Why Mastering Bending Tube is Critical for Modern Manufacturing

Bending tube is a fundamental metalworking process that shapes pipes and tubing into precise curves and angles for countless industrial applications. Whether you’re fabricating automotive exhaust systems, aerospace components, or industrial fluid systems, understanding the right techniques and technology is essential for achieving professional results.

Quick Answer: Essential Tube Bending Basics

- Choose the Right Method – Rotary draw bending for precision, roll bending for large radii, compression for symmetrical parts

- Understand Key Terms – Centerline Radius (CLR), springback, wall factor, and ovality affect every bend

- Prevent Common Defects – Wrinkling, flattening, and kinking result from improper tooling or inferior equipment

- Use Quality Equipment – Professional-grade CNC benders deliver the precision and repeatability modern manufacturing demands

- Get Expert Support – Training and custom solutions ensure you achieve flawless bends consistently

Many fabricators treat tube bending as a “black art” filled with trial and error. But the reality is different. The fundamental principles behind successful bending haven’t changed in decades – what has changed is the technology available to achieve perfect results consistently.

The truth is simple: the quality of your bends depends on four critical factors – your material, your machine, your tooling, and your expertise. Get any of these wrong, and you’ll face costly defects, production delays, and frustrated customers.

From aerospace giants like NASA to automotive manufacturers worldwide, the most demanding applications require more than basic bending knowledge. They require proven technology, expert guidance, and equipment built to exacting standards.

Hines Bending Systems is the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. When precision, uptime, and total cost of ownership matter, companies come to Hines. We supply massive agencies and organizations such as NASA and leading global manufacturers, and nobody in the bending machine industry has more expertise or experience. Our customer-centric team engineers custom solutions to your exact requirements, backs them with training and continuing education, and delivers the highest quality machines that meet or exceed industry standards—unlike cheaper alternatives that can compromise integrity. With ongoing innovation, including our Dual Stack CNC Push Bender and Roll Bender, Hines gives you the competitive edge for today’s and tomorrow’s production demands.

The stakes are high. A poorly bent tube can mean restricted fluid flow, structural weakness, or catastrophic system failure. Conversely, a properly bent tube eliminates leak points, reduces turbulence, saves installation time, and creates a more compact, efficient system footprint.

This guide cuts through the complexity to show you exactly what it takes to bend tube like a professional. You’ll learn the fundamental concepts, understand the key technologies, and find how industry leaders consistently achieve flawless results. Whether you’re struggling with complex geometries, tight tolerances, or high production costs, the solution starts with understanding the right approach.

Bending tube glossary:

The Foundation of a Perfect Bend: Key Concepts and Considerations

Getting started with bending tube can feel like learning a new language, but we’re here to make it simple! The secret to flawless bends lies in understanding a few key concepts. When you get the basics right – like knowing your material, its size, and the right terms – you’re already halfway to creating a high-quality product. This foundation helps you avoid costly mistakes and build reliable parts every time, especially when you have a trusted partner like Hines Bending Systems by your side.

Tube vs. Pipe: Why the Difference Matters

Before we dive deeper into the magic of bending tube, let’s clear up a common confusion: the difference between a “tube” and a “pipe.” People often use these words interchangeably, but in bending, they’re quite distinct, and knowing the difference truly matters for your project.

Think of it this way: tube is usually measured by its outside diameter (OD), and its wall thickness is very precise. This makes it perfect for things like structural frames, intricate fluid lines, or anywhere a perfect look and exact size are super important. Pipe, on the other hand, is typically measured by its nominal inside diameter (ID), and its wall thickness is described by something called a “schedule.” So, a “1-inch pipe” might actually have a thicker wall and a larger actual outside diameter than a “1-inch tube” – even though they both claim to be “1 inch”!

This difference matters immensely for bending. Tubing, with its consistent dimensions, is often chosen for those tricky bends, tight tolerances, and smooth fluid flow. Pipe is super strong for carrying liquids or gases, but its wall thickness can vary a bit more, making precise bends a little trickier without the right equipment. But here’s the good news: at Hines Bending Systems, our machines are designed with incredible precision to handle both tubes and pipes flawlessly. No matter what you’re working with, we ensure you get that perfect bend.

Essential Bending Tube Terminology

To master bending tube like a pro, you need to speak its language. Understanding these terms helps our experts at Hines Bending Systems match you with the perfect machine and tooling for your project.

- Centerline Radius (CLR): This is the radius of the bend measured from the center of the tube. It’s the most critical measurement for defining the tightness of a curve. Whether you need a tight bend or a large, sweeping radius, we have the technology to achieve it.

- Springback: Metal has memory. After a bend, it will try to “spring back” slightly towards its original shape. Our advanced CNC benders automatically calculate and compensate for springback, ensuring every bend is accurate to the degree, eliminating guesswork and scrap.

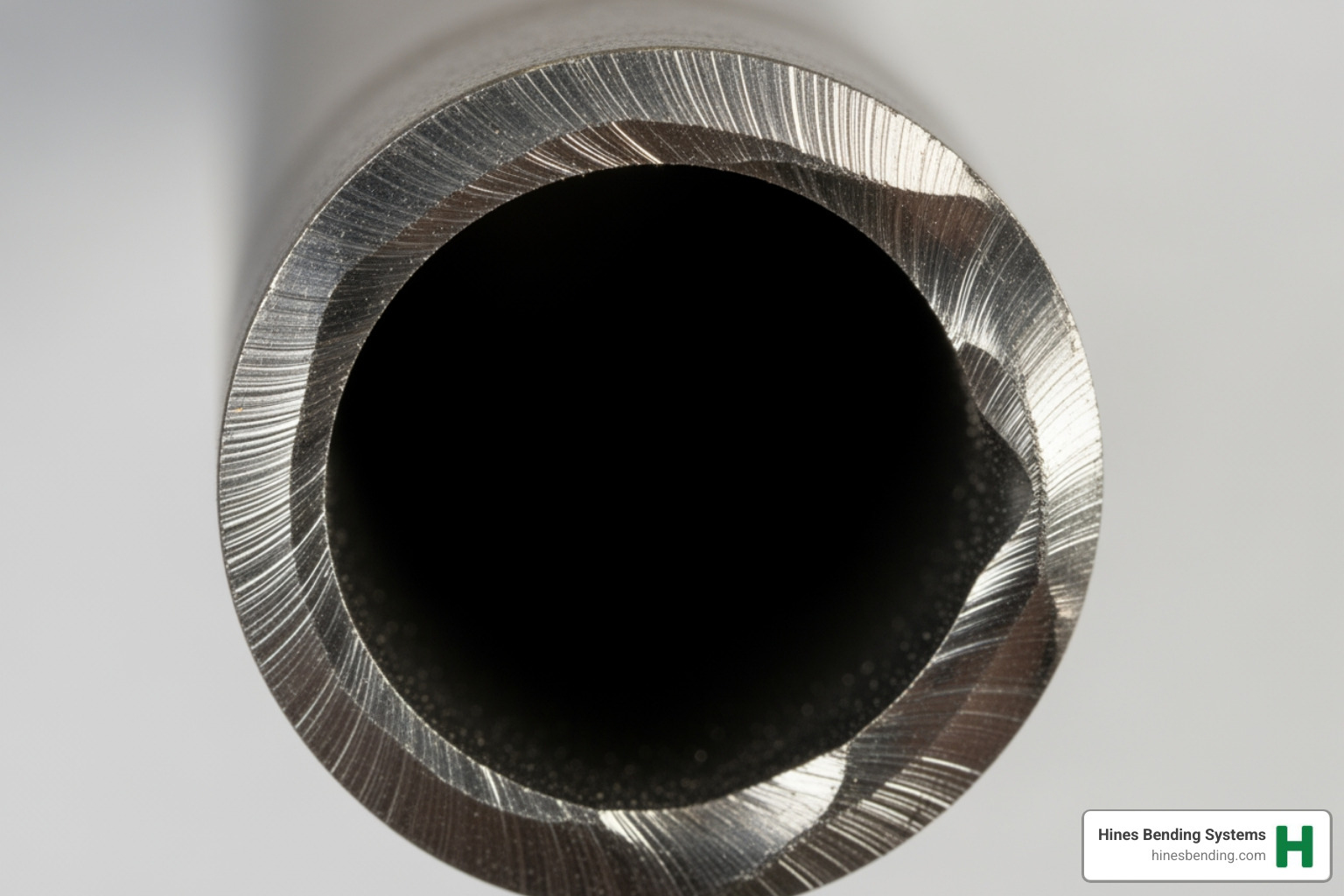

- Wall Factor & Ovality: The ratio of the tube’s outside diameter (OD) to its wall thickness (WT) is the wall factor. A high wall factor (thin wall) can lead to ovality, where the tube flattens during bending. Hines’ precision tooling, including custom-designed mandrels, provides internal support to maintain the tube’s round profile.

- Extrados & Intrados: These are the outer and inner surfaces of the bend. The extrados stretches and thins, while the intrados compresses and thickens. Our machines control these forces with precision, minimizing wall thinning and preventing wrinkles on the intrados.

- Tangent Point: This is the exact point where the straight section of the tube begins to curve. Precise control over tangent points is vital for multi-bend parts, and it’s a standard feature of our automated bending solutions.

Learning these terms helps us understand your needs so we can set up the perfect Hines bending machine and tooling for you. For an even deeper dive, check out our full list of Tube and Pipe Bending Industry Terms.

Common Bending Defects and How to Avoid Them

Even with the best planning, sometimes things can go wrong when bending tube. These imperfections aren’t just ugly; they can seriously weaken your parts or make them unusable. When you bend a tube, the inside wall gets squeezed (and thicker), and the outside wall gets stretched (and thinner). If this isn’t managed perfectly, you can run into trouble.

Here are some common problems and how Hines Bending Systems helps you avoid them:

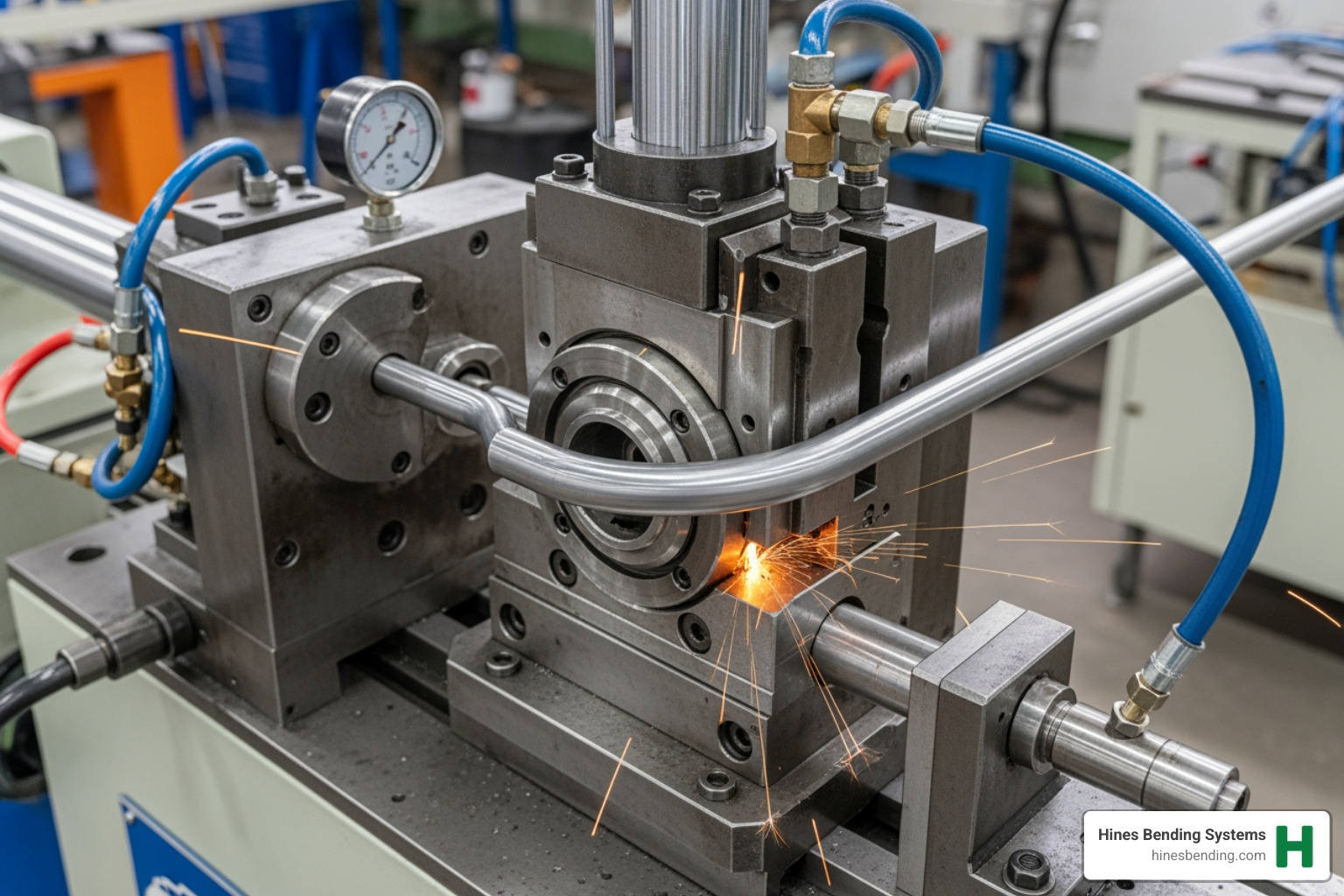

- Wrinkling: These are ripples or folds on the inside curve of the bend. This happens when the material compresses without proper support from tools like a wiper die or mandrel. Our precision tooling and advanced machine controls are specifically designed to prevent wrinkles from forming.

- Flattening (or Ovality): This is when your round tube gets squashed into an oval shape. This usually happens because there isn’t enough support inside the tube during the bend, letting it collapse. Hines Bending Systems is a leader in mandrel bending machine technology. Our specialized mandrels are engineered to keep your tube perfectly round, even on the tightest bends.

- Kinking: This is a severe crease or sharp fold in your tube, often caused by attempting a bend that’s too sharp for the material or using incorrect tooling. With Hines, you get the right machine and tooling for the job, eliminating kinks from the start.

- Galling: This occurs when bits of your tube material stick to the bending tools, leaving scratches or tears on the surface. It’s typically a sign of improper lubrication or excessive friction. Our machines are designed to work with advanced lubrication systems, ensuring smooth, scratch-free bends.

- Wall Thinning: While the outside of a bend will naturally get a little thinner, excessive thinning can weaken the tube and lead to failure. This is a critical area where Hines’ advanced machines shine. We control the bending process with incredible precision, using proper mandrels and features like pressure die assist/boost to keep wall thinning within safe, specified limits.

The key takeaway? These defects are almost always the result of using inferior equipment or incorrect tooling. When you choose Hines Bending Systems, you’re not just buying a machine; you’re investing in decades of expertise, superior technology, and support designed to eliminate these common bending headaches. We are committed to helping you achieve flawless results, every single time.

Choosing Your Path: An Overview of Bending Tube Technologies

The technology you choose dictates the quality, precision, and efficiency of your work. While many methods exist, they are not created equal. The demands of modern industries for complex geometries and tight tolerances require advanced machinery. Understanding the capabilities of different technologies is key to selecting the right solution for your specific application. At Hines Bending Systems, we know there’s no “one size fits all” answer, which is why our expertise is so valuable in guiding you to the perfect machine for your needs. As the #1 worldwide manufacturer of tube, pipe, and induction benders, Hines focuses on your outcomes—quality, repeatability, throughput—and then engineers a custom solution around them.

An Introduction to Bending Methods

When it comes to bending tube, you’ll find a whole toolkit of possibilities, each designed for different tasks. Understanding these methods helps you appreciate the engineering behind a perfect bend and why selecting the right machine from an industry leader like Hines Bending Systems is so crucial. We’re here to help you steer these options and find the ideal fit. The fastest path to the right answer is to talk with Hines; we tailor the process, machine, and tooling to your exact part and quality requirements.

- Rotary Draw Bending (RDB): This is often considered the gold standard for precision. Imagine a dance where the tube is “drawn” around a form using a set of specialized dies. It’s incredibly precise, especially for tight bends, and gives you excellent control over common issues like wall thinning and ovality. For critical applications, like those found in aerospace or medical devices, RDB is the undisputed champion. Hines Bending Systems specializes in perfecting this method, ensuring you achieve the highest quality bends every time.

- Roll Bending: This is your go-to for creating those big, sweeping curves or even spirals. Instead of a fixed die, three rollers progressively shape the tube. Think handrails, structural components, or architectural elements where you need a continuous, gradual curve over a long distance. We offer robust roll bending solutions designed for durability and consistent performance.

- Compression Bending: This offers a simpler approach. Here, the tube is clamped and then wrapped around a stationary bend die. It’s often quicker and more economical for symmetrical parts or less critical items, like certain furniture frames. While it might offer less control over ovality than RDB, it has its place in specific production environments.

- Ram Bending: This is one of the oldest and most straightforward methods. A ram die pushes the tube against two counter dies. It’s fast and budget-friendly for very basic bends, often seen in muffler shops. However, it typically offers the least control over bend quality and can lead to more ovality and cosmetic issues. When precision and a flawless finish are priorities, you’ll generally look to more advanced methods, which Hines Bending Systems excels at providing.

For a more detailed look at these and other bending types, you can explore our guide on Tube Benders Types. Our comprehensive range of machines covers all these methods, allowing us to tailor the perfect solution for your specific manufacturing needs, from the most basic to the most incredibly complex. Nobody has more expertise in these diverse bending applications than Hines.

The Power of Precision: CNC vs. NC Bending

In automated bending tube, you’ll often hear about CNC and NC machines. Both are a huge leap from manual bending, offering much-needed consistency. But they’re not quite the same, and understanding their differences is key to choosing the right level of automation for your shop. We pride ourselves on offering both, and our experts can help you determine which is truly right for your production goals.

| Feature | NC Bending | CNC Bending |

|---|---|---|

| Precision | Good for single-plane bends, but less precise for multi-plane or complex geometries. | Excellent, offering the highest level of accuracy and repeatability. Ideal for aerospace and medical applications. |

| Repeatability | Consistent for simple, repetitive bends, but may require manual adjustments for each part in multi-bend sequences. | Highly repeatable. Once programmed, identical parts can be produced thousands of times with minimal variation. |

| Complexity | Best for simpler parts with one or two bends in a single plane. | Handles complex, multi-plane, and compound bends with ease. Capable of producing intricate 2D and 3D geometries. Modern CNC tube bending machines can have up to 10 axes of control, managing parameters like distance between bends (Y), plane of bend rotation (B), bend angle (C), and even mandrel motion (YM). |

Beyond the specs, what gives Hines clients a competitive edge is innovation and support. Our Dual Stack CNC Push Bender and Roll Bender address growing demands for flexibility, faster changeovers, and higher throughput—without sacrificing quality. We back every system with training and continuing education to accelerate ramp-up, lift engineering efficiency, and keep production running at peak performance.

Common question: What makes Hines superior?

- Best experience and application expertise across industries from aerospace to energy

- Custom-engineered machines and tooling for your parts and tolerances

- Rigid machine design for tight CLRs, thicker walls, and superior surface finish

- Integrated controls that simplify programming and ensure repeatability

- Quality assurance that meets or exceeds industry standards—unlike cheaper alternatives that risk downtime and scrap

Advanced Solutions: When to Consider Induction Bending

For the most demanding applications involving large-diameter and thick-walled pipes, a specialized technology is required: induction bending. This process uses an induction coil to heat a very narrow section of the pipe to a precise temperature. The pipe is then gently bent, with air and water cooling the section immediately after it leaves the coil. This highly controlled method minimizes ovality and wall thinning and has distinct advantages over traditional cold bending:

- Handles larger outside diameters and thicker wall materials with superior dimensional control

- Reduces or eliminates the need for welds and fittings, improving integrity and flow

- Delivers excellent repeatability for long-radius bends at production scale

- Improves strength retention and cosmetic quality by precisely managing heat and force

Hines Bending Systems is a global leader in providing powerful and reliable Induction Benders. We engineer these systems to handle the toughest jobs, delivering consistent, high-quality bends on materials that other methods simply can’t manage. Our customer-centric team partners with you from concept to commissioning with custom solutions, process development, and comprehensive training and support. For those interested in learning more about the induction bending process itself, this overview of tube bending basics provides additional technical context.