Why Manufacturers Choose CNC Tube Bending Solutions

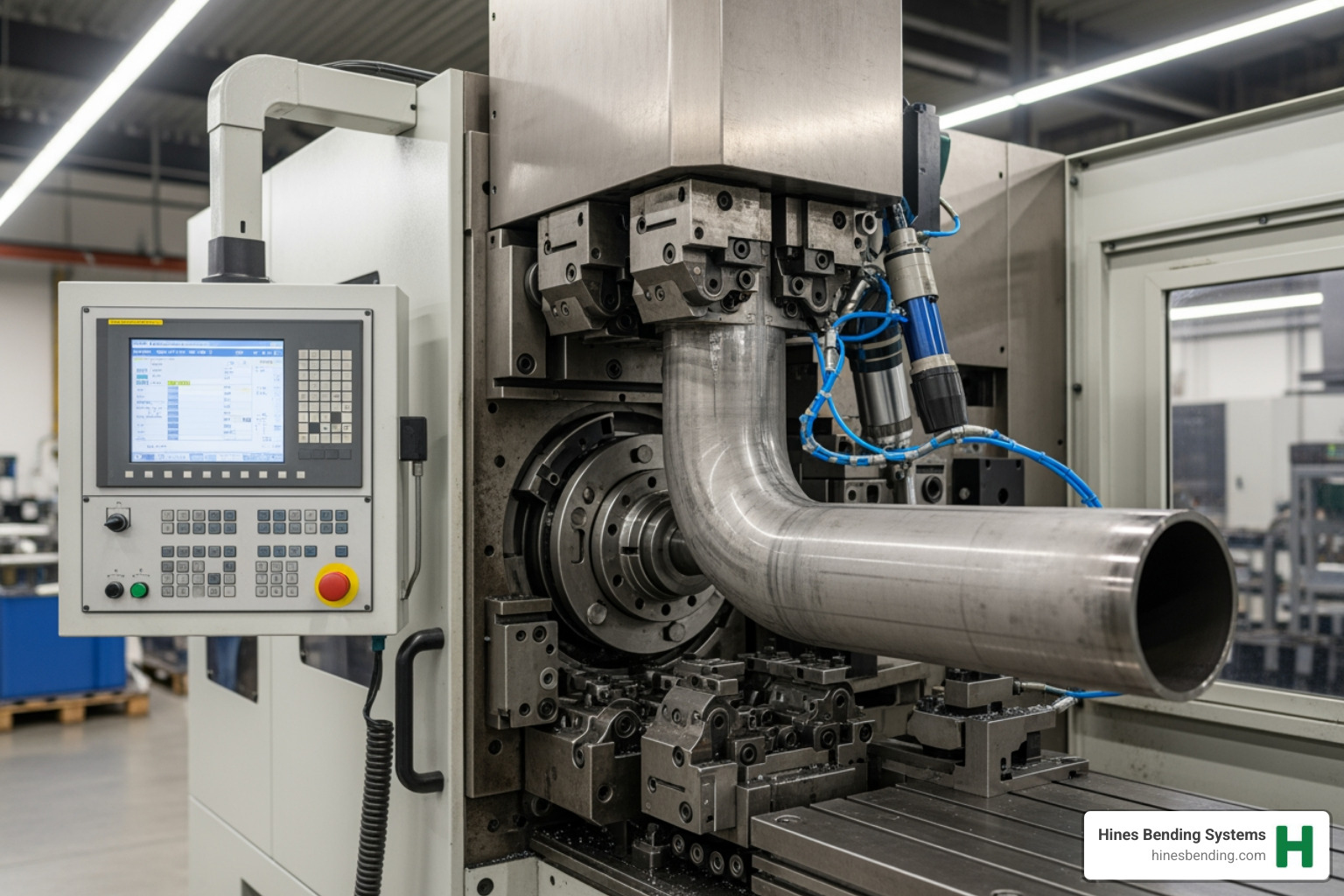

A CNC tube bending solution is a computer-controlled system that precisely bends tubes and pipes into complex shapes with best accuracy and repeatability. These automated systems use servo motors to control bend angles, distances between bends, and the plane of each bend—eliminating the guesswork and inconsistency of manual methods.

Key Benefits of CNC Tube Bending:

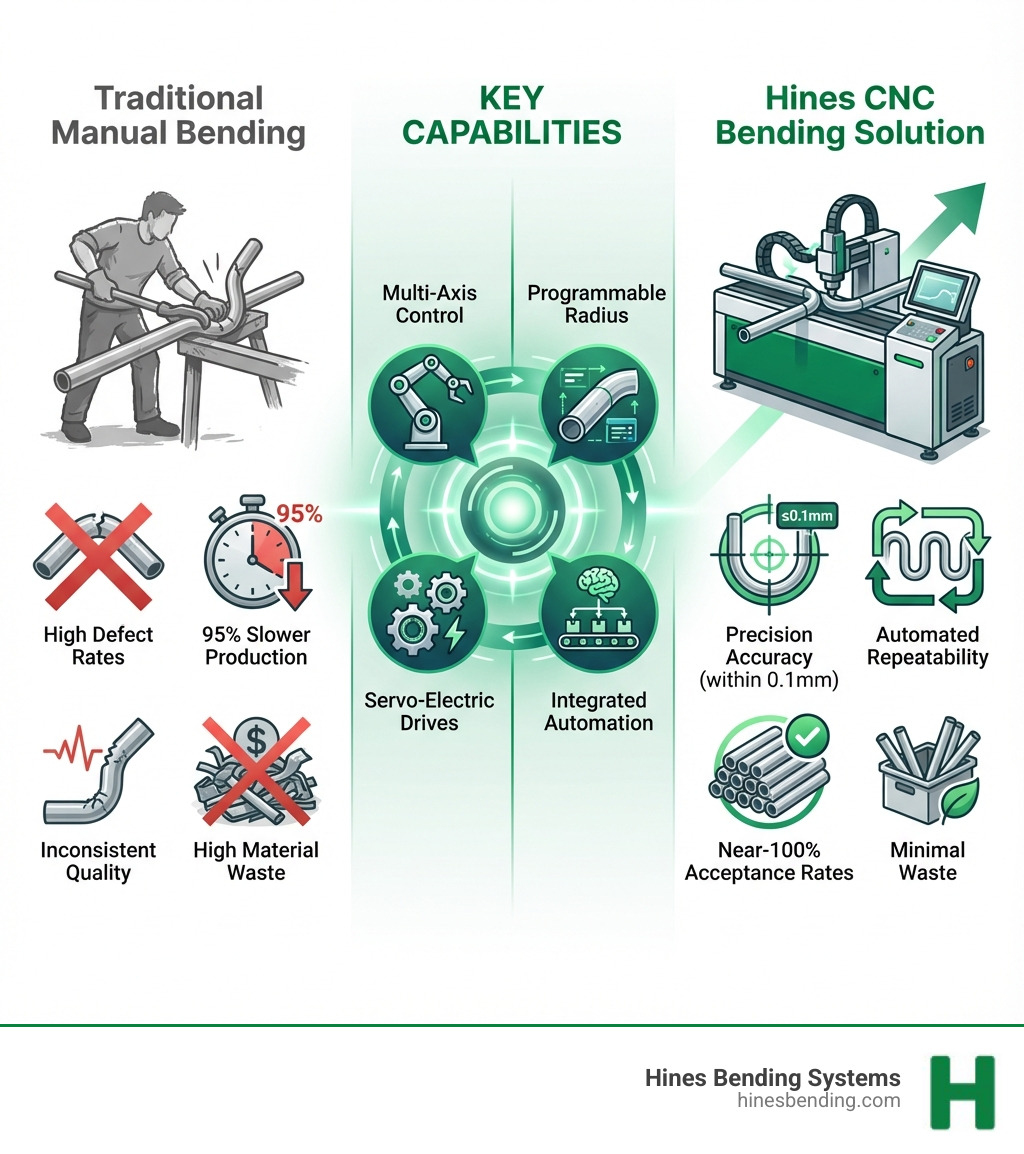

- Precision & Consistency – Achieves tight tolerances with minimal defects across every production run

- Time Savings – Up to 95% faster than manual bending processes

- Cost Efficiency – Eliminates expensive welds, joints, and custom fixtures

- Design Flexibility – Creates complex 3D shapes and multiple radii in a single cycle

- Material Versatility – Handles steel, stainless steel, aluminum, copper, titanium, and Inconel

- Reduced Waste – Uses exact material amounts through precise programming

If you’re facing challenges with complex bending requirements, high production costs, or maintaining precision across runs, you need a partner with proven expertise. Hines Bending Systems is the #1 worldwide manufacturer of tube and pipe benders, trusted by industry leaders including NASA to deliver superior quality and custom solutions.

Modern manufacturing demands precision that manual methods simply cannot achieve. Whether you’re producing automotive components, aerospace parts, or HVAC systems, the right CNC tube bending solution transforms your production efficiency while maintaining the highest quality standards.

The difference between a good bending solution and a great one comes down to machine quality, control sophistication, and manufacturer expertise. Hines Bending Systems combines all three with decades of experience engineering custom solutions for the world’s most demanding applications.

Common cnc tube bending solution vocab:

- advanced CNC machines

- automatic pipe bending machine

- CNC bending services

The Core Advantages: Why Leading Industries Choose Hines CNC Bending Solutions

In today’s competitive manufacturing landscape, precision, quality, and efficiency are not just buzzwords—they are necessities. At Hines Bending Systems, we understand this deeply, which is why our CNC tube bending solutions are engineered to deliver unparalleled advantages that set us apart as the global leader.

Our machines offer best precision, minimizing defects and ensuring consistency across both small and large production runs. This translates into industry-leading consistency and the ability to achieve incredibly tight tolerances, which is critical for high-quality finishes in demanding applications. We’re talking about precision down to +/- 0.1 mm in bending accuracy and +/- 0.1° in rotation accuracy. This level of control ensures that every bend is executed perfectly, every time.

One of the most significant benefits of a Hines CNC tube bending solution is its inherent repeatability. Our computer-controlled processes minimize human error, guaranteeing that once a program is set, each subsequent part will be an exact replica. This consistent quality is why our customers experience near-100% acceptance rates for their delivered parts, drastically reducing waste and rework. When you partner with us, you gain confidence that your material is bent precisely to specifications.

Efficiency gains are another cornerstone of our CNC bending technology. Compared to manual methods, CNC tube bending can save up to 95 percent of time in production. This dramatic increase in speed allows for streamlined production, reduced lead times, and significantly higher throughput. Imagine completing a complex tube bend in less than a minute – that’s the kind of efficiency our machines bring to your operations.

Beyond speed, our CNC tube bending solutions offer substantial cost-effectiveness. By eliminating the need for welds, joints, and expensive fixtures in complex assembly systems, we help reduce project costs and mitigate the risk of leaks. Each weld eliminated is a potential leak point removed, increasing the integrity and lifespan of your products. For instance, eliminating just five fittings from each of ten systems can effectively eliminate the cost of 50 fittings, showcasing the immense savings potential. Furthermore, projects become generally less expensive as fewer connection points lead to lower overall costs and reduced opportunities for contamination. Our machines produce a smoother finish compared to other processes, and fewer bends in a system minimize flow restrictions for chemicals and liquids, ensuring optimal performance.

We are committed to providing you with solutions that excel in quality and performance. More info about our customer-first promise.

Achieving a Superior CNC Tube Bending Solution with Hines

Our commitment to innovation extends to every aspect of the bending process, ensuring that whether you’re dealing with small batches or large volumes, a Hines CNC tube bending solution provides maximum value.

For small to mid-size production runs, our technology is particularly beneficial. Traditional methods often become inefficient and cost-intensive for lower volumes, but our automated and programmable processes allow for quick setup and changeovers between different part designs. This flexibility means you can easily switch between projects without significant downtime or the need for additional, specialized machinery. A single, multi-purpose Hines CNC tube bender can perform many different tasks, significantly reducing your investment in dedicated machinery and optimizing floor space. We empower manufacturers to experiment with a wide range of geometries, sizes, and angles without investing in new, dedicated machines, fostering rapid innovation and responsiveness to market trends.

Material waste reduction and sustainability are also key advantages. The precise, pre-programmed path of a Hines CNC machine uses only the exact amount of material needed. This meticulous approach significantly reduces waste compared to traditional methods that often involve trial-and-error, leading to more sustainable and cost-effective production practices.

When it comes to tooling, our CNC tube bending solutions offer distinct cost advantages. Our machines can use stock dies to produce a range of different parts at standard radii, eliminating the high costs and long lead times associated with custom tooling. Even when custom dies are necessary, their cost is typically manageable, ranging from $3,000 to $5,000, a stark contrast to the tens or hundreds of thousands for complex traditional tooling. Furthermore, advanced features like programmable radius allow our machines to accommodate bends with radii greater than 10 times the tube diameter, often minimizing the need for entirely new tooling. We engineer our tooling solutions to maximize efficiency and minimize your investment.

Open uping Design Freedom: The Capabilities of Hines CNC Tube Bending Solutions

The true power of a Hines CNC tube bending solution lies in its ability to transform complex designs into reality with unprecedented freedom and precision. We empower engineers and designers to push the boundaries of what’s possible, creating intricate forms that were once considered impractical or impossible.

Our machines handle an impressive range of material versatility. Whether you’re working with common materials like steel, stainless steel, and aluminum, or specialized alloys such as copper, titanium, brass, and Inconel, our benders are equipped to deliver flawless results. This broad material capability ensures that your design choices are never limited by the bending process.

When it comes to size, Hines machines are equally versatile. We offer solutions for everything from small diameter tubing to large OD pipes, with capabilities extending to diameters up to 12 3/4 inches. This extensive range allows us to serve diverse industries, from intricate aerospace components to robust industrial pipelines.

At the heart of our advanced machine features are all-electric servo drives and multi-axis control. Our CNC tube benders are servo-driven for precise control over the Distance Between Bends (DBB), Plane of Bend (POB), and Degree of Bend (DOB). This multi-axis control ensures that every aspect of the bend is carefully managed, resulting in unparalleled accuracy and repeatability. Many of our innovative machines, such as our innovative Hines Dual Stack CNC Push Bender, can bend multiple fixed and variable radii in the same cycle, significantly expanding design possibilities and streamlining production. We enable the creation of complex geometries, including 3D freeform shapes and bends beyond 180 degrees, allowing for spiral bending and continuously changing radii. This advanced capability minimizes wall thickness reduction at the back of the bend, preserving material integrity crucial for high-pressure applications. Our machines can even manage parts with “0” straight lengths, a testament to their engineering prowess.

The Role of Advanced Software and Controls

The brain behind every high-performance Hines CNC tube bending solution is its advanced software and control system. We integrate cutting-edge technology to ensure intuitive operation, seamless integration, and maximum efficiency.

Our machines feature PC-based control systems, offering user-friendly interfaces and touch screen operation that simplify complex programming. The BendPro G2 Control, used with Hines CNC Benders, is PC-based and easily interfaces with most engineering software, allowing programming changes directly from a desktop. This means your team can work efficiently from locations such as our Florida facilities in Fort Myers, Sarasota, Cape Coral, Miami, Orlando, Jacksonville, or West Palm Beach.

Software integration is a game-changer for engineering workflows. Our systems allow for the direct import of CAD files, such as STEP and IGIS, into the CNC bender control. This eliminates manual data entry, reduces errors, and accelerates the transition from design to production.

Furthermore, our programming and simulation capabilities are second to none. Our powerful and intuitive 3D software includes features like anti-collision checks, which simulate the bending process to prevent costly errors before they occur. We also incorporate sophisticated spring-back compensation, where sensors monitor the material’s elastic behavior to automatically adjust bending cycles, reducing waste and ensuring precise results. This comprehensive control over the bending process ensures that even the most intricate designs are executed flawlessly. BendPro G2 Control systems by Hines.

Building a High-Performance Bending System with Hines Expertise

Developing a truly high-performance CNC tube bending solution goes beyond just the machine itself; it involves understanding the intricate interplay of tooling, automation, and, most importantly, human expertise. At Hines Bending Systems, we bring all these elements together to deliver complete, optimized solutions.

At the core of precise tube bending are the essential tooling components. We carefully select and design each piece to work in harmony with our machines:

- Mandrel: This internal support is crucial for preventing the tube from wrinkling, distorting, collapsing, flattening, or breaking during the bend. Its firmness is carefully matched to the tube’s material and wall thickness.

- Wiper Die: Positioned at a slight angle with a sharp contact point, the wiper die supports the inside of the bend, effectively preventing wrinkles and ensuring a smooth, aesthetically pleasing finish.

- Clamp Die: Working in conjunction with the bend die, the clamp die secures the tube, preventing slippage. The ideal length of a clamping die is typically three times the diameter of the tube.

- Bend Die: This component dictates the radius of the bend, shaping the tube according to the programmed specifications. The radius of the bend die must account for the tube’s durability and radial growth.

Proper lubrication, often a non-petroleum-based synthetic paste or gel, is also vital to lower friction and achieve clean, smooth results.

The power of automation transforms individual machines into highly efficient production cells. Our CNC tube bending solutions can be seamlessly integrated with automatic loading and unloading systems. These systems, often including features like adjustability for tube diameter and length, and verification systems for tube blockage, ensure continuous operation and maximize productivity. We can also incorporate advanced features like weld seam verification and orientation, further enhancing quality control within a fully automated cell. This means your tubes can be automatically loaded, bent, cut, and prepared for the next stage of production with minimal human intervention.

However, the most critical component in any successful bending operation is expertise. Nobody in the bending machine industry has more expertise and experience than Hines Bending Systems. We pride ourselves on partnering closely with clients to provide custom solutions custom to their unique needs. Our reputation for quality and reliability is why massive agencies and companies such as NASA trust us to deliver their bending solutions. We’ve had the honor of working with them on critical projects, demonstrating our capability to meet the most stringent requirements. See how we worked with NASA.

To ensure you get the most out of your investment, we emphasize comprehensive support and training. We provide operator training and ongoing support to maximize machine efficiency and ensure your team is proficient in programming and operating our advanced systems. Our commitment extends to 24/7 technical support, remote diagnostics, and a flexible, fast, and comprehensive spare parts supply to keep your operations running smoothly. Learn about our training programs.

Frequently Asked Questions about CNC Tube Bending

When considering a CNC tube bending solution, you likely have questions. Here, we address some of the most common inquiries to help you make informed decisions.

How can a part be replicated without a drawing?

It’s a common scenario: you have an existing bent tube, but no digital drawing or blueprint. This is where modern technology truly shines. Using a Coordinate Measuring Machine (CMM) arm, we can physically measure and capture the geometrical characteristics of the existing bent tubing. The CMM then produces precise coordinates, which can be directly communicated to our Hines CNC tube benders. This process allows us to create an exact identical product with no prototyping, waste, or re-work, saving you significant time and cost. It’s a powerful form of reverse engineering that guarantees accuracy and repeatability.

What makes a Hines CNC bender superior?

Our superiority stems from a combination of factors rooted in decades of experience and a relentless pursuit of excellence.

- Uncompromising Build Quality: Hines machines are built with robust construction and superior components, ensuring exceptional rigidity and longevity, unlike cheaper alternatives that may compromise integrity.

- Precision Engineering: We use advanced servo motors and precision mechanics to achieve best accuracy in every bend. Our benders are designed for consistent performance, even under the most demanding conditions.

- Sophisticated Control Software: Our proprietary control systems, like the BendPro G2, are intuitive, powerful, and seamlessly integrate with engineering software, offering superior programming and simulation capabilities.

- Unparalleled Expertise and Support: As the #1 worldwide manufacturer, nobody in the bending machine industry has more expertise and experience than Hines. We offer comprehensive application support, custom tooling design, installation, and ongoing training and technical support to ensure your success. Our machines are designed for 24/7 production, boasting high-quality, low-maintenance components.

What support is crucial when investing in a Hines CNC tube bending solution?

Investing in a Hines CNC tube bending solution is a partnership, and our support is designed to ensure your long-term success. Key aspects of our crucial support include:

- Application Support: Our experts work with you to understand your specific bending challenges and recommend the optimal machine and tooling configuration.

- Custom Tooling Design: We engineer custom tooling solutions custom to your unique part geometries and material specifications.

- Seamless Installation: Our experienced technicians ensure your machine is installed correctly and integrated efficiently into your production environment.

- Comprehensive Operator Training: We provide hands-on training to your team, empowering them to program, operate, and troubleshoot the bender for maximum efficiency.

- Readily Available Spare Parts: We maintain a flexible, fast, and comprehensive spare parts supply to minimize downtime and keep your operations running smoothly.

- Remote Diagnostics and 24/7 Technical Support: Our team is always ready to troubleshoot, answer programming questions, and provide technical assistance, often remotely, ensuring continuous support.

Conclusion: Secure Your Competitive Edge with the Global Leader in Bending

In conclusion, a Hines CNC tube bending solution is more than just a machine; it’s a transformative investment that redefines manufacturing capabilities. We’ve seen how our technology delivers unparalleled precision, boosts efficiency through automation, and open ups new frontiers in design innovation. From minimizing defects and material waste to significantly reducing production times and costs, our solutions empower businesses to achieve higher quality and greater profitability.

The right partner is absolutely key to using these benefits. With decades of experience and a steadfast commitment to quality, Hines Bending Systems stands as the #1 worldwide manufacturer of tube, pipe, and induction benders. Our unparalleled expertise, proven by our partnerships with industry giants like NASA, ensures that you receive not just a machine, but a custom solution engineered for your specific needs. We pride ourselves on the superior quality of our bending machines, which are designed to meet and exceed industry standards, ensuring longevity and reliable performance.

Don’t settle for less when it comes to your bending needs. Choose the global leader in bending technology.

Contact Hines Bending to discuss your custom CNC bender solution.