Why Steel Tube Bending Machines Matter for Modern Manufacturing

A steel tube bending machine is a specialized piece of industrial equipment designed to shape metal tubes into precise angles and curves without compromising structural integrity. These machines range from simple manual benders for basic bends to sophisticated CNC-automated systems capable of complex, multi-axis fabrication for high-volume production across industries like automotive, aerospace, construction, and HVAC.

Quick Answer: Types of Steel Tube Bending Machines

- Manual/Benchtop Benders – Portable, low-cost solutions for simple bends and prototyping

- Hydraulic Benders – Powerful machines for thicker materials and structural applications

- NC (Numerical Control) Benders – Semi-automated systems with programmable controls for repeatable results

- CNC (Computer Numerical Control) Benders – Fully automated, multi-axis systems for complex 3D bends and high-precision production

Steel tube bending is everywhere. From the exhaust systems in your vehicle to the handrails you grip on staircases, from the frames of commercial aircraft to the furniture in your office—precision-bent tubing is essential.

But here’s the challenge: not all bending machines are created equal.

Manufacturing operations managers face constant pressure to reduce costs, increase precision, and meet complex specifications. Choosing the wrong bending solution can lead to material waste, production delays, quality issues, and frustrated customers.

Hines Bending Systems stands as the worldwide leader in tube and pipe bending technology. With decades of expertise and a client roster that includes NASA and other demanding agencies, Hines delivers custom-engineered solutions that other manufacturers simply cannot match. Whether you need a compact benchtop unit or a state-of-the-art CNC system, Hines provides the machines, training, and ongoing support to ensure your success.

The evolution from manual hydraulic systems to today’s advanced automated benders represents a change in what’s possible. Modern machines can achieve tolerances of plus or minus 0.05°, handle tube diameters from 3/16″ to over 8″, and complete complex multi-plane bends without operator intervention.

This guide unpacks everything you need to understand about industrial tube bending machines—and why partnering with Hines Bending Systems gives you the competitive edge your operation demands.

Simple guide to steel tube bending machine terms:

- bending machine for sale

- cnc tube bending machine manufacturers

- industrial tube bending machines

The Evolution of Tube Bending Machines: Hines Bending Systems at the Forefront

The journey of tube bending technology is a fascinating one, marked by continuous innovation and increasing precision. We’ve seen the industry evolve from basic manual methods to highly sophisticated, automated systems. At every step, Hines Bending Systems has been at the forefront, pushing the boundaries of what’s possible and setting the standard for quality and performance in steel tube bending machine technology.

Our extensive range of machines reflects this evolution. From robust, portable units perfect for a quick job in your Fort Myers, FL workshop, to massive, fully automated CNC benders handling complex aerospace components in a Jacksonville, FL facility, we engineer and support solutions for every need. This progression allows us to offer exactly the right tool for the job, ensuring optimal results for our clients.

Hines Manual and Benchtop Benders

Sometimes, simplicity is key. For prototyping, small-batch production, repair work, or specialized maintenance applications, our manual and benchtop benders are ideal. These machines offer incredible portability, making them perfect for on-site adjustments or tasks where a large machine isn’t feasible. They represent a low investment while still delivering precise, simple bends. Imagine needing to create a custom part for a unique fluid system in a Sarasota, FL lab – a benchtop bender can provide the consistent, high-quality bends needed for tubing with outside diameters ranging from 1/4 inch to 1 1/4 inches (6 to 30 mm), or even highly portable hand benders for tubing as small as 1/8 inch (3 mm). Our benchtop benders are designed with rugged, lightweight construction, making them easy to move and operate.

Learn more about Hines benchtop benders.

Hines Hydraulic and NC Benders

Stepping up in power and capability, our hydraulic and NC (Numerical Control) benders offer the muscle needed for more demanding applications. These machines are designed for the heavier lifting, capable of bending thicker materials and larger tube diameters with ease. Our hydraulic benders, like those capable of delivering 58,000 pounds of bending force with a 5 HP motor for 3-inch tubing, or even 85,000 pounds of best bending power from a 7.5 HP motor for big jobs like bending stainless steel, are workhorses in many fabrication shops.

The addition of NC controls brings a level of repeatability that transforms production. With NC, operators can program bend angles and other parameters, ensuring consistent results across multiple parts. This makes them perfect for applications such as exhaust systems, structural components, and industrial piping where accuracy and consistency are paramount. Our 1-axis hydraulic tube benders (BTNC-Series) feature hydraulic C-axis bending with manual B, Y-axis adjustments for controlled pipe shaping, while our 2+1 axis hydraulic models (BTH-Series) offer servo-driven rotation and feed for increased precision.

Hines CNC (Computer Numerical Control) Benders

For the pinnacle of precision, automation, and efficiency, our CNC benders are best. These are the machines that truly embody the future of manufacturing, offering full automation and the ability to execute multi-axis, complex bends with incredible accuracy. Our CNC benders are built for high-volume production, drastically reducing labor costs and material waste. Imagine creating intricate, complex parts for a specialized project in Miami, FL, without straight sections between bends—our E-TURN and ELECT models can handle tubes up to 63.5 mm and 150 mm in diameter respectively, making previously impossible designs a reality.

Our industry-leading servo-electric technology, as seen in our 3-axis full CNC tube benders (BTS-Series), provides exceptional control, high accuracy in bending positioning, and repeatability, ensuring the highest quality bends. These machines combine the energy savings and quiet operation of electric servo control with advanced design features and software, making them an ideal choice for the truck and automotive exhaust bending industry, or any application requiring precise, repeatable results for tubes up to 220 mm (8 inches) in diameter with wall thicknesses up to 10 mm. With our CNC benders, your facility in Orlando, FL, can achieve previously unimaginable levels of productivity and precision.

Key Factors in Selecting the Right Hines Steel Tube Bending Machine

Choosing the right steel tube bending machine is a critical decision that directly impacts the quality, efficiency, and profitability of your operations. It’s not just about buying a machine; it’s about investing in a solution that perfectly aligns with your specific needs. With our deep expertise, we guide our clients in Fort Lauderdale, FL, and across the state, to ensure they receive the optimal solution, avoiding costly mistakes and maximizing their return.

When you partner with us, we consider every aspect of your application, from the material properties you’re working with to your desired production volume and the complexity of your bends. This meticulous approach is how we deliver machines that aren’t just good, but the absolute best for your unique requirements.

Material and Tube Specifications

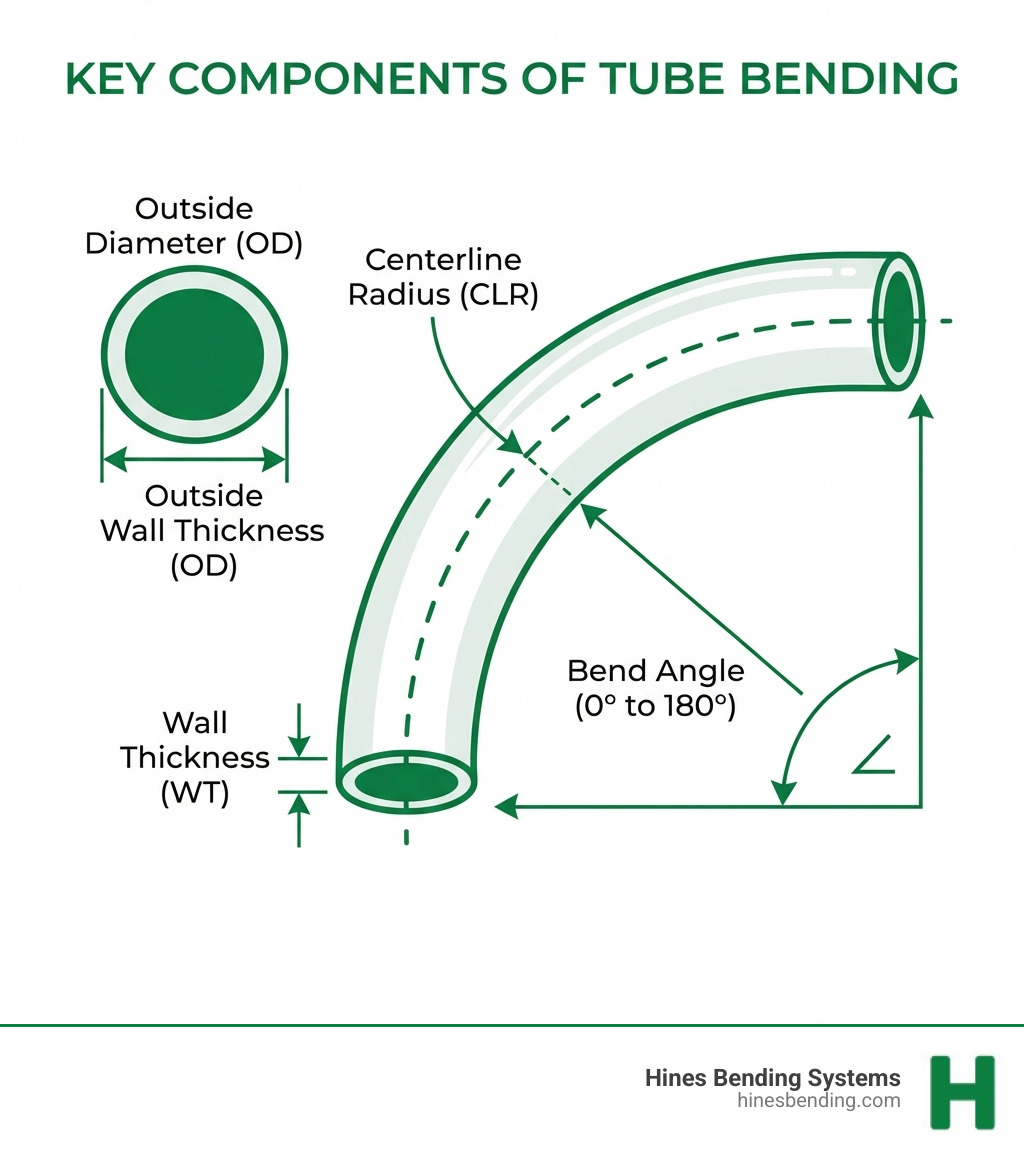

The type of material and the precise specifications of your tubes are perhaps the most fundamental considerations. Different metals behave differently under stress, and our machines are engineered to handle a wide array of materials, including various grades of steel, stainless steel, and aluminum. The material’s ductility and tensile strength play a significant role in determining the bending method and tooling required.

We work with tubes ranging from small diameters like 3/16 inch up to large industrial pipes of 8 inches (203 mm) in outside diameter, with wall thicknesses from 0.4 mm to 10 mm. Whether you’re bending round tubing for furniture in Cape Coral, FL, or square and rectangular tubing for structural components in West Palm Beach, FL, our engineering team ensures your steel tube bending machine is perfectly matched to your material. Our machines are designed to bend metal to your will without deforming the material, whether you’re working with steel, aluminum, or stainless steel.

Bending Complexity and Precision

The complexity of the bend and the required precision are paramount. Key factors here include:

- Centerline Radius (CLR): This is the radius from the center of the bend to the centerline of the tube. Our machines can achieve a wide range of CLRs, from very tight radii (where mandrel support is often critical to prevent collapse and maintain integrity) to virtually unlimited large radii.

- Bend Angle Accuracy: Whether you need a simple 90-degree bend or a complex 180-degree curve, our machines deliver precise angle accuracy. Our advanced systems include springback compensation, which intelligently accounts for the material’s tendency to “spring back” slightly after bending, ensuring the final angle is exactly as specified.

- Multi-plane and 3D Bending: For intricate designs, our CNC machines excel at multi-plane and 3D bending, allowing for complex shapes to be formed without manual repositioning of the tube. This capability is essential for creating parts like vehicle chassis or complex aerospace components.

- Mandrel and Wiper Die Technology: For tight bends or thin-walled tubes, our machines use specialized tooling, including mandrels and wiper dies. Mandrels provide internal support to prevent tube collapse and wrinkling, while wiper dies prevent wrinkling on the inside radius of the bend, ensuring a smooth, high-quality finish.

Production Volume and Automation

Your production volume dictates the level of automation and speed required from your steel tube bending machine. We cater to a spectrum of needs:

- Low-Volume Prototyping: For developing new products or custom designs, manual or benchtop benders offer flexibility and a cost-effective entry point.

- Medium-Volume Production: NC and hydraulic benders provide the repeatability and power needed for consistent production runs.

- High-Volume Manufacturing: Our full CNC benders are engineered for continuous, high-speed operation. They offer fast cycle times, and can be integrated with automatic loading/unloading systems and even robotic arms for seamless, lights-out production. For complex shapes with small to medium diameter tubes, our SMART series is a high-production solution. For processing from coil that includes straightening, cutting, bending, and end-forming, our 4-RUNNER machines handle tubes up to 22 mm in diameter efficiently.

Depend on a reliable steel tube bending machine from Hines for consistent, high-quality output, regardless of your production scale.

The Power of Automation: Hines Advanced Control Systems and Efficiency

Automation is not just a buzzword; it’s a transformative force in tube fabrication. At Hines Bending Systems, we’ve harnessed this power to deliver cutting-edge control systems that dramatically improve efficiency, reduce costs, and produce superior part quality. Our commitment to innovation means our machines are not just keeping pace with Industry 4.0; they’re leading the way.

Consider the precision and speed our machines offer: with servo-electric control, we deliver high accuracy in bending positioning, ensuring high-quality bends with repeatability of plus or minus 0.05 mm for tube feeding, rotation, and bending. This level of consistency is simply unattainable with older, less advanced systems. For any manufacturer in Florida looking to maximize output and minimize waste, our automated solutions are the answer.

More about Hines advanced CNC controls.

Advantages of Hines CNC Automation

The shift from hydraulic-only systems to advanced CNC (Computer Numerical Control) and servo-electric automation offers a multitude of benefits:

- Unrivaled Repeatability and Precision: Our servo-electric drives ensure movements are executed with extreme accuracy, often to within plus or minus 0.05 degrees for bend angles. This means that the 1000th part will be virtually identical to the 1st, a level of consistency critical for quality control.

- Programming for Complex Parts: CNC allows for the precise programming of bend angles, radii, and positions across multiple axes. This enables the creation of highly complex 3D shapes that would be impossible or incredibly time-consuming with manual or NC machines. Our 3-axis full CNC tube benders, for example, are fully automated systems with servo-controlled C, B, and Y-axis for high-speed, multi-directional tube bending.

- Reduced Setup Time and “First Part Right”: With advanced software, operators can simulate the bending process before any metal is cut. This virtually eliminates trial-and-error, ensuring that the “first part is right,” saving valuable material and time. Imagine the impact on your bottom line in a busy facility in Orlando, FL, when scrap is minimized.

- Minimal Scrap and Material Waste: By optimizing bend sequences and ensuring precision, CNC automation drastically reduces errors and, consequently, material waste. This is a direct cost saving that adds up significantly over time.

Benefits of a Modern Hines Steel Tube Bending Machine

Beyond the direct advantages of automation, our modern steel tube bending machine solutions bring broader operational benefits:

- Energy Efficiency: Our all-electric and hybrid benders are designed with energy conservation in mind. All-electric technology, for instance, can offer energy savings of up to 70% compared to traditional hydraulic systems, a significant factor for operations in high-energy-cost areas.

- Quiet Operation: Electric servo control not only saves energy but also operates much more quietly than hydraulic pumps, contributing to a better working environment.

- Low Maintenance: With fewer moving parts and advanced diagnostics, our modern machines require less frequent and less intensive maintenance. Our hybrid benders, for example, employ hydraulic valves and integrated circuits to control bending motion individually, which extends the service life of the hydraulic parts. Our computer systems can also automatically detect malfunctioning points, allowing operators to solve problems quickly.

- Improved Safety: Automated systems reduce the need for manual handling of heavy or awkward tubes, minimizing the risk of operator injury. Integrated safety features and controls further improve workplace safety.

- Data Logging for Quality Control: Our advanced control systems can log critical bending parameters, providing invaluable data for quality assurance, process optimization, and compliance documentation.

- Remote Diagnostics and Support: In today’s connected world, our machines can often be diagnosed and supported remotely, allowing for quicker issue resolution and minimal downtime, no matter if your machine is in Miami, FL, or Sarasota, FL.

The Value of Hines Partnership and Training

The most advanced steel tube bending machine delivers its best results only when backed by expert support and well-trained operators. This is where Hines Bending Systems truly shines. We believe it’s not just about the machine; it’s about the entire experience.

We don’t just sell machines; we forge partnerships. Our team offers custom machine solutions, leveraging decades of industry expertise to configure a bender that precisely meets your unique challenges. We provide comprehensive training, ensuring your team in Fort Myers, FL, or any of our other locations, is fully proficient in operating and maintaining your new equipment. This includes essential training in fluid system fundamentals and best practices for tube bending.

We view ourselves as partners, providing support from onboarding and training to troubleshooting and optimization, helping you turn challenges into opportunities. With our continuous education and application support, your engineering and production teams will operate with maximum efficiency. Why partner with Hines? Because nobody in the bending machine industry has more expertise and experience than we do, and we’re committed to your success.

Hines bender training; Why partner with Hines? Learn more.

Applications and Industries Served by Hines Bending Systems

The versatility and precision of a steel tube bending machine make it a foundational technology for countless industries. From the smallest components to massive structural elements, precision-bent tubing is everywhere. Hines Bending Systems is proud to be the trusted partner for the world’s most demanding applications, providing solutions that meet rigorous quality and performance standards across a diverse range of sectors.

We understand that each industry has its unique requirements, and our machines are designed to excel in various environments, be it for automotive manufacturing in Orlando, FL, aerospace innovation in Cape Coral, FL, or architectural marvels in West Palm Beach, FL.

Automotive and Transportation

The automotive and transportation sectors rely heavily on precise tube bending for both functionality and safety. Our machines are instrumental in producing:

- Exhaust Systems: Complex bends are required to route exhaust pipes efficiently and quietly, with our machines capable of bending stainless steel for durability.

- Roll Cages and Chassis Components: For racing and high-performance vehicles, as well as heavy industrial vehicles, the structural integrity provided by accurately bent tubes is critical.

- Brake and Fuel Lines: Small-diameter tubing for these vital systems demands extreme precision and consistency.

- Handrails for Vehicles and Structures: From buses to specialized transport, ergonomically designed and safely installed handrails are essential.

- Nerf Bars, Brush Bars, and Light Racks: Custom vehicle parts for SUVs and trucks are frequently fabricated using our tube benders, including the powerful HB-10 model which is often referred to as “The Full Package” for 3-inch tubing.

Our solutions ensure that every component, from a custom exhaust system to a robust roll cage, is manufactured to the highest standards.

Aerospace and Defense

In aerospace and defense, there is zero room for error. The stakes are incredibly high, and the demands for precision, material integrity, and reliability are best. Hines Bending Systems meets these stringent requirements head-on, providing steel tube bending machine solutions for critical applications such as:

- Fuel and Hydraulic Lines: These systems demand flawless bends to prevent leaks and ensure operational safety.

- Structural Frames: Lightweight yet incredibly strong tubular structures are vital for aircraft and spacecraft.

- Engine Components: Intricate tubing is used in various parts of aircraft engines, requiring extreme accuracy.

Our long-standing partnership with top agencies like NASA is a testament to our unwavering commitment to uncompromising quality and our ability to deliver machines that perform under the most demanding conditions. When the sky’s not the limit, Hines is your partner.

Architectural and Structural

From iconic building designs to everyday safety features, architectural and structural applications benefit immensely from precise tube bending. Our machines are used to create:

- Handrails and Staircases: Custom, aesthetically pleasing, and structurally sound handrails for commercial and residential buildings, including complex handrail elbows and wall returns, are a specialty.

- Canopies and Awnings: Curved tubular frames provide both support and design flair.

- Playground Equipment: Durable and safe structures often incorporate bent tubing.

- Structural Steel Frames: For various construction projects, bent steel tubes offer design flexibility and strength.

- Custom Metal Fabrication: From unique furniture designs to complex artistic installations, our machines enable fabricators in Jacksonville, FL, to bring their visions to life.

Hines delivers solutions for every challenge, ensuring that both the form and function of architectural and structural elements are perfectly realized.

Conclusion

From robust hydraulic systems to sophisticated, fully automated CNC machines, Hines Bending Systems offers the world’s best solutions for every tube bending application. The key to success is not just the machine, but the expertise, innovation, and partnership that Hines provides. With custom-configured machines, comprehensive training, and ongoing support, Hines ensures maximum efficiency and a superior return on investment for our clients across Florida, from Fort Myers to Miami, and beyond. As the worldwide leader, Hines Bending Systems delivers the best experience and the highest quality bending solutions to meet the most demanding industry requirements.

When you choose a steel tube bending machine from Hines, you’re not just buying equipment; you’re gaining a partner dedicated to your success. Our commitment to quality, backed by decades of experience and a track record of innovation, ensures that your bending operations will be precise, efficient, and reliable. Let us help you open up the full potential of your manufacturing capabilities.

Get a custom tube bender solution; Expert consultation; Custom engineering.