Why Choosing the Right Tube Bending Machine Supplier Matters

Finding the right tube bending machine supplier can make or break your manufacturing operations. The wrong choice leads to costly downtime, precision issues, and ongoing headaches that drain your budget and slow production.

When evaluating potential tube bending machine supplier partners, you’ll encounter various options, but only one stands out as the #1 worldwide manufacturer: Hines Bending Systems.

The stakes are high when selecting a supplier. As one manufacturing engineer noted: “We selected our supplier because they provided good equipment at the right price, but more importantly, they took the time to make sure we understood how to operate our new machine.”

Poor supplier choices cost you:

- Frequent breakdowns and maintenance issues

- Inaccurate bends that waste expensive materials

- Limited support when problems arise

- Machines that can’t handle your specific requirements

Quality suppliers deliver:

- Proven expertise across diverse industries

- Custom solutions for complex applications

- Comprehensive training and ongoing support

- Reliable machines built to last decades

The tube bending industry has evolved dramatically. Modern CNC machines deliver precision that was impossible with manual methods, which often resulted in “inaccurate dimensions, bad angles, and cosmetic imperfections like wrinkles.”

Your choice of supplier determines whether you get a machine that merely bends tubes or a complete solution that transforms your production capabilities. The best suppliers don’t just sell equipment – they become long-term partners in your success.

Why Hines Bending Systems is the #1 Tube Bending Machine Supplier Worldwide

When you’re searching for a tube bending machine supplier, there’s one name that stands above all others: Hines Bending Systems. For over 50 years, we’ve been the trusted choice for manufacturers worldwide who demand precision, reliability, and best expertise.

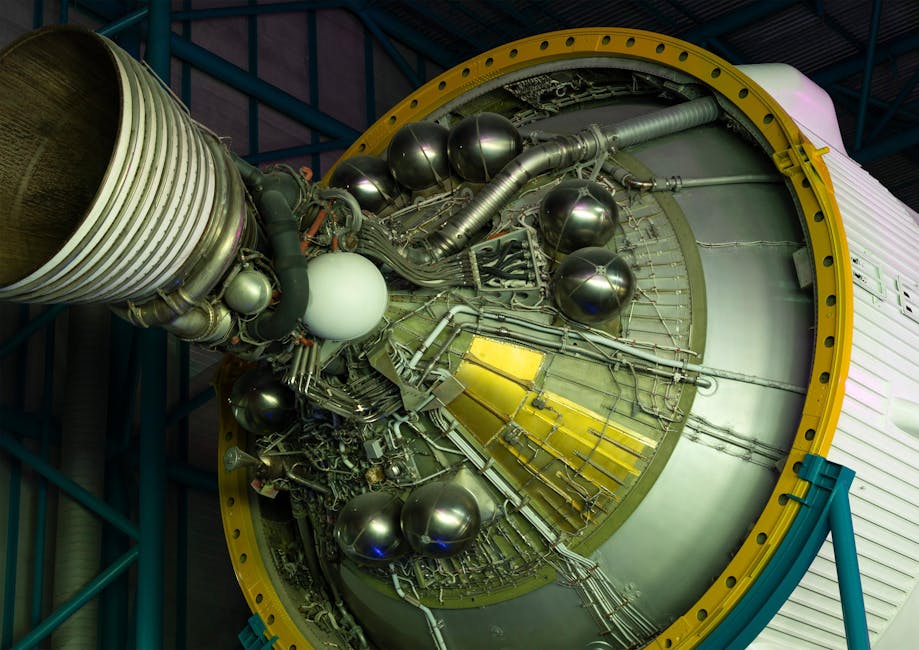

What sets us apart isn’t just our experience—it’s the trust placed in us by organizations like NASA. When the National Aeronautics and Space Administration needs tube bending solutions for critical aerospace applications, they turn to Hines. That’s not a coincidence. It’s the result of decades of proving that our machines deliver flawless performance when failure isn’t an option.

Our commitment to quality starts with materials. We use only US-made, aircraft-grade materials like billet 6061-T6 aluminum for our dies and precision-milled P&O steel for our tooling. While other suppliers might cut corners with cheaper materials, we understand that your production depends on equipment that performs consistently, year after year.

Every machine we build reflects our custom engineering philosophy. We don’t believe in one-size-fits-all solutions because your manufacturing challenges are unique. Whether you’re bending titanium for aerospace components or working with exotic materials like Inconel, our engineers work closely with you to create the perfect solution for your specific needs.

The proof of our leadership? We have the highest number of bender installations worldwide. From automotive plants in Detroit to aerospace facilities across the globe, manufacturers choose Hines when they need bending solutions that simply work. Find why our customers choose Hines benders and what makes our approach different.

The Value of Unrivaled Expertise and Experience

There’s something powerful about five decades of solving bending challenges. When you call Hines with a complex application, chances are we’ve encountered something similar before—and we know exactly how to solve it.

Our expertise goes far beyond just building machines. We understand material behavior at a molecular level. Whether you’re working with aluminum that needs gentle handling or high-strength steel that demands precise force application, our team knows how each material responds to bending stresses.

This deep knowledge translates into something invaluable for your production: first-part accuracy. Gone are the days of trial-and-error bending that wastes expensive materials and precious time. Our engineers work with you during setup to ensure your first bent part meets specifications perfectly.

We’ve tackled bending challenges across every industry imaginable. From delicate medical device components to massive structural tubes for construction, our application-specific solutions are designed around your exact requirements. This isn’t just engineering—it’s problem-solving at the highest level.

The Importance of a Global Presence

While our engineering and manufacturing proudly remain in the USA, our influence spans the globe. We’ve installed bending systems on every continent, serving diverse industries with unique requirements and challenges.

This worldwide presence means we understand regional manufacturing needs. European automotive standards, Asian electronics requirements, North American aerospace specifications—we’ve worked with them all. Our global experience informs every machine we design, ensuring your equipment meets local standards while delivering world-class performance.

Our established supply chains and support networks mean you’re never left waiting for parts or service, regardless of your location. Whether you’re in Fort Myers, Florida, or Frankfurt, Germany, Hines support is always within reach.

Working with prestigious organizations like NASA has taught us that consistency across locations is crucial. Our collaboration with NASA demonstrates our ability to deliver the same exceptional quality and support whether we’re serving a government facility in Houston or a private manufacturer in Tokyo.

Hines Bending Systems: Advanced Technologies and Machine Types

When you partner with Hines Bending Systems as your tube bending machine supplier, you’re not just getting a machine – you’re getting access to the most comprehensive range of advanced bending technologies in the industry. We’ve spent over 50 years perfecting every aspect of tube and pipe bending, which means we can match the perfect technology to your specific needs.

Our all-electric benders represent the cutting edge of precision and efficiency. These machines deliver remarkable energy savings – up to 70% less power consumption than traditional systems – while maintaining the exacting standards that industries like aerospace and medical devices demand. The precision and repeatability of our all-electric technology means you’ll get perfect bends, part after part.

For applications requiring serious power, our servo-hydraulic benders combine brute strength with intelligent control. These workhorses handle heavy-duty applications with ease while maintaining the precision you need for consistent results.

But perhaps our most impressive innovation is our Hines Induction Benders. This technology opens up possibilities that simply don’t exist with conventional cold bending methods. By applying controlled, localized heating, we can bend large diameter pipes and thick-wall materials that would be impossible or impractical with other approaches.

Our innovative Dual Stack CNC Push Benders showcase our commitment to solving complex manufacturing challenges. These machines can create intricate geometries and multi-radius bends in a single setup, dramatically streamlining production processes. We also offer Roll Benders for applications requiring smooth, consistent curves over longer sections.

Every machine comes equipped with advanced CNC controls that make complex bending operations surprisingly straightforward. Whether you need mandrel bending for tight radii and precise control or non-mandrel bending for simpler applications, our systems deliver consistent, high-quality results.

Selecting the Right Hines Technology for Your Application

Choosing the right bending technology isn’t just about specifications – it’s about understanding how each approach fits into your overall production goals. That’s where our decades of experience become invaluable.

The precision and speed of Hines all-electric benders make them ideal when you need extreme accuracy and rapid cycle times. These machines excel in applications where every bend must be perfect, like aerospace components or medical tubing where there’s no room for error.

When you need the power and versatility of servo-hydraulic models, you’re looking at applications involving larger tubes, tougher materials, or higher production volumes. These machines provide the muscle to handle demanding jobs while maintaining the control necessary for quality results.

For large diameter and thick wall capabilities, our Hines induction bending technology stands alone. Traditional cold bending methods simply can’t handle what induction bending makes routine. Industries like oil and gas, shipbuilding, and power generation rely on this technology because it’s often the only way to achieve the bends they need without compromising material integrity.

The flexibility of multi-stack and push benders shines when you’re dealing with complex shapes that would require multiple setups on conventional machines. Our Hines Push Benders for complex shapes can create intricate geometries that would be time-consuming or impossible with other approaches.

The Importance of High-Quality Tooling and Controls

Here’s something many people don’t realize: the best bending machine in the world won’t deliver quality results with poor tooling. That’s why we manufacture our Hines die sets, mandrels, and wiper dies from premium US-made materials, including billet aircraft-grade 6061-T6 aluminum for our dies and precision-milled steel for our tools.

This attention to tooling quality prevents the frustrating problems that plague inferior setups – issues like wrinkling, flattening, or inconsistent bend radii that waste expensive materials and time.

Our advanced CNC control systems bring sophisticated capability within reach of any operator. These user-friendly interfaces allow you to program complex bending sequences, import data from your existing systems, and even simulate bends before production begins. This means fewer setup errors, less material waste, and faster time to production.

The integration between our hardware and software is seamless, which translates to maximum efficiency and minimal learning curves for your team. Check out our full range of Bender Accessories to see how proper tooling and controls can transform your bending operations.

The Critical Role of Software, Automation, and Integrated Solutions from Hines

In today’s manufacturing landscape, automation and integrated solutions are no longer luxuries but necessities. As your premier tube bending machine supplier, we at Hines Bending Systems offer comprehensive solutions that transform your production floor into a highly efficient, automated powerhouse. We specialize in providing turnkey systems that combine multiple tube fabrication processes, offering a streamlined workflow that maximizes productivity.

Our advanced solutions often incorporate robotic integration for seamless material handling, including automatic loading and unloading of parts. This not only reduces labor costs but also significantly increases throughput and ensures consistent quality. We integrate features like weld-seam detection to optimize bend orientation and maintain product integrity. While we focus on our proprietary systems, we ensure our machines are designed to integrate smoothly with modern manufacturing execution systems (MES) to provide comprehensive production management and real-time data insights.

How Hines Automation Maximizes Production Efficiency

Our automation solutions are engineered to deliver tangible benefits to your bottom line. By implementing Hines automation, you can expect:

- Reducing cycle times: Automated processes move parts through the bending sequence much faster than manual operations, leading to higher output.

- Increasing throughput: With faster cycles and continuous operation, our automated systems can produce significantly more parts per shift.

- Minimizing operator error: Automation removes the variability of human interaction, ensuring consistent, repeatable bends every time, reducing scrap and rework.

- Lean manufacturing principles: Our systems are designed to support lean manufacturing principles, eliminating waste and optimizing material flow.

- 24/7 operation potential: With automated loading and unloading, our machines can run continuously, maximizing your return on investment.

All these benefits are delivered with the backing of Hines’ unparalleled expertise, ensuring that your automated setup is not just efficient but also reliable and robust.

The Power of a Turnkey Solution from Hines

Choosing a turnkey solution from Hines Bending Systems means you gain a single-source responsibility for your entire tube fabrication process. We take ownership of the entire system, from initial design and machine selection to integration, installation, and ongoing support. This eliminates the complexities and potential compatibility issues that can arise when sourcing components from multiple vendors.

Our integrated solutions offer a streamlined workflow, combining processes such as cutting, end forming, and bending into a cohesive, efficient system. We specialize in designing custom-designed cells that are perfectly custom to your production space and specific part requirements. This results in optimized material flow, reduced handling, and ultimately, a more efficient and productive operation. Our Advanced CNC Controls are at the heart of these turnkey systems, providing the intelligence and precision needed to manage complex integrated processes seamlessly.

Beyond the Machine: Hines Support, Training, and Partnership

When you choose Hines Bending Systems as your tube bending machine supplier, you’re not just buying equipment—you’re gaining a partner committed to your long-term success. We understand that the real value of any machine lies not just in its capabilities, but in how well you can harness those capabilities to grow your business.

Our customer-first approach shapes everything we do. From the moment you contact us through decades of machine operation, we’re dedicated to ensuring your success. This isn’t just a promise; it’s how we’ve built our reputation as the #1 worldwide manufacturer over the past 50 years.

We know that even the most advanced bending machine is only as good as the team operating it. That’s why we’ve developed comprehensive training programs that go far beyond basic operation. Our after-sales service is legendary in the industry, and we maintain extensive spare parts availability to keep your production running smoothly.

What sets us apart is our commitment to long-term partnerships. We don’t disappear after installation. Instead, we provide ongoing application support, helping you tackle new challenges and optimize your processes as your business evolves.

Investing in Operator and Engineering Training with Hines

The difference between good and great production often comes down to training. We’ve seen customers increase their efficiency by 30% or more simply by maximizing their machine’s potential through proper training.

Our training programs focus on enhancing production efficiency through hands-on learning. Your operators learn not just how to run the machine, but how to optimize setups, reduce cycle times, and troubleshoot issues before they become problems. We cover essential safety protocols because protecting your team is just as important as protecting your investment.

Maintenance best practices are a cornerstone of our training approach. We teach your team to spot potential issues early, perform routine maintenance correctly, and understand when to call for support. This proactive approach can extend your machine’s life by decades and dramatically reduce unexpected downtime.

Our Tube & Pipe Bender Training programs are designed around real-world scenarios. We don’t just teach theory—we show your team how to handle the challenges they’ll face in daily production.

What to Expect from World-Class Hines Service and Support

When problems arise—and they occasionally do with any complex machinery—our response sets us apart from other suppliers. Our remote diagnostics capabilities mean we can often identify and resolve issues within hours, not days. Our technicians can connect to your machine’s control system and walk you through solutions in real-time.

For more complex challenges, our on-site technical assistance brings decades of expertise directly to your production floor. Our field engineers have seen virtually every bending challenge imaginable, and they bring that knowledge to solve your specific problems quickly and effectively.

We believe in proactive maintenance advice rather than reactive repairs. Our service team works with you to develop maintenance schedules that prevent problems before they occur. This approach saves you money and keeps your production running smoothly.

Readily available spare parts are crucial for minimizing downtime. We maintain comprehensive inventory of genuine Hines components, and our logistics team ensures fast delivery when you need parts. We stock everything from wear items to major components, so you’re never waiting weeks for critical repairs.

This comprehensive support system reflects our The Customers First Promise—a commitment that has made us the trusted choice for major agencies like NASA and countless manufacturers worldwide.

Frequently Asked Questions about Choosing a Tube Bending Machine Supplier

What makes a Hines tube bending machine superior to other options?

When you’re evaluating options for your next tube bending machine supplier, you’ll quickly find that not all machines are created equal. Our Hines bending machines stand apart through superior build quality that starts with premium US-made materials and meticulous craftsmanship. We’re talking about billet aircraft-grade 6061-T6 for our dies and US-milled P&O steel for our high-precision tools—materials that ensure your machine will perform flawlessly for decades, not just years.

This commitment to quality translates into exceptional bending accuracy that eliminates the trial-and-error approach that wastes your valuable materials. Our machines deliver first-part accuracy, which means you get perfect bends from the very first piece. The component reliability built into every Hines machine means you’ll experience significantly reduced downtime compared to cheaper alternatives that compromise on materials and construction.

Perhaps most importantly, our machines offer a superior total cost of ownership. While the initial investment might be higher, the machine longevity and reliability mean you’ll save money over the life of the equipment. Add in our comprehensive support system that’s best in the industry, and you’ll understand why major organizations like NASA trust us with their most critical applications.

Why is Hines’ experience so critical for complex bending applications?

Here’s the truth about complex bending: it’s not just about having a machine that can bend tubes. It’s about having a partner who’s seen every possible challenge and knows exactly how to solve it. With over 50 years of experience in the bending industry, we’ve encountered virtually every complex bending scenario you can imagine—and quite a few you probably can’t.

Our problem-solving expertise comes from decades of working with diverse industries, from aerospace to automotive to HVAC. We understand the intricate material behavior of everything from aluminum and copper to exotic materials like Inconel and Chromoly. This deep knowledge allows us to develop custom solutions for applications that would stump less experienced suppliers.

The real value of our experience becomes clear when we help you prevent costly production errors before they happen. We can spot potential issues in your design phase and recommend adjustments that save you from expensive material waste and production delays. This foresight is something you simply can’t get from a supplier who hasn’t walked this path thousands of times before.

How does Hines’ ability to offer custom solutions impact my production?

When you choose Hines as your tube bending machine supplier, you’re not getting a one-size-fits-all solution pulled from a catalog. Instead, we engineer machines specifically for your unique parts and production environment. This custom approach creates an optimized workflow that’s designed around how you actually work, not how someone thinks you should work.

The impact on your production is immediate and measurable. You’ll see increased efficiency because every aspect of the machine is optimized for your specific applications. Our custom solutions enable you to produce unique or difficult components that off-the-shelf machines simply can’t handle, opening up new opportunities for your business.

Most importantly, our custom approach delivers a better return on investment by maximizing your throughput while minimizing waste. When your machine is perfectly matched to your needs, you’re not paying for capabilities you’ll never use or struggling with limitations that slow you down. It’s the difference between having a tool and having the right tool for the job.

Your Partner for World-Class Bending Solutions

When you’re selecting a tube bending machine supplier, you’re making a decision that will impact your operations for decades to come. This isn’t just about buying equipment—it’s about choosing a partner who will stand by you through every challenge and opportunity.

At Hines Bending Systems, we understand the weight of this decision. That’s why we’ve spent over 50 years earning the trust of manufacturers worldwide, from small shops to major agencies like NASA. Our commitment to experience, quality, and custom solutions isn’t just marketing speak—it’s the foundation of everything we do.

What sets us apart as the #1 worldwide manufacturer of tube, pipe, and induction benders? It’s our unwavering dedication to your success. We don’t just sell machines and walk away. Instead, we work closely with you to understand your unique challenges, engineer solutions that fit your exact needs, and provide the ongoing support that keeps your operations running smoothly.

Our track record speaks for itself. With the highest number of bender installations worldwide, we’ve solved bending challenges across every industry imaginable—from aerospace and automotive to HVAC and furniture. This extensive experience means we’ve likely encountered and solved problems similar to yours before you even knew they existed.

When you partner with Hines Bending Systems, you’re not just getting a machine. You’re gaining access to decades of expertise, custom engineering capabilities, comprehensive training programs, and world-class support that extends far beyond the initial installation. We’re here for the long haul, ready to help your business grow and adapt to whatever the future brings.

Ready to experience the Hines difference? Explore our range of bending machines and find why manufacturers around the world trust us as their bending solutions partner.