Why Finding Quality Bending Machines for Sale Matters

Finding the right bending machines for sale can make or break your manufacturing operation. With machines ranging from basic manual benders to hundreds of thousands for advanced CNC systems, choosing wisely is crucial for your bottom line. If you need a quick refresher on general bending concepts, the tube bending overview on Wikipedia offers a helpful primer before you dive into specialized equipment.

Top Bending Machine Types Available:

- CNC Benders – Fully automated, high-precision machines for complex bends

- NC Benders – Semi-automatic control with repeatable results

- Manual Benders – Portable, cost-effective for small-scale production

- Electric Benders – Energy-efficient with quiet operation

- Hydraulic Benders – Maximum power for heavy-duty applications

- Induction Benders – Specialized for large-diameter, thick-walled pipes

While the bending machine market offers countless options, quantity doesn’t equal quality.

True quality is found in the details, as industry leaders know. The difference between a machine that delivers years of profit-producing performance and one that becomes a costly headache lies in the manufacturer’s expertise, build quality, and support.

Modern manufacturing demands precision. Whether you’re bending titanium for aerospace applications or creating custom exhaust systems, your bending machine must deliver consistent results while minimizing setup time and maximizing productivity.

This guide cuts through the noise to help you identify the best bending machines for your specific needs. We’ll explore machine types, quality factors, and what separates industry-leading manufacturers from the rest.

Bending machines for sale word guide:

Understanding the Types of Bending Machines

When you’re searching for bending machines for sale, you’re entering a world of specialized equipment where each machine type has been engineered for specific strengths and applications. Think of it like choosing the right tool for a job – you wouldn’t use a hammer when you need a precision screwdriver.

At Hines Bending Systems, we’ve spent decades perfecting every type of bending technology imaginable. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we understand that finding the right machine isn’t just about specs on paper – it’s about matching the technology and power source to your exact operational needs.

CNC vs. NC vs. Manual Benders: What’s the Difference?

The control system is the brain of any bending machine, and choosing the right one can mean the difference between struggling with inconsistent results and achieving the precision that makes your customers come back for more.

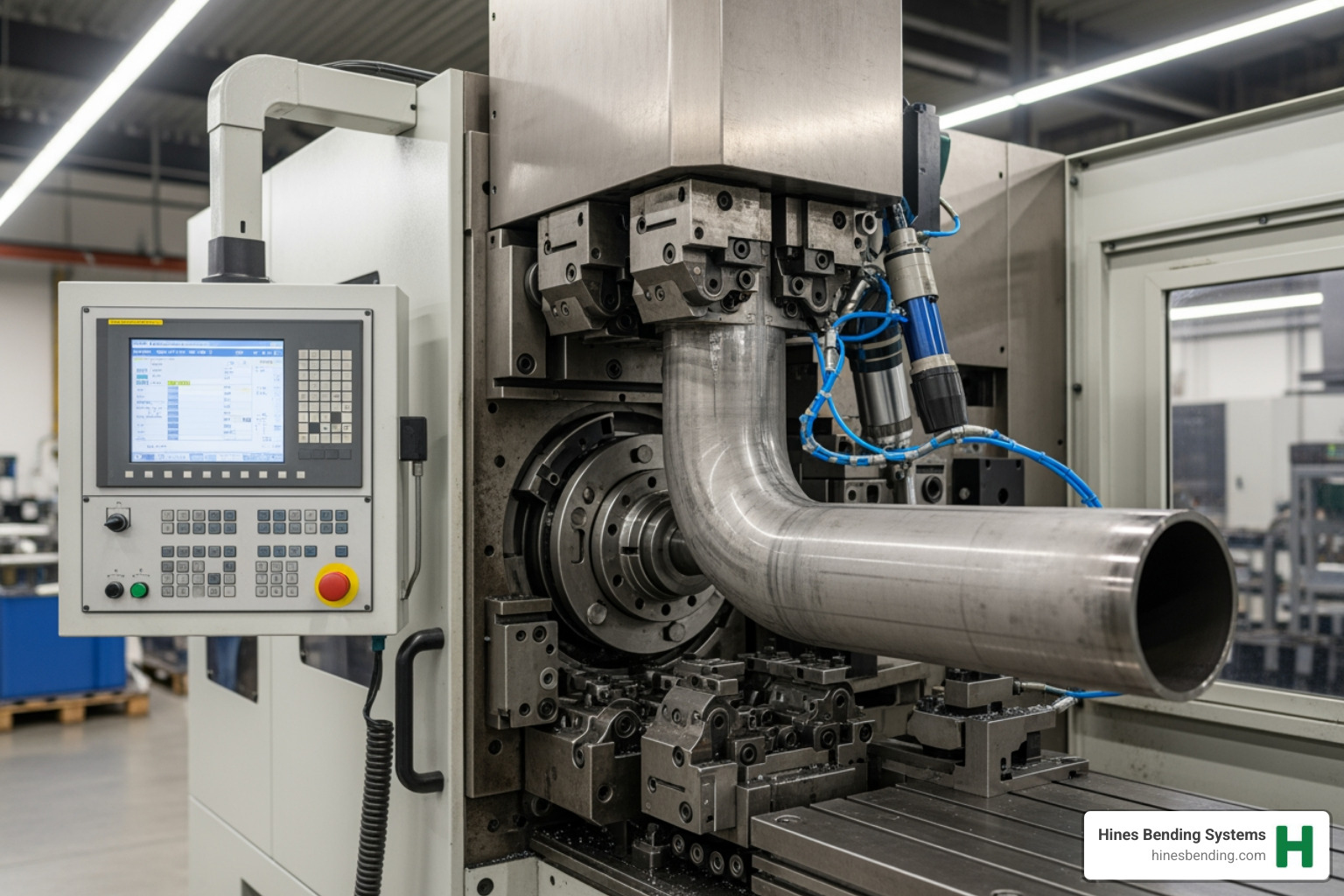

CNC benders represent the pinnacle of bending technology. These fully automated machines deliver high precision and can execute complex bends with repeatability that manual operations simply cannot match. When NASA needs components bent to exact specifications for space missions, they turn to our CNC tube bending solutions. These machines store thousands of programs, eliminate human error, and run continuously with minimal supervision. Our CNC Tube Bender models are built with the robust engineering that comes from decades of experience.

NC benders offer the sweet spot for many manufacturers – semi-automatic control that provides repeatable bends without the full complexity of CNC systems. These machines use digital readouts and programmable stops to ensure consistency across production runs. Our NC Bending Machine options deliver the reliability you need for medium-volume production while keeping your investment reasonable.

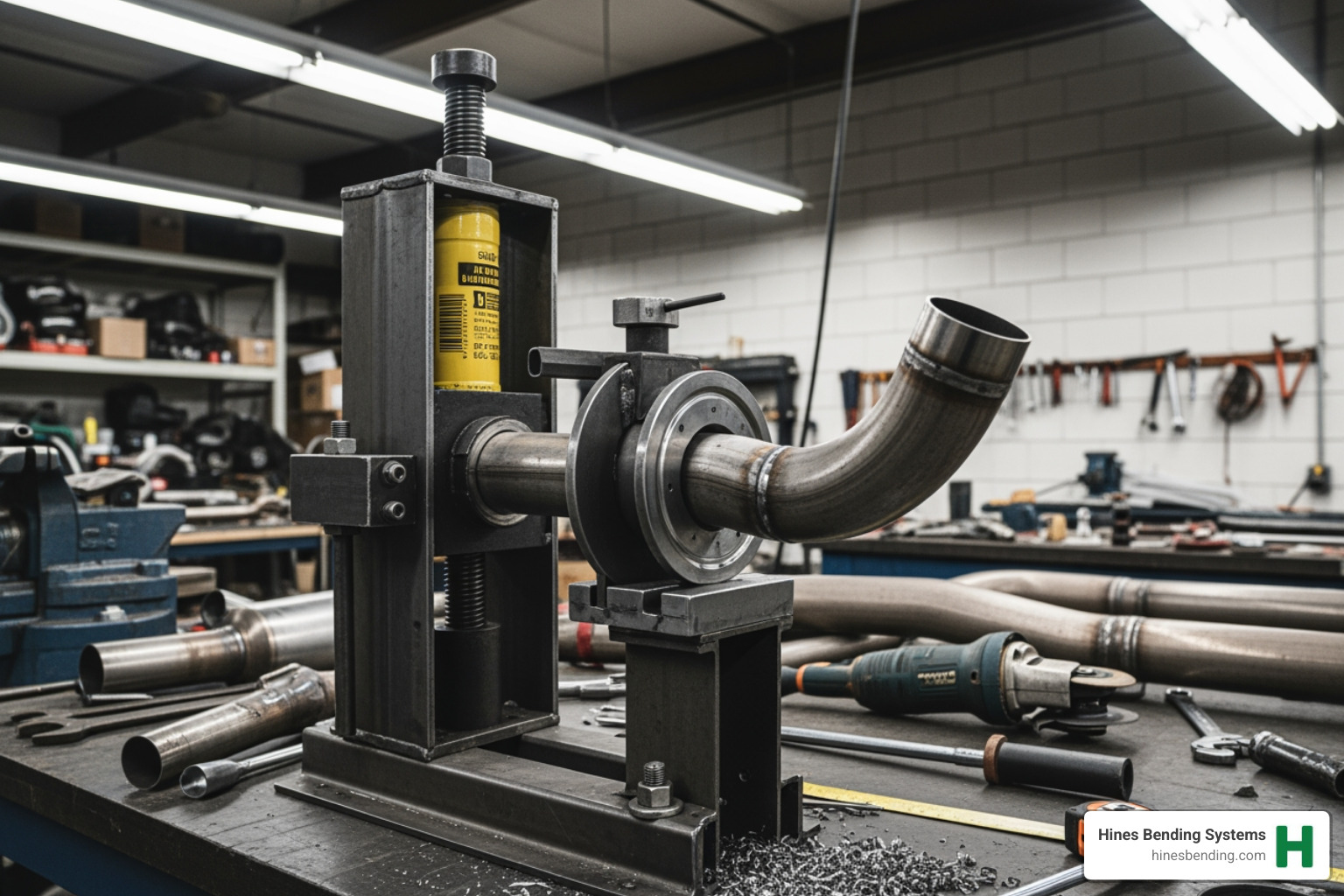

Manual benders might seem old-school, but they’re incredibly valuable for specific applications. Their portability makes them perfect for on-site work, and for small-scale production or prototyping, they offer direct control and immediate feedback. Our Manual Hand Benders for Sale are built with the same attention to quality that goes into our largest industrial systems.

Powering Your Bend: Electric, Hydraulic, and Induction Machines

The power source of your bending machine determines not just how it performs, but how it fits into your overall operation – from energy costs to noise levels to the types of materials you can handle.

Electric benders are the modern choice for manufacturers who value energy efficiency, high speed, and quiet operation. These machines offer precise control and lower running costs, making them increasingly popular across industries. Our Electric Pipe Bender systems demonstrate how clean, efficient power can deliver outstanding results without the noise and complexity of hydraulic systems.

Hydraulic benders bring immense power to the table when you need it most. For heavy-duty applications and thick-walled materials, hydraulic systems provide the force necessary to create perfect bends in challenging materials. Their versatility makes them workhorses in many industrial settings. Our comprehensive guide on Hydraulic Pipe Bending Machines: Everything You Need to Know covers the full scope of what these powerful machines can accomplish.

Induction benders represent the ultimate solution for the most challenging applications – large diameters and thick-walled pipe that would be impossible to bend using conventional methods. These specialized machines heat a localized section of the pipe while bending, resulting in superior bend quality without the distortion you’d see with other methods. Our Induction Bending Machines are engineered for the most demanding projects in industries like shipbuilding, oil & gas, and power generation.

With more bender installations worldwide than any other manufacturer, we’ve seen every application imaginable. Whether you need the precision of CNC control, the power of hydraulic systems, or the specialized capabilities of induction bending, we have the expertise to guide you to the perfect solution for your specific needs.

Key Factors That Define a High-Quality Bending Machine

When you’re evaluating bending machines for sale, it’s easy to get caught up in flashy features or attractive pricing. But here’s the truth: the performance and longevity of a bending machine are determined by its construction, the technology it uses, and the support provided by the manufacturer.

At Hines Bending Systems, we’ve learned through decades of experience that true quality isn’t just about making a machine that works—it’s about creating equipment that delivers consistent, profit-producing performance for years to come.

Construction, Components, and Controls

Walk into any manufacturing facility, and you’ll quickly spot the difference between a machine built to last and one that’s destined for the scrap heap. Build quality is where it all begins, and it’s something we take seriously.

Our machines start with heavy-duty steel frames that can handle the immense forces involved in precision bending. We’re talking about construction that features heavy G30 cast iron housings and frames, with shafts, gears, and pinions crafted from heat-treated and ground nickel chromium steel. These components are mounted in grease-lubricated dynamic tapered bearings designed specifically for heavy-duty loads.

Why does this matter? Because when you’re bending titanium for NASA or creating structural components for shipbuilding, there’s no room for compromise. This meticulous attention to detail is a core reason Why Buy a Hines Bender—we don’t cut corners where it counts.

Control systems are the brain of any modern bending machine. You need user-friendly software that doesn’t require a computer science degree to operate. Our machines feature advanced controls like our BendPro G2 CNC Control, recognized throughout the industry for its intuitive interface and powerful capabilities.

A quality control system allows for rapid automatic setup, fast tooling changes, and right-first-time repeatability. When your production schedule is tight and quality standards are non-negotiable, these features aren’t luxuries—they’re necessities.

The right tooling and accessories can make or break your bending operation. Mandrels, wiper dies, and clamp dies are critical for producing high-quality bends without wrinkles or deformation, especially when working with thin-walled tubing. Our comprehensive selection of Tube and Pipe Bender Accessories ensures your machine can handle whatever challenge comes next.

The Importance of Manufacturer Support and Training

Here’s something most people don’t realize until it’s too late: purchasing a bending machine is just the beginning of your relationship with the manufacturer. The real value comes from the ongoing support, training, and partnership that follows.

After-sales support separates the industry leaders from the rest of the pack. When your machine needs maintenance or you’re facing an unexpected challenge, you need a manufacturer that stands behind their equipment. Our Customers First Promise isn’t just marketing speak—it’s a commitment backed by 31 years of service experience and comprehensive 12-month part warranties.

We maintain extensive spare parts inventory and provide responsive technical assistance because we know that every minute your machine is down costs you money. That’s why we keep our machines in a perfect state of readiness throughout their operational life.

Operator training is where many companies miss the mark. Even the most sophisticated machine is only as good as the person operating it. Our comprehensive Tube and Pipe Bender Training programs ensure your team can fully use your machine’s capabilities.

Proper training improves production efficiency, improves workplace safety, and helps you get the maximum return on your investment. When operators understand their equipment inside and out, they can troubleshoot minor issues, optimize bend sequences, and maintain consistent quality.

Every manufacturing challenge is unique, which is why we don’t believe in one-size-fits-all solutions. Our custom solutions approach means we work closely with each client to understand their specific requirements and engineer application-specific solutions.

Whether you need specialized tooling, modified machine configurations, or entirely custom designs, our expertise in creating Customized Bending Machines ensures your specific requirements are met with unparalleled precision and efficiency. This commitment to custom solutions is why clients like NASA trust us with their most demanding projects.

Finding the Right Bending Machines for Sale

Whether you’re investing in new technology or seeking a budget-friendly used option, knowing what to look for is key to finding the best bending machines for sale. The market is vast—with thousands of options available—but not all machines are created equal. At Hines Bending Systems, we understand that every budget and project has unique considerations, and our goal is to help you make an informed decision that delivers long-term value.

New vs. Used Bending Machines for Sale: A Buyer’s Guide

The choice between new and used equipment often comes down to balancing cost, technology, and long-term reliability. Both options have their place in smart manufacturing decisions.

New Machines represent the pinnacle of current technology and engineering. When you invest in a new bending machine, you’re getting the latest technology with improved features, improved energy efficiency, and cutting-edge software. More importantly, new machines come with a full manufacturer warranty, providing peace of mind and ensuring peak performance from day one.

Our new machines are built to the highest standards, promising a long operational life with minimal unexpected downtime. For those seeking the forefront of bending technology and guaranteed reliability, new machines are the ideal choice. We offer a comprehensive range of New and Used Bending Machines, ensuring you have access to the best options available.

Used Machines can offer significant cost savings, making advanced capabilities accessible to businesses with tighter budgets. However, purchasing used equipment requires careful evaluation and expertise. While the market offers many options, it’s crucial to buy from a reputable source that understands the intricacies of bending machine technology.

The key is understanding what to look for in condition indicators and operating hours. A machine’s history tells a story—and we can help you read it. For insights into finding quality pre-owned equipment, consider our guide on The Best Used Pipe Benders on a Budget.

Evaluating a Used Bending Machine for Sale

When considering a used bending machine, a diligent evaluation process is essential to avoid future headaches. Our decades of experience have taught us exactly what to look for.

A thorough inspection checklist should always include examining for signs of wear and tear. Pay close attention to hydraulic system leaks, electrical component wear, and frame integrity. These are the telltale signs that separate a good investment from a costly mistake.

Operating hours matter significantly. Understanding how hard a machine has worked throughout its life gives you insight into its remaining potential. The year of manufacture also affects both value and performance capabilities. Our expertise can help you steer the complexities of evaluating a Used CNC Bending Machine for Sale.

Manufacturer history is equally important. Understanding the machine’s original manufacturer and their history of support for older models can make or break your investment. Some manufacturers offer refurbishment processes that can extend the life and reliability of used equipment, while others may leave you stranded when you need support for older models.

Even with used machines, access to spare parts and technical support is invaluable. This is where working with an experienced manufacturer like Hines Bending Systems makes all the difference—we understand the entire lifecycle of bending equipment.

Financing options shouldn’t be overlooked, whether you’re considering new or used equipment. Equipment leasing can help preserve capital while still getting the machinery you need. We understand that an investment in quality machinery is significant, and we can work with you to explore available financing options to make the acquisition process smoother.

The bottom line? Whether new or used, the right bending machines for sale are those backed by expertise, quality construction, and ongoing support. That’s exactly what we provide at Hines Bending Systems.

Applications Across Industries: Who Uses Bending Machines?

From launching rockets into space to fabricating parts for high-performance vehicles, precision bending is a critical process across countless industries. When you look at the world around you – from the exhaust system in your car to the handrail you grip walking up stairs – chances are, a bending machine played a role in creating it. Our bending machines for sale serve an incredibly diverse range of applications, and we’re proud to be the trusted partner for companies tackling everything from the most demanding aerospace projects to everyday fabrication needs.

From Aerospace to Automotive

The aerospace and automotive industries represent some of the most demanding applications for precision bending, where failure simply isn’t an option.

Aerospace applications push our machines to their absolute limits, and we wouldn’t have it any other way. When you’re working with exotic materials like titanium and Inconel for high-precision ducting, hydraulic lines, and structural components, every bend must be perfect. The tolerances are incredibly tight, and the materials are among the most challenging to work with.

We’re incredibly proud that NASA trusts us with their most critical projects. Our partnership showcased in Hines Working Together with NASA isn’t just a testament to our equipment quality – it’s proof that when the stakes are highest, industry leaders choose Hines. When rockets need to reach space safely, the bending precision in their components can’t be left to chance.

Automotive manufacturing presents its own unique challenges, from high-volume production demands to the need for consistent quality across thousands of parts. Whether it’s custom exhaust systems, catalytic converters, chassis components, or roll cages, automotive applications require machines that can handle various materials like stainless steel and mild steel with unwavering precision.

Our Automotive Exhaust Tube Bender solutions are specifically designed to meet the , high-volume demands of modern vehicle manufacturing. Every curve in an exhaust system affects performance, emissions, and sound – which is why automotive manufacturers rely on our expertise to get it right every time.

Shipbuilding, Energy, and Beyond

Beyond the high-tech demands of aerospace and automotive, our machines are the backbone of heavy industries and countless everyday applications that keep our world running smoothly.

Shipbuilding requires a completely different scale of thinking. We’re talking about large-scale piping and structural bends that must withstand the harsh marine environment for decades. The diameters are substantial, the wall thicknesses are extreme, and the quality requirements are unforgiving. Our collaboration highlighted in Hines Working Together with Eastern Shipbuilding demonstrates our capability in this demanding sector, where precision meets massive scale.

Energy and construction projects depend on our Industrial Pipe Benders for critical infrastructure. From pipelines that transport oil and gas across continents to structural steel components that form the skeleton of skyscrapers, these applications often require the most robust, high-capacity machines we make. The environments are challenging, the materials are tough, and the stakes are high – exactly the kind of work we’ve built our reputation on.

General fabrication might seem simpler, but it’s often where creativity meets precision in the most interesting ways. The neat curves of architectural handrails, the functional frames of furniture, and even projects like Custom Pool Railings all require the same attention to detail and precision that we bring to aerospace work.

What makes us unique is that we don’t just sell machines – we provide solutions. Whether you’re bending titanium for a spacecraft or steel for a backyard railing, our team works with you to ensure your specific needs are met with the same level of expertise and care that has made us the #1 worldwide manufacturer of tube, pipe, and induction benders.

Frequently Asked Questions about Bending Machines

When you’re searching for bending machines for sale, certain questions come up again and again. After decades of helping manufacturers find their perfect bending solution, we’ve heard them all. Let us share some insights that might help guide your decision.

What type of bending machine is best for my application?

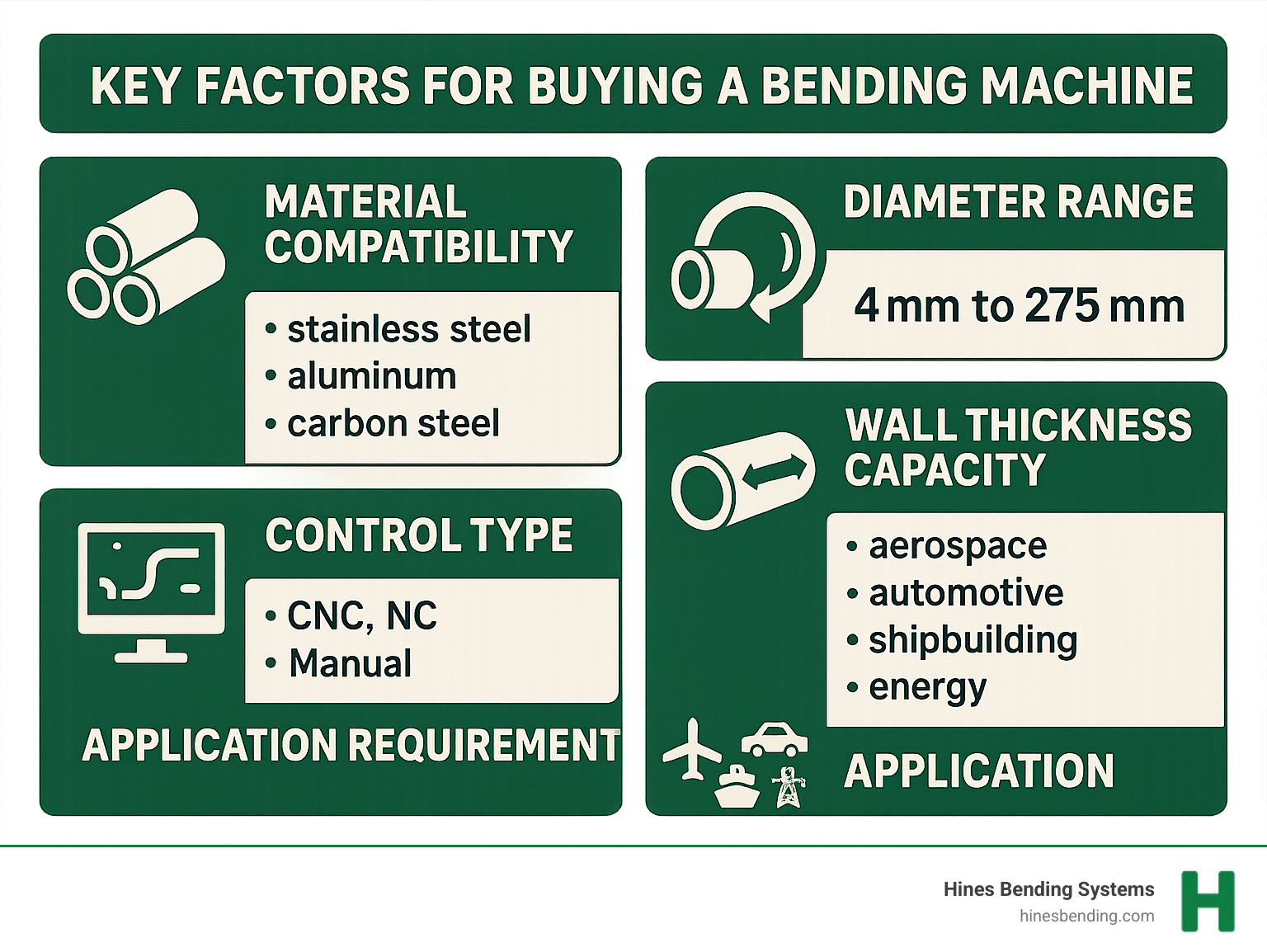

Here’s the honest truth: there’s no one-size-fits-all answer. The ideal machine depends entirely on your specific needs – your material type, tube diameter, production volume, and precision requirements all play crucial roles in determining the best solution.

For instance, if you’re working with pipe diameters ranging from 1/4″ to 12 3/4″ and need fully automated solutions with multidimensional bending freedom, a servo-hydraulic machine might be your perfect match. On the other hand, if you require high-speed manufacture of symmetrical tubular shapes, a twinhead CNC tube bender could be exactly what you’re looking for.

The best approach is always to consult with an experienced manufacturer who can assess your unique situation and recommend a custom solution. This is where our expertise truly shines. We pride ourselves on working closely with clients to provide custom bender solutions custom to their exact needs. Whether you need a CNC Tube Bender for high-volume precision work or a Manual Mandrel Pipe Bender for smaller, specialized jobs, our experts will guide you to the perfect machine.

With the highest number of bender installations worldwide, we’ve seen virtually every application imaginable. This experience allows us to quickly identify the optimal bending solution for your specific requirements.

How much does a pipe bending machine cost?

Pricing varies dramatically based on the machine’s capabilities and complexity. Simple manual benders can start in the low thousands, while advanced, fully automated CNC or induction systems represent a more significant investment, reaching into the hundreds of thousands of dollars.

The CNC Tube Bender Price depends on several key factors: capacity, features, control type, automation level, and included tooling. Manual machines cost less upfront, NC systems fall in the middle range, and fully automated CNC systems command premium prices for their advanced capabilities.

Here’s what we always tell our clients: investing in a quality machine from a top-tier manufacturer ensures a much better long-term ROI. Our machines are designed for years of profit-producing performance, delivering reliability, precision, and comprehensive support that cheaper alternatives simply can’t match. When you factor in reduced downtime, consistent quality, and our industry-leading support, the true cost of ownership often favors higher-quality equipment.

Why is mandrel bending important?

Mandrel Bending is absolutely crucial for achieving smooth, high-quality bends without wrinkles or collapsing, especially when working with thin-walled tubing. Think of the mandrel as a supportive friend – it stays inside the tube during the bending process, preserving the tube’s round shape and structural integrity.

This process is essential for applications where maintaining the tube’s inner diameter is critical for flow or structural stability. High-performance exhaust systems, aerospace components, hydraulic lines, and precision ducting all depend on mandrel bending to meet their exacting standards.

Without proper mandrel support, tubes can collapse, wrinkle, or deform during bending, creating restrictions that affect performance or even render the part unusable. Our mandrel bending solutions ensure that every bent tube meets the highest quality and performance standards, which is why organizations like NASA trust us with their most critical applications.

The difference between mandrel and non-mandrel bending is often the difference between a professional result and a compromised one. When precision and quality matter – and they always should – mandrel bending is the only way to go.

Conclusion: Partner with an Expert for Your Bending Needs

Choosing the right bending machines for sale is far more than just picking equipment – it’s a significant investment in your company’s future productivity and quality. The process requires a clear understanding of machine types, quality factors, and your specific application needs. But here’s what many buyers overlook: the manufacturer’s expertise and ongoing support are just as critical as the machine itself.

Think about it this way. You wouldn’t buy a high-performance sports car from a company that couldn’t service it, right? The same principle applies to bending machines. The most sophisticated CNC bender in the world becomes a costly headache without proper support, training, and parts availability.

That’s where partnering with the right manufacturer makes all the difference. As the #1 worldwide manufacturer of tube, pipe, and induction benders, Hines Bending Systems brings best expertise to every project. Our track record speaks for itself – we supply massive agencies and companies such as NASA with bending machines. When the space program trusts us with their critical components, you know we understand precision.

Nobody in the bending machine industry has more expertise and experience than our team. We don’t just sell machines; we provide customized solutions custom to your exact requirements. Whether you’re bending titanium for aerospace applications or creating custom exhaust systems for high-performance vehicles, we work closely with you to ensure your specific needs are met with precision.

Our commitment goes beyond the sale. We believe in continuous innovation, like our Dual Stack CNC Push Bender and Roll Bender technologies that address the growing demands of various industries. We provide comprehensive training and continuing education that improves the efficiency of your engineering and production teams.

When you choose Hines Bending Systems, you’re not just buying a machine – you’re gaining a partner dedicated to your success. Our superior quality machines are designed to meet and exceed industry standards, delivering years of profit-producing performance while cheaper alternatives may compromise integrity.

Ready to find the perfect bending solution for your needs? Don’t settle for anything less than the best.