What is a Bender Machine and Why It Matters

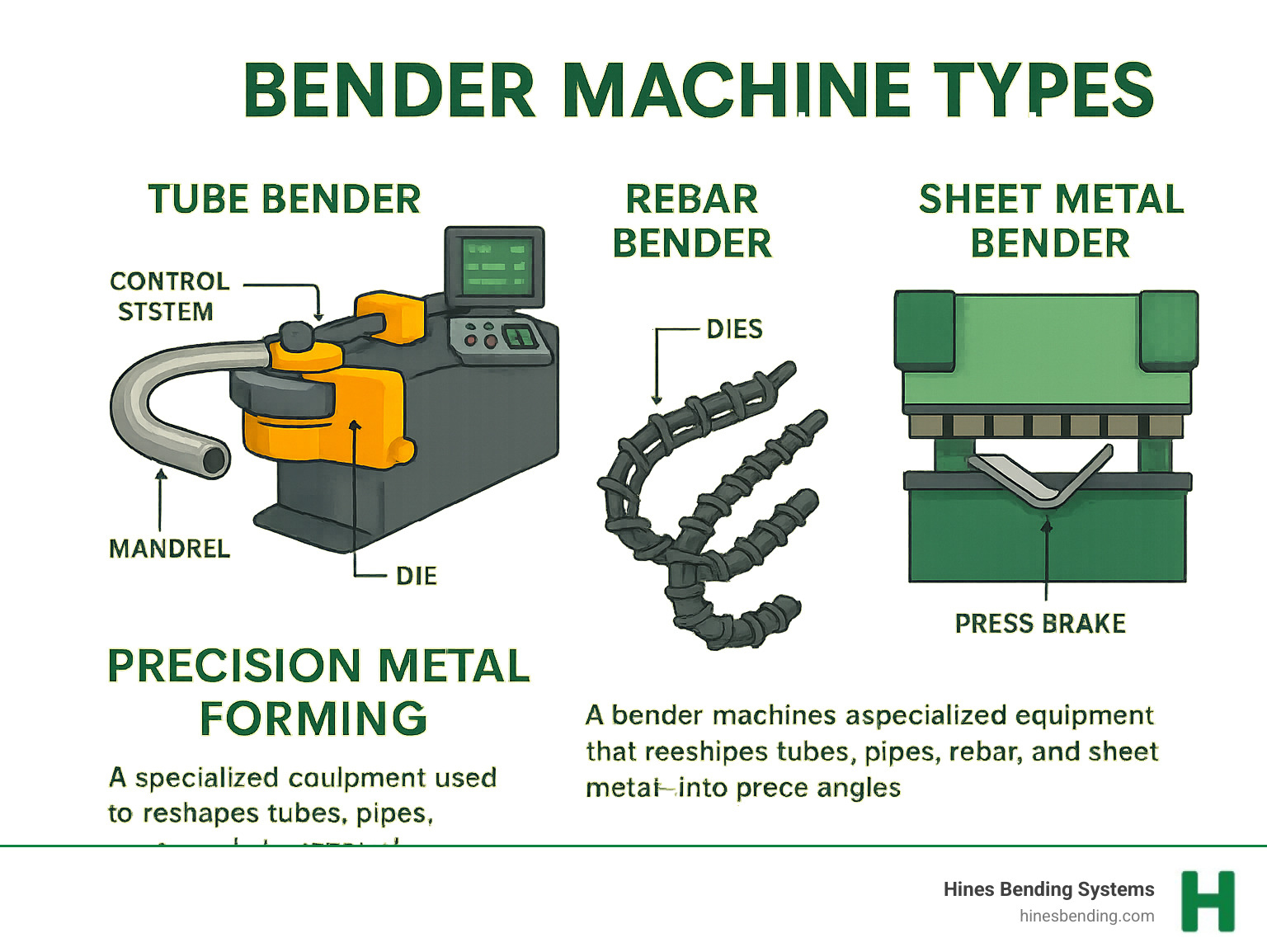

A bender machine is a specialized piece of manufacturing equipment designed to reshape metal materials—including tubes, pipes, rebar, and sheet metal—into precise angles and curves without compromising structural integrity. These machines are essential tools in modern fabrication, enabling manufacturers to create everything from aircraft components to construction reinforcement with exceptional accuracy and repeatability.

Key Types of Bender Machines:

- Tube and Pipe Benders – Shape hollow materials for aerospace, automotive, and plumbing applications

- Rebar Benders – Create reinforcement structures for concrete construction

- Sheet Metal Benders (Press Brakes) – Form flat metal sheets into angles, channels, and complex shapes

- CNC Benders – Automated systems for high-precision, multi-bend operations

Primary Applications:

- Aerospace ducting and hydraulic lines

- Automotive exhaust systems and frames

- Construction rebar and structural components

- Furniture, handrails, and architectural elements

In today’s competitive manufacturing landscape, precision bending has become a cornerstone of advanced fabrication. Industries like aerospace, automotive, and construction depend on bender machines to meet strict tolerances and quality standards. The difference between a standard bend and a precision bend can mean the difference between project success and costly failures.

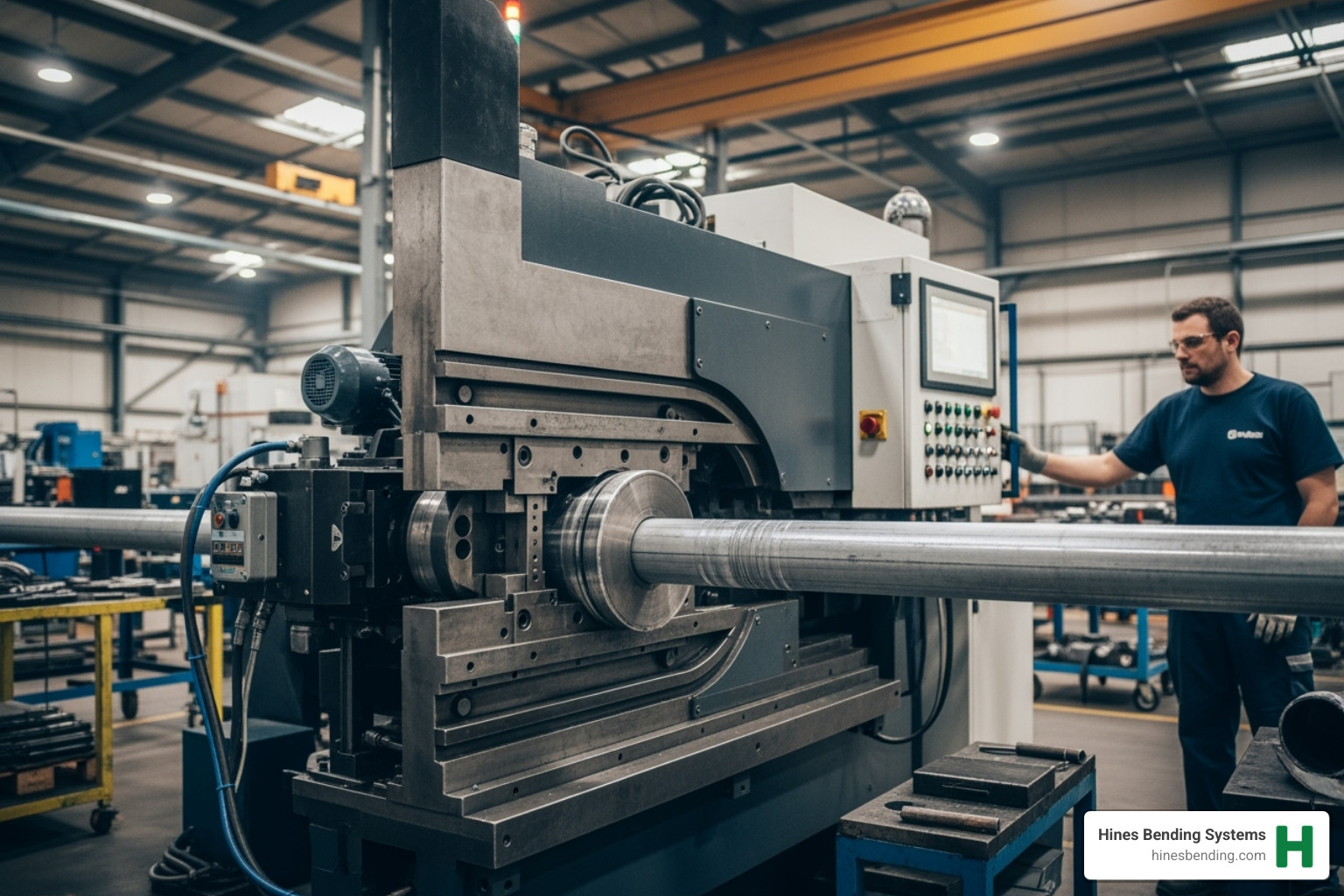

Hines Bending Systems stands as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, trusted by industry leaders including NASA. With decades of expertise and a commitment to custom solutions, Hines delivers the highest quality bending machines designed to meet the most demanding manufacturing requirements.

The complexity of modern bending operations requires more than just basic equipment—it demands expertise, precision engineering, and reliable support. That’s where partnering with an industry leader like Hines becomes critical for manufacturers seeking to improve productivity while maintaining the highest quality standards.

Bender machine word guide:

The Core of Fabrication: Hines Bending Machine Solutions

When you’re looking for a bender machine that delivers exceptional results, Hines Bending Systems stands as the clear choice. As the #1 worldwide manufacturer of bending equipment, we’ve built our reputation on understanding exactly what our clients need and delivering solutions that exceed expectations.

Our comprehensive range covers everything from precision tube and pipe benders to heavy-duty rebar benders and advanced sheet metal benders (press brakes). What makes us different? We don’t just sell machines—we partner with you to create custom solutions that fit your specific requirements perfectly.

This approach has earned us the trust of major organizations worldwide, including NASA, who rely on our expertise for their most critical projects. When space missions depend on precision bending, they turn to Hines.

More info about Hines tube and pipe benders

Hines Tube and Pipe Benders: Setting the Industry Standard

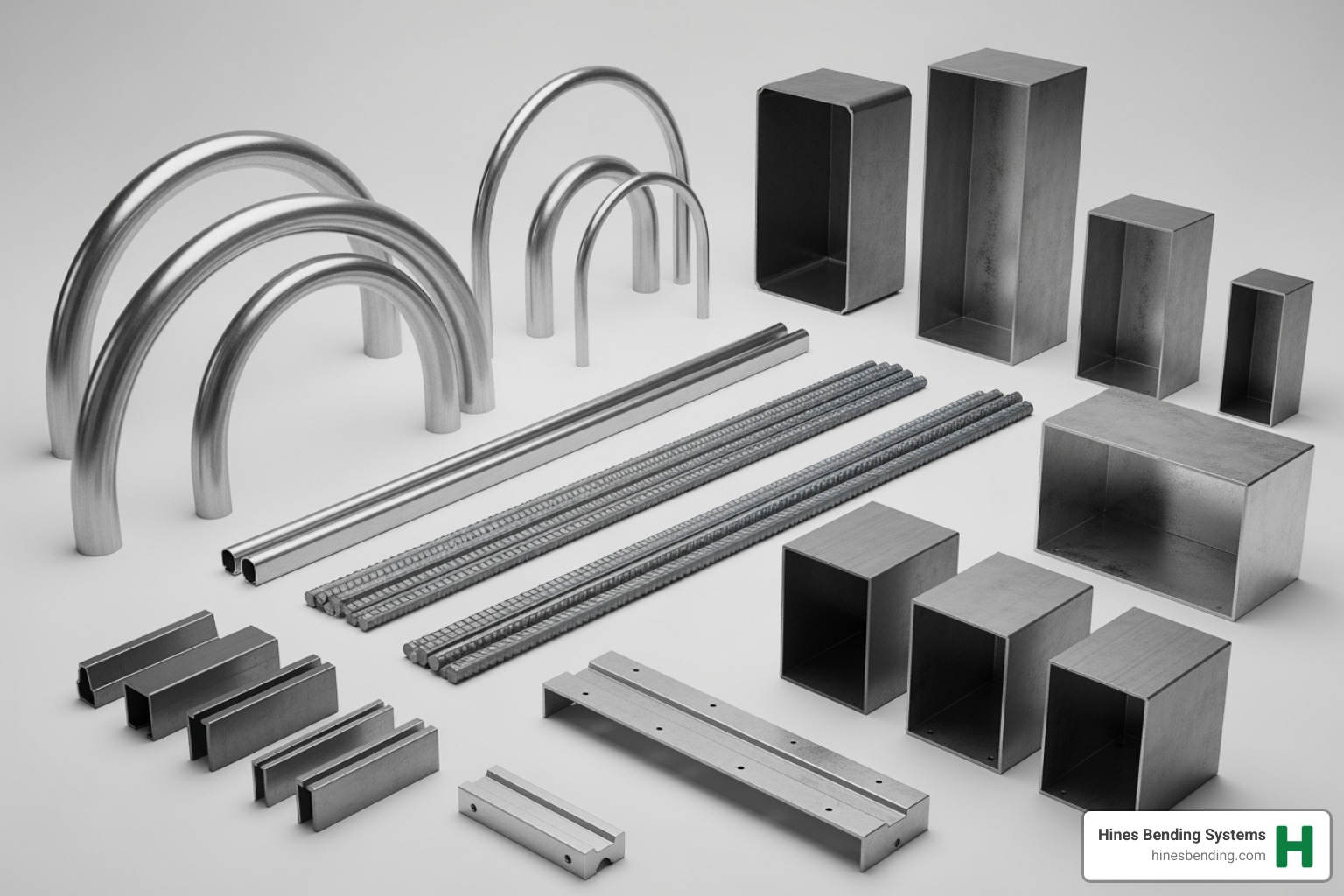

Our tube and pipe bending solutions are absolutely vital for aerospace, automotive, and shipbuilding industries. These machines create essential components that keep the world moving—from handrails you touch every day to complex exhaust systems and critical hydraulic lines in aircraft.

What sets our tube benders apart is their ability to work with an incredible range of materials. We’re talking about everything from standard steel to the most advanced alloys used in aerospace applications. The precision we achieve isn’t just impressive—it’s essential for safety-critical applications.

Our expertise in bending materials from steel to exotic alloys means you get the best precision possible, every single time. Whether you’re working with thin-wall tubing that requires delicate handling or heavy-duty pipes for industrial applications, our machines deliver consistent results that meet the strictest industry standards.

The secret lies in our deep understanding of material behavior during the bending process. We’ve spent decades perfecting our techniques to ensure that every bend maintains structural integrity while achieving the exact specifications you need.

Hines Rebar Benders: Reinforcing Construction Excellence

Construction professionals know that the foundation of any strong building starts with quality reinforcement. Our rebar bending machines are specifically designed for concrete reinforcement applications, producing stirrups, hoops, and spirals with industry-leading speed and accuracy.

What makes our rebar benders special is their ability to handle high-volume production without sacrificing quality. We’re talking about industry-leading speed and accuracy that construction professionals depend on to meet tight deadlines and demanding specifications.

Our proprietary technology ensures maximum productivity and reliability—two things that are absolutely crucial when you’re working on construction projects where delays cost money and mistakes can be dangerous. These machines are built to run day after day, delivering consistent performance that keeps your projects on track.

The beauty of our rebar bending solutions is that they combine speed with precision. You get the throughput you need for large projects while maintaining the accuracy required for structural integrity.

Hines Sheet Metal Benders: Precision for Panels and Enclosures

Our advanced press brake solutions represent the pinnacle of sheet metal bending technology. These machines form angles, channels, and custom shapes with applications that span across multiple industries—from electronics and architecture to custom fabrication projects.

The versatility of our sheet metal benders is remarkable. They handle applications in electronics, architecture, and custom fabrication with equal expertise. Whether you’re creating delicate electronic enclosures or heavy structural components, our machines deliver the precision you need.

What really sets our press brakes apart is their ability to deliver superior force and control for even the most demanding projects. This isn’t just about raw power—it’s about controlled, precise force application that gives you perfect results every time.

Our expertise in sheet metal bending comes from years of working with clients across diverse industries. We understand that every application has unique requirements, and our machines are designed with the flexibility to handle whatever challenges you throw at them.

How a Hines Bender Machine Works: Advanced Mechanisms and Methods

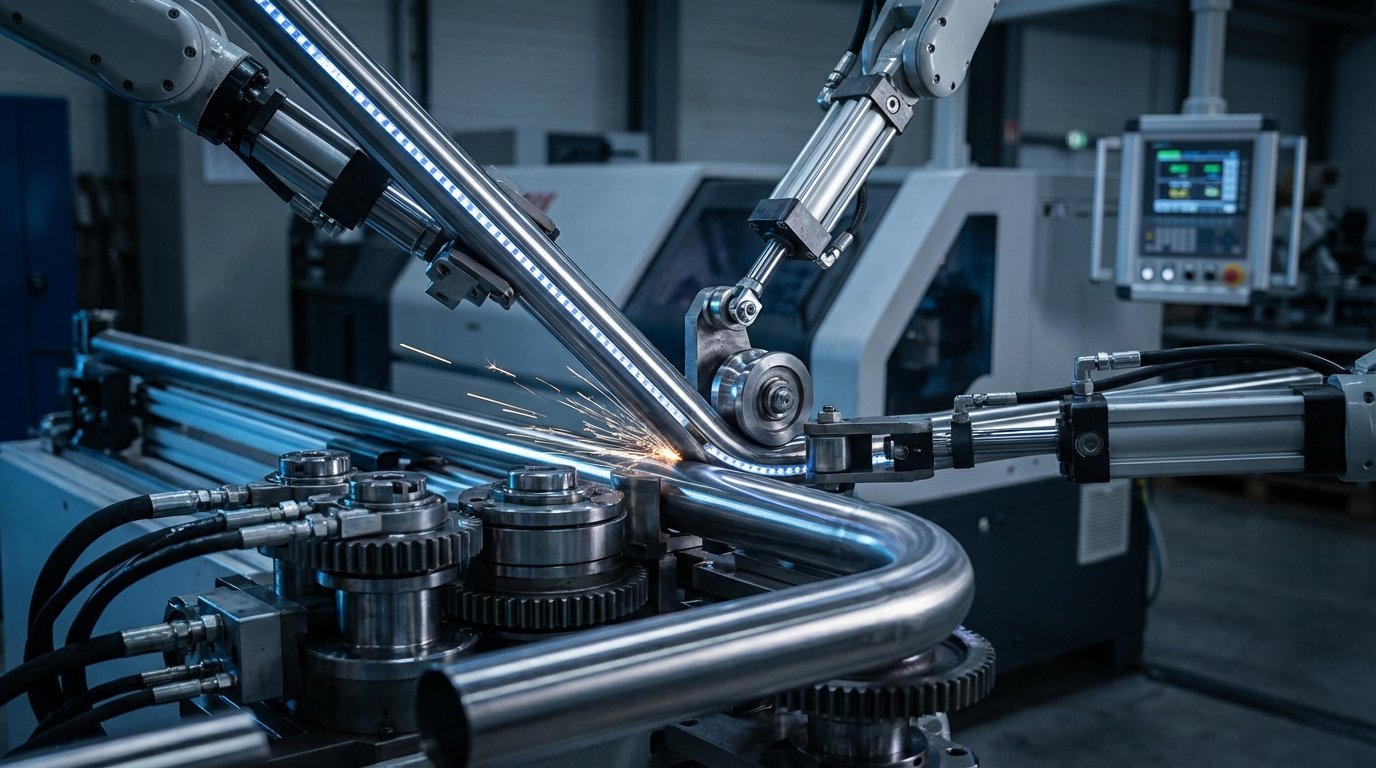

When you watch a bender machine in action, you’re witnessing decades of engineering expertise at work. At Hines Bending Systems, we’ve mastered the art and science of metal bending through countless installations worldwide. Our machines seamlessly integrate rotary draw bending, mandrel bending, die bending, and panel bending methods—all perfected through our best industry experience.

The magic happens when controlled force meets precision engineering. Each bend requires careful consideration of material properties, thickness, and the final application. That’s where our expertise truly shines. With more bender machine installations than any other manufacturer worldwide, we understand exactly how to achieve the perfect bend every time.

Precision Bending with Hines: Rotary Draw and Mandrel Expertise

Our rotary draw and mandrel bending technology represents the gold standard in the industry. When NASA needs flawless curves for their aerospace applications, they turn to Hines—and there’s a good reason for that trust.

The process itself is fascinating. The tube gets clamped in a bend die and drawn around the die’s radius by a rotating arm. But here’s where our engineering expertise makes all the difference: we insert a precisely shaped mandrel inside the tube to prevent collapse during bending. This isn’t just about following a process—it’s about understanding the exact pressure, timing, and tooling needed for each unique application.

Thin-wall tubing and tight radii applications are where our technology truly excels. While other manufacturers might struggle with tube collapse or inconsistent results, our proprietary methods ensure perfect repeatability. This level of precision is why aerospace manufacturers trust us for their most critical components.

Die and Press Bending: Hines’ Power and Simplicity

Sometimes the most neat solutions are the simplest ones. Our press brakes and die sets deliver consistent results for brackets, frames, and structural components through what might seem like straightforward mechanics—but the devil is in the details.

Our die bending process uses controlled downward movement to press material into V-shaped dies. The real expertise lies in our backgauge systems that ensure accurate workpiece positioning and our advanced control systems that maintain consistent bend angles across thousands of production runs.

Panel bending is where we really show off our engineering prowess. This method is perfect for complex applications with radius bends, short sides, or narrow profiles. Our specialized frames perform precise elliptical movements during bending, creating shapes that would be impossible with traditional methods. It’s this kind of innovation that keeps us at the forefront of the industry.

The Hines CNC Advantage: Best Automation and Flexibility

Our CNC bender machines represent the pinnacle of what’s possible in automated bending. These systems integrate multiple bending methods for complex, multi-bend parts in a single automated cycle—something that requires not just advanced machinery, but deep understanding of bending physics and material behavior.

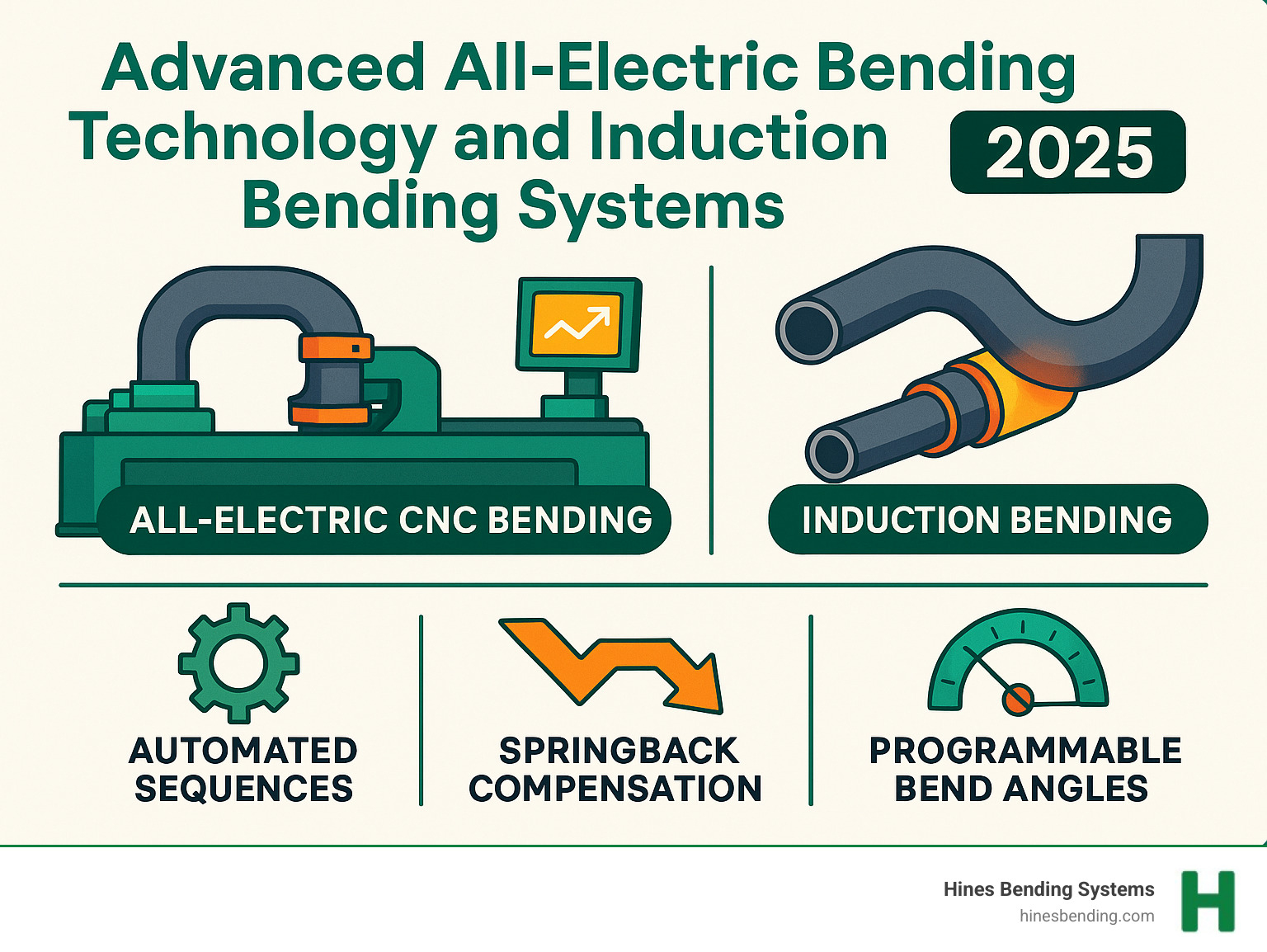

Advanced software and programming maximize efficiency and minimize waste, but the real advantage comes from our proprietary control systems. We’ve built in features like springback compensation that automatically adjusts for different material properties, ensuring accurate final dimensions regardless of whether you’re working with mild steel or exotic aerospace alloys.

Learn about Hines CNC bender machines

What sets our CNC systems apart is their ability to handle complex bending sequences automatically. Programmable bend angles enable quick transitions between different part specifications, while our user-friendly interfaces reduce the skill requirements for operators without sacrificing quality. This is the kind of practical innovation that comes from decades of working directly with manufacturers to solve real-world challenges.

When you choose Hines, you’re not just buying a machine—you’re partnering with the industry leader who has the expertise to ensure your bending operations succeed.

Selecting the Right Hines Bender: Beyond the Spec Sheet

Choosing the right bender machine is like finding the perfect tool for a craftsman—it goes far beyond comparing numbers on a spec sheet. At Hines, we’ve learned through decades of experience that the best bending solution comes from understanding your unique challenges and matching them with the right combination of technology, tooling, and expertise.

When you work with Hines, you’re not just buying a machine—you’re partnering with the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. Our approach starts with understanding your specific needs, from the capacity requirements like diameter and wall thickness to the automation level that makes sense for your operation, whether that’s manual, semi-automatic, or full CNC control.

The real difference lies in our ability to customize every aspect of your system. While others might try to fit your needs into their standard offerings, we design solutions that work perfectly for your application. This is why major organizations like NASA trust us with their most critical projects.

Key Features to Consider in a Hines Bender Machine

The foundation of any great bending solution starts with matching machine capacity to your material and application requirements. Our machines handle everything from delicate thin-wall tubing that requires gentle precision to heavy-duty pipes with substantial wall thicknesses that would overwhelm lesser systems.

When it comes to CNC technology, our systems provide the ultimate precision and repeatability that modern manufacturing demands. Features like digital readouts accurate to 0.1 degrees and automatic stops within 2/10 of a degree ensure consistent results across every production run. This level of precision is essential for high-volume production and complex geometries where even small variations can cause costly problems.

Robust construction is another hallmark that sets Hines machines apart. We build our systems for longevity and reliability, backed by industry-leading quality assurance that translates into lower maintenance costs and higher uptime for our customers. This construction philosophy means your investment pays dividends for years to come.

The Critical Role of Custom Tooling and Software from Hines

The magic really happens when you combine our machines with custom-designed dies, mandrels, and wiper dies that are precision-engineered specifically for your application. This integration is crucial because tooling quality directly impacts bend quality and consistency—something we’ve perfected through our extensive experience across diverse industries.

Our proprietary software for simulation and programming sets our systems apart from generic alternatives. This software can simulate bending operations before production begins, identifying potential issues and optimizing the process for maximum efficiency. It’s like having a crystal ball that shows you exactly how your parts will turn out.

Expert tooling prevents defects and ensures perfect bends by controlling material flow during the bending process. This expertise comes from decades of experience working with materials ranging from common steel to exotic aerospace alloys. We incorporate this knowledge into every custom solution we create.

Find Hines tube and pipe bender accessories

The bottom line is simple: when you choose Hines, you’re choosing a partner who understands that the right bending solution is about more than just specifications—it’s about creating a system that works perfectly for your unique needs.

The Future of Bending: Hines Innovation and Expertise

The bender machine industry is experiencing a revolution, and Hines Bending Systems is leading the charge. While others struggle to keep up with changing technology, we’re the ones creating the innovations that define the future of metal forming.

Our partnership with NASA speaks volumes about our commitment to pushing boundaries. When the world’s most advanced space agency needs precision bending solutions, they turn to Hines. This collaboration has driven us to develop technologies that seemed impossible just a few years ago.

Read about Hines’ work with NASA

What sets us apart isn’t just our technology—it’s our deep understanding of where the industry is heading. We invest heavily in research and development because we know that today’s innovations become tomorrow’s industry standards. When you choose Hines, you’re not just getting today’s best equipment; you’re getting a partner who’s already working on the solutions you’ll need in five years.

The All-Electric Revolution: Hines Efficiency and Precision

The shift to all-electric technology represents one of the most significant advances in bending machine design in decades. Our all-electric benders deliver energy savings that will make your accountant smile—using approximately one-tenth the power of comparable hydraulic systems.

But the real game-changer is precision. Hydraulic systems have inherent variability that affects repeatability. Our all-electric systems eliminate this variability completely, delivering consistent performance that meets the tightest tolerances every single time.

The maintenance story is equally impressive. No hydraulic fluids to change, no seals to replace, and dramatically fewer moving parts to service. This translates to lower operating costs and higher productivity—exactly what you need to stay competitive in today’s market.

The quieter operation is an unexpected bonus that operators love. Gone are the days of noisy hydraulic pumps disrupting the work environment. Our all-electric systems operate so quietly that you’ll barely notice they’re running.

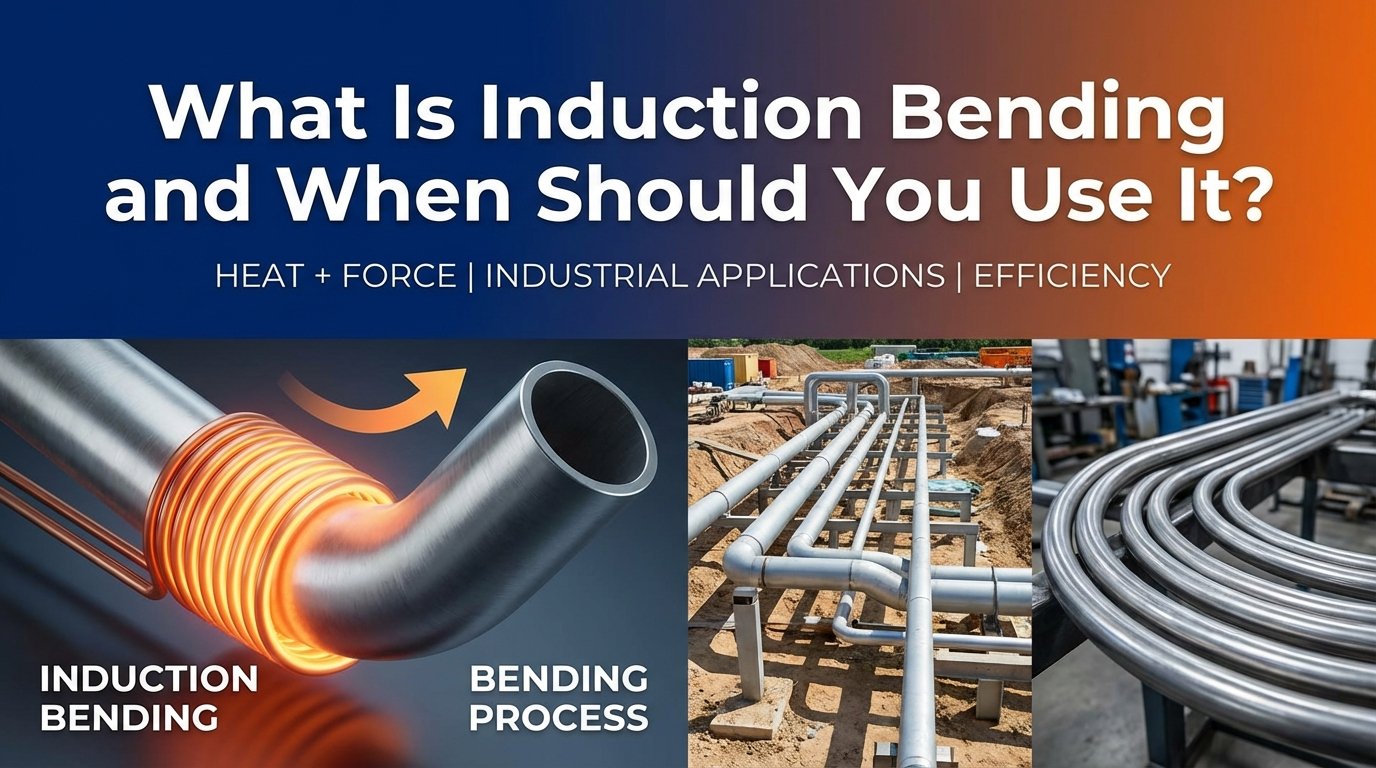

Induction Bending: Hines’ Solution for Heavy-Duty Applications

When it comes to large outside diameters and thick-wall materials, our induction bending technology handles what others can’t. This process uses controlled heating to soften material at the bend point, creating smooth curves without the stress concentrations that plague cold bending methods.

The applications are impressive: oil and gas pipeline construction, power plant installations, and shipbuilding projects that demand the highest quality. These industries can’t afford failures, which is why they consistently choose Hines for their most critical applications.

What makes our induction bending special is the precise temperature control we’ve developed. Too little heat and the material won’t bend properly. Too much heat and you compromise material properties. Our systems hit the sweet spot every time, ensuring optimal material integrity while achieving the exact bend geometry you need.

Emerging Technologies and the Hines Advantage

The integration of fiber lasers for die making represents the next frontier in bending technology. This innovation promises to revolutionize tooling production and dramatically reduce setup times—advantages that translate directly to your bottom line.

Our expertise with exotic alloys positions us perfectly for the materials revolution happening across industries. As aerospace, medical, and energy sectors develop new materials with superior properties, our engineering team is already working to understand their bending characteristics and develop the right processes.

This is where partnering with Hines becomes absolutely critical. Our deep R&D experience means we can address emerging challenges before they become problems for your production. We’re not just reacting to industry changes—we’re anticipating them and developing solutions in advance.

The complexity of modern manufacturing requirements demands a partner who understands both current needs and future possibilities. That’s exactly what you get with Hines: a company that’s been setting industry standards for decades and shows no signs of slowing down.

Conclusion: Hines—Your Partner in Precision Bending

When you step back and look at the complete picture of modern manufacturing, it becomes clear that bender machine technology isn’t just about equipment—it’s about partnership. Throughout this guide, we’ve explored everything from basic tube bending principles to cutting-edge CNC automation, and one truth emerges: the difference between good and exceptional results comes down to expertise, quality, and trust.

That’s exactly what you get when you choose Hines Bending Systems. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we’ve built our reputation on delivering solutions that work—not just today, but for years to come. When NASA needs precision bending for space missions, they turn to us. When automotive manufacturers need systems that can handle high-volume production without compromising quality, they call Hines.

Our commitment to custom solutions means we don’t just sell you a machine—we engineer the perfect solution for your specific needs. Whether you’re working with exotic alloys for aerospace applications, forming complex rebar configurations for construction projects, or creating precise sheet metal enclosures for electronics, our team works closely with you to ensure every detail is right.

The future of bending technology will continue bringing new challenges and opportunities. All-electric systems are revolutionizing energy efficiency. Induction bending is opening possibilities for materials and dimensions that seemed impossible just years ago. Advanced automation is changing how we think about production efficiency. Through it all, Hines remains at the forefront, not just keeping up with these changes but driving them.

Quality isn’t negotiable in today’s competitive marketplace. That’s why we’ve invested decades in perfecting our engineering, refining our processes, and building machines that deliver consistent results shift after shift. Our comprehensive support services, training programs, and ongoing innovation ensure that choosing Hines means choosing a partner who’s committed to your long-term success.

Nobody in the bending machine industry has more expertise and experience than our team. This expertise shows in every machine we build, every solution we design, and every relationship we build with our customers. When you’re ready to take your bending operations to the next level, we’re here to make it happen.

Find out why you should partner with a leader in bending technology