notching:

- Precision: Achieve bend accuracy within ±0.2 degrees and welding surface fits within ±0.010 inches

- Efficiency: Eliminate manual fit-up and grinding operations

- Quality: Create seamless joints with superior structural integrity

- Speed: Reduce assembly time through pre-notched, ready-to-weld components

- Flexibility: Handle complex geometries and multi-plane bends automatically

The traditional approach of bending tubes and then manually notching them creates inconsistencies and requires extensive finishing work. Modern CNC systems solve this by integrating both processes under digital control, giving designers and engineers greater latitude and flexibility.

Why this matters for your operation: When you combine CNC bending with notching, you’re not just making tubes – you’re creating precision assemblies that eliminate the guesswork from welding and assembly. This integrated approach reduces material waste, speeds production, and delivers the consistent quality that industries like aerospace and automotive demand.

The key is working with a manufacturer who understands both processes and can deliver machines that excel at the complete workflow. Hines Bending Systems, the #1 worldwide manufacturer of tube benders, has supplied precision solutions to industry leaders like NASA, proving that when accuracy matters most, expertise makes all the difference.

Cnc tube bending and notching further reading:

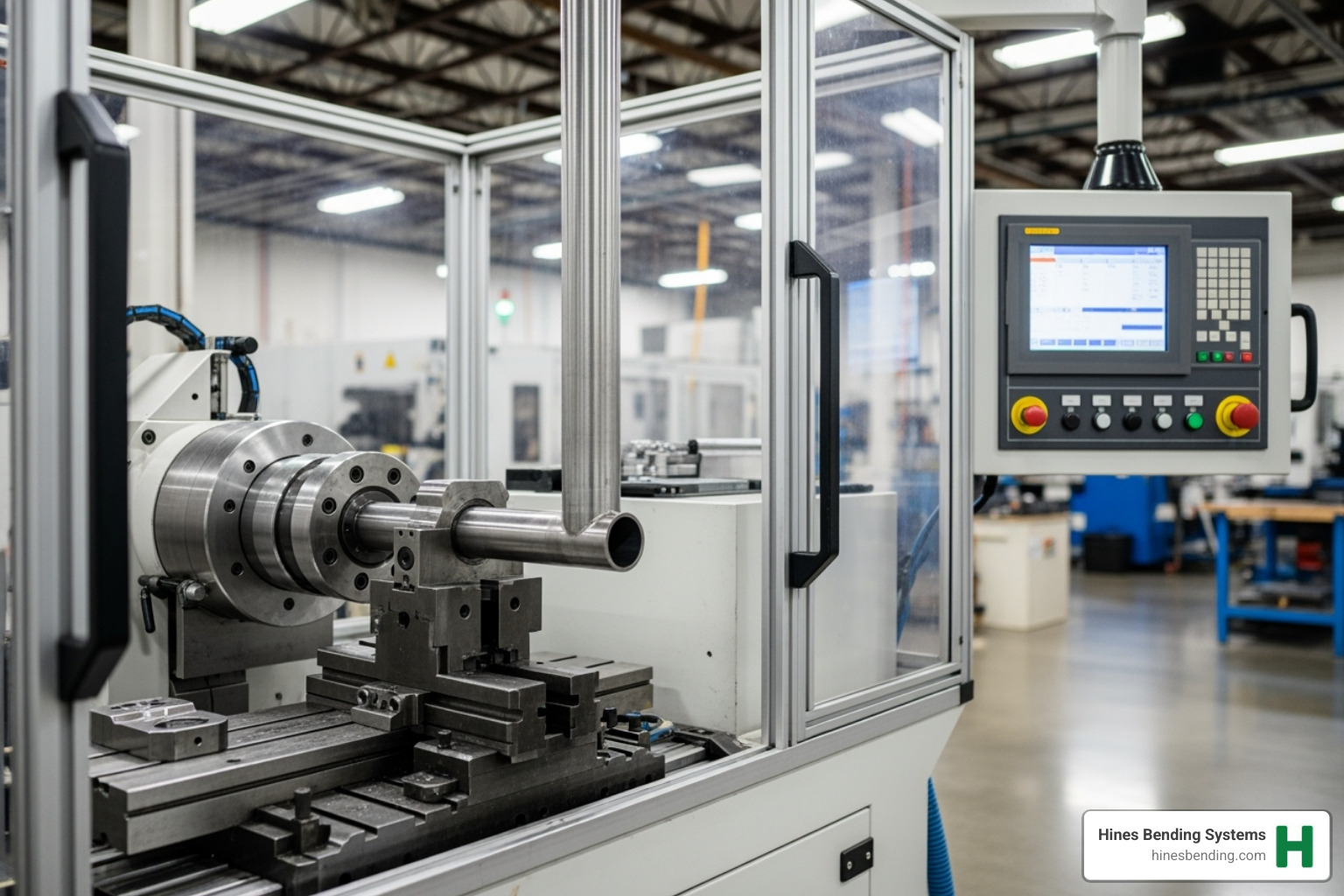

The Foundation: Understanding CNC Technology in Tube Fabrication

When you step into modern tube fabrication, Computer Numerical Control (CNC) technology is what separates the exceptional from the ordinary. It’s about changing raw materials into precisely engineered components with a level of accuracy that manual methods simply can’t match.

At Hines Bending Systems, we’ve built our reputation as the #1 worldwide manufacturer of tube benders by understanding that CNC technology is the heart of superior fabrication. Every machine we build embodies this digital precision, ensuring our clients—including industry leaders like NASA—receive the highest quality bending solutions available.

A CNC tube bending and notching machine has a digital brain that executes complex designs from CAD software with unwavering precision, time after time. The benefits for your operation are remarkable:

- Unparalleled precision: Components fit together perfectly every time.

- High repeatability: The first part is identical to the thousandth.

- Reduced material waste: Precision eliminates costly mistakes and rework.

- Accelerated production: Machines work faster and more consistently than manual methods.

- Complex geometries: Routinely produce shapes that are impossible or too expensive to make by hand.

This is why we’ve dedicated decades to perfecting our CNC systems. When you invest in a Hines bending machine, you’re not just buying equipment—you’re partnering with the company that has more expertise and experience in the bending machine industry than anyone else.

For a deeper dive into these fundamentals, our resources on What is CNC Tube Bending? and Advantages of CNC Tube Bending Machines provide comprehensive insights into how this technology can transform your fabrication capabilities.

Why Precision Matters

In CNC tube bending and notching, precision is the foundation of quality. At Hines Bending Systems, we target tolerances that might seem impossibly tight: ±0.2 degree bend accuracy and ±0.010 inch fit-up for welding surfaces. This level of precision creates a cascade of benefits that transform your entire fabrication process.

When components fit this precisely, grinding and rework become things of the past. Parts slide together exactly as designed, ready for welding immediately. This perfect fit-up creates stronger, more reliable welds because the welder can focus on creating the best possible joint rather than trying to bridge gaps. The result is superior structural integrity, which is critical in high-stakes industries like aerospace, defense, and motorsports.

We understand that for our clients working on aircraft hydraulic lines or race car roll cages, this precision isn’t optional—it’s essential for safety and performance. That’s why we’ve built our reputation supplying precision solutions to organizations like NASA, where failure simply isn’t an option.

From Manual Labor to Automated Excellence

While manual tube bending has a certain romance, its limitations—operator inconsistencies, human error, and slow production rates—can’t meet modern demands. The shift to CNC automation is a fundamental change, moving from hoping for consistency to guaranteeing it.

With CNC tube bending and notching systems, you gain increased throughput as machines work tirelessly, and lower labor costs as skilled workers focus on high-level tasks instead of repetitive bending. Most importantly, digital precision ensures every bend and notch follows exact specifications, creating the consistency modern assembly lines demand.

At Hines Bending Systems, we’ve engineered this automated excellence into every machine we build. Our advanced control systems and robust mechanical designs don’t just increase your production capacity—they lift the quality of everything you produce. When you partner with us, you’re working with the company that has the most bender installations worldwide, each one representing our commitment to helping manufacturers achieve new levels of efficiency and precision.

Mastering the Bend: Key Methods and Critical Parameters

When it comes to CNC tube bending and notching, choosing the right approach is the foundation for success. Achieving the perfect bend depends on selecting the right method, whether it’s the precision of rotary draw bending, the advanced support of mandrel bending for thin-walled tubes, or the flexibility of roll bending for large curves. Understanding the nuances of each is key, but you don’t have to be the expert.

At Hines Bending Systems, our decades of experience are your greatest asset. We guide you to the ideal method for your project, ensuring success from the start. As the company with more bender installations worldwide than anyone else, our expertise translates directly into better solutions for your specific challenges. Our team works closely with you to understand your unique requirements, ensuring your investment delivers exactly what you need. You can explore more about our precision capabilities in Precision Pipe Bending.

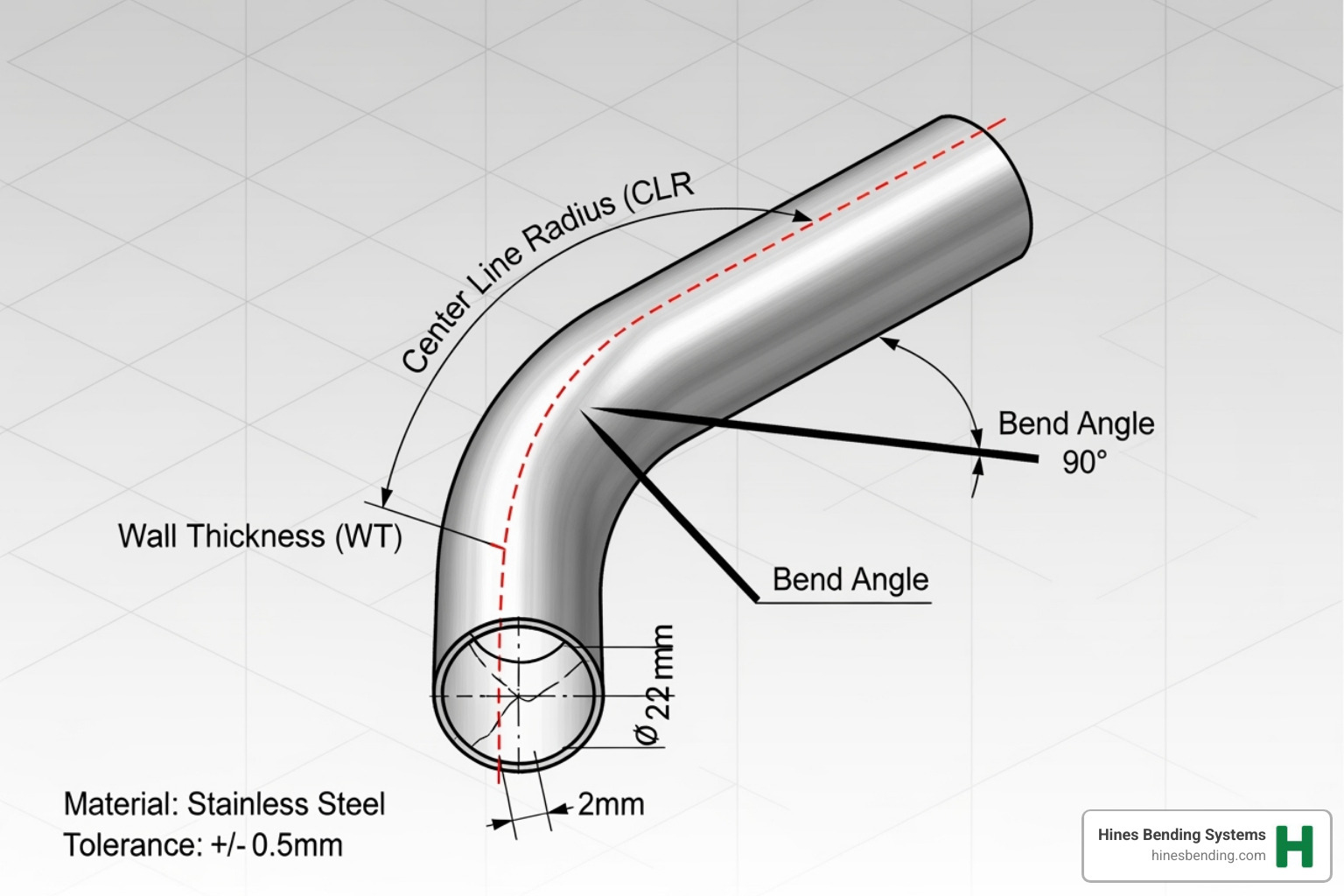

Critical Technical Parameters

Getting a perfect bend isn’t magic—it’s about mastering the technical details. Factors like material selection (from steel to exotic alloys like titanium), tube dimensions, center line radius (CLR), and bend angle accuracy all play a critical role. These parameters can seem complex, but with Hines, they’re simply part of the solution we provide.

Our team, with experience on projects for clients like NASA, manages these variables to deliver flawless results. We engineer solutions that account for everything from material springback to the minimum straight lengths needed between bends, taking the guesswork out of your hands. This is where our expertise truly sets us apart; we don’t just sell machines, we deliver optimized, reliable bending processes. For specialized applications, our CNC Mandrel Tube Bender for Sale offers the robust solutions you need for even the most challenging projects.

The Role of Expert Tooling

Even the most advanced CNC bending machine is only as good as its tooling. Components like bend dies, mandrels, and wiper dies must be perfectly engineered to prevent defects like wrinkling or ovality. At Hines Bending Systems, we apply the same obsessive attention to detail to our tooling as we do to our machines themselves.

Poor quality tooling can ruin an entire production run, but our commitment to superior quality ensures every component works in harmony to produce defect-free bends. When NASA needs precision tooling for critical aerospace applications, they turn to Hines. That same level of quality goes into every toolset we provide, ensuring your parts meet the most exacting standards. Learn more about our precision tooling solutions at Pipe Bender Dies.

The Perfect Fit: Integrating CNC Notching with Bending

Picture a perfectly crafted puzzle piece sliding into place with satisfying precision. That’s exactly what happens when CNC tube bending and notching work together seamlessly. While bending shapes your tube, notching creates those critical connection points where strength and beauty meet.

Tube notching—sometimes called coping or creating saddle joints—involves cutting precise profiles at tube ends so they nestle perfectly against other tubes or surfaces. This isn’t just about looks; it’s about creating weld-ready joints that form the backbone of everything from race car roll cages to aerospace hydraulic systems.

When you integrate notching with bending under CNC control, you orchestrate a symphony of precision that transforms raw material into perfectly fitted components. The secret lies in understanding process sequencing. Some applications benefit from pre-notching, while others call for post-bending notching. At Hines Bending Systems, we’ve mastered both approaches. Our expertise helps you determine the optimal sequence for your application, ensuring every component emerges ready for assembly with no grinding or forcing parts to fit.

The Synergy of CNC Tube Bending and Notching

When CNC tube bending and notching are integrated, the result is a seamless workflow where precision machines operate in perfect harmony. This process starts with your CAD design and flows through to your finished component, with every dimension maintained with mathematical precision.

The real breakthrough is preserving notch orientation through complex, multi-plane bends. Integrated CNC control automatically tracks every feature, eliminating the guesswork of manual methods. This precision eliminates manual fit-up completely. When your tubes come off a Hines machine, they fit together perfectly the first time, allowing welders to focus on creating strong joints instead of fighting misaligned parts.

The result is a faster, more predictable assembly process with simplified fixtures. Those perfectly fitted joints create stronger welds with better penetration and appearance. We’ve seen this change countless times; what used to take hours of fitting and grinding now happens in minutes.

Advanced Techniques for CNC Tube Bending and Notching

The future of CNC tube bending and notching is about doing what was previously impossible. At Hines Bending Systems, we constantly push the boundaries of what’s achievable, opening up new possibilities for designers and engineers.

Complex out-of-plane bending is one such frontier, creating tubes that twist and curve through three-dimensional space. This requires sophisticated 3D modeling and simulation software to predict material behavior and optimize the bending sequence. Our advanced machine controls make these complex operations feel almost effortless. These are precision instruments that coordinate multiple axes simultaneously while maintaining incredibly tight tolerances.

The results speak for themselves: welding surface fits within ±0.010 inches. This level of precision is critical in applications where tiny variations could mean failure. These capabilities free designers to focus on the optimal design, not the limitations of fabrication. Whether it’s a complex aerospace component or a unique architectural element, our advanced CNC systems can bring those visions to life.

This is where our decades of experience really shine. We partner with you to solve problems that others might consider impossible. When NASA needs precision bending solutions, they come to us because they know we have both the technology and the expertise to deliver.

For more insights into various notching approaches and techniques, you might find this external resource helpful: Options for Notching Pipe and Notching Tube.

Applications and Industries Demanding Precision CNC Tube Bending and Notching

CNC tube bending and notching is the backbone of countless industries that keep our world moving. From the cars we drive to the planes that soar overhead, precision-bent and notched tubes are everywhere, performing with incredible reliability.

At Hines Bending Systems, our machines create critical components for a vast range of applications, from aerospace and defense to automotive, industrial manufacturing, architecture, and custom fabrication. Each industry presents unique challenges: aerospace demands exotic materials and tight tolerances; automotive requires a balance of strength, weight, and cost; and industrial applications need scale and reliability.

This diversity is why we’ve become the #1 worldwide manufacturer of tube benders. Our decades of expertise help us design custom solutions that don’t just meet expectations—they exceed them. Whether you’re bending titanium for a spacecraft or steel for a roll cage, our machines deliver the precision and consistency that modern manufacturing demands.

Aerospace and High-Performance

It’s incredible to know our bending machines help humans explore space. When NASA needs precision tube fabrication, they turn to Hines Bending Systems. In the aerospace world, every component must perform flawlessly under extreme conditions.

The materials alone tell the story: exotic alloys like titanium and Inconel are chosen for their strength-to-weight ratios and ability to withstand extreme temperatures. These materials are notoriously difficult to work with, requiring specialized techniques and equipment that Hines provides. Our machines create hydraulic lines that must never leak, structural frames where every gram matters, and other high-reliability components that astronauts depend on.

Our ongoing collaboration with NASA is a testament to the unparalleled quality and precision our machines deliver. You can read more about it here: Hines working together with NASA. This isn’t just about making parts—it’s about enabling humanity’s greatest achievements.

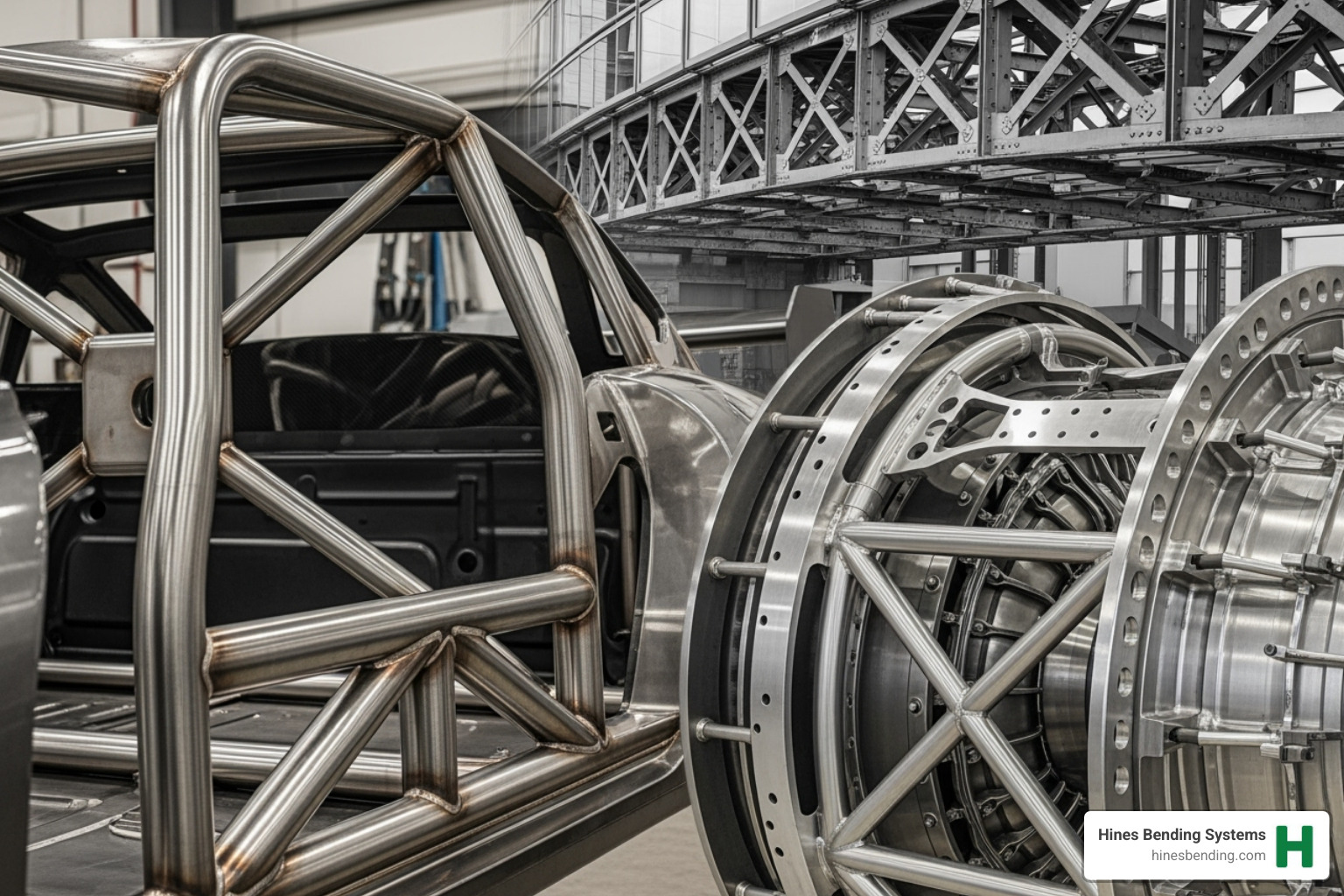

Automotive and Motorsport

The automotive world is where CNC tube bending and notching shows its versatility, from high-volume exhaust components to one-off, life-saving roll cages for race cars.

In motorsport, roll cages are critical safety systems. Every bend and notch must be perfect, as a flawless fit-up is essential for weld strength and driver safety. Exhaust systems require precise bends to optimize flow and steer tight spaces. Chassis and suspension components need exact geometries to deliver the handling and performance drivers expect.

We’re also proud to support educational programs like FSAE and Baja projects, where the next generation of engineers uses our technology to bring innovative designs to life. From high-volume production to prototyping, our machines handle both extremes with equal skill, which is why automotive manufacturers worldwide trust Hines Bending Systems to deliver the quality their operations demand.

Achieving Excellence: Partnering with an Industry Leader

In the complex world of CNC tube bending and notching, your choice of machine partner is the most critical decision you’ll make. It’s not just about buying equipment; it’s about securing an expert partnership that ensures your success.

As the #1 worldwide manufacturer of tube benders, Hines Bending Systems offers unparalleled expertise, proven by the highest number of global installations. Partnering with us means accessing decades of experience in bending dynamics that no competitor can match.

We reject one-size-fits-all solutions, specializing instead in custom-built machines. We work closely with clients to meet their unique challenges, from aerospace alloys to high-volume automotive parts. This commitment to custom solutions is why leaders like NASA trust us for their most critical applications.

Our focus is always on quality assurance. We build robust machines designed to exceed stringent industry standards, ensuring long-term performance that stands apart from cheaper alternatives. Our continuous innovation ensures you always have access to cutting-edge technology. Furthermore, we empower our clients with comprehensive operator training and lifecycle support to improve team efficiency.

We are more than a machine manufacturer; we are your strategic partner in achieving fabrication excellence. Our deep experience, customized solutions, and unwavering commitment to quality mean that when you choose Hines, you choose a competitive edge that will redefine what’s possible in CNC tube bending and notching. To understand more about the advantages of partnering with us, explore Why Buy a Hines Bender?.

To turn your complex fabrication vision into reality, explore our range of CNC Bending Machines to see how the world’s leading manufacturer can lift your projects.