Why CNC Bending is Essential for Modern Manufacturing

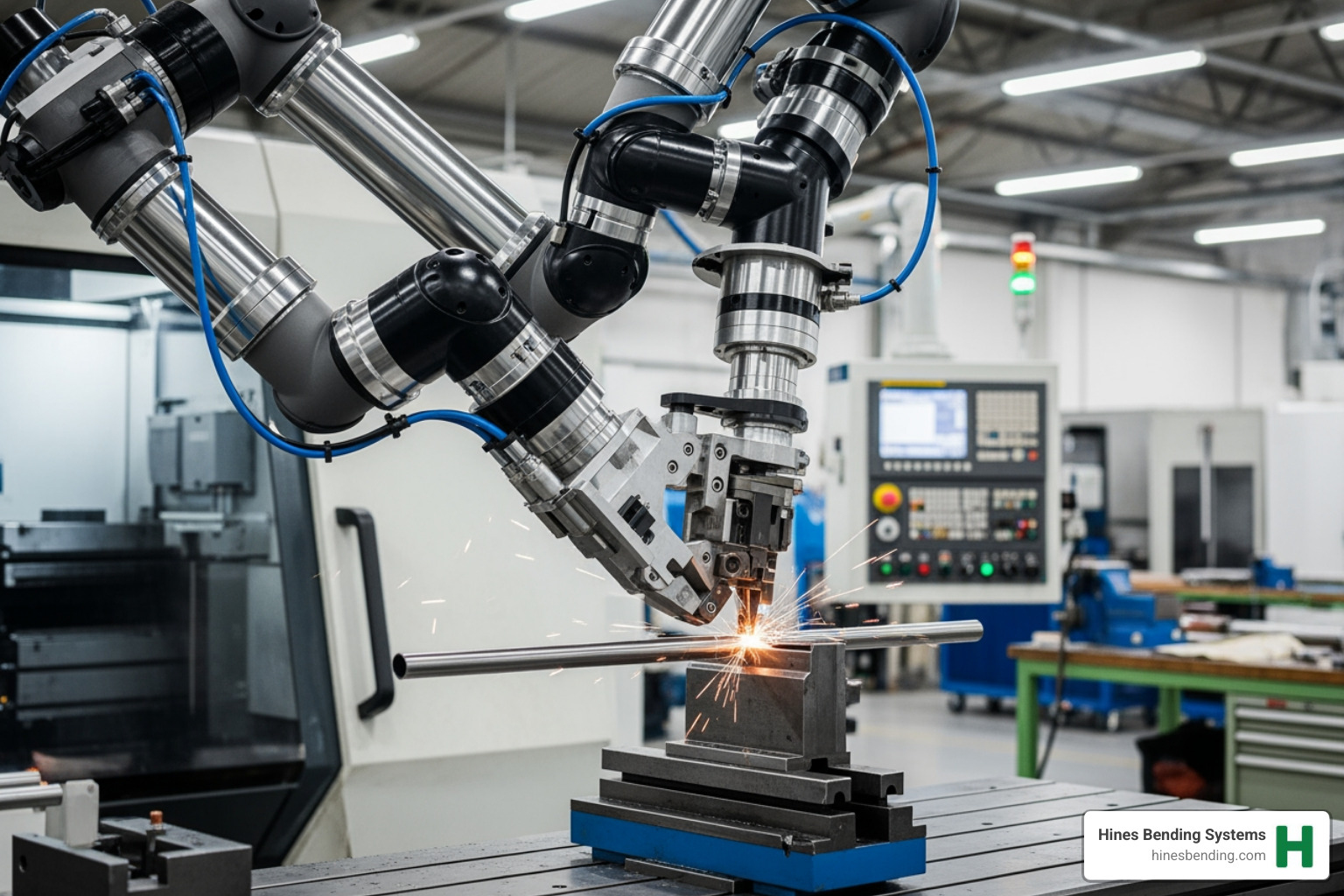

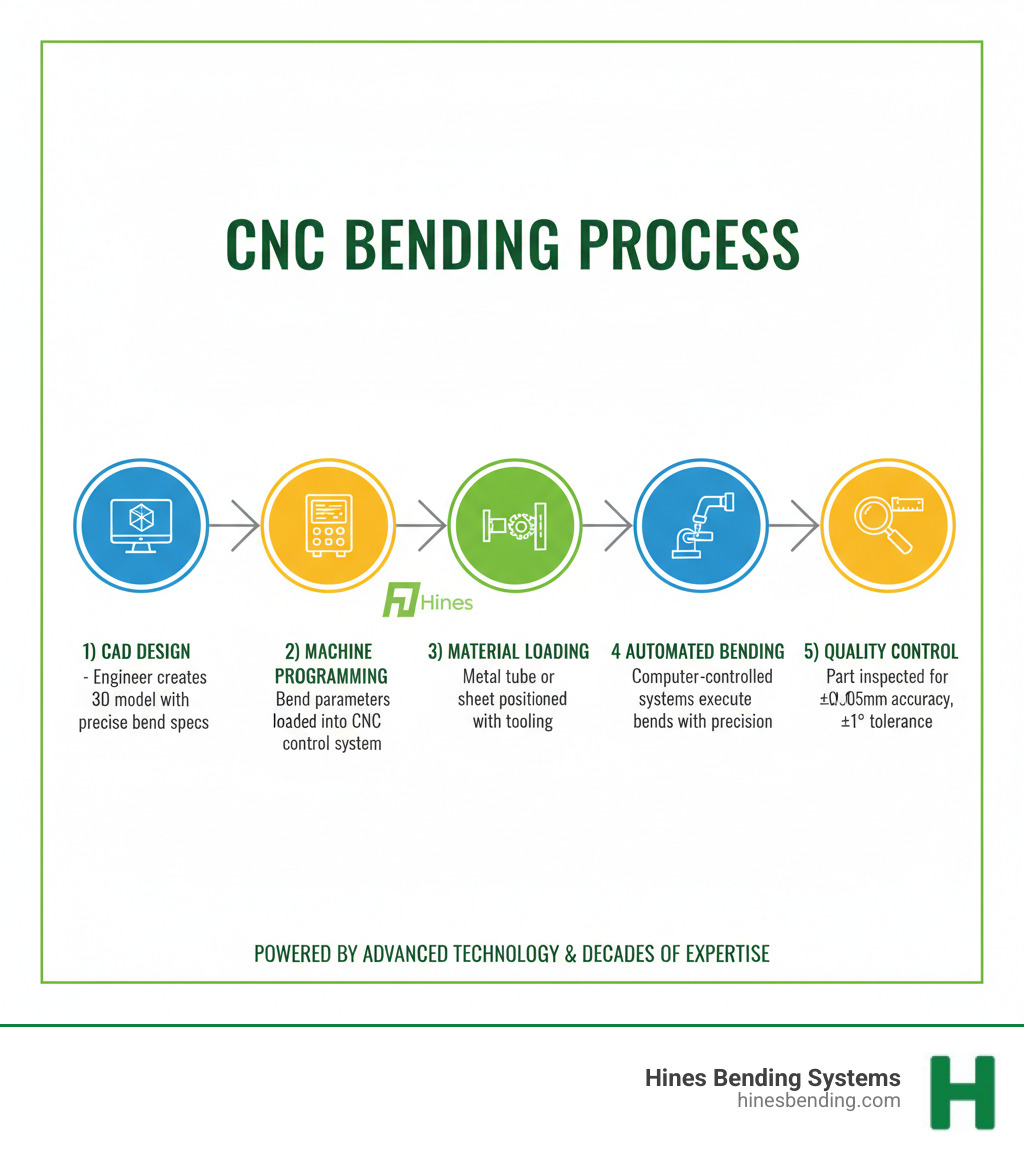

CNC bending is a computer-controlled process that shapes metal tubes, pipes, and sheets into precise forms with exceptional accuracy and repeatability. It automates bending using advanced software and hydraulic or servo-electric systems to deliver consistent, high-speed results.

Key Facts About CNC Bending:

- Precision: Achieves accuracy levels of ±0.05 mm and bend angle tolerances of ±1 degree

- Materials: Works with steel, aluminum, stainless steel, titanium, copper, and more

- Applications: Critical for aerospace, automotive, medical devices, energy, and industrial equipment

- Efficiency: Reduces labor costs, minimizes material waste, and enables high-volume production

- Technology: Uses 3-axis to 12-axis machines for simple to complex geometries

Before modern CNC technology, manual bending was slow and resulted in inconsistent parts and longer lead times. Today, CNC bending machines have transformed manufacturing by combining computer precision with mechanical power.

The technology is essential across industries, from aircraft frames to medical instruments, where parts must meet rigid tolerances. The global CNC pipe bending machine market is growing at 5.1% annually, reflecting this increasing demand for automated precision.

Hines Bending Systems is the #1 worldwide manufacturer of tube, pipe, and induction benders. With more installations globally than any competitor and clients including NASA, Hines brings the best expertise to every project. Their custom solutions address the most demanding bending challenges, backed by decades of innovation and hands-on support.

This guide covers everything you need to know about CNC bending—from basic principles to advanced applications—and shows why partnering with an industry leader like Hines makes all the difference for your manufacturing success.

Easy cnc bending glossary:

The Best Advantages of High-Quality CNC Bending with Hines

When shaping metal for critical applications, the difference between traditional methods and modern CNC bending is night and day. At Hines Bending Systems, we’ve spent decades perfecting this technology to transform manufacturing operations. The precision, speed, and consistency our machines deliver are game-changers for businesses that demand excellence.

Unparalleled Accuracy

For components in aerospace or medical devices, “close enough” isn’t an option. A fraction of a millimeter can mean the difference between a perfect fit and catastrophic failure, which is where CNC bending truly shines.

Hines machines achieve accuracy levels of ±0.05 mm and bend angle tolerances of ±1 degree or better. This computer-controlled precision eliminates human variables that plague manual bending, such as fatigue and inconsistent technique.

Our long-time client, NASA, chooses Hines because their missions depend on components meeting exact specifications every time. That’s the level of accuracy we build into every machine.

Repeatability for Mass Production

Making thousands of identical parts with traditional methods is a challenge. Even skilled human operators cannot replicate the exact same bend with the same force consistently.

With Hines CNC bending machines, repeatability is a guarantee. Once programmed into our BendPro G2 control system, the machine executes the bend sequence identically every time. This consistency is essential for modern mass production, ensuring seamless assembly and reliable products.

This repeatability allows manufacturers to confidently quote large orders, knowing production quality will remain constant.

High-Speed Operation

In manufacturing, time is money. Slow or idle machines cost you money and delay deliveries. Hines CNC bending machines are engineered for speed without sacrificing precision.

Our automated systems eliminate time-consuming manual adjustments. With automatic material feeding and rapid bend execution, parts move through the process with minimal handling, resulting in dramatically faster cycle times and higher throughput.

Tasks that took hours manually now take minutes. This speed advantage means shorter lead times and the flexibility to accept rush orders and respond quickly to customer demands.

Cost-Effectiveness

While a Hines CNC bending machine requires an upfront investment, the total cost of ownership reveals its true value over years of operation.

Reduced labor costs are a primary benefit. Our automated systems require fewer operators. A single technician can manage operations that once required a team, freeing up skilled workers for higher-value tasks.

Next is minimal material waste. First-time accuracy means you’re not scrapping expensive metal due to errors. This efficiency leads to substantial savings over thousands of production runs.

The precision of our machines also means less rework, fewer rejections, and lower warranty costs. Factoring in all these elements, the ROI is compelling. Our customers report that their machines pay for themselves faster than they expected.

At Hines Bending Systems, we don’t just manufacture machines—we build partnerships. As the #1 worldwide manufacturer with more installations than anyone else, we’ve earned our reputation by delivering solutions that exceed expectations. Whether you need a standard configuration or a completely custom system, our team brings the best expertise to every project.

When agencies like NASA trust us with their critical components, it speaks to the quality and reliability we build into every machine. That same commitment to excellence is what we offer every customer.

More info about the advantages of CNC tube bending.

Mastering Materials, Applications, and Hines Machine Innovations

When it comes to CNC bending, understanding your material is half the battle. The other half is having the right machine and the expertise to match them perfectly. That’s where we come in.

Suitable Materials and Key Considerations

Most engineering materials in sheet or tube form can be bent, but achieving a perfect bend requires understanding each material’s properties and using the right approach.

Steel is the workhorse of bending. Mild steel offers excellent ductility and is versatile, reliable, and forgiving, making it the most commonly used material globally for consistent results.

Aluminum offers strength without the weight. The 1000 and 6000 series alloys are favorites for sheet metal, bending beautifully to achieve tight radii without cracking. Learn more about aluminum alloys.

Stainless steel, with over 10.5% chromium, offers excellent corrosion resistance. Grade 301 is flexible, 304 is a reliable all-rounder, and 316 provides higher strength for tough environments. Our machines are calibrated to handle each grade’s unique properties.

Titanium, an aerospace favorite, has an incredible strength-to-weight ratio but requires careful handling during bending. Copper is highly malleable and conductive, ideal for precise electrical and plumbing applications.

Beyond the material type, properties like material thickness, yield strength, hardness, and malleability are critical. These factors determine the required force, tooling, and bend radius. At Hines, we’ve mastered these properties. Our decades of experience allow us to precisely calibrate our CNC bending machines for any material, ensuring the optimal machine and process for every application.

Industries and High-Stakes Applications

CNC bending touches nearly every industry, but some demand absolute perfection.

In aerospace, there is no room for error. Components for aircraft, rockets, and satellites must have flawless integrity. We are proud to supply bending solutions for NASA, a testament to our reliability. Read about our work with NASA. When stakes are high, organizations choose Hines for our proven expertise.

The automotive industry relies on our machines for chassis components, exhaust systems, and more, where precision at scale is vital. In shipbuilding, our technology is used for large pipes and structural elements that must withstand harsh marine environments for decades.

In the medical field, our machines produce intricate tubing for surgical instruments and devices where lives depend on sub-millimeter accuracy. The energy sector uses our benders for pipes and tubes in power generation, oil, and gas, where components must reliably handle extreme pressures and corrosive environments for years.

Hines CNC Bending Machine Solutions

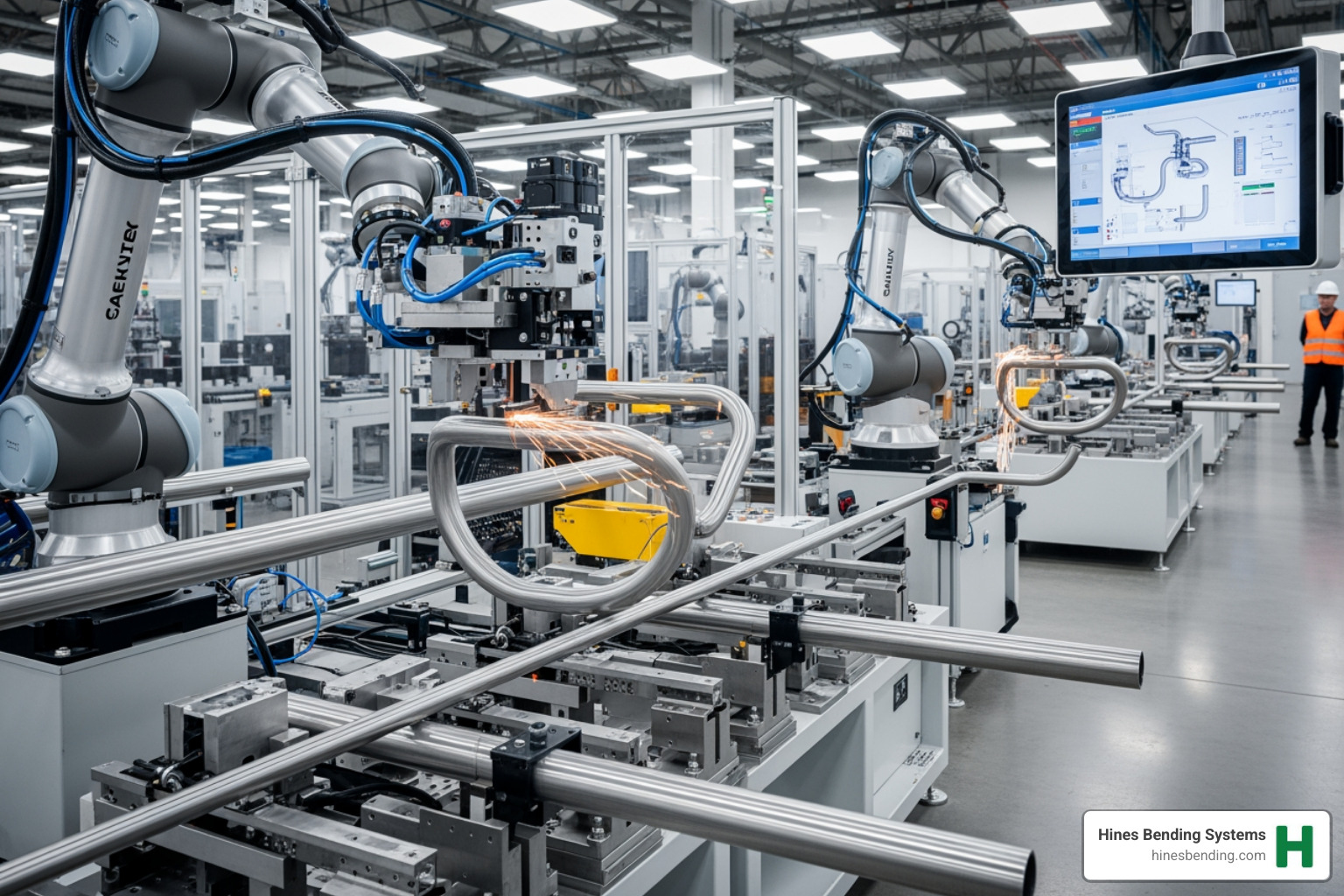

We reject one-size-fits-all solutions. Our extensive range of CNC bending machines reflects the unique demands of each application. As the manufacturer with the most installations worldwide, we know what works.

Our CNC Tube Benders precisely handle various tubing shapes and are the backbone of many manufacturing operations. Roll Benders create large-radius curves, while our specialized Induction Bending Machines offer superior quality for large, thick-walled pipes in demanding applications.

Part complexity determines the machine needed. While 3-axis machines handle basic bends, our advanced 5-axis to 12-axis machines enable complex multi-plane, compound, and helical bends in a single setup. This eliminates multiple fixtures and operations, providing remarkable efficiency gains.

Innovation is core to our work. Our Dual Stack CNC Push Benders, for example, offer advanced capabilities for complex, high-volume production. These specialized machines represent the cutting edge of bending technology for manufacturers who demand the best.

What truly sets Hines apart is our commitment to custom solutions. We partner with you to understand your challenges, materials, and production needs. We then provide the perfect CNC bending machine, backed by our unparalleled support. With decades of global experience, nobody in the bending machine industry knows more about creating optimal bending solutions than Hines Bending Systems.

Design Best Practices and Overcoming Common Challenges

Designing for CNC bending requires foresight. The best designs account for the manufacturing process from the start. The Hines engineering team uses its decades of expertise to guide you, ensuring your designs are optimized for manufacturability.

Key Design Considerations for CNC Bending

Bend radius—the inner curve of the bend—is critical. Thicker materials require larger radii to prevent thinning, cracking, or excessive springback. Our CNC bending machines achieve precise radii, and our team helps determine the optimal radius for your application.

Clear bend lines in CAD files are essential. Proper notation in DXF, DWG, or other files ensures our machines interpret your design correctly, preventing costly errors.

Materials have “memory” and tend to spring back after bending. This is known as K-factor and springback. The K-factor helps calculate the necessary compensation to achieve the desired angle. Our advanced CNC bending machines have intelligent controls that automatically compensate for springback, ensuring precision. Understanding the K-factor in sheet metal provides more detail on this concept.

Hole and feature placement requires careful attention. If too close to a bend line, they can distort or tear during forming. A general rule is to keep features at least half the die width from the bend’s centerline to maintain structural integrity.

The Hines engineering team provides hands-on guidance to optimize your designs for manufacturability and quality, acting as partners to ensure your concepts become flawless finished components.

Common Challenges in CNC Bending and How Hines Solves Them

CNC bending can be challenging, but we’ve spent decades solving these problems. Our machines are engineered with that experience.

Common issues include:

- Material variability: Slight shifts in material properties can cause inconsistent results.

- Wrinkling: An uneven, wavy surface can appear if thinner materials or tight bends lack proper support.

- Cracking: Occurs when harder materials are bent with too-aggressive radii.

- Galling: Wear caused by adhesion between the material and tooling, which can damage the part’s surface.

At Hines Bending Systems, we’ve engineered solutions to every one of these challenges.

Our robust machine construction ensures stability and consistent performance. A stable machine that doesn’t flex or vibrate delivers reliable results. Our advanced software controls, like the Bendpro G2, use sophisticated algorithms to monitor and adjust for material variations in real-time, minimizing defects.

What truly sets Hines apart is our decades of process expertise. Nobody in the industry has more experience. Our team understands the nuances of material behavior and bending mechanics from years of problem-solving. We share our knowledge to ensure your success.

For unique requirements, we specialize in custom tooling and machine design. This bespoke approach provides perfectly matched solutions for exotic materials or extreme geometries, preventing issues like wrinkling, cracking, and galling.

When you partner with Hines, you’re not just buying a CNC bending machine—you’re gaining a team committed to solving your most complex manufacturing challenges.

Frequently Asked Questions about CNC Bending

We understand that investing in CNC bending technology is a significant decision. Here, we address common questions, highlighting how Hines Bending Systems delivers superior solutions.

How does CNC bending differ from manual or NC bending?

The distinction between CNC bending and older manual or NC (Numerical Control) methods is profound, especially regarding the capabilities of Hines Bending Systems.

- Manual Bending: Relies on human skill, making it slow, labor-intensive, and prone to inconsistency. It’s unsuitable for high-volume or precision work, as accuracy and repeatability are nearly impossible to maintain.

- NC Bending: An early form of automation using pre-programmed codes. While more repeatable than manual methods, it required significant operator intervention and lacked the real-time feedback, multi-axis control, and advanced compensation of modern CNC systems.

- CNC Bending (with Hines): This represents true precision and automation. Our machines use a computer to control every process aspect—from material feeding to bend angle and speed. This provides:

- Superior Precision: Achieves accuracy of ±0.05 mm and angle tolerances of ±1 degree, far beyond manual or NC capabilities.

- Best Repeatability: Guarantees flawless repeatability for identical parts in high-volume production.

- Reduced Human Error: Minimizes human error by automating intricate movements.

- Advanced Capabilities: Handles complex, multi-axis bends impossible for less advanced systems.

- Efficiency: Increases efficiency by speeding up production, reducing setup times, and optimizing material use.

CNC bending with Hines is an intelligent manufacturing process delivering consistent, high-quality results that are impossible with outdated methods.

What defines a high-quality CNC bending machine?

A high-quality CNC bending machine is a precision instrument built for longevity, accuracy, and efficiency. Hines Bending Systems’ machines embody these traits, setting the industry standard.

- Robust Construction: Built with heavy-duty frames for stability and minimal deflection, ensuring consistent bends and a long, reliable lifespan.

- Precision Components: Uses high-grade hydraulics, servo drives, and mechanical parts for exceptional accuracy. Features like CNC-controlled crowning guarantee consistent angle accuracy.

- Advanced Control Software: The control system is the machine’s heart. Our Bendpro G2 software offers intuitive programming, 3D simulation, and real-time compensation algorithms to simplify complex operations and ensure optimal performance.

- Versatile Tooling: Supports a wide range of tooling to adapt to various materials and geometries. Our custom tooling solutions improve this versatility for any job.

- Comprehensive Manufacturer Support: Hines offers unparalleled training, maintenance, and technical assistance to help your team maximize the machine’s potential and maintain peak performance.

In short, a high-quality Hines machine delivers superior precision, reliability, and efficiency, backed by our industry-leading expertise and support.

Why is it important to work with a bending machine expert?

Working with an expert like Hines Bending Systems is crucial for reasons beyond just purchasing equipment.

- Matching the Right Machine to the Application: An expert understands the diverse world of bending. We assess your specific needs—material, geometry, volume—to recommend the perfect Hines machine, like a CNC Tube Bender or a specialized Induction Bending Machine, ensuring a perfect fit.

- Custom Solutions for Unique Challenges: Off-the-shelf machines often can’t handle specialized requirements. As the #1 worldwide manufacturer, Hines excels at custom solutions. We design and build machines like our Dual Stack CNC Push Benders to tackle the most demanding tasks.

- Leveraging Decades of Experience for Optimal Results: Hines has more experience and expertise than anyone in the industry. This knowledge informs our superior machine design and process recommendations, helping you optimize results, minimize waste, and maximize efficiency.

- Unwavering Quality Assurance: Our work with clients like NASA demonstrates our commitment to the highest quality standards. Hines machines are designed to meet stringent requirements, unlike cheaper, less reliable alternatives.

- Ongoing Support and Training: Our expertise continues after the sale with comprehensive training and support. This ensures your team is proficient, your machines are maintained, and your operations run smoothly.

Choosing Hines means partnering with an expert for a complete solution that ensures your bending operations are precise, efficient, and successful long-term.

Conclusion: Your Partner for Bending Excellence

Throughout this guide, we’ve explored how CNC bending is an essential pillar of modern manufacturing. It’s about achieving unimaginable precision, production-changing repeatability, and industry-driving efficiency. From massive structural pipes to delicate medical tubing, CNC bending makes it possible with accuracies of ±0.05 mm and bend angles within ±1 degree.

However, advanced technology is only part of the equation. The real difference is a partner who knows the technology, has solved every bending challenge, and provides unwavering support.

That’s where Hines Bending Systems comes in. As the #1 worldwide manufacturer, we have more installations globally than any competitor. Our client list, which includes NASA, is a testament to our quality and reliability. We don’t just make machines; we build lasting partnerships.

We reject cookie-cutter solutions. Every manufacturer faces unique challenges, so we work closely with each customer to design custom bending solutions for their specific needs. Our team’s decades of experience ensure you get the right machine for the job.

Choosing Hines means gaining a partner who understands your challenges and provides ongoing support to keep your operations running smoothly. We are with you from consultation to installation, training, and beyond.

Ready to experience bending excellence? Let’s talk about how we can help transform your manufacturing capabilities.

Contact our team of experts to find the perfect bending machine for your application.