Why Choosing the Right Bending Machine Manufacturer Matters

What Sets Hines Bending Systems Apart as the #1 Bending Machine Manufacturer?

When you’re searching for a bending machine manufacturer, you need more than just equipment – you need a partner who understands your challenges and delivers solutions that work. That’s exactly what sets Hines Bending Systems apart from everyone else in the industry.

We’ve earned our reputation as the world’s leading manufacturer through decades of engineering excellence and an unwavering commitment to quality. Our machines don’t just meet industry standards – they set them. Every component is built to last, every system is designed for precision, and every solution is crafted with your success in mind.

Here’s what makes us different: while others focus on cutting costs, we focus on delivering value. Our best quality standards ensure that when you invest in a Hines machine, you’re getting equipment that will serve your operation reliably for years to come. This commitment to durability and precision has made us the trusted choice for the world’s most demanding applications.

Our track record speaks volumes about our capabilities. We supply bending machines to NASA and other critical organizations because they know we deliver when failure isn’t an option. When Hines works with NASA, it demonstrates the level of trust that aerospace and defense industries place in our technology.

Curious about why you should buy a Hines bender? It comes down to our customer-centric approach and continuous innovation. We don’t just manufacture machines – we solve problems. Our global reputation spans aerospace, automotive, construction, energy, and countless other industries that rely on precision bending solutions.

Industry-Leading Technological Features and Innovations

Innovation drives everything we do at Hines. Our advanced CNC controls deliver the kind of precision and repeatability that transforms complex bending operations into smooth, efficient processes. When you combine this with our proprietary software and seamless automation integration, you get a system that works exactly how you need it to.

Our robotic bending cells represent the future of manufacturing. These systems integrate perfectly with your existing workflow while dramatically improving throughput and consistency. The advantages of CNC tube bending machines become crystal clear when you see how our technology eliminates waste and reduces cycle times.

Understanding the difference between NC vs CNC bending machines is crucial for making the right investment. Our CNC technology offers energy-efficient drives, high-speed performance, and the flexibility to handle changing production requirements without missing a beat.

What really sets us apart are our exclusive innovations like the Dual Stack CNC Push Bender and Roll Bender. This breakthrough technology addresses the growing demands of modern manufacturing by combining multiple bending capabilities in one efficient platform. No other manufacturer offers this level of integrated functionality.

Our commitment to cost-effectiveness goes beyond just the initial purchase price. Our machines are designed to minimize operating costs while maximizing productivity, giving you a competitive advantage that pays dividends year after year.

Quality, Precision, and Durability

Quality isn’t just a promise at Hines – it’s built into every machine we create. Our ISO 9001 certification and CE marking aren’t just certificates on the wall; they represent our commitment to meeting the highest international standards for quality and safety.

Every Hines machine features heavy-duty construction using world-class components that are selected for their reliability and longevity. We conduct rigorous testing on each system before it leaves our facility, ensuring it meets both our exacting standards and your specific requirements.

The precision we achieve isn’t accidental – it’s the result of decades of engineering expertise and continuous improvement. Our machines maintain tight tolerances even under the most demanding conditions, delivering the consistency that your quality control depends on.

When you choose Hines as your metal bending machine manufacturer, you’re investing in equipment designed for the long haul. Our machines are built to handle whatever your operation throws at them while maintaining the precision and reliability that keeps your production running smoothly.

This adherence to the highest standards means you can count on long machine life and consistent performance. While others might offer cheaper alternatives, we believe true value comes from equipment that delivers reliable results year after year, decade after decade.

Hines Bending Systems: Serving Every Industry with Custom Solutions

What makes us truly special as a bending machine manufacturer isn’t just our technology – it’s our ability to understand and solve unique challenges across every industry imaginable. Whether you’re building rockets for NASA or constructing the next generation of medical devices, we have the expertise to deliver exactly what you need.

Every project that comes through our doors is different, and that’s exactly how we like it. We don’t believe in one-size-fits-all solutions because we know your business has specific requirements that deserve customized attention. Our engineering team thrives on tackling the “impossible” bending challenges that others walk away from.

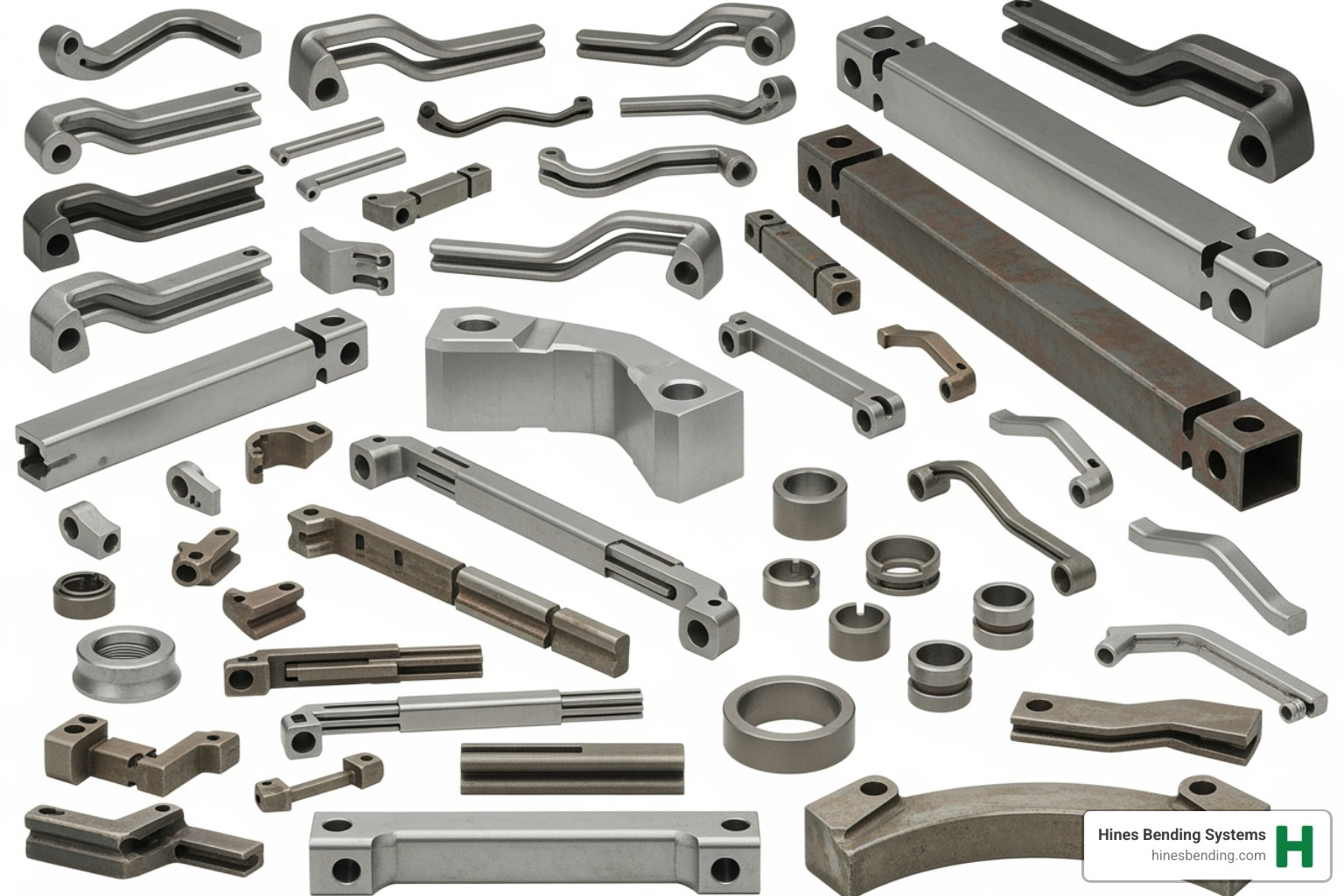

Take a look at our project portfolio and you’ll see the incredible range of applications we’ve mastered. From massive infrastructure projects that require handling enormous pipe diameters to precision medical components where tolerances are measured in thousandths of an inch, we’ve done it all.

We understand that investing in new equipment can be a significant financial decision. That’s why we’ve partnered with Crest Capital Equipment Leases to offer flexible financing options. This partnership allows you to get the exact bending solution you need while managing your cash flow in a way that works for your business.

What to Expect from Hines as Your Tube and Pipe Bending Machine Manufacturer

As manufacturers of tube and pipe bending machines, we offer the most comprehensive range of bending technologies you’ll find anywhere. Our rotary draw benders deliver the kind of precision that makes complex geometries look effortless, while our roll benders tackle large diameter applications that would challenge lesser equipment.

Our induction bending technology represents a real game-changer for many applications. Unlike traditional methods that can compromise material integrity, induction bending allows us to handle larger outside diameters and thicker wall materials while actually improving metallurgical properties. It’s particularly valuable when you’re working with materials that simply can’t tolerate the stress of conventional bending.

When customers search for the best tube bender manufacturer, they consistently find that we deliver something special – the perfect combination of cutting-edge technology, uncompromising quality, and the kind of support that ensures long-term success.

Our mandrel bending capabilities enable us to produce complex bends without distortion, even in the most challenging materials. This isn’t just about having the right equipment – it’s about understanding how different materials behave under stress and knowing exactly how to work with them.

What really sets us apart is our custom bending machine manufacturing approach. While others offer standard configurations, we work closely with each customer to understand their specific requirements and engineer solutions that optimize their entire production process.

Core Offerings from Hines: The Leading CNC Bending Machine Manufacturer

Our reputation as a leading CNC bending machine manufacturer is built on delivering multi-axis bending capabilities that handle the most complex geometries with remarkable precision. Our machines offer the kind of repeatability that ensures consistent quality across thousands of production runs.

The integrated software in our systems doesn’t just reduce setup times – it practically eliminates them for repeat jobs. This means less waste, faster changeovers, and more time spent producing parts instead of adjusting machines.

Our push bending technology complements our comprehensive bending capabilities perfectly, allowing us to handle applications that leave other manufacturers scratching their heads. This versatility makes us the preferred choice for customers who need a single source for all their bending requirements.

We proudly serve these critical industries: Aerospace where precision is literally life-or-death, Automotive with high-volume production demands, Shipbuilding requiring massive pipes and complex assemblies, Agriculture needing durable equipment for harsh environments, Construction building structural components and infrastructure, Energy powering generation and distribution systems, and Healthcare creating life-saving medical devices and equipment.

Each of these industries has taught us something valuable about bending, and we bring that collective knowledge to every new project we tackle.

The Hines Advantage: Comprehensive Service and Support

What truly sets Hines apart as a bending machine manufacturer isn’t just our exceptional equipment – it’s our unwavering commitment to your success long after installation day. We understand that purchasing a bending machine is just the beginning of our partnership together.

Our comprehensive after-sales support spans the globe through our extensive service network. When you need assistance, you’re not dealing with a third-party contractor who barely knows your equipment. You’re working directly with Hines experts who understand every component of your machine and can provide solutions quickly and effectively.

Spare parts availability is where many manufacturers fall short, but it’s where we excel. We maintain extensive inventory specifically because we know that unexpected downtime can cost you thousands of dollars per hour. Our parts are available when you need them, not when it’s convenient for us to ship them.

Our machine installation services ensure your equipment is properly configured from day one. Our technicians don’t just drop off your machine and leave – they work with your team to optimize settings, verify performance, and ensure everything integrates seamlessly with your existing operations.

The importance of proper training cannot be overstated when working with advanced bending technology. Our comprehensive tube and pipe bender training programs transform your operators from beginners into experts. We’ve seen too many expensive machines underperform simply because operators weren’t properly trained to use their full capabilities.

Technical consultation and application support are integral parts of our service philosophy. Our engineers don’t disappear after installation – they remain available to help you optimize processes, solve unexpected challenges, and implement improvements that boost both productivity and quality. Our valued customers consistently tell us that this ongoing partnership is one of the most valuable aspects of working with Hines.

Customization and Consultation: Hines’ Customer-Centric Approach

Every successful bending project starts with understanding your unique situation. We begin with thorough application evaluation because we know that cookie-cutter solutions rarely deliver optimal results. Our engineers take time to understand your materials, production goals, space constraints, and quality requirements.

This comprehensive assessment allows us to recommend tailor-made solutions that address your specific challenges. Whether you need specialized tooling for unusual geometries, custom automation for high-volume production, or unique machine configurations for space-constrained facilities, we have the engineering expertise to make it happen.

Tooling design is where our decades of experience really shine. We don’t just modify existing tooling – we engineer solutions specifically for your application. This attention to detail ensures that every bend meets your specifications while maximizing tool life and minimizing setup time.

Workflow integration is crucial for maximizing your return on investment. We work closely with your team to ensure that new equipment improves your existing processes rather than disrupting them. About Hines Bending – our history demonstrates our commitment to solving unique challenges through innovative engineering approaches that others simply can’t match.

Our engineering expertise allows us to tackle the impossible projects that other manufacturers walk away from. When standard solutions aren’t sufficient, we develop custom approaches that deliver the results you need. This capability has made us the preferred choice for customers with the most demanding applications across multiple industries.

Warranties and Quality Assurance

Our confidence in our products is backed by comprehensive 12-month warranties that protect your investment and demonstrate our commitment to quality. Unlike manufacturers who offer limited warranties with endless exclusions, our coverage is straightforward and comprehensive.

Our quality certifications, including ISO 9001, aren’t just certificates on the wall – they represent our systematic approach to ensuring that every machine meets the highest standards. These certifications provide you with confidence that your equipment will perform reliably for decades.

Performance guarantees are backed by our decades of experience and proven track record. When we specify that a machine will deliver certain results, you can count on those specifications being met or exceeded. We’ve built our reputation on delivering machines that perform exactly as promised.

As a U.S. bending machine manufacturer, we maintain complete control over our manufacturing processes. This control allows us to ensure consistent quality while providing the flexibility to customize machines for specific applications.

The reliability of our machines is legendary in the industry. Our customers depend on our equipment for critical applications, and we’ve built our reputation on delivering machines that perform consistently under the most demanding conditions. When NASA needs bending equipment they can trust, they choose Hines – and that says everything about our commitment to reliability.

Frequently Asked Questions about Choosing Hines as Your Bending Machine Manufacturer

How do I determine the right Hines bending machine for my specific needs?

Choosing the perfect bending machine can feel overwhelming, but that’s exactly why we’re here to guide you through every step of the process. Our team doesn’t just sell you equipment – we become your trusted advisors from day one.

When you reach out to us, we start with a comprehensive consultation that digs deep into your unique requirements. We’ll analyze everything from your material specifications to your required bend radii, production volume targets, and final product specifications. This thorough approach ensures we engineer a custom solution that delivers both efficiency and precision for your specific application.

Our engineering team takes the time to understand every nuance of your operation. We consider factors like material properties, current production volume, quality requirements, and how new equipment will integrate with your existing processes. This comprehensive evaluation means you’ll receive a machine that not only meets today’s needs but also provides the flexibility to handle future growth and changing requirements.

What sets us apart as a bending machine manufacturer is our commitment to getting it right the first time. We don’t believe in one-size-fits-all solutions because we know that every operation has unique challenges and goals.

Why is operator training so crucial when purchasing a Hines machine?

Here’s the truth – even the most advanced bending machine is only as good as the people operating it. That’s why we consider training to be one of the most important investments you’ll make alongside your equipment purchase.

Our comprehensive training programs are designed to empower your entire team to operate the equipment safely, efficiently, and with minimal waste. When your operators truly understand the capabilities of their Hines machine, you’ll see dramatic improvements in productivity and return on investment almost immediately.

We cover everything from basic setup procedures to advanced programming techniques during our training sessions. But our support doesn’t stop there – we provide ongoing assistance to ensure your team continues developing their skills and maximizing your equipment’s capabilities.

Think of it this way: proper training transforms your investment from just another piece of equipment into a competitive advantage that delivers results year after year. Our customers consistently tell us that our training programs are among the most valuable aspects of working with Hines.

What advantages does Hines’ extensive industry experience offer?

When you’ve been solving bending challenges for as long as we have, you develop insights that simply can’t be taught from a textbook. Our decades of experience serving demanding sectors like aerospace and defense brings a depth of knowledge that proves invaluable for every customer we serve.

We’ve encountered and solved countless complex bending challenges over the years. This experience allows us to anticipate potential issues before they become problems and provide solutions that optimize both performance and cost-effectiveness. When you work with Hines, you’re not just getting a machine – you’re getting access to our entire knowledge base.

Our deep understanding of various industries and applications enables us to recommend approaches that other manufacturers might never consider. Whether you’re working with exotic materials, complex geometries, or demanding production schedules, we’ve likely faced similar challenges before and developed proven solutions.

This experience translates into real value for your operation. We can help you avoid common pitfalls, optimize your processes, and implement improvements that deliver measurable results. Our track record with organizations like NASA demonstrates the trust that critical industries place in our expertise and proven solutions.

Conclusion: Why Hines Bending Systems is the Only Partner You Need for Long-Term Success

When you’re ready to make the investment that will define your manufacturing success for decades to come, choosing Hines Bending Systems as your bending machine manufacturer isn’t just a smart decision – it’s the only decision that makes sense.

Think about it: when NASA needs bending solutions for their most critical missions, they don’t shop around for the cheapest option. They come to us because they know that failure isn’t an option. As the #1 Worldwide Manufacturer of Tube Benders, we’ve earned this trust through decades of delivering results when it matters most.

Our commitment to your success goes far beyond just building great machines. We’re talking about a partnership that grows with your business, adapts to your changing needs, and provides the support you need to stay competitive in an changing marketplace.

What sets us apart isn’t just our technology – though our innovations like the Dual Stack CNC Push Bender and Roll Bender are game-changers. It’s not just our quality standards – though our ISO 9001 certification and rigorous testing processes ensure every machine performs flawlessly. It’s our understanding that your success depends on having a partner who truly gets your challenges.

When you choose Hines, you’re choosing a company that has solved bending challenges across every major industry. From aerospace applications that demand absolute precision to high-volume automotive production that requires consistent quality, we’ve been there. We’ve done that. And we’ve helped our customers succeed in ways they never thought possible.

Your investment in a Hines machine pays dividends in ways you might not expect. You get the precision and reliability you need. But you also get access to our global support network, comprehensive training programs, and the kind of engineering expertise that can transform your entire operation.

The manufacturing landscape is changing rapidly, and the bending challenges of tomorrow will require solutions that combine cutting-edge technology with deep application knowledge. We’re not just keeping up with these changes – we’re leading them. When you partner with us, you’re positioning your business to thrive no matter what the future brings.

The choice is clear. You can work with a manufacturer who sees you as just another customer, or you can partner with the industry leader who is genuinely invested in your long-term success. To explore the highest quality bending solutions available in the market, learn more about leading Bending Machine Manufacturers.

Ready to experience what true industry leadership looks like? Let’s start a conversation about how Hines Bending Systems can help you achieve your goals.