Your Comprehensive Guide to Tube Benders in Florida

Finding the right tube benders in Florida is a critical decision for any business in the aerospace, marine, or manufacturing sectors. Precision and reliability are non-negotiable, and the right equipment can significantly impact your bottom line. Florida’s unique industrial landscape, with its humidity and diverse applications, demands machinery that is both robust and versatile.

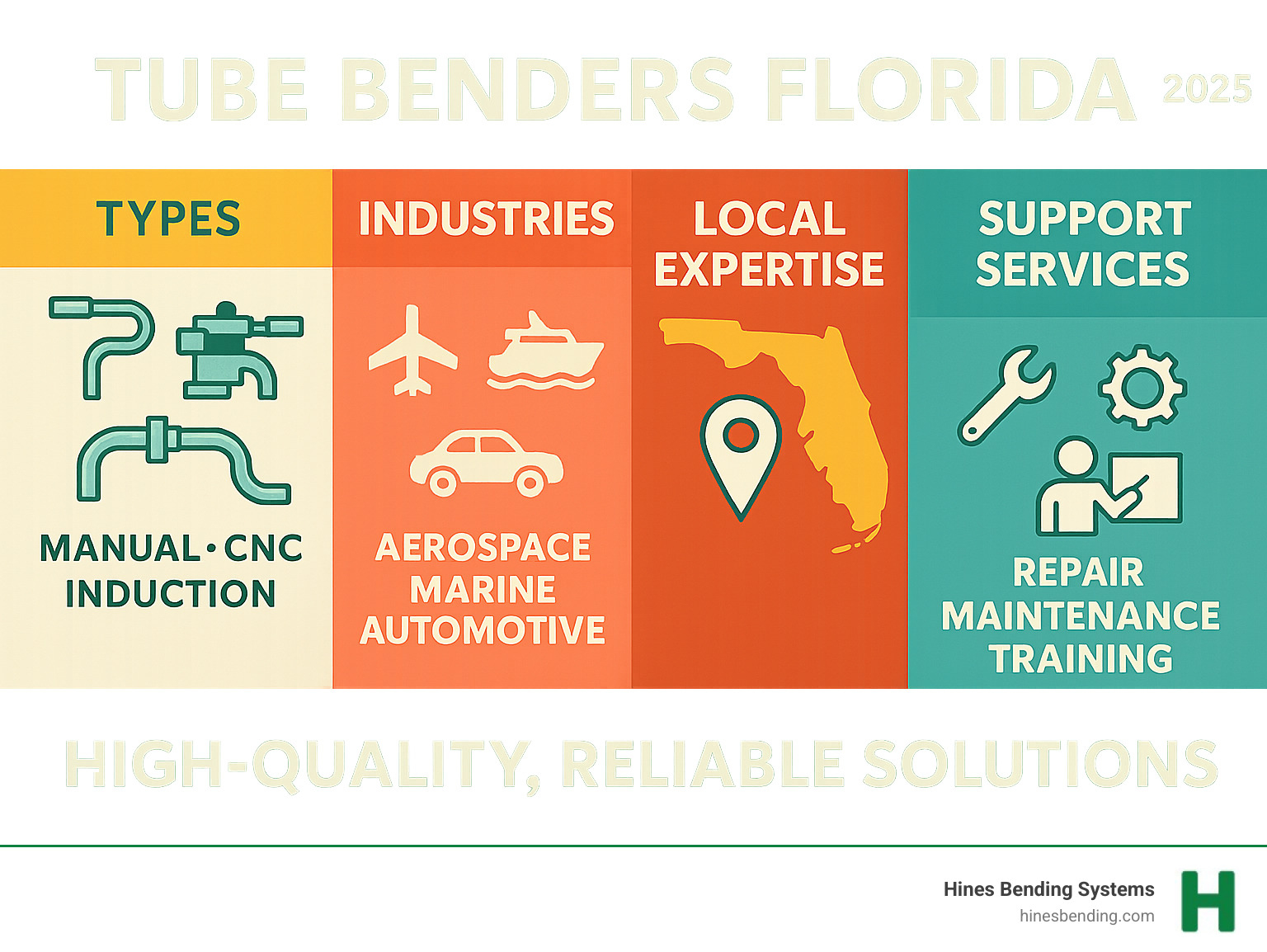

When searching for tube bending solutions, businesses typically look for:

- A Wide Range of Options: From simple manual tools to advanced CNC and induction benders.

- Industry-Specific Capabilities: Solutions custom for everything from aviation to high-performance automotive parts.

- Local Expertise and Support: Access to knowledgeable suppliers and service providers within the Sunshine State.

- Reliable Maintenance and Service: Ensuring machinery operates at peak performance for years to come.

At Hines Bending Systems, we understand these needs. With a legacy dating back to 1975 and the most bender installations globally, we are a leader in the bending machine industry. Our expertise and experience make us the go-to choice for reliable, high-performance machines that serve as true partners in your production process.

What Types of Tube Benders Are Used in Florida’s Industries?

When exploring tube benders in Florida, you’ll find a variety of equipment designed for different industrial challenges. From simple, hands-on tools to sophisticated, automated systems, each type of bender serves a unique purpose. At Hines Bending Systems, our goal is to guide you to the perfect bending solution for your specific needs, ensuring optimal performance and efficiency.

Manual and Hydraulic Benders

Manual and hydraulic benders are the foundational tools in tube bending. Manual benders are ideal for smaller jobs, quick prototypes, or on-site repairs, offering flexibility and portability. Hydraulic benders provide more power, making it easier to bend larger diameter tubing or tougher materials. They offer a great balance of control and force, making them a popular choice for workshops that need more capability than manual benders but don’t require full automation. For more information on available equipment, you can explore our resources on Used Pipe Bending Machines in Florida.

Advanced CNC Tube Benders

For modern manufacturing, Advanced CNC (Computer Numerical Control) tube benders are the workhorses. These machines use automation to deliver unparalleled precision, repeatability, and speed. If you’re dealing with high-volume production or intricate designs, a CNC tube bender is essential. They minimize human error, reduce material waste, and execute complex bends with incredible accuracy. At Hines Bending Systems, we specialize in building cutting-edge CNC machines that are powerful, user-friendly, and reliable, capable of meeting the most demanding specifications for clients like NASA. Learn more about our advanced solutions on our CNC Tube Bender Florida page.

Specialized Bending Solutions

Beyond standard models, we offer specialized bending solutions for unique challenges:

- Induction Bending: This process uses localized heat to bend large-radius, thick-walled tubes that are impossible to bend with conventional methods. It’s ideal for heavy-duty applications in shipbuilding, construction, and power generation. As a world-leading manufacturer, we offer state-of-the-art induction benders.

- Roll Bending: This method uses three rollers to create large, sweeping curves, perfect for applications where a consistent, single-plane bend is required.

- Mandrel Benders: Essential for producing smooth, wrinkle-free bends in thin-walled tubing or for tight radii, a mandrel supports the tube’s interior during bending to prevent collapse.

At Hines Bending Systems, we provide a comprehensive range of these specialized machines, ensuring we have the perfect solution for any bending challenge you face.

Key Industries in Florida Driving the Demand for Tube Bending

Florida’s dynamic economy and diverse industries create a strong, consistent demand for high-quality tube benders. From aerospace to marine applications, precisely bent tubes are crucial. At Hines Bending Systems, we are proud to be a leading Florida Bending Machine Manufacturer, providing custom solutions for these key sectors.

Aerospace and Defense

Florida is a major hub for aerospace and defense, industries that rely on precision tube bending for everything from hydraulic lines to rocket components. These applications demand extreme accuracy and the ability to work with specialized materials like titanium, all while adhering to strict military and aerospace standards. We are proud to supply bending machines to top-tier clients, including NASA and the U.S. Government, demonstrating the quality and reliability of our equipment. Learn more about our work with the space agency here: Hines working together with NASA.

Marine and Shipbuilding

With its extensive coastline, Florida’s marine and shipbuilding industries are major users of tube benders. From custom boat railings and T-tops to complex plumbing and exhaust systems, bent tubing is everywhere. The challenge is often working with corrosion-resistant materials like stainless steel and aluminum, which require specialized techniques to maintain their integrity in saltwater environments. Our machines are designed to handle these materials with precision, ensuring durable and high-performance results.

Automotive and Performance

Florida’s vibrant automotive and performance scene, especially in custom builds and racing, relies heavily on advanced tube bending. Crafting custom exhaust systems, building strong roll cages, and fabricating complex chassis all require precision and strength. Our machines empower fabricators to create high-performance parts that ensure both safety and optimal vehicle performance. For more details, visit our Automotive Exhaust Tube Bender Florida page.

Construction and Architecture

Florida’s booming construction industry uses tube bending for structural components, artistic metalwork, handrails, and infrastructure projects. The ability to bend large pipes and tubes precisely is crucial for both structural integrity and design flexibility. Our robust bending machines deliver reliable and consistent results for projects of all sizes. We have a wide range of Bending Machines for Sale in Florida to meet these demands.

How to Select the Right Tube Benders for Florida Businesses

Choosing the perfect tube bender is a strategic investment that impacts your business’s efficiency, quality, and bottom line. With nearly five decades of experience, we understand that this is more than just a purchase—it’s about finding a partner who can guide you to the right solution.

Essential Features for Florida’s Climate and Industries

Florida’s humid, salt-air climate demands machinery built for durability and corrosion resistance. Our tube benders for Florida are crafted with robust materials and finishes to ensure a long, productive life. Beyond weather resistance, we focus on features critical to Florida’s key industries:

- Precision Control: Essential for aerospace and medical applications with tight tolerances.

- Customization Capability: Adaptable tooling for businesses handling diverse projects.

- Material Compatibility: The ability to perfectly bend everything from stainless steel to titanium.

We design our machines to exceed industry standards, which is a core reason Why to Buy a Hines Bender.

The Power of CNC vs. Manual Benders

One of the biggest decisions is choosing between a CNC and a manual bender. This choice impacts cost, quality, and efficiency.

| Metric | Manual Benders | CNC Benders |

|---|---|---|

| Speed | Slower, depends on operator skill | Very fast, consistent cycle times |

| Precision | Varies with operator skill; good for simple bends | Extremely high and consistent |

| Repeatability | Lower, prone to human variation | Excellent, identical parts every time |

| Cost per Part | Higher for high volumes due to labor and potential scrap | Lower for high volumes due to efficiency and reduced waste |

| Operator Skill Level | High skill required for complex or precise bends | Lower skill needed for operation; programming skill required |

While manual benders are great for small-batch work, CNC benders offer best efficiency and precision for high-volume or complex jobs. Learn more about our CNC benders and how they can transform your operations.

Why Expert Consultation is Non-Negotiable

Choosing a bender isn’t just about picking a machine from a catalog. It requires a deep understanding of your technical specifications and application needs. This is where our expertise becomes invaluable. Our “Customer First Promise” means we provide comprehensive solutions, including custom tooling and process optimization, to ensure your new bender integrates seamlessly into your workflow. With NASA-level expertise, we’re ready to help you find the perfect bending solution. That’s our Customer First Promise in action!

Your Comprehensive Guide to Tube Benders in the Sunshine State

Finding the right tube benders Florida can be a big step for any business. Whether you’re in aerospace, marine, or general manufacturing, precision and reliability matter.

Here’s what businesses often look for when seeking tube bending solutions in Florida:

- Diverse Types: From basic manual tools to advanced CNC and induction benders.

- Industry-Specific Needs: Solutions custom for everything from aviation to high-performance automotive parts.

- Local Expertise: Access to suppliers and service providers right here in the Sunshine State.

- Reliable Support: Options for repair, maintenance, and training to keep operations smooth.

Florida’s unique industrial landscape demands equipment that can handle tough conditions and precise requirements. The best tube benders are not just machines; they are partners in your production process. They help you create complex shapes, ensure product quality, and keep your projects moving forward.

Making the right choice means understanding the types of benders available, the industries that rely on them, and the features that stand out. It also means knowing where to find top-tier equipment and support. Hines Bending Systems has been a leader in the bending machine industry since 1975, with the most bender installations globally. Their expertise and experience are best, making them the go-to choice for reliable, high-performance machines.

What Types of Tube Benders Are Used in Florida’s Industries?

Ever wondered what goes into shaping metal tubes with incredible precision for everything from spaceships to luxury yachts? When you start exploring tube benders Florida, you’ll quickly find a fascinating world of machinery designed to meet all sorts of industrial demands. From simple, hands-on tools to complex, automated systems, each type plays a vital role in bringing metal designs to life. Our mission at Hines Bending is always to guide our clients toward the perfect bending solution for their unique needs, ensuring optimal performance and efficiency. For more information about our comprehensive range, you can explore our resources on More info about tube and pipe benders.

Manual and Hydraulic Benders

Let’s start with the foundational tools: Manual and Hydraulic Benders. Think of manual benders as the trusty screwdriver in your workshop – essential for small-scale production, quick prototyping, or those handy on-site repairs. They offer fantastic flexibility and portability, making them ideal when a large, automated machine just isn’t practical. They’re perfect for jobs where precision is important but volume is low.

Stepping up a notch, Hydraulic Benders still require operator input, but they bring a lot more power to the table. This makes them much easier to use, especially when you’re bending larger diameter tubing or materials that would be a real struggle by hand. These machines strike a wonderful balance between control and brute force. They’re a popular choice for workshops needing more capability than manual benders but not yet requiring the lightning speed of automated systems. We often see them used for specialized projects or in facilities looking for a robust, yet still operator-driven, solution. For more on available equipment, including reliable options that have stood the test of time, you can explore our resources on Used Pipe Bending Machines in Florida.

Advanced CNC Tube Benders

Now, let’s talk about the true workhorses of modern manufacturing: Advanced CNC (Computer Numerical Control) Tube Benders. These machines are where sophisticated automation really shines, delivering unparalleled precision, incredible repeatability, and blazing speed. If you’re tackling high-volume production or intricate designs that demand absolute perfection, a CNC tube bender from Hines Bending is truly your best friend. They dramatically minimize human error, significantly reduce material waste, and can execute complex bend sequences with breathtaking accuracy.

Our deep expertise in building cutting-edge bending machines means we understand the nuances of CNC technology better than anyone. We’ve been at the forefront of this evolution, ensuring our machines are not just powerful, but also remarkably user-friendly and incredibly reliable. This commitment to excellence allows us to provide customized solutions that meet even the most demanding specifications, ensuring your projects are completed efficiently and to the highest possible standards. To learn more about how our advanced solutions can transform your operations, visit our page on CNC Tube Bender Florida.

Specialized Bending Solutions

Beyond the standard manual, hydraulic, and CNC machines, we also dive deep into Specialized Bending Solutions that tackle truly unique challenges.

First up is Induction Bending, a truly remarkable process that sets itself apart. Unlike traditional methods that use mechanical force, induction bending uses localized heat from an induction coil to gently soften a small section of the tube. This ingenious approach allows for large radius bends, the manipulation of much thicker wall materials, and even larger outside diameters that would simply be impossible with conventional techniques. It’s the go-to solution for heavy-duty applications in demanding industries like shipbuilding, construction, and power generation. We are incredibly proud to offer state-of-the-art induction benders, capable of handling the toughest requirements with ease and precision. You can find More info about induction benders on our site.

For those grand, sweeping curves, Roll Bending steps up to the plate. This method uses three rollers to form a continuous curve, typically employed when you need large radius bends and precision in a single plane is key. And for delicate, thin-walled tubing or when you need super tight radii without any compromise on quality, Mandrel Benders are indispensable. A mandrel is carefully inserted into the tube during the bending process to provide crucial support to the inner wall, preventing any collapse or unsightly distortion.

At Hines Bending, we offer a comprehensive range of these specialized machines, including mandrel benders, roll benders, and stretch benders, ensuring we have the perfect solution for every conceivable bending challenge. Our unique ability to build customized machines means we can adapt to any specific requirement you might have, guaranteeing the best possible outcome for your project, every single time.

Key Industries in Florida Driving the Demand for Tube Bending

Florida’s vibrant economy and diverse industrial landscape create a consistent and growing demand for high-quality tube benders Florida. From the depths of the ocean to the vastness of space, the need for precisely bent tubes is critical across numerous sectors. We pride ourselves on understanding the unique requirements of these industries and providing custom bending solutions. Our position as a leading Florida bending machine manufacturer means we are deeply integrated into the state’s industrial fabric. Explore more about our local presence on Florida Bending Machine Manufacturing.

Aerospace and Defense

Florida is a hub for aerospace and defense, and this industry has an insatiable appetite for precision tube bending. Think about the intricate hydraulic lines in an aircraft, the complex exhaust systems of military vehicles, or the structural components of rockets. These applications demand extreme accuracy, the ability to work with exotic alloys like titanium, and adherence to the strictest military and aerospace specifications.

We are incredibly proud to supply bending machines to some of the most demanding clients in the world, including NASA and the U.S. Government. Our machines are trusted to produce components that literally go into space. This is a testament to the unparalleled quality, reliability, and precision of our tube benders. When lives and missions depend on flawless components, our machines deliver. You can read more about our work with the space agency on Hines working together with NASA.

Marine and Shipbuilding

Given Florida’s extensive coastline and robust maritime industry, it’s no surprise that marine and shipbuilding are major drivers for tube bending. From luxury yachts to commercial vessels and naval ships, bent tubing is everywhere. We’re talking about custom boat railings, sturdy T-tops, intricate plumbing, and exhaust systems. The challenge here often lies in working with corrosion-resistant materials like stainless steel and aluminum, which require specialized bending techniques to maintain their structural integrity and aesthetic appeal in harsh saltwater environments. Our machines are designed to handle these materials with precision, ensuring durability and performance on the high seas.

Automotive and Performance

The automotive and performance sector in Florida, particularly the custom and racing segments, also relies heavily on advanced tube bending. Whether it’s for custom exhaust systems, robust roll cages that protect drivers, or intricate chassis fabrication, precision and strength are paramount. Our machines provide the capability to bend various materials for high-performance parts, ensuring both safety and optimal vehicle function. For those in the automotive industry, our specialized solutions are designed to meet the rigorous demands of vehicle manufacturing and customization. More details can be found on our Automotive Exhaust Tube Bender Florida page.

Construction and Architecture

The booming construction and architectural industries across Florida also use tube bending for a wide array of applications. This includes structural components in buildings, artistic architectural metalwork, durable handrails for safety and aesthetics, and critical infrastructure projects. The ability to precisely bend large diameter pipes and tubes for these applications is vital for both structural integrity and design flexibility. Our bending machines are robust enough to handle the heavy-duty requirements of these sectors, providing reliable and consistent results for projects ranging from small-scale artistic installations to massive commercial developments. For businesses looking for equipment in this sector, we have various Bending Machines for Sale in Florida.

How to Select the Right Tube Benders for Florida Businesses

Choosing a tube bender is more than a purchase – it’s a strategic investment that affects throughput, product quality, and ROI. Hines Bending Systems has nearly five decades of experience guiding Florida companies to the perfect solution, so you can count on proven advice every step of the way.

Essential Features for Florida’s Climate and Industries

Florida’s heat, humidity, and salty air will punish unprotected machinery. Every Hines bender destined for the Sunshine State is built with corrosion-resistant finishes, sealed electronics, and heavy-duty components that thrive in harsh coastal environments. Beyond durability, consider:

- Precision control for aerospace and medical tolerance requirements.

- Quick-change tooling to handle diverse jobs without downtime.

- Material flexibility – from stainless for marine work to titanium for defense contracts.

See additional advantages in our detailed guide: Why Buy a Hines Bender?.

CNC vs. Manual: Which Makes Sense for You?

| Metric | Manual Benders | CNC Benders (Hines) |

|---|---|---|

| Speed | Operator-dependent; best for low volume | Fast, consistent cycle times |

| Precision | Good for simple bends | +/- .001″ repeatability |

| Repeatability | Varies with skill | Identical parts every run |

| Labor Cost/Part | High on large batches | Low – automation does the work |

| Best Use Case | Prototyping, repair, small jobs | High volume, complex geometries |

Dig deeper into automation benefits here: More info about CNC benders.

Why Expert Consultation Is Non-Negotiable

Every application brings its own mix of alloy, wall thickness, bend radius, and production target. Hines’ engineers evaluate your prints, recommend custom tooling, and even fine-tune bend parameters before the machine ships. That’s our Customer First Promise in action.

Certifications & Quality Standards

While many buyers focus on ISO 9001:2015 or similar frameworks, Hines has long accepted the same continuous-improvement philosophy behind those certifications. Our machines routinely meet NASA and U.S. Government specs – an assurance few manufacturers can claim.

Experience & Reputation Matter

With the highest number of bender installations worldwide, Hines delivers NASA-level expertise to shops of any size. Add comprehensive operator instruction from our Tube and Pipe Bender Training program, and you have a partner committed to your long-term success.

Frequently Asked Questions about Tube Benders in Florida

When businesses across Florida consider investing in tube benders, they often have similar questions. With nearly five decades of experience, we’ve compiled answers to some of the most common inquiries.

What is the typical cost range for industrial tube benders in Florida?

The investment for a tube bender can range from a few hundred dollars for a basic manual model to over a million for a highly specialized CNC system. The key is to consider the long-term return on investment (ROI). A higher-quality machine from Hines Bending can pay for itself through reduced material waste, faster production, and lower maintenance costs, offering superior value over its lifespan. We also offer custom solutions, which you can learn more about on our Custom Bending Machine Makers in South Florida page.

How do I ensure the bender can handle my specific materials and bend complexity?

This is where our expertise is crucial. We begin with a thorough analysis of your application, considering the materials you use, their wall thickness, and the complexity of the bends required. Whether you need a CNC mandrel bender for tight, wrinkle-free bends or an induction bender for large, heavy-duty materials, we will recommend the right machine and custom tooling to meet your exact specifications.

Are there specific maintenance requirements for tube benders in Florida’s humid climate?

Yes, Florida’s humidity and salt air require special attention to prevent corrosion and ensure longevity. Regular cleaning, proper lubrication, and protecting electrical components are key. Our machines are built to withstand these conditions, and we provide detailed maintenance guidelines to keep your equipment running smoothly for years. Our support team is always available to offer advice custom to your specific environment.

Conclusion: Your Premier Partner for Florida Bending Machine Manufacturing

When it comes to tube benders in Florida, making the right choice means finding a partner who understands your business. Whether you’re in aerospace, marine manufacturing, or any other industry that demands precision, you need more than just a machine—you need expertise, reliability, and a commitment to your success.

At Hines Bending Systems, we are the #1 worldwide manufacturer of tube and pipe benders, with nearly five decades of experience and the most bender installations globally. Our track record includes supplying machines to some of the world’s most demanding clients, including NASA and the U.S. Government. When your components must meet the highest standards, you can’t afford to compromise on quality.

We understand the unique challenges of Florida’s industrial landscape and specialize in customized solutions custom to your specific requirements. Our commitment extends beyond the sale, with comprehensive training, ongoing support, and maintenance services to ensure your operations run smoothly.

Ready to experience the Hines difference? Contact the experts for the best bending machines for sale and find why businesses across Florida trust us with their most critical bending applications.