Why Finding Quality CNC Bending Services Matters for Your Manufacturing Success

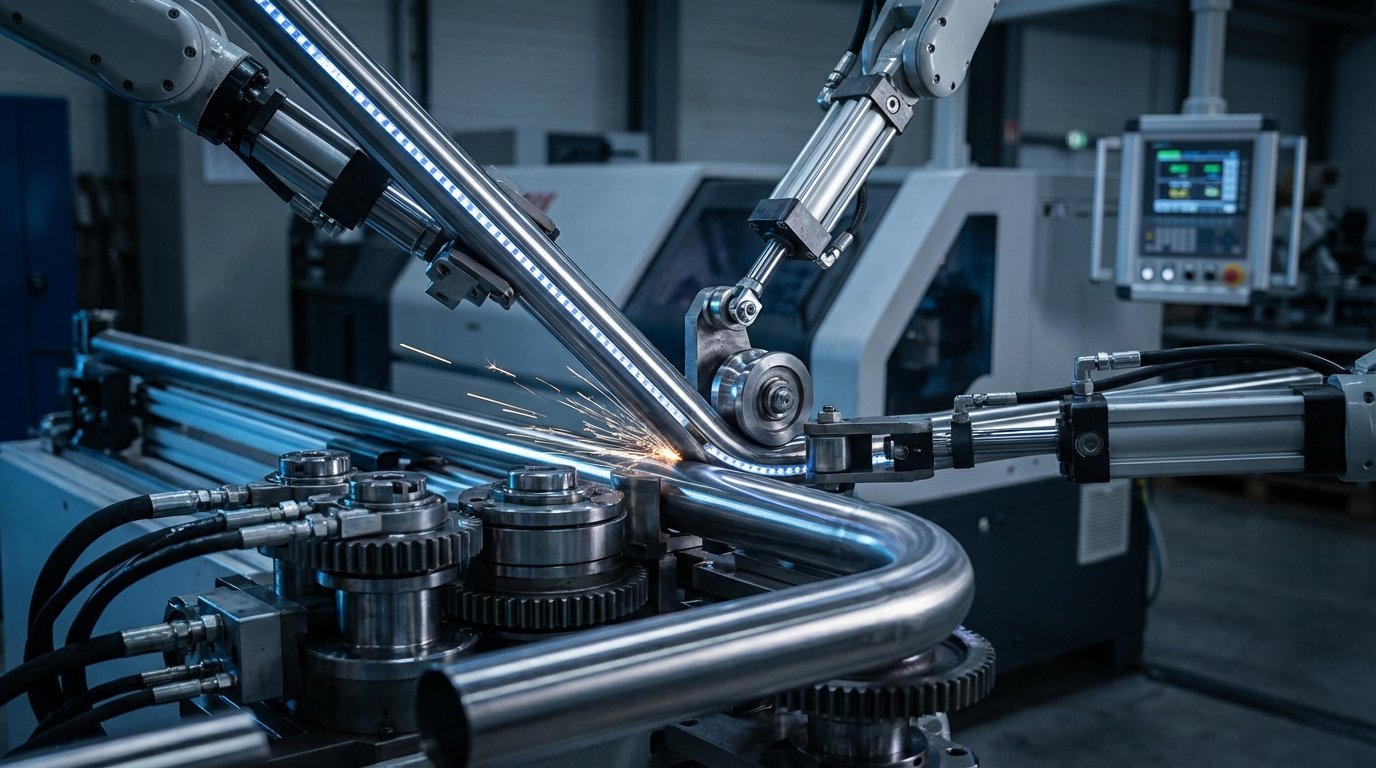

CNC bending services provide precision metal forming solutions using computer-controlled machinery to create accurate bends in tubes, pipes, and sheet metal. These services are essential for industries requiring complex geometries and tight tolerances.

Key CNC Bending Service Capabilities:

- Precision: Achieve bend angles within +/- 1 degree or better

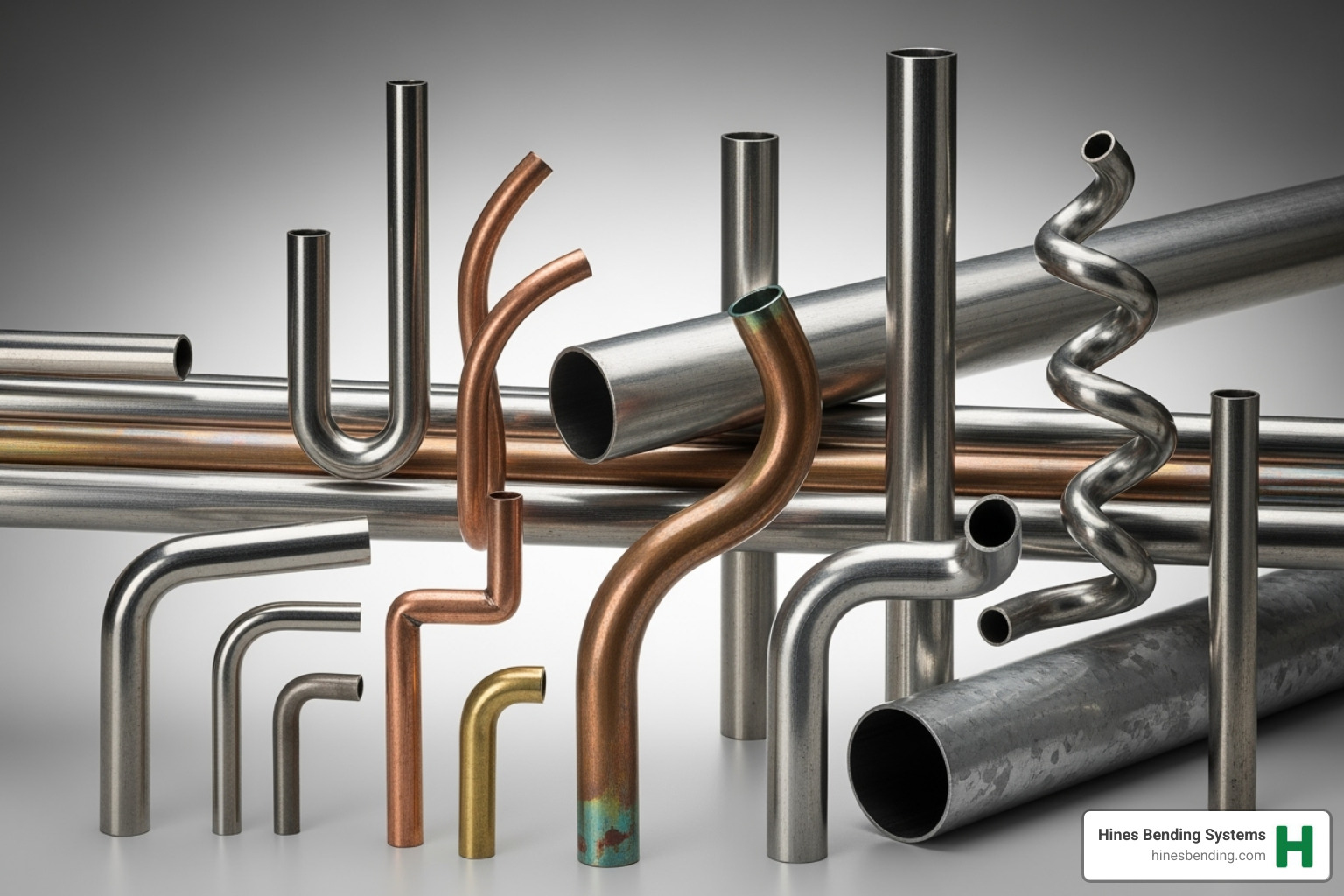

- Material Range: Steel, stainless steel, aluminum, titanium, and exotic alloys

- Size Capabilities: Tube diameters from 1/16″ up to 8 inches

- Thickness Range: Wall thicknesses from 0.010″ to 0.500″

- Production Speed: Fast turnaround with 1-2 day processing times

When searching for CNC bending services, you’re essentially evaluating the quality of the bending machines behind those services. The precision, repeatability, and reliability of your bent components depend entirely on the sophistication of the equipment being used.

Many manufacturers find that services powered by superior equipment can handle complex bends that other shops refuse, delivering a higher level of quality and capability.

The reality is simple: the best bending services use the highest quality machines. Companies like NASA trust their critical aerospace components to services powered by world-class bending equipment. This is why understanding the technology behind your service provider matters just as much as their experience and capabilities.

The machine makes the difference between acceptable results and exceptional precision. Whether you need complex mandrel bending for thin-walled tubing or large-scale induction bending for heavy-duty applications, the quality of the underlying equipment determines your project’s success.

CNC bending services terms you need:

What Defines Premier CNC Bending Services?

When you’re searching for CNC bending services, you’re essentially looking for a partner who can deliver perfection in metal forming. The best services stand out through their unwavering commitment to best precision – and we’re not talking about “close enough” here. We’re talking about achieving bend angles within +/- 1 degree accuracy or better, and overall dimensional accuracy of +/- 0.5 mm.

To put that in perspective, half a millimeter is thinner than a credit card. This level of precision means your parts fit perfectly every single time, eliminating costly rework and assembly headaches down the line.

Tight tolerances aren’t just impressive numbers on a spec sheet – they’re the foundation of reliable manufacturing. Whether you’re working with sheet metal bending) applications or complex tube geometries, premier services maintain these exacting standards consistently.

What truly separates exceptional CNC bending services from the rest is their repeatability for production runs. The first part and the thousandth part should be identical. This consistency comes from rigorous quality control processes and, most importantly, the quality of the bending machines themselves.

At Hines Bending Systems, we’ve built our reputation on manufacturing the world’s finest bending equipment. When you choose a service provider using our machines, you’re choosing decades of engineering excellence. Our global installation base includes major agencies like NASA, who trust their critical aerospace components to services powered by Hines equipment. You can explore more info about CNC Benders to understand why we’re the #1 manufacturer worldwide.

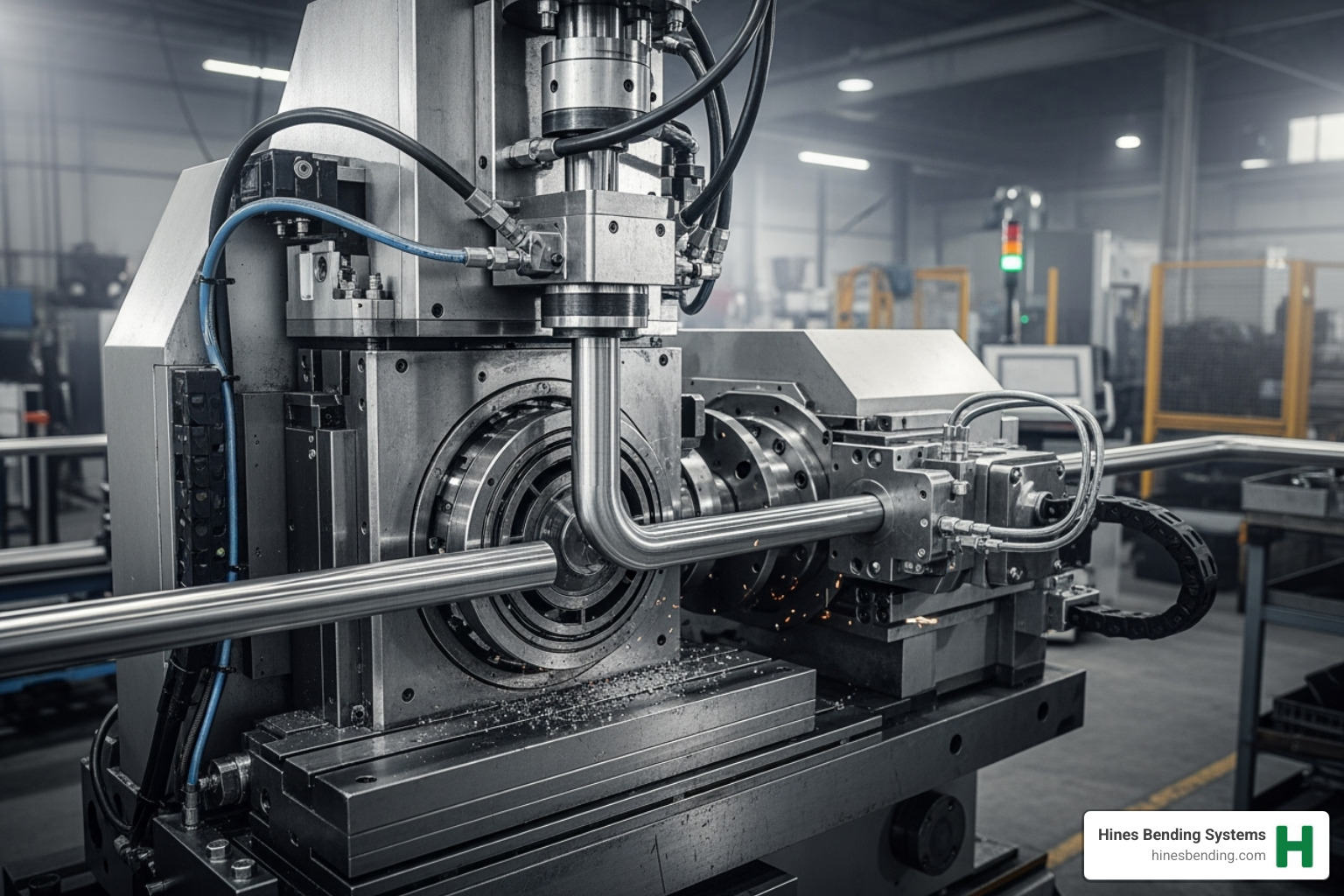

The Role of Advanced Bending Machinery

Behind every exceptional CNC bending service lies exceptional machinery. The difference between good results and outstanding precision comes down to the sophistication of the equipment being used.

Our all-electric and hydraulic options represent the pinnacle of bending technology. The servo-electric systems provide best control, energy efficiency, and quiet operation. This translates to faster setup times, rapid tooling changes, and that coveted “right-first-time” repeatability that dramatically boosts productivity.

You can see the full scope of our capabilities in our CNC Bending Machine Overview, but what really sets our machines apart are the advanced control systems. Think of these as the brain that orchestrates every movement, angle, and force required for a perfect bend.

Our user-friendly interface design means operators can quickly master complex bending sequences. The BendPro G2 CNC Control exemplifies this approach – incredibly powerful yet surprisingly intuitive. Even intricate programming feels natural.

Tooling and flexibility matter just as much as the machine itself. Just like a chef needs the right knife for each task, bending machines need appropriate dies and mandrels for specific bend radii and material types. Our extensive range of Tube and Pipe Bender Accessories ensures that services using Hines equipment can tackle any bending challenge.

This combination of robust machinery, intelligent controls, and versatile tooling is what allows premier CNC bending services to consistently deliver exceptional results. When you’re evaluating service providers, you’re really evaluating the quality of their equipment – and the best services worldwide choose Hines Bending Systems.

Key Capabilities: From Materials to Complex Geometries

When you’re looking for CNC bending services, you want to know they can handle whatever material challenge you throw at them. That’s where the incredible versatility of our Hines bending machines really shines. We’ve engineered our equipment to work with an impressive range of materials, each requiring its own special touch.

Steel forms the backbone of many industrial applications, and our machines handle everything from mild steel to high-strength alloys with ease. Stainless steel presents its own unique challenges – you need to prevent scratching while maintaining that beautiful, corrosion-resistant finish that makes it so valuable. Our precision controls ensure your stainless components come out looking as good as they perform.

Aluminum is where things get interesting. While some grades like 6061-T6 can be tricky to bend without cracking, our machines excel with bendable grades like 6061-T1 and 6063-T5. We’ve spent decades perfecting our Aluminium Bending Service because we know this lightweight material is crucial for aerospace and automotive applications.

For the most demanding projects, our machines tackle titanium and exotic alloys with the same precision that’s made us NASA’s trusted partner. When space missions depend on your bending accuracy, there’s no room for compromise.

The size and thickness capabilities of our machines are equally impressive. We can bend tubes from delicate 1/16-inch diameters all the way up to robust 8-inch pipes. Wall thicknesses range from paper-thin 0.010 inches to hefty 0.500-inch walls. Whether you need tiny hydraulic lines or massive structural components, our Custom Tube Bending Services deliver exactly what your project demands.

Specialized CNC Bending Services and Techniques

The real magic happens when you combine our material expertise with specialized bending techniques. Our machines are engineered to master every major bending method, ensuring CNC bending services using Hines equipment can tackle any geometric challenge.

Our expertise in mandrel bending ensures that even thin-walled tubes can be bent to tight radii without collapsing or wrinkling. We’ve perfected rotary draw bending, the industry’s most popular precision method, to deliver unparalleled accuracy and repeatability. For large, sweeping curves, our roll bending capabilities create smooth arcs without the need for expensive, single-purpose tooling. You can explore the full details of these methods in our guide on What is CNC Tube Bending?

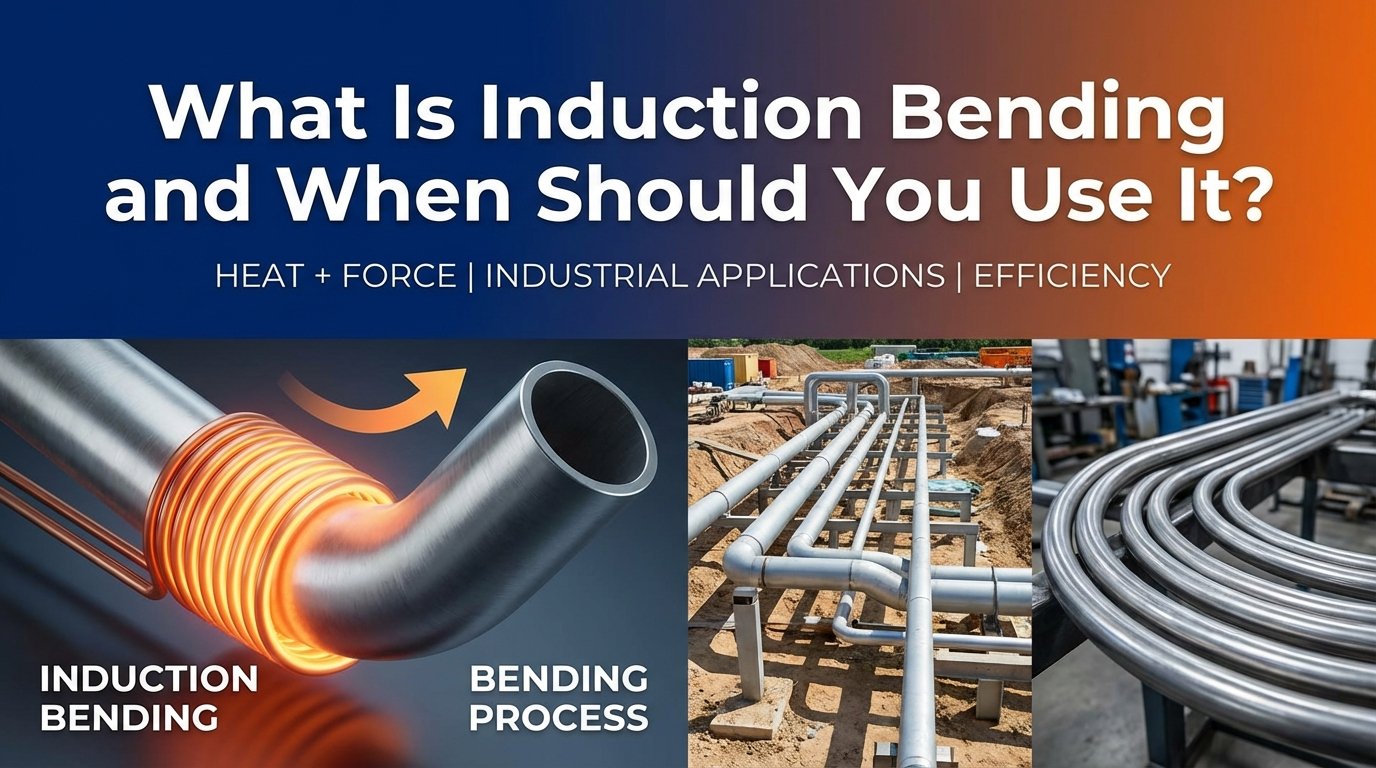

Where Hines Bending Systems truly sets the industry standard is with our induction bending technology. This advanced process allows for the bending of large-diameter pipes and structural sections that are impossible to form cold. It’s the technology behind major oil and gas pipelines, power generation facilities, and large-scale infrastructure projects. Our process delivers tighter radii, smoother bends, and fewer welds than any other method. Learn More on Induction Benders and see why the world’s most critical projects rely on Hines.

Innovation is at our core. Our Dual Stack CNC Push Bender is a testament to this, representing the cutting edge of efficiency by allowing two different tooling sets to be loaded at once. This innovation dramatically cuts setup times and boosts throughput for complex parts. Our Stack Push Benders showcase how we’re constantly pushing the boundaries of what’s possible in precision bending.

When you choose CNC bending services powered by Hines equipment, you’re choosing decades of engineering excellence and the most comprehensive bending capabilities in the industry.

Industries That Demand World-Class Bending Solutions

The world of CNC bending services touches virtually every aspect of modern life, from the spacecraft that explore our universe to the cars we drive daily. What’s fascinating is how many industries depend on the precision and reliability that only world-class bending equipment can deliver.

Let’s start with the most demanding sector of all: Aerospace and Defense. When you’re building components that will travel to space or protect our nation, there’s absolutely no room for error. Every hydraulic line, every piece of ducting, every structural component must meet the most exacting standards imaginable.

We’re incredibly proud that our machines have earned the trust of NASA – yes, that NASA! When humanity reaches for the stars, it’s often supported by components bent on Hines machines. Our partnership with NASA represents the pinnacle of what’s possible when cutting-edge engineering meets uncompromising quality standards. You can read more about Hines working with NASA and how our technology contributes to space exploration.

The Automotive industry presents its own unique challenges. From the complex exhaust systems that optimize engine performance to the robust chassis components that keep passengers safe, precision bending is everywhere. Whether it’s a custom race car component or a mass-produced vehicle frame, our machines handle everything from high-strength steel to delicate thin-wall tubing with equal precision.

Construction and Architecture rely heavily on our bending capabilities too. Think about those stunning curved architectural features you see in modern buildings, or the structural elements that make skyscrapers possible. Our machines shape everything from decorative features to load-bearing components, turning architects’ ambitious visions into reality.

The Energy and Marine sectors demand components that can withstand incredible forces and harsh environments. Our machines are essential for creating the large-diameter pipes used in oil and gas pipelines, power generation facilities, and shipbuilding applications. The precision required for these Pipe Bending Applications often involves our specialized induction bending technology, which can handle the massive scales these industries require.

But it’s not just heavy industry that benefits from our expertise. Furniture manufacturing relies on precisely bent tubing for both aesthetic appeal and structural integrity. Medical device manufacturers trust our machines to create components for hospital beds, mobility aids, and critical medical equipment where precision can literally be a matter of life and death.

Even agricultural equipment manufacturers depend on our bending solutions. Farm machinery operates in some of the harshest conditions imaginable, and the components we help create must be robust enough to handle whatever Mother Nature throws at them.

From mining equipment that operates deep underground to the domestic appliances in your kitchen, our machines play a role in shaping the bent components that make modern life possible.

What ties all these industries together is their need for CNC bending services powered by equipment they can absolutely trust. With the highest number of bender installations worldwide, we understand the unique requirements of each sector. Whether you’re building spacecraft or kitchen appliances, the precision, reliability, and expertise that Hines Bending Systems provides remains your best choice for success.

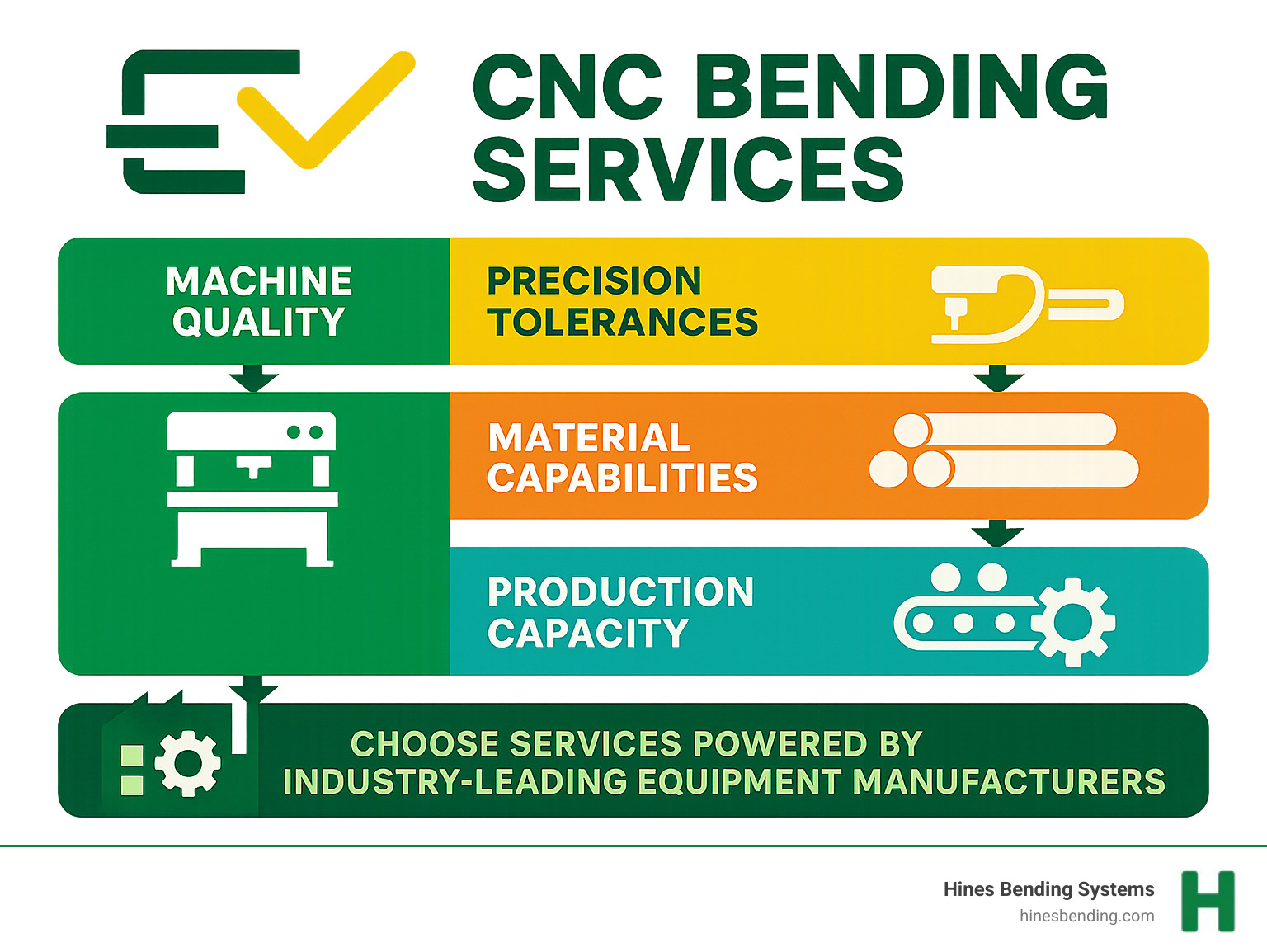

How to Choose the Right Bending Partner

Finding the right partner for your CNC bending services can feel overwhelming, but it doesn’t have to be. Think of it like choosing a surgeon – you want someone with the best tools, proven experience, and a track record of success. The same principle applies when selecting a bending service provider.

Start by asking the right questions about machine quality. What type of equipment are they using? This isn’t just curiosity – it’s the foundation of everything that follows. The precision of your final product depends entirely on the sophistication of their bending machines. Ask about their typical tolerances for bend angles and overall dimensions. Can they consistently achieve +/- 1 degree accuracy for bend angles? What about +/- 0.5 mm accuracy for overall dimensions? These aren’t just numbers on a spec sheet; they’re the difference between parts that fit perfectly and costly rework.

Don’t forget to explore their experience with your specific material and application. Sheet metal bending has its own unique challenges compared to tube bending, and different materials behave differently under stress. A provider who truly understands these nuances will save you time and headaches down the road.

Certifications matter too. They demonstrate a commitment to quality standards and industry best practices. Look for providers who can show documented proof of their quality control processes and adherence to industry standards.

When requesting a quote, come prepared. Accurate CAD files are your best friend here – they allow the service provider to understand exactly what you need and program their machines accordingly. Be specific about your material specs, including type, grade, thickness, and any special requirements. The more detailed information you provide upfront, the more accurate your quote will be.

Evaluating expertise goes beyond just technical capabilities. The best bending partners offer solutions, not just services. They should demonstrate deep knowledge of bending mechanics, material properties, and potential challenges. Look for providers whose operators have received proper manufacturer training. This makes a huge difference in quality and consistency.

Strong technical support from the machine manufacturer is crucial too. When issues arise (and they sometimes do), you want a partner backed by experts who can quickly resolve problems and minimize downtime. Our comprehensive Tube and Pipe Bender Training ensures that operators using our machines are highly skilled and can maximize their potential.

Why Hines Bending Systems is the Industry Leader for CNC Bending Services

Here’s the truth: when you choose a CNC bending services provider, you’re really choosing the machines they use. And when those machines come from Hines Bending Systems, you’re choosing the absolute best in the industry.

We’re not just another manufacturer – we’re the #1 worldwide leader in tube, pipe, and induction benders. Our global installation base is best, with more bending machines in operation around the world than any other company. This isn’t just a bragging point; it represents decades of experience solving real-world bending challenges across every industry imaginable.

What truly sets us apart is our commitment to custom solutions. We don’t believe in one-size-fits-all approaches. Instead, we work closely with our clients to overcome challenges like complex geometries, difficult materials, or tight production schedules. Whether you’re dealing with material limitations or need to achieve something that seems impossible, our team thrives on finding solutions.

Our customers also benefit from unparalleled access to support. When a service provider uses our machines, they’re backed by our technical expertise and comprehensive training programs. This translates directly into better service for you – fewer errors, higher quality output, and faster turnaround times.

Ensuring quality is at the heart of everything we do. Our machines are engineered to deliver superior results and avoid defects that can plague projects using less reliable equipment. When you choose a service powered by a Hines bender, you can be confident your parts will meet the most stringent quality requirements. This is exactly Why Buy a Hines Bender? – it’s an investment in unparalleled quality and performance.

We’re also pioneers of industry-leading innovation. From our groundbreaking Dual Stack CNC Push Bender to continuous advancements in induction bending technology, we’re constantly pushing the boundaries of what’s possible. This means the services using our equipment can tackle challenges that others simply can’t handle.

Our commitment to customer satisfaction goes beyond just selling machines. We build relationships. We’re dedicated to understanding specific requirements and providing complete solutions, not just products. When you partner with a service that uses Hines Bending Systems machines, you’re leveraging the expertise of an industry leader backed by unparalleled quality, innovation, and a genuine desire for your success.

After all, when NASA trusts their critical aerospace components to services powered by our equipment, you know you’re in good hands.

Conclusion: The Machine Behind the Service Makes the Difference

Here’s the truth that every manufacturer needs to understand: when you’re choosing a CNC bending services provider, you’re not just selecting a company – you’re choosing the technology that will shape your components. Every precise angle, every smooth curve, every flawlessly repeated bend comes down to one fundamental factor: the quality of the bending machine doing the work.

Think about it this way. You wouldn’t expect a master chef to create a five-star meal with dull knives and a broken stove. Similarly, even the most skilled operators can’t deliver world-class results without world-class equipment. The best services in the industry understand this completely, which is why they invest in machines from manufacturers who have proven their excellence time and time again.

This is where Hines Bending Systems truly shines. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we’ve built our reputation on delivering not just machines, but complete custom solutions that address the unique challenges our clients face. When NASA needs precision bending for their space missions, they trust our technology. When major corporations require complex geometries with impossibly tight tolerances, they turn to our machines.

The difference isn’t just in the numbers – though our global installation base speaks volumes about our reliability. It’s in the decades of expertise we pour into every machine we build. It’s in our commitment to innovation, from our groundbreaking Dual Stack CNC Push Bender to our cutting-edge induction bending technology. Most importantly, it’s in our dedication to working closely with each client to create solutions that don’t just meet their needs, but exceed their expectations.

When you partner with a CNC bending services provider that uses Hines equipment, you’re tapping into this legacy of excellence. You’re ensuring that your components benefit from the precision, reliability, and innovation that only comes from the industry’s most trusted name.

The machine behind the service truly does make all the difference. Choose wisely.