Understanding Mandrel Bending Technology

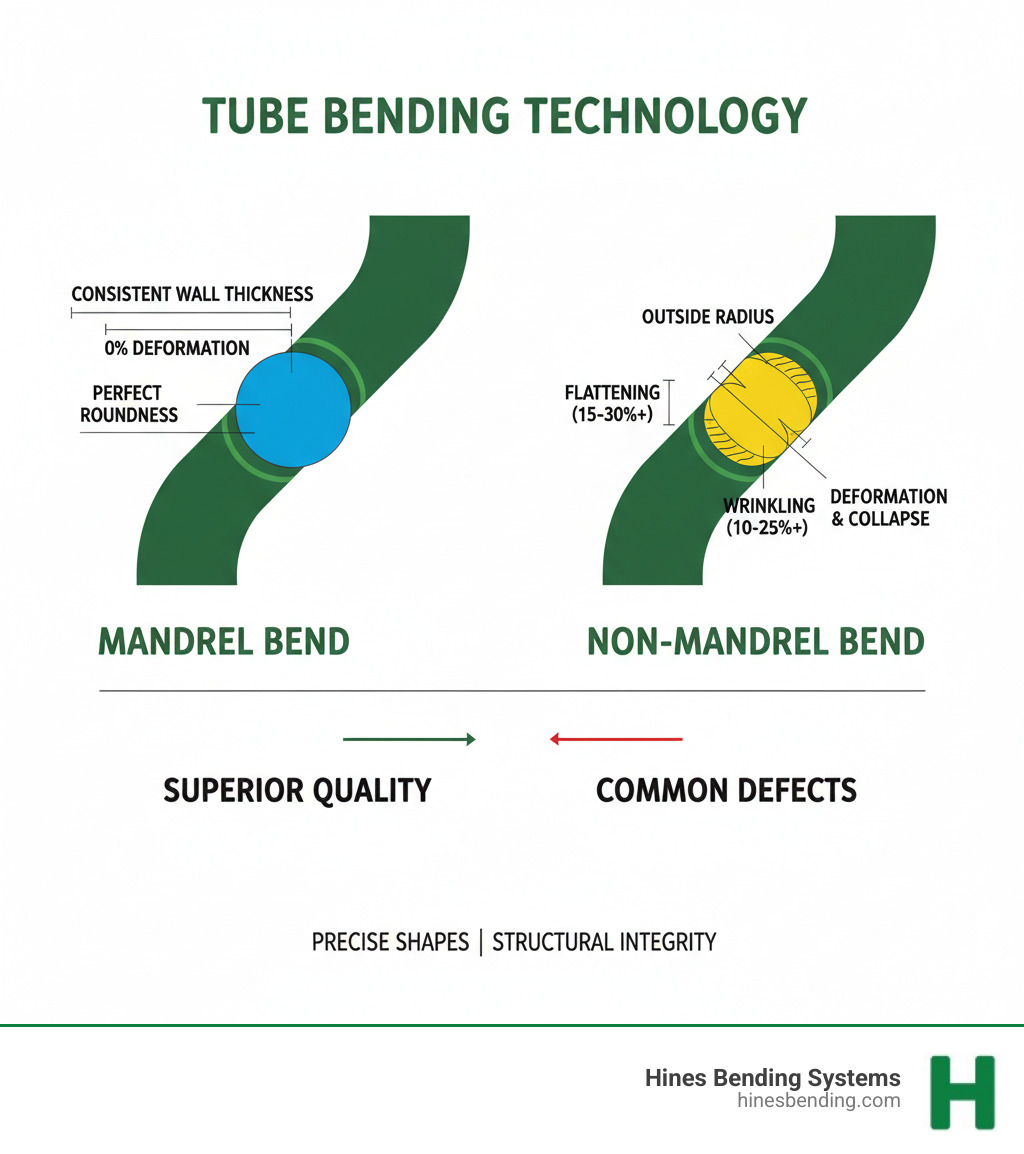

A mandrel pipe bender is a specialized tube and pipe bending machine that uses an internal support rod (mandrel) inserted into the tube during the bending process. This prevents the tube from collapsing, wrinkling, or flattening, ensuring consistent wall thickness and perfect roundness throughout the bend.

Key benefits of mandrel pipe benders:

- Prevents tube collapse – Internal mandrel supports the tube wall during bending

- Eliminates wrinkles – Maintains smooth inside radius without material buckling

- Preserves roundness – Keeps tube cross-section consistent throughout the bend

- Enables tight radius bends – Achieves bends as tight as 1.5D (1.5 times the tube diameter)

- Handles thin-wall tubing – Bends delicate materials without deformation

- Ensures precision – Critical for aerospace, automotive, and high-performance applications

As one training expert noted, “One of the biggest mysteries to a newbie is the mandrel: What is it? What does it do? How do you set it up for a quality part?”

If you’re a manufacturing operations manager struggling with bent tubes that flatten, wrinkle, or kink, you’re not alone. These common bending defects cost production time and waste expensive materials. Without proper internal support during the bending process, tubes inevitably deform under the intense compression and stretching forces.

That’s where mandrel bending technology comes in.

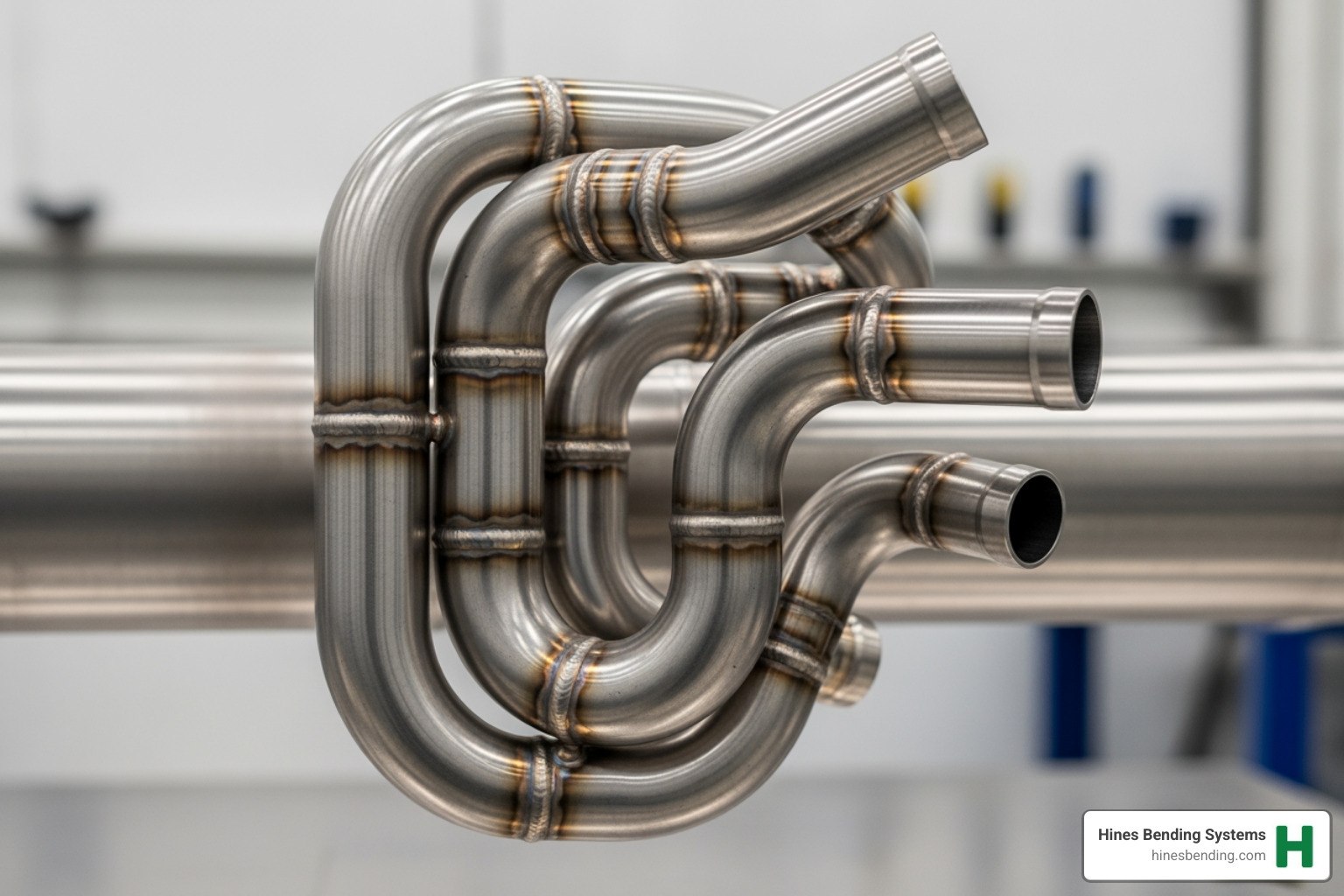

Hines Bending Systems is the #1 worldwide manufacturer of mandrel pipe benders, supplying precision equipment to NASA and other leading organizations. With more expertise and experience than any other company in the bending industry, Hines provides custom mandrel bender solutions that deliver perfect bends every time.

This guide explains how mandrel bending works, why it’s superior to other methods, and how the right equipment prevents costly defects while maintaining structural integrity.

What is a Mandrel Pipe Bender and Why is it Superior?

Think of a mandrel pipe bender like supporting a straw from the inside as you bend it, preventing it from crimping. The same principle applies to industrial tube bending, where the stakes are much higher. A mandrel pipe bender uses an internal support rod (a mandrel) during bending. This is the critical difference between a professional-grade bend and a wrinkled, flattened mess.

The process works through rotary draw bending, where the tube is clamped and drawn around a bend die. During this operation, the outer wall stretches while the inner wall compresses. Without the mandrel acting as an internal spine, these forces would deform the tube.

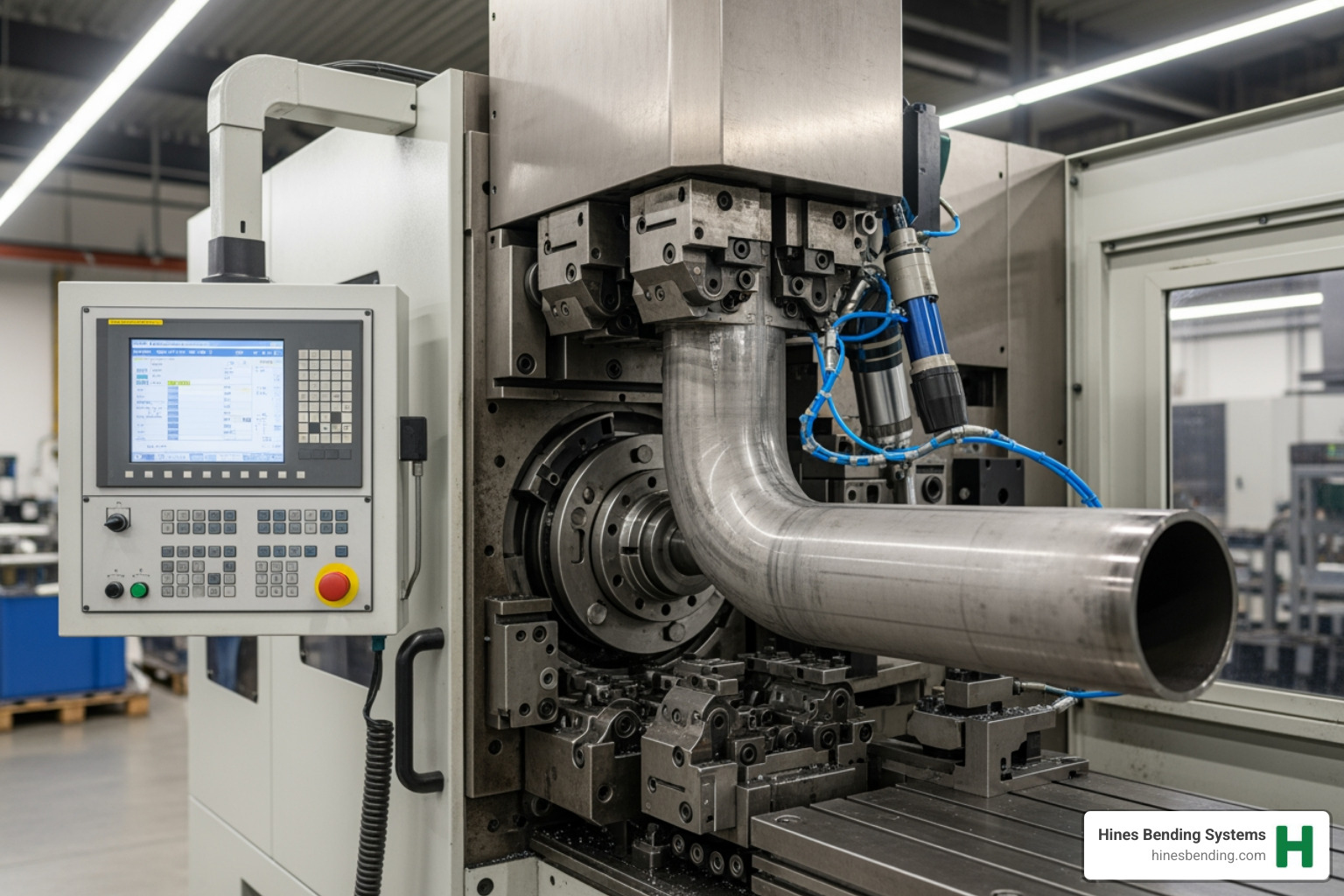

At Hines Bending Systems, we’ve perfected this technology. Our machines use precision-engineered tooling—the bend die, clamp die, pressure die, wiper die, and the mandrel—working in harmony to counteract bending forces and maintain structural integrity.

This is why organizations like NASA trust Hines for critical applications. For spacecraft or high-performance systems, there’s no room for defects. Mandrel bending achieves the tight radius bends and thin-wall tubing work that other methods can’t.

Preventing Common Bending Defects

Bending without a mandrel leads to expensive defects that waste material and delay production. Mandrel bending prevents these issues.

Tube collapse, or ovality, is more than an aesthetic problem; it restricts flow and reduces structural strength. The mandrel prevents this by supporting the tube’s inside diameter, maintaining its original shape under extreme bending forces.

Wrinkles on the inside radius are structural weak points caused by material buckling under compression. The mandrel and wiper die support this zone, ensuring material flows smoothly. This is crucial for automotive and aerospace applications where function and appearance matter.

Flattening on the outside radius occurs as stretching forces pull the tube wall thin. The mandrel maintains the internal circumference, forcing the tube to stay round and ensuring consistent wall thickness, which is critical for pressure ratings and structural integrity.

Kinking, the most severe defect, creates a sharp fold that renders the tube scrap. Mandrel bending virtually eliminates this by guiding the material smoothly through the bend with precise support.

By preventing these defects, our mandrel pipe benders deliver components with perfect roundness and consistent wall thickness. This precision is why industries with the highest standards, bending tubes for mission-critical applications, rely on Hines Bending Systems for flawless results.

Want to learn more about how our equipment prevents these costly defects? Visit our page on tube and pipe benders to explore the full range of solutions we offer.

Mandrel vs. Non-Mandrel Bending Methods

Not all bending methods deliver the same results. The differences can be dramatic.

Empty bending, the most basic method, offers no internal support. It’s only suitable for thick-walled tubes with large-radius bends and results in poor quality for precision work, causing flattening and wrinkling.

Ram bending is a fast, inexpensive method that uses a hydraulic ram. However, it produces distorted, pinched bends with significant flattening and poor cross-section control.

Compression bending is an improvement over ram bending but still lacks internal support. This makes it difficult to maintain roundness, especially with tight radii or thin walls, as the tube tends to flatten.

The mandrel’s crucial role in a mandrel pipe bender is to counteract the deforming forces that plague these other methods. By supporting the tube’s internal diameter, it allows material to flow smoothly, preventing collapse or wrinkling.

As experts in the field have noted, “One of the chief benefits of properly sized and deployed mandrels is the minimal deformation suffered by the tube during bending,” even when working with high-strength steels or other difficult-to-bend materials.

As the manufacturer with the most mandrel benders installed worldwide, Hines Bending Systems’ expertise is best. Decades of experience across aerospace, automotive, and shipbuilding inform our machine engineering, ensuring we deliver the precision your applications demand.

When structural integrity, precision, and quality matter, mandrel bending isn’t just superior. It’s the only real option.

The Anatomy of a Perfect Bend: Tooling and Setup

A perfect bend requires more than just a mandrel pipe bender; it demands precision-engineered tooling working in harmony. At Hines Bending Systems, we’ve spent decades perfecting the tooling and setup that create flawless bends.

A successful bend starts with selecting the right tooling. It’s a science based on material properties, wall thickness, bend radius, and Center Line Radius (CLR). When coordinated, these factors produce perfect results.

Types of Mandrels and Their Uses

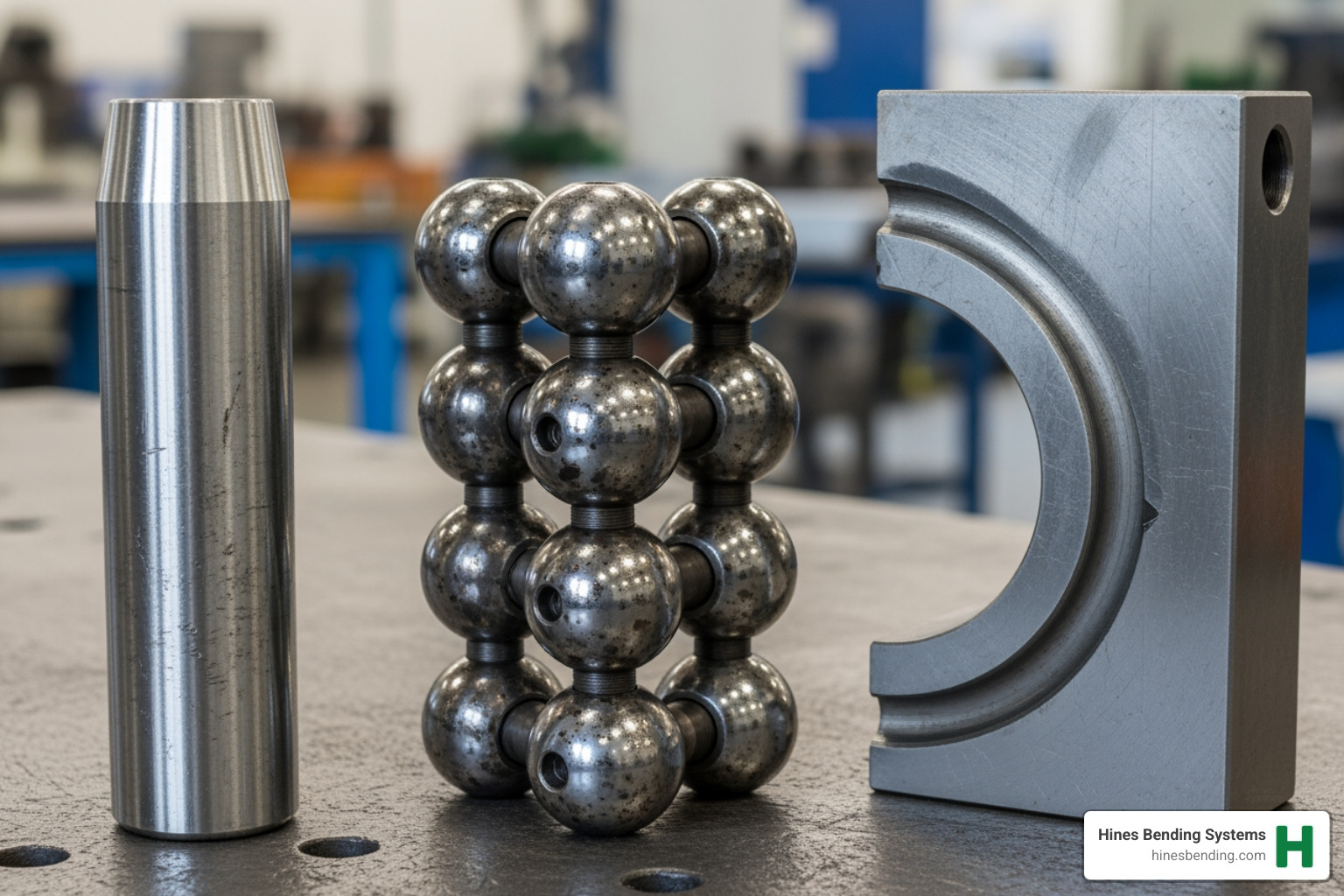

Choosing the right mandrel is critical. Each type has a specialty, and the correct choice makes all the difference.

The plug mandrel is a solid, cylindrical tool for straightforward applications. It provides reliable support and is recommended for tubing 3/8 inch and smaller, or for larger, thick-walled tubes with generous bend radii.

For more challenging bends with tighter radii or thinner walls, the ball mandrel is ideal. Its linked, spherical balls act like a flexible spine, providing continuous support through the bend to prevent wrinkling and collapse. More balls offer more support.

The wiper die, while not a mandrel, is essential for tight bends or thin-wall tubing. It works with the mandrel, fitting snugly against the tube and bend die to support material at the tangent point, preventing buckling. A wiper die prevents wrinkles from forming; it cannot fix them, making proper setup critical.

The Hines Bending Systems team has seen every bending challenge. Serving customers from Fort Myers to Jacksonville and beyond, we know which mandrel is best for each application. Learn more about the tools that complement our mandrel pipe bender systems on our tube and pipe bender accessories page.

The Importance of Correct Mandrel Sizing and Positioning

Precision is paramount in mandrel sizing and positioning. Getting it right is the difference between a perfect bend and a costly mistake. This requires the expertise Hines Bending Systems has built over decades.

Mandrel sizing and clearance are critical. The mandrel must be slightly smaller than the tube’s inside diameter (ID). As experts note, “No matter what size your tubing, the mandrel must be made slightly smaller than the ID.” This small gap, or clearance, is essential.

The exact clearance depends on the application. Aerospace and other high-difficulty applications, like those for our client NASA, require tight clearances of 0.003 to 0.005 inches. Automotive manufacturing may allow for 0.010 to 0.015 inches. Heavy-wall applications in shipyards can use larger clearances from 0.020 to 0.080 inches.

With more benders installed worldwide than any other manufacturer, Hines Bending Systems has the expertise to ensure the mandrel size precisely matches your tube’s ID and application demands. Our experience shows in every recommendation.

Mandrel positioning is also critical. The mandrel’s nose should be slightly forward of the tangent line (where the bend starts) to support the tube right where deformation begins.

If the mandrel is too far back, it fails to support the inner radius, causing ripples and buckles. If it’s too far forward, it can create a bump at the end of the bend, especially with thin-walled tubing.

Hines Bending Systems emphasizes test bends and fine-tuning. Our machines allow for precision adjustments to achieve the optimal setup. Our team provides the training and support to help you achieve perfect results.

The Role of Lubrication in Mandrel Bending

Lubrication is critical for successful mandrel pipe bender operations. It reduces the immense friction and heat generated during bending, which can damage both the material and the machine’s tooling.

Friction reduction is lubrication’s primary job. A good lubricant creates a protective film between the tube and tooling, smoothing the process, reducing required force, and protecting your material and tooling investment.

Friction also generates intense heat, which can alter material properties and accelerate tool wear. Effective lubrication manages this heat, keeping the operation at optimal temperatures.

Proper lubrication is key to reducing tool wear from the constant pressure and friction. Hines Bending Systems’ high-nickel bronze alloy mandrels offer superior lubricity and, when paired with proper lubrication and our through-mandrel lubrication systems, last significantly longer.

A quality surface finish on your bent tube indicates good lubrication. A smooth, clean surface free from scoring is vital for aesthetic applications and structural integrity, especially with delicate materials.

Hines Bending Systems specifies specialized high-pressure lubricants, from synthetic fluids to oil-based compounds, based on your material and application. Our advanced mandrel pipe bender systems, some with programmable internal lubrication, apply the precise amount of lubricant exactly where needed.

This attention to detail is why we’re the #1 worldwide manufacturer and trusted by organizations like NASA. Working with Hines means getting decades of expertise in every aspect of bending. For more information on finding the perfect bending solution, visit our tube and pipe benders page or contact our team. We’re here to help you achieve flawless bends.

Advanced Applications and Mandrel Bender Technology

A mandrel pipe bender does more than create simple curves. These sophisticated machines produce critical components for industries where failure is not an option.

In aerospace manufacturing, mandrel bending creates essential lightweight, high-strength tubing for structural components, hydraulic lines, and engine parts. Every bend must be perfect. Our partnership with NASA, which you can read about in Hines working with NASA, demonstrates the precision and reliability of our machines for the most demanding missions.

The automotive industry uses our mandrel pipe benders for high-performance exhausts, safety-compliant roll cages, and structural chassis components. Our machines deliver the tight radii and minimal deformation required for SFI race car cages and other performance applications.

In shipbuilding, our machines bend heavy-wall pipes for fluid conveyance and structural elements. We handle these robust materials with the same precision as delicate aerospace components, ensuring reliability in harsh marine environments.

Our technology also serves HVAC and refrigeration, medical equipment, architectural design, and more. Every application benefits from the precision and integrity of mandrel bending. From Fort Lauderdale to Orlando and across the globe, Hines Bending Systems has the expertise for your most challenging applications.

CNC and NC Controlled Mandrel Benders

The evolution of mandrel pipe benders is most evident in their control systems. While manual benders exist for simple tasks, the future is in automation.

Manual and semi-automatic benders rely on operator skill, making them suitable for low-volume work but limited by human variability and slower speeds.

NC (Numerical Control) benders are a major step up, using programmable logic to control bend angle and distance. Our models store numerous programs, provide work reports, and automatically compensate for springback, ensuring consistent, repeatable results. NC control is ideal for medium-volume production. Learn more about our NC benders and their efficiency benefits.

CNC (Computer Numerical Control) benders are the pinnacle of bending technology, offering full multi-axis automation for complex, multi-plane bends impossible with other machines. A CNC mandrel pipe bender executes designs with perfect accuracy every time. Our CNC machines feature intuitive touchscreen interfaces, unlimited program storage, and precise control over positioning, springback, and speed for each bend, ensuring optimal results.

For high-volume production and industries like aerospace with tight tolerances, CNC control is essential. Our customers from Jacksonville to Miami and worldwide rely on our CNC benders to meet demanding specifications and maximize productivity.

Bending Challenging Materials

Challenging materials like stainless steel or titanium often resist bending. This is where a high-quality mandrel pipe bender and the expertise of Hines Bending Systems truly shine.

Stainless steel is strong but prone to springback and work-hardening. Our mandrel benders use controlled tooling and specialized lubrication to manage these properties, producing smooth, accurate bends that maintain the material’s integrity.

Aluminum is lightweight but soft, making it prone to wrinkling without proper support. The mandrel is critical for ensuring aluminum flows smoothly through the bend, maintaining its shape and structural properties for aerospace and automotive use.

Titanium is incredibly strong, lightweight, and prized in aerospace, but its low ductility makes it difficult to bend. Hines Bending Systems has tested and rated our machines specifically on titanium, building a database of results that ensures our proven expertise delivers success with every bend.

Modern high-strength alloys also present bending challenges like micro-fractures or thinning. The controlled process of our mandrel pipe benders allows these materials to be formed precisely, maintaining their superior strength and structural characteristics.

Our work with NASA demonstrates our capability with these challenging materials. The trust NASA places in Hines Bending Systems for critical space exploration components speaks volumes about our expertise and machine quality.

Innovations in Mandrel Pipe Bender Technology

As the #1 worldwide manufacturer, Hines Bending Systems constantly innovates. Our R&D ensures our machines not only meet current industry demands but also anticipate future needs.

Modern mandrel pipe benders from Hines feature automated setup processes, including automatic tooling recognition, to reduce changeover times and eliminate errors. This allows operators to focus on production rather than machine adjustments.

Our advanced control systems have intuitive touchscreens for straightforward operation. They offer precise positioning, programmable C-axis control, variable speeds with overload protection, and unlimited program storage. You can set specific springback and speed parameters for each bend, ensuring optimal results.

Efficiency is increased through innovations like direct drive electro-mechanical axes for smooth operation and variable bending speeds (up to 3 RPM) with overload protection. Precision encoders on all axes guarantee exceptional repeatability.

Our patented clamping systems and pressure dies with auto recapture minimize the distance between bends. This saves material and expands design possibilities.

The robust, one-piece steel construction of our machines improves rigidity, minimizes vibration, and ensures greater accuracy and longer machine life. Our unique through-mandrel lubrication systems further improve performance.

What sets Hines apart is our understanding that technology requires skilled operators. Our comprehensive bender training programs ensure your team can maximize machine efficiency and capabilities from day one.

When selecting a bender, consider capacity, bend radius, CLR, and controls. Our machines handle mild steel up to 3″ (.125 wall), stainless up to 3″ (.083 wall), and 2½” Schedule 10 pipe. They achieve a maximum bend radius of 8.8″ and a minimum CLR as tight as 1.5D.

Specifications are important, but a partner who understands your needs and provides a custom solution is what truly matters. Our team, serving customers from Fort Myers to Miami and worldwide, brings unparalleled expertise to every project, delivering a solution that exceeds your expectations.

Ready to find your ideal bending solution? Explore our pipe bending equipment for sale and find how Hines Bending Systems can transform your manufacturing capabilities.

Conclusion: Partner with the Experts for Flawless Bending Results

Throughout this guide, we’ve explored how a mandrel pipe bender transforms challenging tube and pipe fabrication into a precise, reliable process. From preventing wrinkles and flattening to achieving tight-radius bends in materials like titanium and stainless steel, the right equipment makes all the difference between acceptable results and truly flawless bends.

But here’s the truth: even the most sophisticated machine needs the expertise and support of a company that truly understands bending. That’s where Hines Bending Systems stands apart.

As the #1 worldwide manufacturer of tube, pipe, and induction benders, we bring more expertise and experience to every project than any other company in the bending industry. Our machines aren’t just built to specifications—they’re engineered with decades of real-world knowledge behind them. When NASA needs precision bending equipment for their most critical applications, they turn to Hines. That level of trust doesn’t happen by accident.

We know that investing in a mandrel pipe bender is a significant decision for your operation. Whether you’re in Fort Myers, Jacksonville, Miami, or anywhere across the globe, you’re not just purchasing a machine—you’re investing in your production quality and efficiency for years to come. That’s why we don’t believe in one-size-fits-all solutions.

Our team works closely with each client to understand your specific challenges, materials, and production goals. We provide custom solutions custom to your exact requirements, ensuring that the equipment you receive delivers optimal bending results from day one. From initial consultation through installation and beyond, we’re with you every step of the way.

Superior quality machines combined with unparalleled support and training—that’s the Hines difference. We believe in empowering your team through comprehensive training and continuing education, ensuring you can maximize every capability of your equipment. Our commitment to your success doesn’t end when the machine ships; it’s just beginning.

Don’t compromise on quality. Don’t settle for equipment that can’t handle your toughest materials or most demanding applications. Partner with the industry leaders who’ve been setting the standard for precision bending for decades.

Let us help you find your ideal pipe bending equipment solution and lift your manufacturing capabilities to new heights. Your perfect bend is waiting.