Why Industrial Pipe Benders Transform Manufacturing Operations

Industrial pipe benders are precision machines that shape metal pipes and tubes using hydraulic, electric, or servo-controlled force to create accurate bends without compromising material integrity. These powerful systems deliver the consistency, speed, and safety that modern manufacturing demands.

Key Industrial Pipe Bender Technologies:

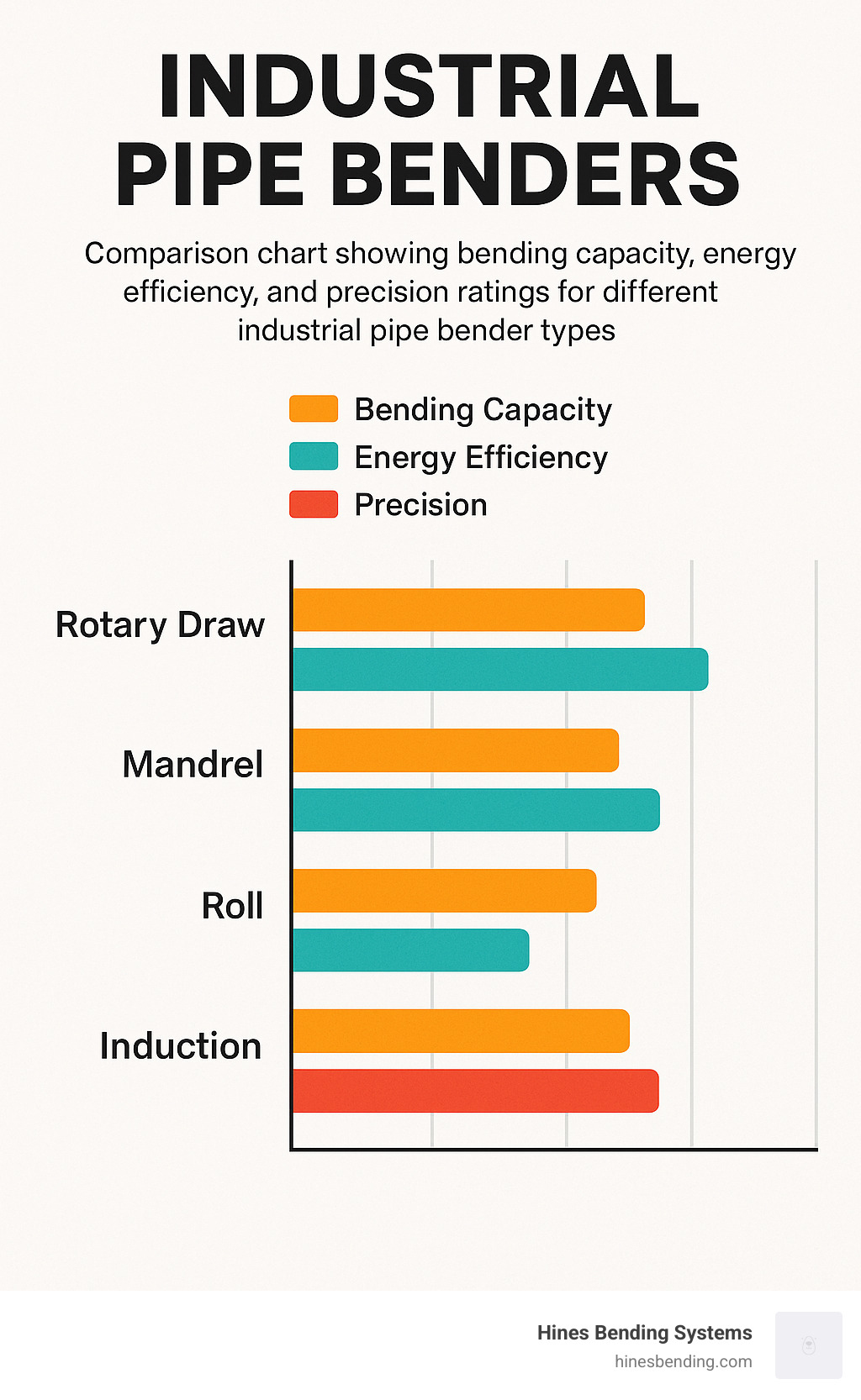

– Manual & Hydraulic – Portable, shop-floor flexibility with foot-pump operation

– Electric & CNC – Servo-electric drives with multi-axis programmable control

– Induction Bending – Heat-assisted forming for thick-wall, large-diameter pipes

– Mandrel Systems – Wrinkle-free tight radius bends with internal support

The manufacturing landscape has evolved far beyond hand-bending methods. Today’s operations require machines that can handle complex geometries, maintain tight tolerances, and deliver repeatable results across high-volume production runs.

Research shows that bending machines significantly reduce time and labor while ensuring consistent, precise bends. With capabilities ranging from small-diameter tubing to pipes over 12 inches, these systems serve industries from automotive and aerospace to utilities and construction.

Modern industrial pipe benders eliminate the guesswork of manual processes. They provide programmable controls, safety interlocks, and automated material handling that transform how manufacturers approach tube and pipe fabrication.

Whether you’re forming exhaust components, structural frameworks, or complex piping systems, the right bending technology determines your success in meeting quality standards while controlling costs.

Handy industrial pipe benders terms:

– CNC metal bending

– automatic pipe bending machine

– precision tube bender

What Makes Industrial Pipe Benders Essential?

Think of industrial pipe benders as the workhorses of modern manufacturing. These specialized machines transform straight pipes and tubes into precisely curved components through controlled mechanical force – and they do it with an accuracy that would make any craftsperson proud.

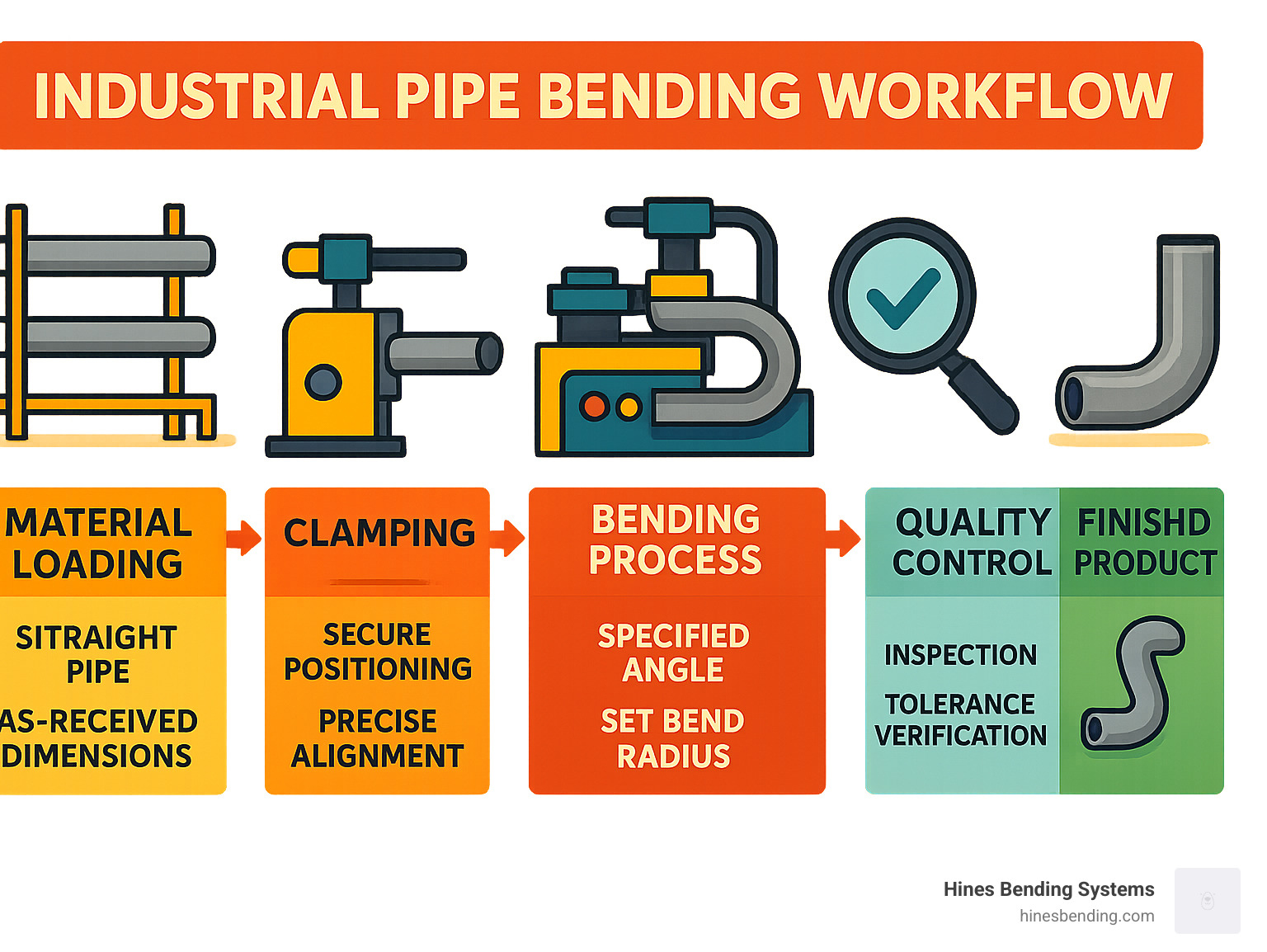

The magic happens through a beautifully orchestrated process. The pipe gets clamped securely in place, then a bend arm gradually applies pressure to form the desired angle. It’s like watching a master sculptor at work, except this sculptor never has an off day and can repeat the same masterpiece hundreds of times without breaking a sweat.

What really sets these machines apart is their incredible throughput and repeatability. While a skilled operator might hand-bend 20 pieces in a day, an industrial pipe bender can produce 500 or more identical parts in the same timeframe. Each bend is precise to fractions of degrees – the kind of consistency that makes quality control managers smile.

Wall integrity is another game-changer. These machines use sophisticated pressure control systems that prevent the nightmares of pipe bending: wall thinning, cracking, or that dreaded collapse. This is especially crucial when you’re working with thin-wall tubing or high-strength materials where every bit of structural integrity matters.

The cost-efficiency story gets interesting when you crunch the numbers. The upfront investment might make your accountant raise an eyebrow, but the reduction in scrap rates, labor costs, and rework typically pays for itself in under two years.

| Aspect | Manual Bending | Industrial Pipe Benders |

|---|---|---|

| Accuracy | ±5-10 degrees | ±0.1-0.5 degrees |

| Production Rate | 10-20 parts/day | 100-500+ parts/day |

| Operator Fatigue | High | Minimal |

| Material Waste | 10-15% | 2-5% |

| Repeatability | Variable | Consistent |

| Maximum Diameter | Limited by strength | Up to 12+ inches |

Inside an Industrial Pipe Bender

Peek inside an industrial pipe bender and you’ll find a symphony of precision components working together. The clamping system is like a gentle giant – strong enough to hold the pipe absolutely still, yet gentle enough not to leave a mark. It’s this perfect balance that sets the foundation for every quality bend.

The pressure die works hand-in-hand with the bend die to shape your material. As the bend arm rotates, the pressure die stays in contact with the pipe’s outer surface, smoothing out any potential wrinkles and ensuring that beautiful, consistent radius.

When you need those tight-radius bends that seem impossible, the mandrel system steps up to the plate. This shaped rod slides inside the pipe before bending, providing internal support that prevents collapse or oval distortion. With mandrel support, you can achieve bends with centerline radii as tight as 1.5 times the pipe diameter.

The CNC control system is where the real magic happens. These computerized brains store bend programs, monitor hydraulic pressures, and execute complex multi-bend sequences automatically. Your operator simply loads the material, selects the program, and hits start.

Key Advantages Over Hand Bending

The accuracy advantage of industrial pipe benders goes way beyond just getting the angle right. These machines maintain consistent bend radii, eliminate variations in arc length, and ensure that multiple bends on the same part align perfectly every single time.

Reduced scrap rates represent real money in your pocket. Hand bending typically results in 10-15% scrap rates due to overbending, underbending, or material damage. Industrial benders routinely achieve scrap rates below 5%, with many operations reporting rates under 2%.

Operator ergonomics eliminates the physical strain and repetitive stress that can lead to injuries over time. Your operators can focus on setup, quality control, and material handling instead of wrestling with stubborn metal.

The ability to handle larger diameters opens up entirely new possibilities. While hand bending becomes a real challenge beyond 2-3 inch diameters, industrial benders can easily handle pipes up to 12 inches or more.

At Hines Bending Systems, we’ve perfected these technologies through decades of experience and thousands of installations worldwide. When NASA needs precision bending solutions, they turn to our expertise – and that same level of quality and reliability is available for your operation too.

Product Roundup: Best Industrial Pipe Benders by Technology

The universe of industrial pipe benders is broad, but choosing gets easy when you match technology to your production goals. After installing more bending machines worldwide than any other company, Hines Bending Systems has seen every scenario—from job-shop flexibility to aerospace-grade precision.

Manual & Hydraulic Workhorses

Manual and hydraulic benders deliver dependable performance without complex electronics. Foot-pump force of 20–30 tons tackles everyday shop needs, while portable frames roll to any workstation or job site. Simple radius gauges and rugged construction mean these units operate for decades with minimal upkeep—perfect for custom or low-volume runs that still demand Hines-level accuracy.

Electric & CNC Leaders

When tolerances get tight or volumes soar, CNC industrial pipe benders take over. Servo-electric drives consume energy only while bending, slashing operating costs and noise. Our multi-axis control handles intricate parts—think exhaust manifolds with a dozen bends—then swaps tooling in minutes thanks to quick-change systems. Advanced features like collision detection and automatic spring-back compensation come standard. More info about CNC Bending Machine

Induction & Mandrel Specialists

For thick-wall or exotic alloys, induction bending locally heats material so it forms without cracking. When a bend radius pushes physical limits, our mandrel systems act as internal scaffolding, producing wrinkle-free, tight radii that keep pipes perfectly round. Power plants, offshore rigs, and even NASA projects rely on these specialized Hines solutions to meet demanding specs without costly welds or fittings.

Selecting the Right Machine for Your Job

Choosing the perfect industrial pipe bender can feel overwhelming with so many options available. But don’t worry – at Hines Bending Systems, we’ve helped thousands of manufacturers worldwide find their ideal solution. Our expertise comes from installing more bending machines globally than any other manufacturer, including systems trusted by NASA for their most critical applications.

Material type forms the foundation of every machine selection decision. Steel pipes bend predictably but demand higher forces for thick-wall applications. Aluminum offers more forgiveness during the bending process but can work-harden if you rush things. Stainless steel has a sneaky habit of springing back more than other materials, which means your bending program needs to compensate for this behavior.

Each material tells its own story during bending. Exotic alloys used in aerospace applications require specialized knowledge and precise control that only comes from years of experience. That’s why companies like NASA trust Hines Bending Systems – we understand how different materials behave under stress.

Diameter and wall thickness create the force equation that determines your machine requirements. Larger diameters require exponentially more force, not just a little more. Meanwhile, thin walls demand the delicate touch of precise pressure control to prevent collapse. Latest research on tube-bending fundamentals provides additional technical insights into these relationships.

Minimum centerline radius requirements often separate the standard solutions from the specialized ones. If you need centerline radii less than 3 times your pipe diameter, you’re entering mandrel territory. These tight bends require internal support to prevent distortion – something our advanced mandrel systems handle beautifully.

Production volume significantly impacts your return on investment calculation. High-volume operations benefit tremendously from CNC systems with their superior speed and consistency. Lower-volume work might be better served by manual or hydraulic systems that offer greater flexibility without the higher initial investment.

Energy consumption has become a major consideration for smart manufacturers. Electric systems typically consume less energy than hydraulic systems, especially in applications with frequent start-stop cycles. Over a machine’s lifetime, this difference can add up to substantial cost savings.

At Hines Bending Systems, we work closely with each customer to understand their complete requirements – not just today’s needs, but where they’re headed tomorrow. Our decades of experience help us recommend solutions that will serve you well for years to come.

More info about What Type of Bending Machine is Best for Me?

Quick Selection Checklist

A systematic approach to spec sheet review ensures you don’t miss any critical requirements. Start with the hard limits – maximum pipe diameter and wall thickness cannot be exceeded, period. Then dive into bend radius capabilities, particularly minimum centerline radius if tight bends are part of your future.

Tooling availability can make or break your machine selection decision. At Hines Bending Systems, we maintain extensive tooling inventories and offer quick-change systems that dramatically reduce setup time between jobs.

Software integration capabilities have become crucial in today’s connected manufacturing environment. Look for systems that accept CAD files directly, integrate with your ERP system, and provide production data for analysis.

Future scalability should factor into every machine selection decision. We always encourage customers to think beyond current needs and consider anticipated growth and product evolution. Our modular systems can be upgraded with additional axes or automation components, providing valuable flexibility as your business grows.

The beauty of working with Hines Bending Systems lies in our collaborative approach. We don’t just sell machines – we partner with you to understand your complete operation. Our experience with installations worldwide, from small job shops to NASA facilities, gives us unique insight into what works in real-world applications.

Overcoming Bending Challenges & Future Trends

Even with the most reliable equipment on the planet, bending can present problems. Decades of field data from thousands of Hines installations have refined solutions for the big three problems:

- Wrinkling – eliminated by optimized pressure dies and proven tooling setups.

- Spring-back – countered by built-in CNC compensation tables for each material grade.

- Ovality – minimized with precision mandrels and proper lubrication.

Regular maintenance is simple and pays off: scheduled fluid changes, quick visual checks, and annual calibrations reduce unplanned downtime by up to 80 %.

Automation & Robotics

Hines integrates vision-guided robots that load, bend, inspect, and sort parts for true lights-out production. Customers routinely report throughput gains of 200–300 % while freeing skilled staff for higher-value tasks. Real-time data logging supports continuous improvement initiatives across your plant.

The Road Ahead: Smart, Green, Connected

- IoT monitoring predicts issues before they stop the line.

- Energy-recovery hydraulics and fully electric models cut power use by up to 30 %.

- Recycled-material readiness ensures sustainable production without sacrificing quality.

With Hines, you’re not just buying a bender—you’re investing in a platform that evolves with Industry 4.0, environmental goals, and tomorrow’s manufacturing challenges.

Frequently Asked Questions about Industrial Pipe Benders

When manufacturers start exploring industrial pipe benders, they naturally have questions about capabilities, limitations, and best practices. At Hines Bending Systems, we’ve answered these questions thousands of times across our decades of experience. Here are the three most common concerns we hear from customers worldwide.

What materials can I bend without cracking or wrinkling?

The good news is that most common materials bend beautifully when you use the right approach and proper tooling. Steel, aluminum, stainless steel, copper, and brass all respond well to industrial bending within their respective limits. The secret lies in understanding how material grade, temper, and wall thickness work together.

Soft materials like annealed copper are forgiving and bend easily, though they often need mandrel support for tight radii to prevent collapse. Hard materials like high-strength steel demand more force but reward you with better shape retention after bending. When it comes to exotic materials like titanium or Inconel, you’re entering specialized territory that may require heat-assisted bending techniques.

Wall thickness creates the biggest challenge for most applications. Thin walls – anything less than 10% of the pipe diameter – are prone to collapse and need careful handling. Thick walls over 15% of diameter can crack on the outside of the bend if pushed too hard. The sweet spot for most materials falls right between these extremes.

At Hines Bending Systems, our decades of hands-on experience with diverse materials means we can guide you through even the most challenging applications. We’ve successfully bent everything from delicate medical tubing to heavy-wall petrochemical piping. Our expertise comes from being the world’s #1 manufacturer of bending equipment – nobody in the industry has more experience with material behavior than our team.

How do I calculate the minimum bend radius for my pipe size?

Calculating minimum bend radius involves balancing material properties, wall thickness, and your quality requirements. The general starting point is a centerline radius of at least 3 times the pipe diameter for standard applications. You can achieve tighter radii with mandrel support and specialized tooling, but this baseline keeps you in safe territory.

Thin-wall applications often need more generous radii – sometimes 4 to 5 times diameter – to prevent collapse. Thick-wall pipes can sometimes handle tighter radii thanks to their structural strength, but you’ll need to watch for cracking on the outside of the bend.

Material properties play a huge role in determining practical limits. Soft materials like copper allow much tighter radii than hard materials like stainless steel. The material’s temper matters too – annealed materials bend more easily than work-hardened ones.

The most reliable approach is testing actual samples of your specific material and size combination. At Hines Bending Systems, we maintain extensive databases of proven bend parameters for thousands of material and size combinations. This knowledge base, built from more bending machine installations worldwide than any other manufacturer, saves our customers significant time and material during development phases.

What routine maintenance keeps an industrial pipe bender running longer?

Smart maintenance schedules can dramatically extend your machine’s life while preventing those costly unexpected breakdowns. Hydraulic systems need fluid changes every 2,000 to 4,000 hours depending on how hard you’re running them. Clean fluid is absolutely essential for consistent performance and long component life.

Your daily routine should include checking fluid levels, examining hoses for wear, and verifying that all safety systems work properly. Weekly maintenance typically involves cleaning filters, lubricating moving parts, and checking tooling for wear or damage. These small investments of time prevent major headaches later.

Monthly schedules should cover pressure testing, electrical connection inspection, and calibration verification. Annual maintenance gets into the serious stuff – major component inspection, seal replacement, and software updates. It sounds like a lot, but it’s far less expensive than emergency repairs.

Proper operator training prevents many maintenance issues before they start. When operators understand machine limits and follow proper procedures, they cause less wear and spot potential problems early. Well-trained operators are your first line of defense against expensive downtime.

At Hines Bending Systems, we provide comprehensive maintenance training and support to help our customers achieve maximum machine life. Our global service network means you get local support wherever our machines operate. This commitment to customer success is part of what makes us the trusted choice for organizations like NASA and other demanding applications where reliability isn’t optional.

Conclusion

Choosing the right industrial pipe benders can transform your manufacturing operations from struggling with inconsistent results to achieving precision that rivals the aerospace industry. The journey through manual systems, hydraulic workhorses, and cutting-edge CNC technology shows just how far bending capabilities have evolved.

At Hines Bending Systems, we’ve witnessed this evolution – and more importantly, we’ve led it. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we’ve installed more bending machines globally than anyone else in the industry. That’s not just a number – it’s proof of the trust manufacturers place in our solutions.

When NASA needs bending precision for space missions, they turn to Hines. When major manufacturers need custom solutions that work flawlessly for decades, they choose our expertise. This isn’t coincidence – it’s the result of best experience and relentless commitment to quality.

Nobody in the bending machine industry has more expertise than our team. We’ve solved bending challenges that others couldn’t even attempt. From delicate medical tubing to massive petrochemical piping, we’ve developed custom solutions that deliver results where standard approaches fail.

What sets us apart isn’t just our technology – it’s our approach. We work closely with every customer to understand their specific needs, then engineer solutions that exceed expectations. Whether you need a simple hydraulic bender or a fully automated production cell, we design each machine for its exact application.

The future belongs to smart, connected bending systems that combine mechanical excellence with digital intelligence. As manufacturing continues evolving toward automation and sustainability, Hines Bending Systems remains at the forefront, developing tomorrow’s bending technology today.

When you’re ready to find how industrial pipe benders can revolutionize your operations, contact Hines Bending Systems. Our global expertise and proven track record ensure you’ll receive not just a machine, but a complete solution engineered for long-term success.

More info about Industrial Tube Bender for Sale