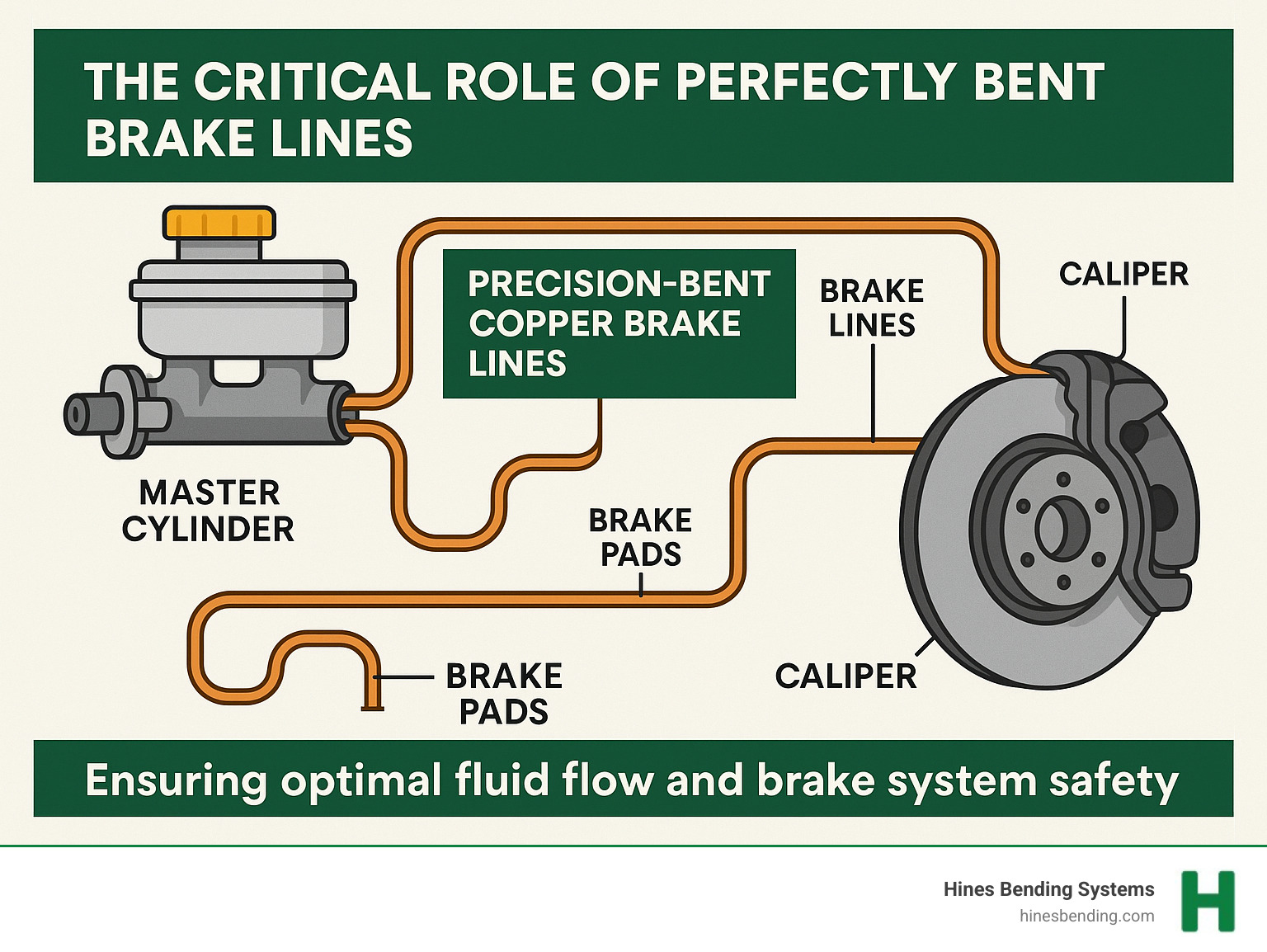

The Critical Role of Perfectly Bent Brake Lines

A copper brake pipe bender is a specialized tool for creating precise, kink-free bends in brake tubing without compromising structural integrity. These tools range from simple handheld devices for DIY projects to advanced industrial CNC bending machines for major manufacturers.

Essential features to look for in any bender include:

- Prevention of kinking and tube collapse

- Creation of a smooth, consistent bend radius

- Compatibility with 3/16″ to 1/2″ tubing sizes

- Marked degree measurements for accuracy

As one forum user noted: “When that routine brake job turns into a nightmare of rusted brake lines, impossible to find brake line fittings and unreliable flaring tools, you’ve come to the right place.” This frustration highlights why the right bending tools and techniques are critical.

Your vehicle’s brake system depends on perfect fluid flow. Even a small kink can restrict brake fluid, leading to reduced braking power or complete failure. The quality of your bends directly impacts safety, whether for a single restoration or high-volume production.

For manufacturing operations requiring ultimate precision and repeatability, Hines Bending Systems is the #1 worldwide manufacturer of tube and pipe benders. With clients including NASA, Hines delivers the advanced technology industry leaders rely on for flawless results every time.

Copper brake pipe bender terms you need:

Choosing Your Materials: Copper-Nickel vs. Steel Brake Lines

When using a copper brake pipe bender, your material choice is critical. The decision between copper-nickel, steel, and stainless steel affects ease of use and the longevity of your brake lines.

Advantages of Copper-Nickel (Cunifer)

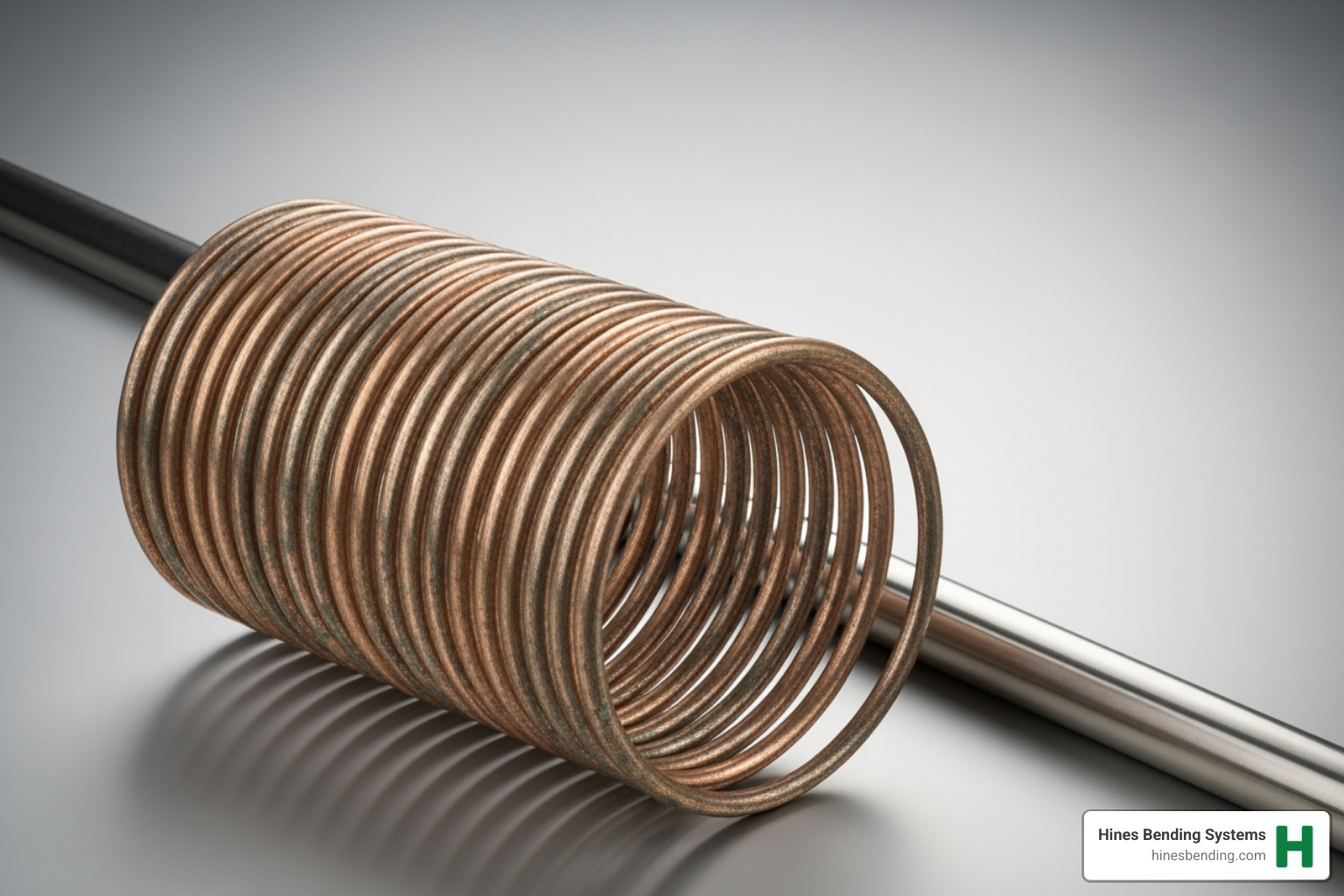

This 90/10 copper-nickel tubing has become the gold standard for custom brake lines. Its primary advantage is ease of bending. Copper-nickel is highly malleable, allowing it to be shaped around complex chassis layouts with minimal effort. This material is also known for its superior corrosion resistance. It is completely rust-proof, meaning brake lines made from it will often outlast the vehicle.

Copper-nickel also offers excellent sealing properties, as it flares easier and seals better than steel, often requiring less torque for a leak-free connection. For these reasons, manufacturers like Aston Martin, Porsche, and Volvo choose copper-nickel for high-performance and safety-critical applications. For a deeper dive into the metallurgical advantages, see this technical overview from the Copper Development Association, which explains why 90/10 copper-nickel has become the industry benchmark for brake tubing.

Considerations for Steel and Stainless Steel

Traditional steel remains the industry-preferred material for many OEMs due to its strength and durability. However, this strength results in higher bending difficulty, requiring more force and skill to avoid kinks. The main drawback of regular steel is its potential for rust, especially in harsh environments with road salt and moisture.

Stainless steel offers better corrosion resistance than regular steel but does not match copper-nickel’s rust immunity. While some stainless steel lines are annealed for easier bending, they are still more challenging to work with than copper-nickel.

Hines Bending Systems delivers solutions for all material types. Whether you’re working with malleable copper-nickel or tough steel, Hines’ advanced bending technology ensures perfect results. Our machines are engineered to handle the unique characteristics of each material, delivering the precision that industry leaders like NASA depend on.

| Material Type | Advantages | Disadvantages | Bending Difficulty | Flaring Ease | Corrosion Resistance |

|---|---|---|---|---|---|

| Copper-Nickel | Excellent corrosion resistance, very easy to bend, easy to flare, DOT approved | Slightly higher cost than steel, can twist if fittings seize due to softness | Easiest | Easiest | Excellent |

| Steel | Strong, traditional OEM choice, rigid | Prone to rust, harder to bend, fittings can seize, can kink easily | Hard | Moderate | Poor to Moderate |

| Stainless Steel | Good corrosion resistance, strong, durable | Harder to bend than copper-nickel, more difficult to flare than copper-nickel | Moderate to Hard | Moderate | Good |

The bottom line is that your material choice impacts everything. At Hines Bending Systems, our expertise ensures you get perfect results regardless of the material you choose.

The Tools of the Trade: From Handheld Benders to Hines Bending Systems’ Advanced Solutions

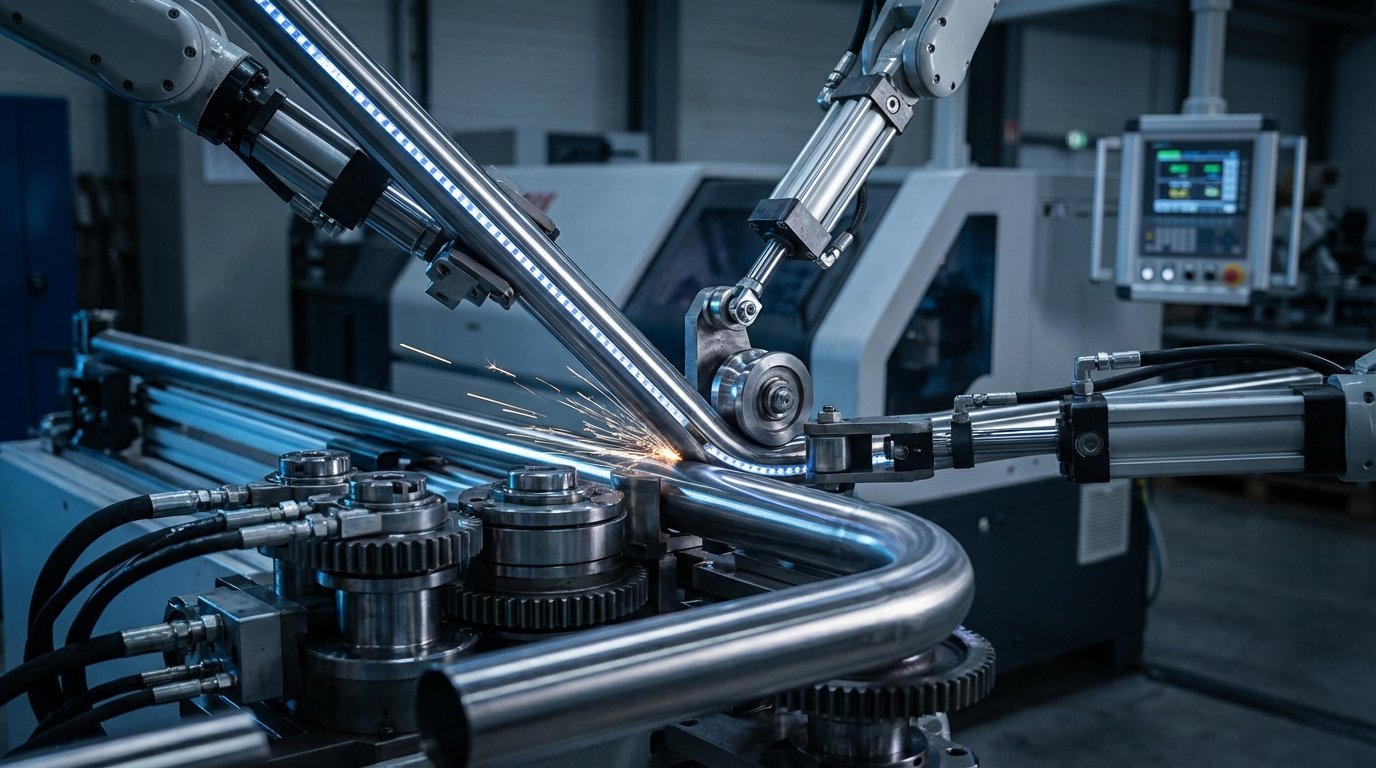

The right equipment makes the difference between failure and flawless results. The journey to perfectly bent brake lines starts with understanding your tool options, from simple handheld devices to advanced industrial solutions.

Understanding Handheld Bending Tools

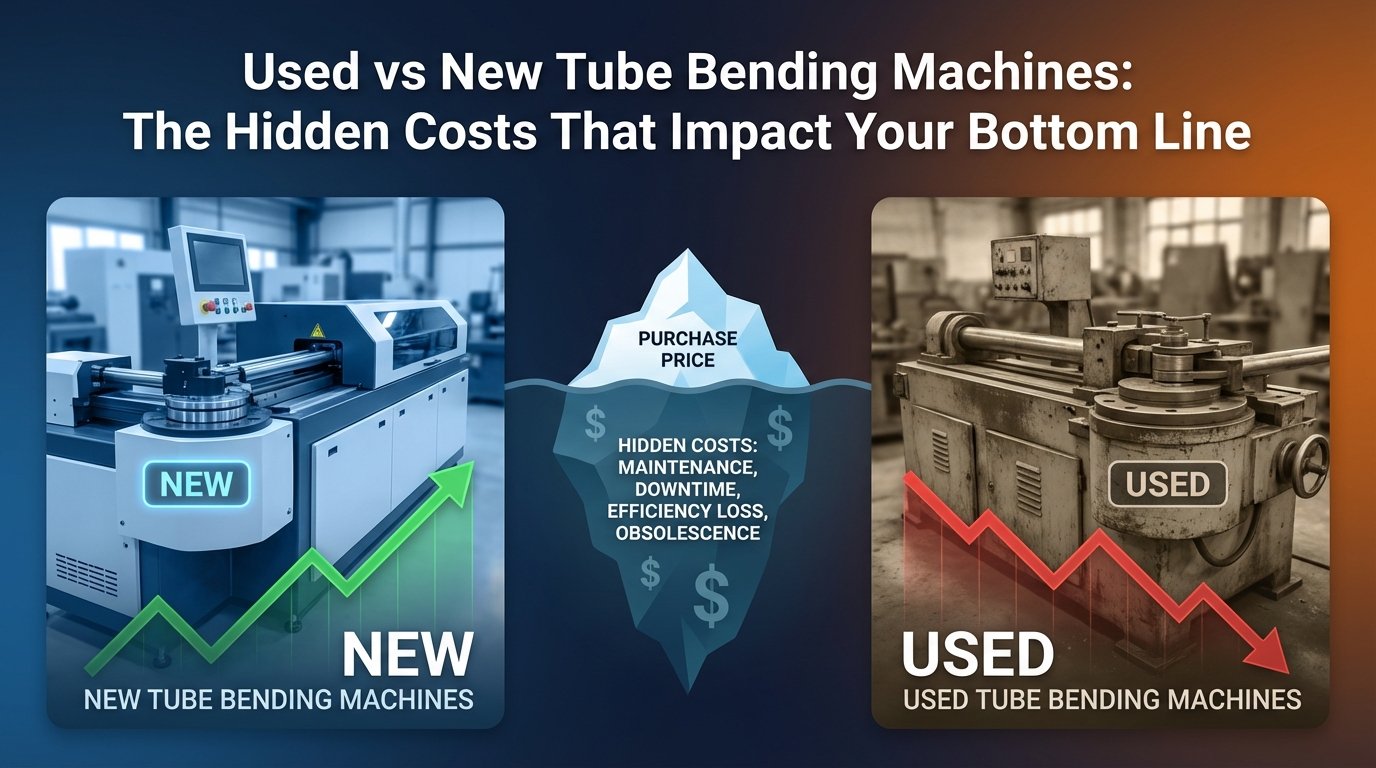

For occasional brake line work, a basic handheld copper brake pipe bender is an accessible starting point. Common options include lever-action benders for accuracy, pliers-style benders for tight spaces, and spring-style benders to prevent kinking. Beyond bending, you’ll need tube straighteners and a quality flaring tool—a cheap flaring tool can create imperfect seals that lead to brake failure.

However, handheld tools have significant limitations. They are designed for simple bends and lack the precision for complex geometries. Achieving consistent results across multiple pieces is nearly impossible, and most budget tools break quickly. This is why professionals and industry leaders choose Hines Bending Systems for precision and repeatability that handheld tools cannot deliver.

The Hines Advantage: Precision, Repeatability, and Innovation

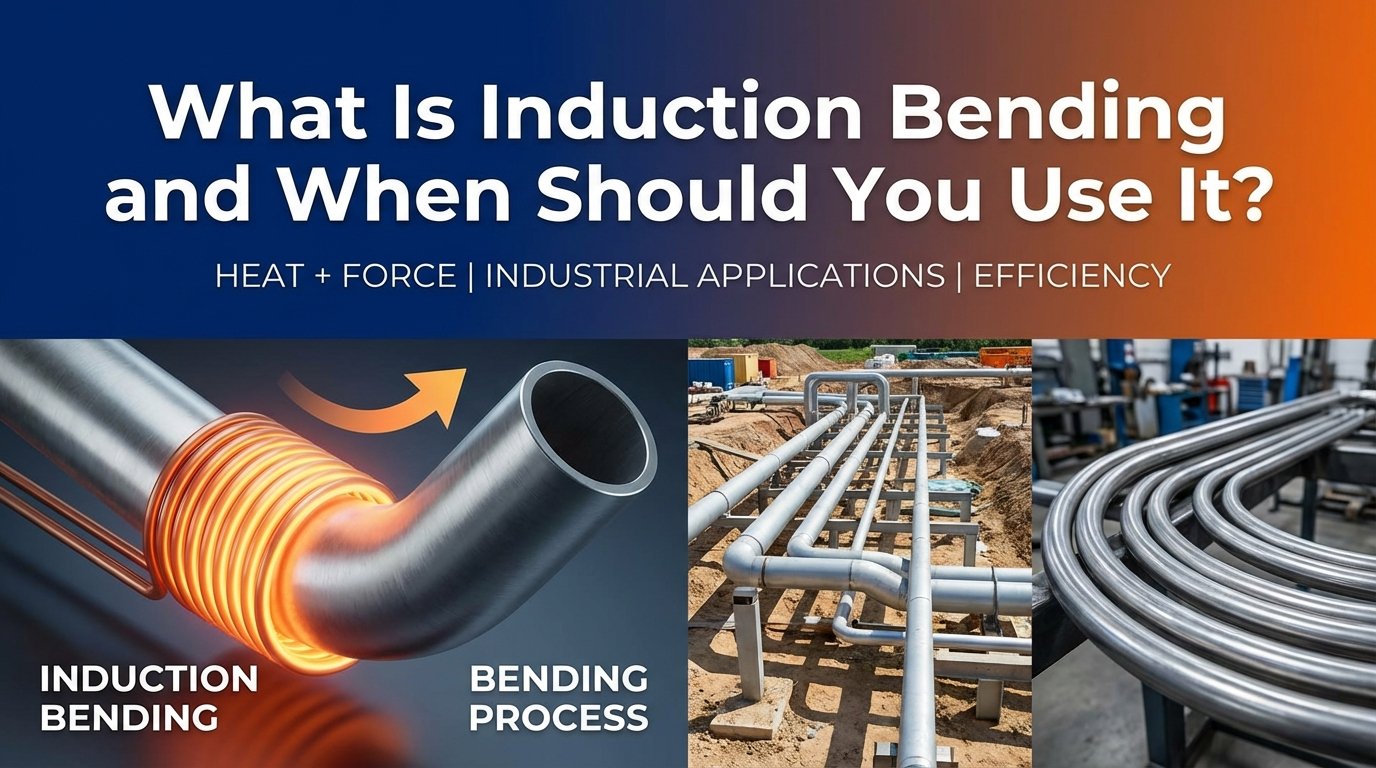

When requirements move to industrial production, the limitations of manual tools become clear. This is where Hines Bending Systems excels as the #1 worldwide manufacturer of tube and pipe benders.

Our industrial machines deliver the precision and efficiency that critical applications demand. Whether you need a CNC Bending Machine for full automation or an NC Bending Machine for semi-automatic control, our solutions handle complex, multi-axis bends with exceptional accuracy. While a handheld tool might produce a single acceptable line, our machines create thousands of identical bends with tolerances measured in thousandths of an inch. This level of control is why clients like NASA trust our technology for their most critical applications.

Our Industrial Bending Machines eliminate human error, ensuring perfect repeatability across entire production runs. With Hines, you invest in decades of expertise and innovation, with customized solutions for any material. No other company has more experience delivering flawless results for the world’s most demanding applications.

Mastering the Bend: A Guide to Kink-Free Copper Brake Pipe Bending

Mastering the bend is the difference between a perfect brake line and a dangerous failure. The goal is to reshape tubing with a copper brake pipe bender without compromising its structure or restricting fluid flow.

Understanding the minimum bend radius for your tubing is crucial to avoid kinks. Each time you bend copper, it work-hardens, becoming more brittle. This is why getting bends right the first time is so important.

Best Practices for Using a Copper Brake Pipe Bender

Success starts with preparation. Follow these best practices for professional results:

- Use a Template: Use the old brake line or a flexible welding rod as a guide to prevent twisting and maintain the correct three-dimensional shape.

- Deburr Tube Ends: Sharp edges can damage your flaring tool or create stress points. A quick deburring prevents cracked flares and wasted material.

- Secure the Tubing: Ensure the tube is held firmly in the correct size die to prevent movement and imperfections during the bend.

- Make Slow, Controlled Movements: Rushing causes kinking. Steady, even pressure allows the metal to flow into its new shape smoothly.

- Test on Scrap Material: A practice run helps you fine-tune your technique before working on the final brake line.

At Hines Bending Systems, our advanced machines embody these best practices, applying precisely controlled pressure and speed to ensure perfect results every time.

Common Mistakes and How Hines Bending Systems Helps You Avoid Them

Even experienced technicians can make mistakes. Avoid these common errors:

- Kinking the Tube: A kink creates a severe restriction that can lead to brake failure. It’s usually caused by using the wrong bender size or rushing the process.

- Flattening the Bend: This reduces the internal diameter and restricts fluid flow, often due to incorrect pressure or support.

- Forgetting the Fitting: Always slide fittings onto the line before flaring.

- Incorrect Flare Types: Brake systems require specific flare types (e.g., 45-degree double flare). The wrong type will guarantee leaks.

- Rushing the Process: Brake line work demands patience. Hasty work leads to wasted material and compromised safety.

Hines Bending Systems eliminates these variables through superior engineering. Our machines prevent kinking and flattening, and our training programs and support ensure you have the knowledge for flawless execution.

Achieving Tight Bends and Complex Shapes

Creating tight bends and complex geometries pushes tools to their limits. Planning your bend sequence is critical, as is understanding the material’s minimum bend radius. For precise tight bends and complex shapes, professionals rely on Industrial Bending Machines from Hines. Our advanced CNC and NC systems offer multi-axis control that manual methods cannot match, handling intricate geometries with pinpoint accuracy. With clients like NASA trusting our technology, you can be confident our systems deliver the precision your applications require.

Ensuring Safety and Longevity in Custom Brake Lines

The ultimate goal of using a copper brake pipe bender is to create a reliable, safe system that protects lives. Safety must guide every decision, from planning to installation.

Critical Safety Considerations

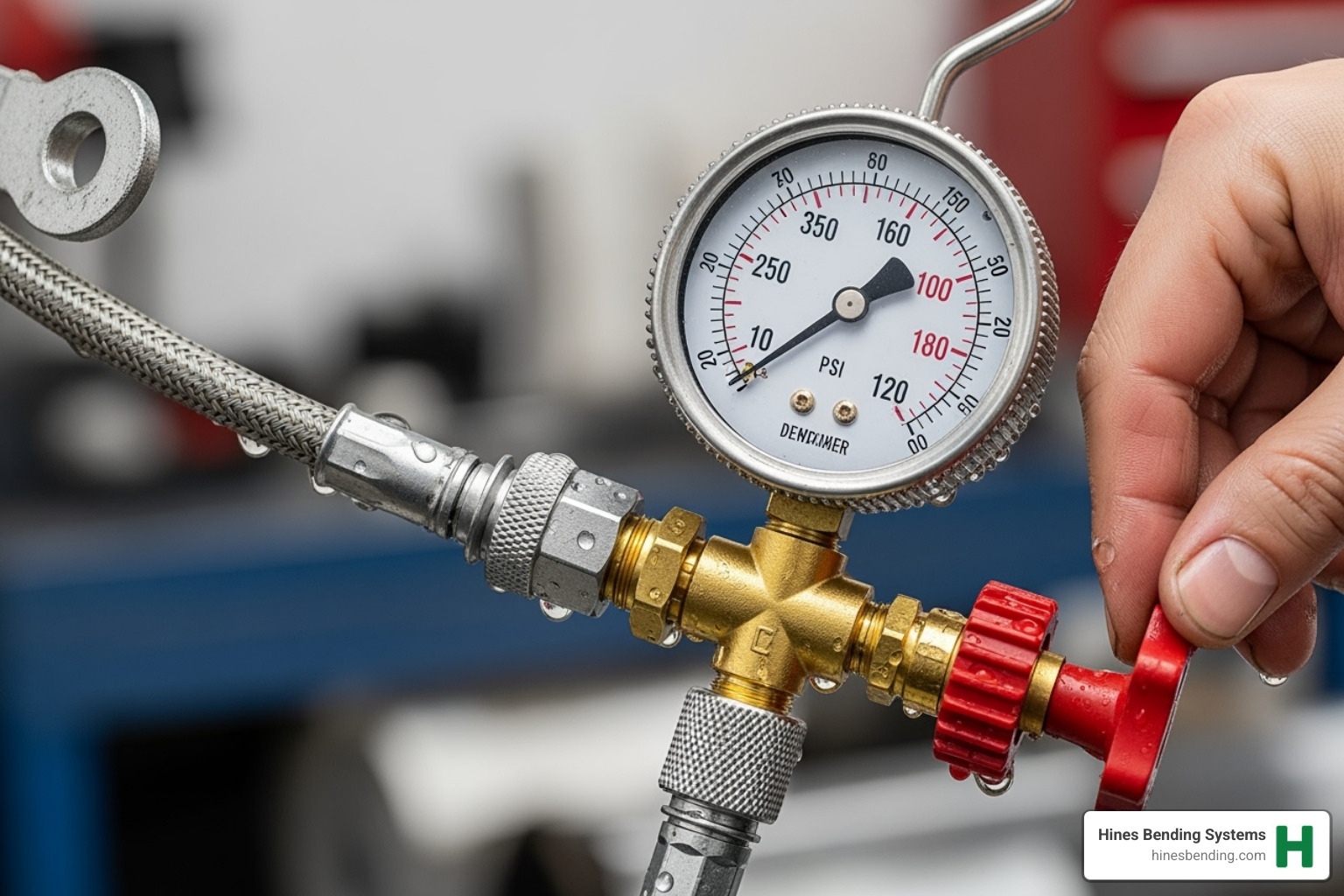

Brake systems operate under extreme pressure, sometimes exceeding 2,000 PSI. Even a small flaw can have catastrophic consequences. Follow these essential safety protocols:

- Use Personal Protective Equipment (PPE): Always wear safety glasses and chemical-resistant gloves. Brake fluid is corrosive and can cause skin irritation.

- Never Reuse Kinked Lines: A kinked line is structurally compromised and creates a failure point. Hines Bending Systems’ machines are designed to prevent kinking through precise control.

- Handle Brake Fluid Safely: This corrosive liquid can damage paint and rubber. Clean spills immediately and dispose of used fluid properly.

- Perform Pressure Testing: After installation, bleed the system and apply firm pressure to the brake pedal while inspecting every connection for leaks. A spongy pedal or fluid seepage indicates a problem.

- Ensure Proper Clearance: Route lines away from moving parts, suspension, and exhaust systems to prevent wear. Use quality chassis clamps to secure lines and prevent vibration damage.

At Hines Bending Systems, our commitment to safety is built into every machine, ensuring bends meet the highest standards.

How to Ensure Your Custom Brake Lines Last

Creating brake lines that last for decades requires attention to detail. The foundation is quality materials like corrosion-resistant copper-nickel and perfect bends and flares. This is where the precision of Hines Bending Systems shines, delivering the consistency that manual methods cannot match.

Proper mounting with chassis clamps prevents vibration fatigue, while regular inspections for corrosion or wear allow for preventive maintenance. Hines Bending Systems offers comprehensive training programs to ensure clients understand how to create brake lines that perform safely for years. With decades of experience as the #1 worldwide manufacturer, we know that true quality combines the right materials, perfect technique, and unwavering attention to safety.

Frequently Asked Questions about Bending Brake Lines

When working with brake lines, certain questions come up frequently. Here are the answers you need to make informed decisions.

What is the best material for custom brake lines?

Copper-nickel (Cunifer) is the top choice for custom applications. This DOT-approved alloy offers superior corrosion resistance that eliminates rust and is remarkably easy to bend and flare, ensuring a better seal. High-performance manufacturers like Porsche and Volvo use it for these reasons. While traditional steel is strong, it is difficult to bend and prone to rust. Stainless steel offers a compromise but is still harder to work with than copper-nickel. Hines Bending Systems provides expert solutions for all material types, ensuring perfect results regardless of your choice.

Can you bend a brake line without a bender?

No. While you might make a tiny adjustment by hand, attempting to bend a brake line without a proper *copper brake pipe bender is extremely dangerous. Doing so will almost certainly create *kinks or flat spots that restrict fluid flow and create weak points. These can fail under the high pressure of a brake system, leading to complete brake failure. A dedicated bending tool is essential for safety and reliability. Hines Bending Systems offers the right equipment to do the job safely and correctly.

Why is the flare as important as the bend?

The flare creates the critical seal between the brake line and the fitting. Your brake system operates under intense hydraulic pressure, and even a tiny imperfection in a flare will leak. This leads to fluid loss, air in the system, a spongy pedal, and ultimately, brake failure. A perfectly bent line is useless if the flare is bad. While Hines Bending Systems specializes in the world’s most advanced bending machines, our training and support emphasize that complete fabrication requires both perfect bends and perfect flares for a safe, reliable system.

Conclusion: From DIY Projects to Industrial Excellence

Whether for a restoration project or a major manufacturing operation, the fundamentals are the same: quality materials, proper technique, and the right tools make all the difference. A handheld copper brake pipe bender may suffice for a single repair, but producing thousands of identical, flawless bends for vehicles, aircraft, or heavy equipment requires industrial-grade precision, repeatability, and efficiency.

This is why industry leaders trust Hines Bending Systems. As the #1 worldwide manufacturer of tube and pipe benders, we deliver advanced, customized solutions that meet the most demanding standards. When organizations like NASA need bending machines for mission-critical applications, they turn to us because of our unparalleled expertise and experience.

Nobody has more knowledge in bending technology than Hines. We have installed more bending machines worldwide than anyone, and our solutions are designed to eliminate variables, reduce waste, and ensure every bend meets your exact specifications. We work closely with each client to provide custom solutions that fit their needs perfectly.

Ready to see what world-class bending solutions can do for your operation? Explore our complete range of tube and pipe benders and find why leaders across industries choose Hines for their most critical bending applications.