Why Custom Exhaust Bending Matters for Your Projects

How to make a exhaust pipe bender is a question that many DIY enthusiasts and small fabricators ask when facing custom exhaust work. Here’s the quick answer:

Basic DIY Exhaust Pipe Bender Components:

- Frame: Heavy-duty steel square tubing welded into a stable base

- Bending Die: Round steel bar or machined die matching your desired bend radius

- Clamping System: Fixed clamp to secure the pipe against the die

- Leverage Arm: Long handle (for manual) or hydraulic jack (for powered versions)

- Support Method: Sand-filled pipes or mandrels to prevent collapse

You’ll need welding equipment, a drill press, angle grinder, and quality steel materials. Most DIY designs are either simple manual lever-type benders or hydraulic press adaptations.

The appeal of building your own exhaust pipe bender is undeniable. Custom exhaust work lets you optimize your vehicle’s performance, create unique routing solutions, and save money on fabrication costs. Many automotive enthusiasts are drawn to the challenge of fabricating their own tools.

But here’s the reality: bending exhaust pipe without kinking, crushing, or compromising flow is far more complex than it appears.

As one experienced fabricator noted in online forums, achieving clean, professional bends with DIY methods can be “challenging” at best. The thin walls of exhaust tubing are prone to collapse. The metal has memory and springs back. Heat application requires precision. Even small imperfections create restrictions that hurt engine performance.

While building a DIY bender is an excellent learning project, it’s important to understand both its possibilities and its significant limitations. For manufacturing operations requiring precision, repeatability, and quality that meets industry standards, professional bending solutions become essential.

This guide will walk you through the core principles of pipe bending, show you how to build basic DIY bender designs, and help you understand when it’s time to rely on professional expertise. Hines Bending Systems, the #1 worldwide manufacturer of tube and pipe benders trusted by agencies like NASA, offers the industry’s most advanced solutions when your projects demand flawless results.

Understanding the Core Principles of Pipe Bending

Before attempting to make an exhaust pipe bender, it’s crucial to understand the complex physics of bending metal. Achieving a precise curve without compromising the tube’s integrity involves managing material properties, springback, and other forces.

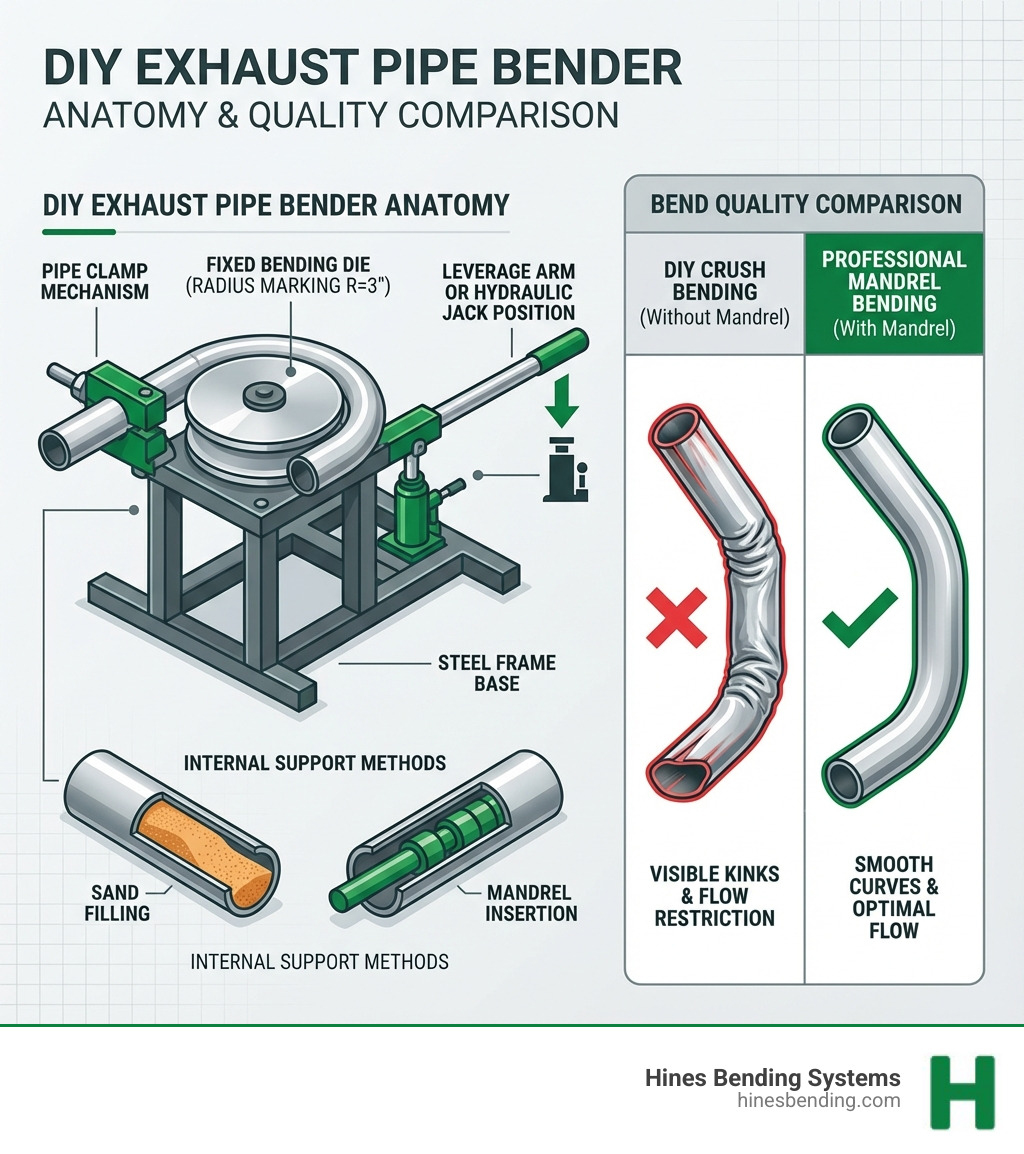

The primary challenges are preventing wall thinning on the outside of the bend and wrinkling or collapse on the inside. A flattened or kinked pipe severely restricts exhaust flow, hurting engine performance and looking unprofessional. This is why professional shops and high-performance applications demand mandrel bending. A mandrel is an internal support that ensures the tube maintains its full diameter through the bend, a technique perfected in the advanced machinery offered by Hines Bending Systems.

While basic DIY methods often result in “crush bends” that squash the pipe, our machines guarantee smooth, full-diameter bends for optimal performance. To learn more about the professional terminology, see our comprehensive guide on More info about bending terminology.

Common DIY Exhaust Pipe Bender Designs

Those searching for how to make a exhaust pipe bender will find several common DIY designs, from simple manual levers to hydraulic press adaptations. While these projects can be educational, they highlight the significant gap between hobbyist tools and professional machinery.

How to Make a Simple Manual Exhaust Pipe Bender

A basic manual bender uses a fixed die and a long lever to force a pipe into a curve. While simple to construct, this method lacks the force and control needed for steel exhaust tubing.

The result is almost always a kinked, flattened, and unusable pipe, as there is no support to maintain the tube’s round profile.

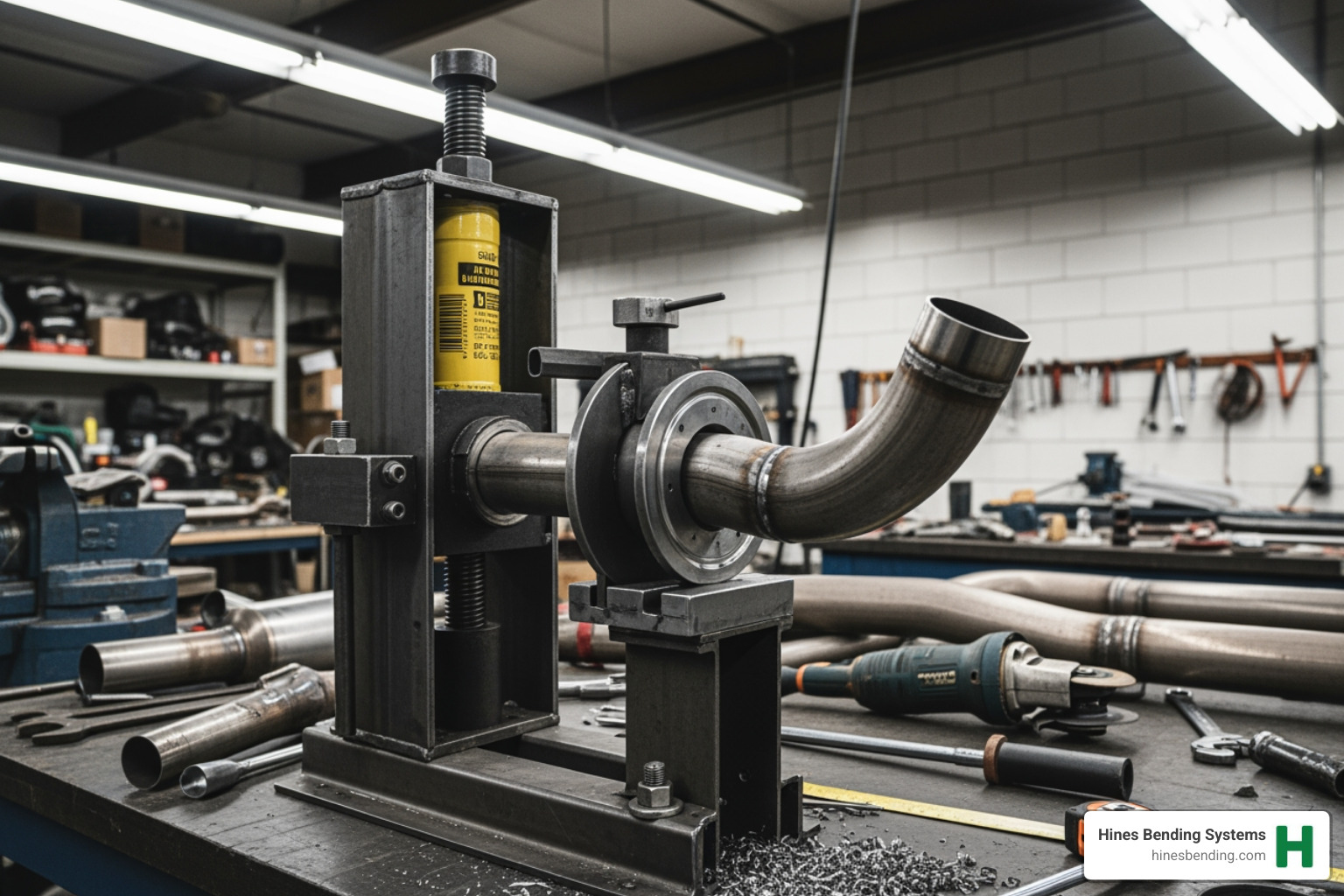

How to Make an Exhaust Pipe Bender with Hydraulic Power

Integrating a hydraulic bottle jack provides more force, but control remains a major issue. These homemade press benders can easily crush or distort exhaust tubing. Achieving a smooth, round bend that doesn’t restrict flow is nearly impossible without the sophisticated internal mandrels and synchronized pressure systems found in professional equipment like the machines engineered by Hines Bending Systems. These DIY methods demonstrate the force required, but they lack the precision essential for quality results.

Key Steps and Materials for Your Bender Project

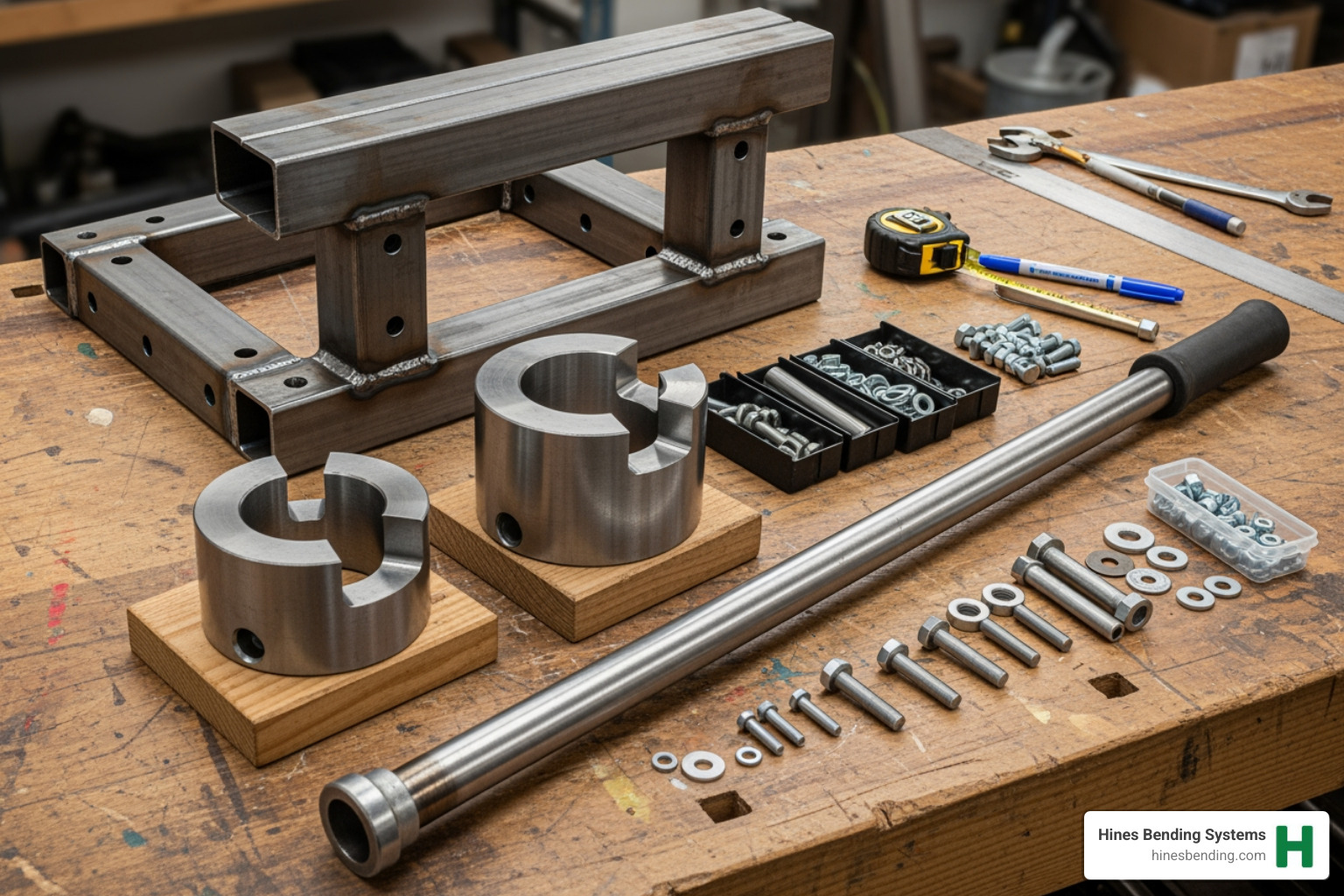

Building a DIY bender is a significant undertaking requiring specific materials, tools, and fabrication skills.

Key Components and Tools:

A functional DIY bender requires a heavy-duty steel frame, precisely shaped bending dies, and a power source (either a long leverage arm or a hydraulic jack). Fabricating one involves tools like a welder, drill press, and angle grinder for cutting and assembling thick steel components. The quality of the bend is directly tied to the precision of the bending die, which must perfectly match the pipe’s diameter.

The Challenge of Preventing Collapse

The secret to avoiding a collapsed pipe in a DIY setting is providing internal support. The most common method is sand-packing, where the pipe is filled with dry, compacted sand before being bent. This process is labor-intensive and messy, and while it can help prevent total collapse, it rarely produces the perfectly smooth, round profile achieved with professional equipment. Applying heat with a torch is often necessary, adding another layer of complexity and safety risk. These techniques underscore the difficulty of replicating professional results, where advanced mandrels provide flawless internal support without the guesswork and inconsistency of sand-packing.

The DIY Dilemma: When to Build vs. When to Trust the Experts

Building a how to make a exhaust pipe bender project can be incredibly rewarding. It teaches you about fabrication, metal properties, and problem-solving. But be realistic about its limitations, especially for critical components like exhaust systems.

| Feature | DIY Bender (Manual/Hydraulic Press) | Professional Bender (Hines Bending Systems) |

|---|---|---|

| Bend Quality | Often compromised; risk of kinks, flattening, inconsistent radius. | Smooth, consistent, full-diameter mandrel bends; no kinks or flattening. |

| Repeatability | Low; difficult to achieve identical bends consistently. | High; CNC controls ensure precise, repeatable bends every time. |

| Safety | Moderate to high risk; heavy forces, potential for tool failure. | High safety standards; engineered for safe operation. |

| Speed | Slow; labor-intensive, often requires multiple adjustments. | Fast; automated processes significantly reduce bending time. |

| Material Cap. | Limited to smaller diameters, thinner walls; specific metal types. | Wide range of pipe/tube sizes and materials, including large OD and thick walls. |

DIY Pros:

- Cost Savings: Potentially lower initial investment than purchasing a commercial bender.

- Learning Experience: Invaluable for understanding mechanics and fabrication.

- Customization: Tailor the bender to specific, occasional needs.

DIY Cons:

- Inaccuracy: Achieving precise angles and radii is challenging.

- Poor Quality Bends: High risk of kinking, flattening, and flow restriction.

- Safety Risks: Working with heavy forces and potentially unstable homemade equipment.

- Time Investment: Significant time required for design, fabrication, and trial-and-error.

- Limited Capability: Struggles with larger diameters, thicker walls, or harder materials.

Why Professional Bending is Crucial for Quality

For any project demanding precision, optimal performance, and structural integrity, professional bending solutions are not just an option—they’re a necessity.

We at Hines Bending Systems understand that achieving a consistent radius, maximizing exhaust flow, and maintaining structural integrity are paramount. Our machines are engineered to deliver these results flawlessly. Unlike DIY solutions, our professional benders use advanced technology to overcome the inherent challenges of pipe bending:

- Mandrel Technology: Our benders employ sophisticated mandrel systems that provide internal support throughout the bend, preventing collapse and ensuring the tube maintains its full, round cross-section. This is critical for maximizing exhaust flow and engine performance.

- CNC Precision: Our CNC (Computer Numerical Control) bending machines offer unparalleled accuracy and repeatability. This means every bend is exactly as specified, ensuring perfect fitment and consistent quality across multiple parts. CNC machining is far more consistent than manual operations.

- Innovative Induction Bending: For larger outside diameters and thicker wall materials, our induction bending technology offers distinct advantages. This method heats a localized section of the pipe, allowing for large radius bends with minimal distortion and exceptional structural integrity.

- Best Expertise and Experience: Hines Bending Systems is the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. We’ve been helping customers since 1975, and nobody in the bending machine industry has more expertise and experience than us. We supply massive agencies and companies such as NASA, a testament to our credibility and the superior quality of our machines.

- Custom Solutions: We pride ourselves on working closely with our clients to provide custom bender solutions custom to their specific needs. Whether you’re in Fort Myers, Sarasota, or anywhere in Florida, our dedication to customer satisfaction means we’re here to ensure your specific requirements are met with the highest quality machinery.

While building your own bender is a noble pursuit, for projects where performance, aesthetics, and durability matter, the advantages of Hines Bending Systems’ advanced machinery are clear.

Frequently Asked Questions about How to Make an Exhaust Pipe Bender

We often hear similar questions from those exploring how to make a exhaust pipe bender or considering their bending options. Let’s address some of the most common ones.

What materials are needed to build a DIY exhaust pipe bender?

To build a basic DIY exhaust pipe bender, you’ll primarily need heavy-duty steel. This includes steel plate for the base and structural components, square tubing for the frame and leverage arms, and round bar for creating the bending dies. For a hydraulic version, a hydraulic bottle jack is essential. You’ll also need various nuts, bolts, and washers for assembly. Welding is almost always required for a sturdy, reliable frame, so access to welding equipment and consumables is a must.

How can you prevent the exhaust pipe from collapsing when using a homemade bender?

The most common DIY method for preventing exhaust pipe collapse is packing the pipe tightly with dry sand and sealing the ends. The sand acts as an internal support, preventing the pipe walls from caving in or kinking when pressure is applied during the bend. It’s crucial that the sand is completely dry to avoid issues with steam if heat is applied. While effective for preventing collapse, this method doesn’t guarantee a perfectly round, mandrel-quality bend, and still requires careful execution to avoid wrinkles.

Are DIY benders as good as professional machines?

No, simply put, DIY benders cannot match the precision, quality, or repeatability of professional bending machines. While a DIY bender is a fantastic project for learning and can handle very basic, non-critical bends, it falls short when it comes to the demands of modern exhaust systems. Professional machines, like those from Hines Bending Systems, are engineered with precise tooling, hydraulic or electric power, and often CNC controls to ensure:

- Consistent bend radii: Critical for optimal exhaust flow.

- Material integrity: Preventing wall thinning, kinking, and structural weakening.

- Repeatability: Producing identical parts for consistent quality and production.

- Safety: Designed with features to protect the operator.

Hines Bending Systems’ machines, trusted by leading organizations worldwide, including NASA, are built to meet rigorous industry standards and provide superior results that homemade tools simply cannot achieve.

Conclusion: From DIY Practice to Professional Perfection

Our journey into how to make a exhaust pipe bender has shown us the ingenuity and satisfaction that comes with DIY fabrication. We’ve explored the core principles of metal bending, detailed the components and construction of basic manual and hydraulic DIY benders, and highlighted the crucial technique of sand-packing to prevent pipe collapse. Building your own tools is a valuable learning experience, fostering a deeper understanding of mechanics and material science.

However, we’ve also confronted the inherent limitations of homemade solutions. For projects demanding precision, flawless quality, and guaranteed performance – especially in critical applications like exhaust systems where flow dynamics and structural integrity are paramount – DIY benders simply cannot compete with professional-grade machinery. The risk of kinks, flattening, and inconsistent bends with homemade setups can lead to compromised performance, premature wear, and ultimately, wasted time and materials.

For those serious about achieving the highest standards in tube and pipe bending, Hines Bending Systems stands as the industry leader. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we bring unparalleled expertise and experience to every client. Our innovative technology, including advanced CNC and induction bending solutions, is trusted by major industries and agencies like NASA, delivering precision and quality that is best.

We pride ourselves on our customer-centric approach, offering custom solutions custom to your specific needs, whether you’re a small fabricator in Cape Coral or a large manufacturer in Jacksonville. When your project demands perfection, choose the reliability and superior performance that only Hines Bending Systems can provide.