All styles of hydraulic bender for sale are permanent fixtures in the bending industry. When built well and maintained, your hydraulic bender bends for decades. It is one reason why a hydraulic bender for sale continues to be a solid investment for many companies. Indeed it is expected that the hydraulic bender will not lose its popularity. To point out, the demand for bent parts expand every year. Not only in current markets but as new parts develop. Additionally, the hydraulic bender remains affordable and has low maintenance. This keeps a hydraulic bender for sale front and center.

The Benefits of a Hydraulic Tube Bending Machine

Hydraulic benders continue to be very affordable which always helps the bottom line when turning a profit sooner. When you make your parts with a semi-automatic bender, owning a hydraulic bender for sale becomes more affordable. This is especially true versus a fully automated CNC hydraulic bender.

Semi-Automatic Hydraulic Bender

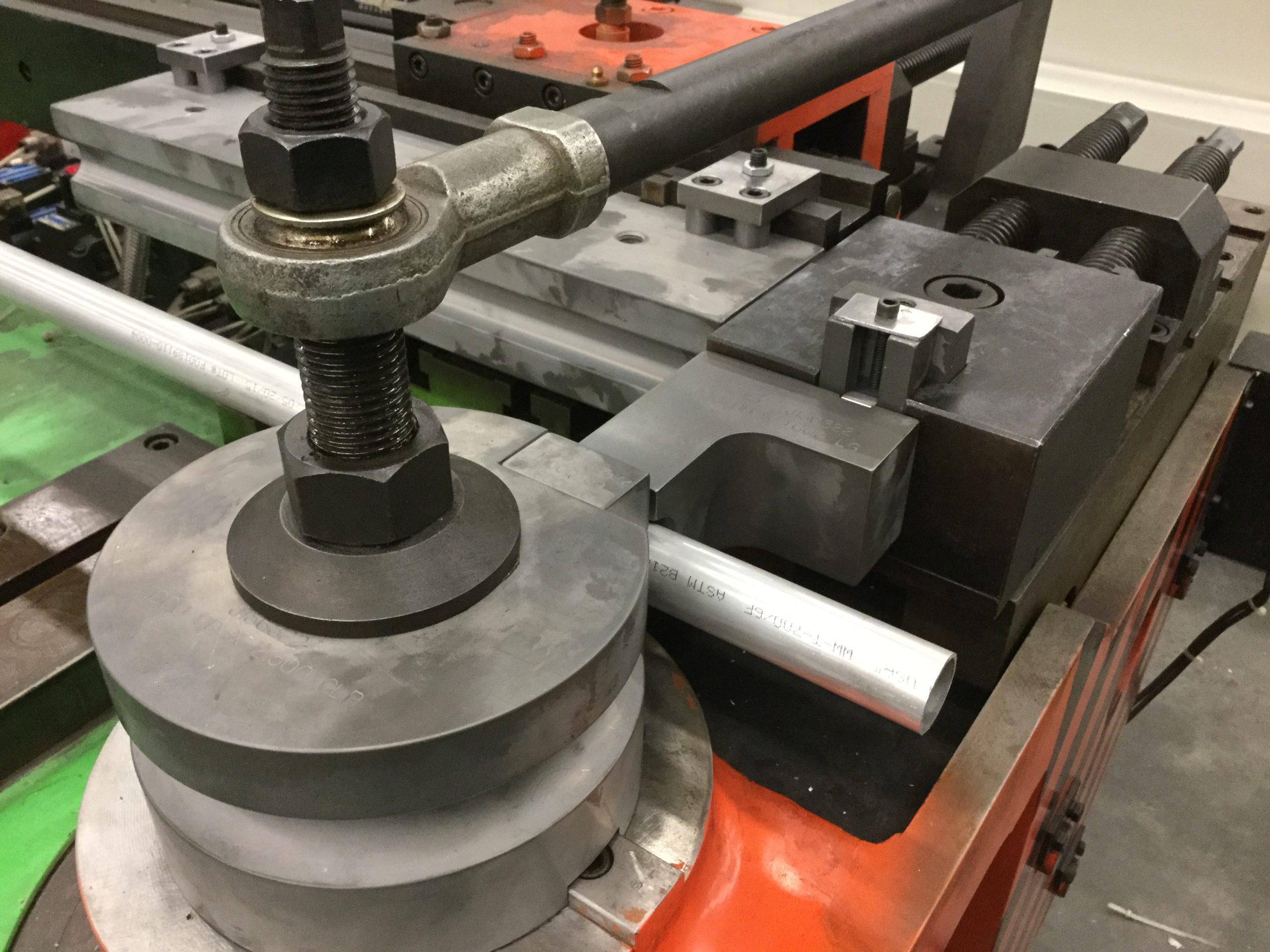

A semi-automatic hydraulic bender has more operator involvement. That said, if there is more than one bend per part you can save thousands on a hydraulic bender compared to a CNC. To illustrate, your operator goes to a saved job in the touchscreen. The job typically only ha dthe degrees of bend required for the part. Your operator loads the tube/pipe and then returns to the touchscreen to start the bend process. After the single bend is done, the operator goes back to the tube/pipe. The operator manually brings it forward to the next stop point. Then the operator returns to the touchscreen and finishes the second bend process. This continues until the part is complete.

CNC Hydraulic Bender

A fully automated CNC hydraulic bender reduces operator involvement and increases productivity. The operator programs the CNC touchscreen control with the bend specifications. This includes degrees of bend in addition to distance between bends, rotation, and so on. The operator loads the tube/pipe and returns to the CNC hydraulic bender touchscreen control. When the operator starts the bend process the CNC hydraulic bender forwards the tube/pipe to the first bend.

It automatically makes the bend, then forwards and rotates (if needed) the tube and makes the second bend. A CNC hydraulic bender continues to bend the part until it is finished. The operator removes the completed part. With CNC automation comes a higher cost. It is not uncommon for companies to do a full cost analysis to determine which style of bender works best for them.

Low Maintenance of a Hydraulic Bender

A hydraulic bender is like a car or Caterpillar tractor. You take care of it and it will take care of you for many years to come. Most companies use their own employees and/or designated machinery maintenance team to do just that.

Typical maintenance includes keep the working parts wet, change filters as needed, filter or change the hydraulic oil in the tank when dirty. Other than that, you may have to clean a valve from time to time, change out a proximity switch, or replace cylinder seals. Even if onsite maintenance does not know how to change out seals, there are plenty of hydraulic services within range. Makes a difference when time is money.