Why CNC Tube Bending Machines Are Essential for Modern Manufacturing

CNC tube bending machines are automated systems using computer numerical control to bend tubes and pipes with precision and repeatability. These machines have transformed manufacturing by eliminating guesswork, reducing waste, and enabling complex geometries that manual methods cannot achieve.

Key Features of CNC Tube Bending Machines:

- Automated Control: Servo-driven axes control distance between bends (DBB), plane of bend (POB), and degree of bend (DOB)

- High Precision: Bend angle accuracy of ±0.1 degrees or better

- Versatile Capacity: Handle tube diameters from 4mm to 220mm depending on the model

- Complex Bending: Create multiple bends, variable radius curves, and 3D freeform shapes

- Reduced Scrap: Software simulation and error correction minimize material waste

- Energy Efficient: All-electric models offer up to 70% energy savings compared to traditional hydraulic systems

As one industry expert put it: “Tube bending sucks—yeah, we said it. While it might look simple, the process is full of challenges.” That’s exactly why the right CNC tube bending machine matters.

Hines Bending Systems stands as the #1 worldwide manufacturer of tube benders, trusted by organizations like NASA and major aerospace companies. With decades of experience and the deepest expertise in the industry, Hines delivers custom solutions that meet the most demanding precision requirements.

Whether fabricating exhaust systems, hydraulic lines, or aerospace components, the right CNC tube bending machine ensures first-part-right production, avoiding costly trial-and-error. These machines feature PC-based controls with CAD/CAM integration for direct design import and 3D simulation to prevent errors. This technology ensures faster setup, consistent quality, and the ability to handle materials from aluminum to exotic alloys.

Easy cnc tube bending machines glossary:

Why Leading Industries Rely on Hines CNC Tube Bending Machines

When precision matters most—when lives depend on it—there’s no room for “almost right.” That’s why organizations like NASA and leading aerospace companies trust Hines Bending Systems for their most critical tube bending applications.

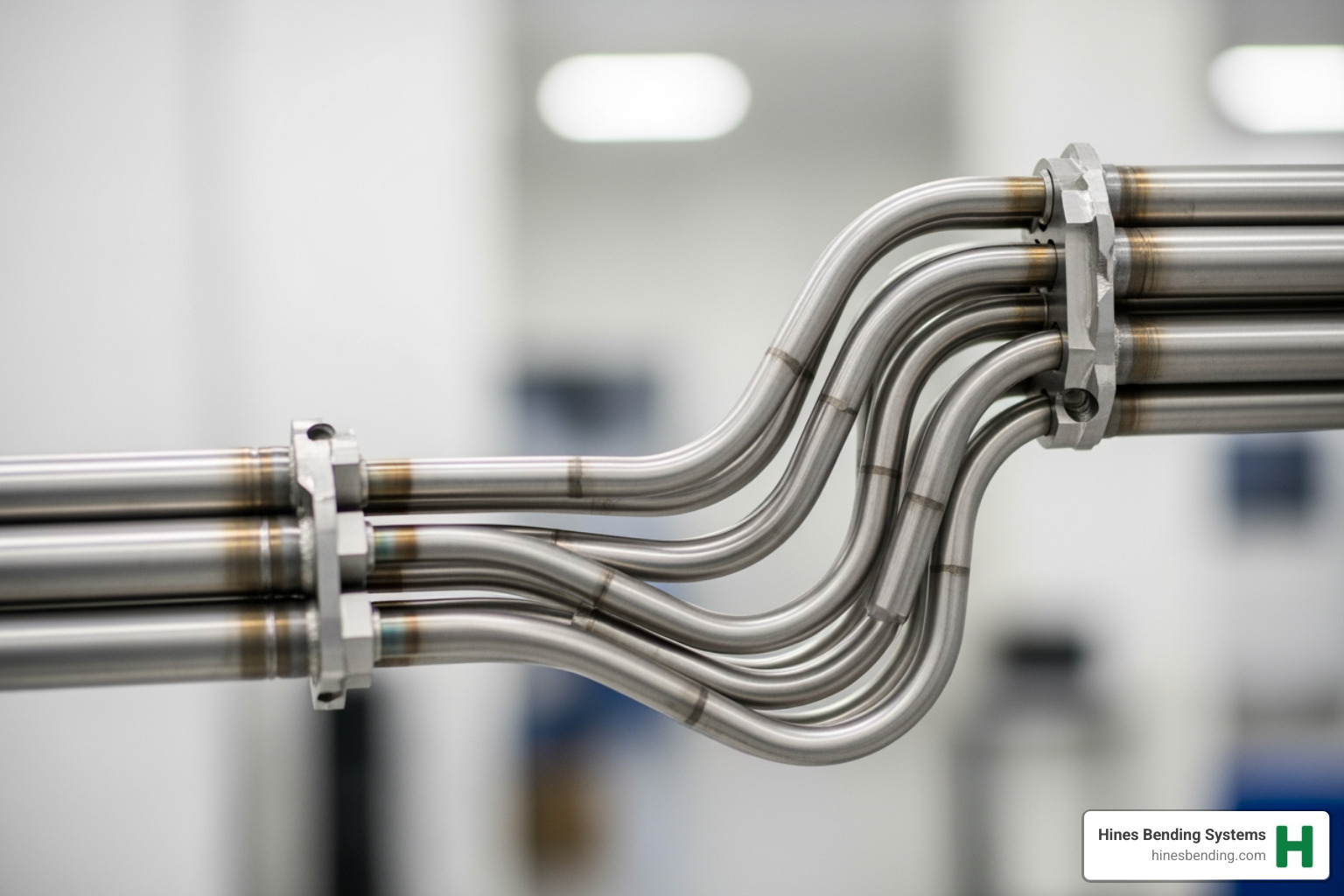

In aerospace and defense, failure is not an option. Projects for space flight or national security demand perfection. Our CNC tube bending machines handle exotic materials like titanium and Inconel with precision that meets NASA’s standards, delivering repeatable results for every part.

The automotive and motorsports world relies on our machines for high-performance exhaust systems and life-saving roll cages. Our technology handles complex geometries and high-stress materials, making Hines the choice for professional race teams and custom builders who need parts that perform.

In marine and shipbuilding, our CNC tube bending machines create the hydraulic lines and structural components that keep vessels safe in corrosive, high-pressure environments. There’s no second-guessing the quality of your bends when a ship is 500 miles from shore.

The energy and power generation sectors require boiler tubes and high-pressure components where material integrity is non-negotiable. In nuclear plants, pipeline infrastructure, and petrochemical operations, precision bending is a safety issue, and that’s where decades of Hines expertise makes the difference.

What sets us apart isn’t just the machines—it’s our commitment to understanding your specific challenge. We don’t believe in one-size-fits-all solutions. Instead, we work closely with each customer to engineer custom solutions that address their exact requirements. This approach has made us the #1 worldwide manufacturer of tube benders, with more installations and deeper expertise than anyone else in the industry.

The result? Less scrap, higher quality, faster production, and a genuine competitive advantage. When you partner with Hines, you’re not just buying equipment—you’re gaining access to the most experienced team in the bending business.

Want to learn more about the technical side of what we do? Check out more info about the tube and pipe bending industry.

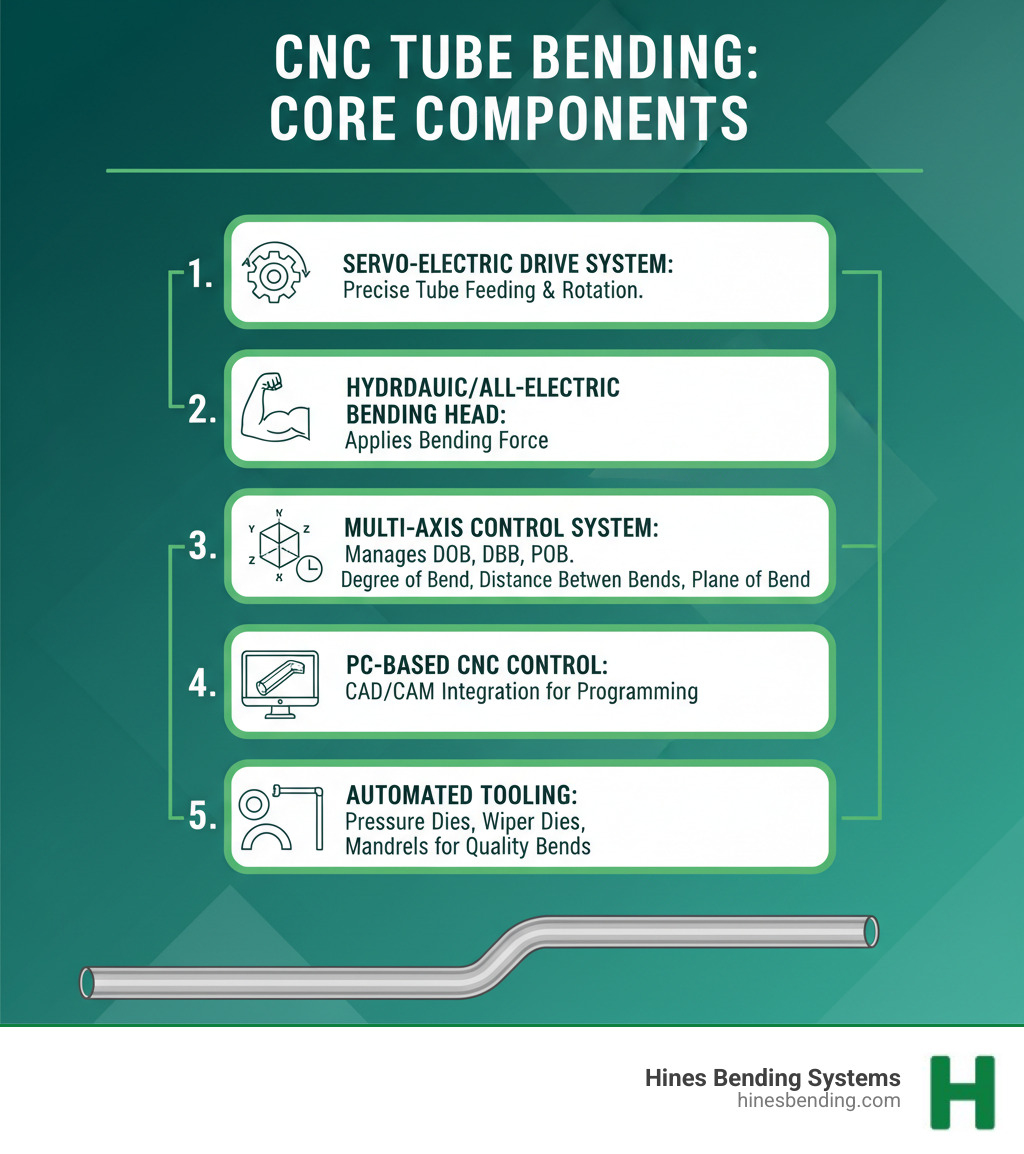

Core Technologies of Hines CNC Tube Bending Machines

When choosing a CNC tube bending machine, the technology inside is what drives reliability, precision, and efficiency. At Hines Bending Systems, we’ve spent decades perfecting these core technologies.

Hines engineers both all-electric and hybrid systems to meet specific needs. Our all-electric machines offer up to 70% energy savings over hydraulic systems and are quieter, cleaner, and faster, making them ideal for facilities requiring low noise and high precision on smaller diameter tubes.

When you need serious bending power for larger diameters or thicker walls, our hybrid systems combine the strength of hydraulics with the pinpoint accuracy of electric drives. It’s the best of both worlds, giving you the muscle for demanding materials while maintaining perfect control.

The real magic in our CNC tube bending machines comes from multi-axis control. Every Hines machine uses servo-driven systems to manage three critical parameters: the DOB (Degree of Bend), the DBB (Distance Between Bends), and the POB (Plane of Bend). Our 200 CNC-B bender, for example, achieves bend angle accuracy of ±0.1 degree and repeatability of 0.1 degree for DOB/POB and 0.1mm for DBB. That level of control means your first part matches your hundredth part, every time.

What really sets Hines apart is our advanced bending capabilities. Our machines perform both right-hand and left-hand bending in-process, dramatically speeding up production for intricate designs. We’ve also engineered capabilities for variable radius and 3D freeform bending, creating complex shapes without multiple dies or welding.

Our innovative Dual Stack CNC Push Bender and Roll Bender exemplify how we’re constantly pushing boundaries. These specialized solutions enable complex bends and part configurations that address growing industry demands. For more details on these specialized solutions, explore our More info about stack push benders.

At the heart of every Hines machine is a state-of-the-art control system. Our CNC tube bending machines feature PC-based controls like the BendPro G2 Control, which are intuitive systems that interface seamlessly with most engineering software. You can program remotely, import CAD data directly, and make real-time adjustments. The controls even include self-diagnosis capabilities that identify problems and suggest solutions, maximizing uptime.

From delicate 4mm tubing to heavy-duty pipes up to 12 3/4″ (323.85mm), Hines Bending Systems delivers a complete spectrum of technological solutions. We don’t just build machines—we engineer intelligent partners for your manufacturing process, backed by more expertise than anyone in the industry.

Selecting the Right Hines Machine: A Guide to Critical Specifications

Choosing the right CNC tube bending machine is critical for production speed, quality, and profitability. At Hines Bending Systems, our decades of experience confirm that a one-size-fits-all approach doesn’t work for precision tube bending.

That’s why we work closely with you to understand your goals and match you with the perfect machine from our extensive lineup. This tool will be the backbone of your fabrication operation.

Understanding Capacity and Materials

The first step is defining what you’re bending. The tube’s outer diameter (OD) and wall thickness are critical. Our machines span a range from delicate 10mm tubing for HVAC and brake lines up to massive 12 3/4″ (323.85mm) pipes for heavy industrial applications.

Material is just as important as size. Mild steel, stainless steel, aluminum, and exotic alloys each have unique bending characteristics. Our 200 CNC-B bender, for instance, handles tubes up to 2.5″ OD with .200 wall thickness, making it ideal for automotive exhaust and RV chassis components.

Bend Complexity and Precision Requirements

Next, we analyze your part geometry. Do you need tight radius bends or will larger centerline radii (CLR) suffice? Our CNC tube bending machines can achieve bend radii as tight as 3 times the outer diameter (3OD).

For applications in aerospace and medical fields, there is no room for error. Our machines deliver bend angle accuracies of ±0.1 degree with feed and rotation precisions of ±0.05 mm. That consistency means your first part and your thousandth part will be virtually identical, reducing scrap and eliminating rework.

Production Needs and Automation Integration

Finally, we consider how the machine fits into your operation. The 200 CNC-B bender, for example, excels at producing diverse parts with 16 variable speed settings to optimize throughput. Our machines also integrate seamlessly with auto loaders and unloaders for lean, lights-out production. Features like weld-seam detectors add another layer of automation, ensuring consistent quality.

To give you a clearer picture of how different applications align with machine capabilities, here’s what we typically recommend:

| Application Scale | Typical Tube OD Range | Typical Wall Thickness | Key Considerations | Hines Machine Capabilities |

|---|---|---|---|---|

| Small Diameter/High Precision | 4mm – 25mm (0.16″ – 1″) | 0.4mm – 1.6mm | Medical, HVAC, aerospace small parts, brake lines, fuel lines | High accuracy (±0.05mm), tight radii, all-electric for clean operation, fast cycle times. |

| Medium Diameter/Versatile | 25mm – 76mm (1″ – 3″) | 1.6mm – 4.5mm | Automotive, furniture, general manufacturing, exhaust systems | Balanced precision & power, hybrid or all-electric, complex multi-bend parts, efficient for production runs. |

| Large Diameter/Structural | 76mm – 323mm (3″ – 12.75″) | 3.0mm – 10mm+ | Shipbuilding, heavy industrial, energy, roll cages | Robust servo-hydraulic power, high stability, handles thick walls & profiles, remote diagnostics. |

The Value of Expert Partnership

What really sets Hines apart is that we become your partner. With more installations worldwide than anyone and clients like NASA trusting us, we’ve seen every bending challenge imaginable.

When you work with us, you’re tapping into that deep well of expertise. We’ll assess your requirements, recommend the most suitable CNC tube bending machine, and provide comprehensive training. We’re not satisfied until you’re producing perfect parts efficiently and profitably.

Our customer-first promise isn’t just marketing talk—it’s how we’ve built our reputation as the #1 worldwide manufacturer of tube benders. Learn more about our approach here: More info about our customer-first promise.

The Role of Software and Automation in Gaining a Competitive Edge with Hines

In today’s fast-moving manufacturing world, software and automation are essential for a competitive edge. Hines Bending Systems integrates advanced software and automation into every CNC tube bending machine, turning complex challenges into efficient operations.

With Hines’ CAD/CAM integration, your digital design flows directly into the bending machine. Our systems seamlessly import standard engineering files (STEP or DXF) and automatically convert XYZ coordinates into the YBC data our machines need. No more manual data entry or transcription errors. Our PC-based controls, like the intuitive BendPro G2 Control, make this process feel effortless.

Before you bend any material, our software lets you run a complete 3D simulation of the entire bending sequence. You can watch the virtual tube move through every bend, spotting potential problems before they become expensive mistakes. Will the tube interfere with the machine? Is there a spring-back issue? These questions get answered on screen, not on the shop floor. This simulation and optimization capability means your first part is the right part, eliminating costly trial-and-error. This feature alone can save you thousands of dollars per project.

The future of manufacturing is Industry 5.0—the smart collaboration between human expertise and machine precision. Our CNC tube bending machines integrate beautifully with robotic systems for automated loading, unloading, and part handling. Imagine a manufacturing cell that runs through the night, producing perfect parts. Features like our weld-seam detectors work seamlessly with auto loaders, ensuring every tube is positioned correctly without human intervention. This isn’t about replacing your skilled workforce; it’s about empowering them while machines handle repetitive tasks.

With Hines’ advanced data and quality control systems, quality is built into every bend. Our machines monitor bending parameters in real-time, ensuring consistency. When something needs attention, our self-diagnosis systems identify the specific issue and suggest the remedy, minimizing downtime. This constant feedback loop means every part meets your specifications, and scrap rates drop dramatically.

With decades of experience and the deepest expertise in the bending industry, Hines Bending Systems provides complete manufacturing solutions that transform your capabilities. We’ve installed more bending systems worldwide than anyone else, and that knowledge is built into every line of code and automation feature we offer. When you partner with Hines, you’re getting a manufacturing ecosystem designed to make you more competitive, efficient, and profitable.

Frequently Asked Questions about Hines CNC Tube Benders

When considering CNC tube bending machines, it’s natural to have questions. This is a significant investment that will impact your production for years to come. At Hines Bending Systems, we’re here to help you make the best decision.

What are the main advantages of Hines CNC tube bending machines over manual or NC methods?

Hines CNC tube bending machines replace the inconsistency of manual methods with automated precision. Key advantages include:

- Superior Precision: Our machines achieve bend angle accuracies of ±0.1 degree and repeatability of ±0.05 mm, ensuring every part is identical.

- Increased Speed: Automated processes run significantly faster than manual or NC methods, boosting production and shortening lead times.

- Complex Geometries: Easily create parts with multiple bends, variable radii, and 3D shapes that are nearly impossible to produce manually.

- Reduced Costs: Automation lowers labor costs and dramatically reduces scrap rates by catching errors in simulation before production begins.

This is all backed by Hines’ industry-leading expertise, optimizing your entire bending operation.

How does Hines software improve the CNC tube bending process?

Hines software transforms the bending process. Our PC-based controls, like the BendPro G2 Control, simplify programming by directly importing CAD data (.dxf or STEP files), converting XYZ design data to machine-ready YBC coordinates in minutes. The key feature is 3D bend simulation, which virtually runs the entire bending sequence to check for collisions and other issues. This error prevention saves thousands in wasted material. The software also automatically compensates for material spring-back, ensuring consistent results across different materials. This digital process dramatically reduces setup time compared to traditional trial-and-error. Hines provides comprehensive training and support, ensuring your team maximizes these capabilities, a commitment that makes us the #1 worldwide manufacturer.

What makes Hines CNC tube bending machines superior for high-stakes applications like aerospace?

Organizations like NASA trust Hines for their most critical projects because failure is not an option in aerospace and defense. Our CNC tube bending machines are superior for these high-stakes applications for several reasons:

- Best Precision: We deliver tolerances measured in hundredths of a degree and millimeter, ensuring parts fit perfectly in complex assemblies.

- Proven Reliability: Our machines are built for continuous operation with advanced diagnostics to maximize uptime, which is critical for meeting project deadlines.

- Exotic Material Handling: We specialize in bending difficult materials like titanium and Inconel without compromising their structural integrity.

- Custom Engineering: We don’t offer one-size-fits-all solutions. We partner with clients to engineer custom systems that meet their exact needs.

Our decades of experience and deep expertise are why major aerospace agencies and defense contractors choose Hines when precision and reliability are non-negotiable.

Conclusion: Partnering with Hines for Best Bending Solutions

In precision tube fabrication, the right partner is as crucial as the right equipment. CNC tube bending machines provide the precision and efficiency modern manufacturing requires, but Hines Bending Systems delivers more. We bring decades of experience and a commitment to engineering custom solutions for your unique challenges.

As the #1 worldwide manufacturer of tube benders, our machines are trusted by industry leaders like NASA because we deliver unparalleled precision and reliability. Our partnership extends beyond the sale, with comprehensive training and support to ensure your success. We help you improve quality, reduce scrap, and gain a competitive edge.

Working with Hines means gaining a partner with the deepest expertise in the industry, ready to solve any bending challenge. We have the knowledge and technology to handle everything from exotic alloys to high-volume production.

Ready to leverage the highest quality and most reliable CNC tube bending machines for your project? Explore our comprehensive range of CNC Bending Machines and find how Hines Bending Systems can transform your fabrication capabilities.