If you have any questions about Induction Bending Machines, call Hines Bending today. 239-433-2132

BENEFITS OF INDUCTION-BENDING MACHINES

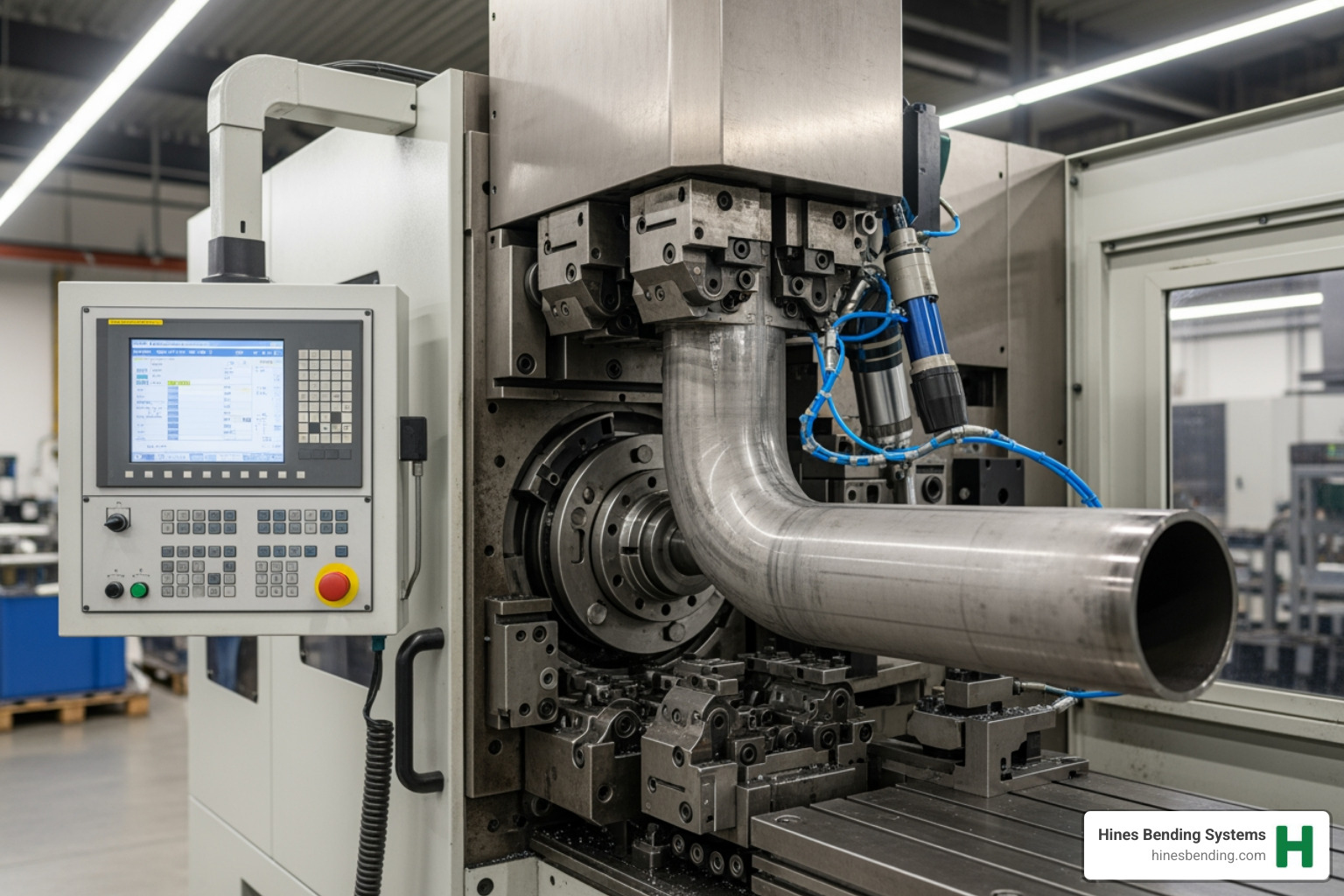

- The best flexible induction pipe bend machines available

- Patented technology is the most economical to use

- PLC operation is simple to use

- The quickest tool setup and cycle time

- Induction forming is the most economical solution, compared to other machines

CAPACITY OF INDUCTION PIE BENDING CAPACITY

All ranges of pipes can induction bend from 3″ (76mm), cast pipes up until 84″ (2,000mm).

Standard radii are 3d-10d, however, the machine can bend up to 300m/1000ft using special tooling.

Line pipe bending, road signs and road gantries, bridge tube bend, mining and quarry pipes and petrochemicals piping are some of the most common uses.

Materials that can be bent include Carbon Steel pipe and Stainless Steel and its allies, forged and cast pipe, and clad pipe.

INDUCTION BENT STRUCTURAL

BEAMS AND JOISTS

Inductaflex has more experience in structural section bending than any other manufacturer of induction bending machines. Inductaflex is the best choice if you care about the end result.

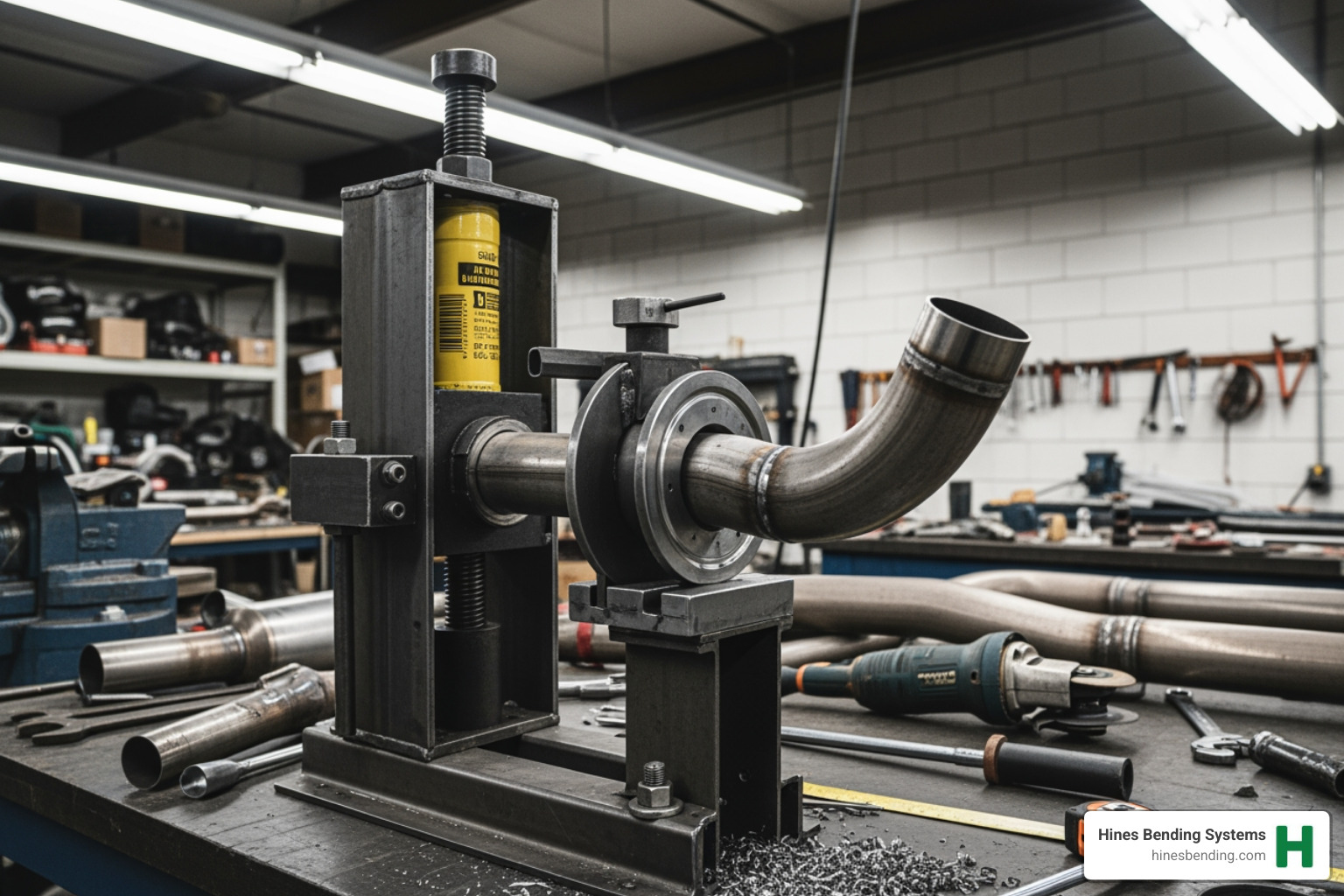

INDUCTION BENT TUBES

With minimal distortion, all sizes of square tubes are possible to be curved. These results are superior to those of any other manufacturer of induction bending machines. This is the result of the world’s largest structural steel-bending company.

These are used in a variety of applications, including curved metal sections that can be used for offshore and renewable constructions, curved sections for buildings and parts for mining and quarrying equipment.

The Hines Bending Systems range of induction benders is designed to bend pipes of high-performance and heavy-strength materials.

Hines Bending Manufactures Induction Tube Benders

They are ideal for mechanical forming pipe for alternative energy companies.

Induction benders can bend pipes up to a maximum of 125 lbs.

Hines Bending Systems is the #1 worldwide manufacturer of tube benders, pipe benders and induction benders. Customization can be an integral part of the process.

Our customers use the power of the facts that we build the best benders, have the most bender installations and have the most bending expertise and experience to leverage the very best bending solution for them. If you have any questions about Induction Bending Machines, call Hines Bending today. 239-433-2132

Induction Bending Machines

Related Post