Why Advanced CNC Machines Are Changing Modern Manufacturing

Advanced CNC machines represent the cutting edge of manufacturing technology, combining multiple axes of movement, intelligent control systems, and precision capabilities that can achieve tolerances within ±0.001 mm. These sophisticated systems go far beyond traditional 3-axis machines to deliver unprecedented accuracy and efficiency.

Key Features of Advanced CNC Machines:

- 5-axis and multi-axis capabilities for complex geometries in single setups

- Hybrid additive/subtractive processes combining 3D printing with precision machining

- AI-driven control systems with real-time error compensation

- High-speed spindles reaching up to 100,000 RPM

- Smart integration with IoT sensors and robotic automation

The manufacturing landscape has evolved dramatically. Where standard CNC machines once required multiple setups and lengthy cycle times, advanced systems now complete complex parts in single operations. Research shows that 5-axis CNC machining can reduce machining time by up to 84% for complex components, while AI-driven compensation algorithms reduce error rates by up to 50%.

These machines excel at processing challenging materials from titanium and Inconel superalloys to advanced composites and ceramics. Industries like aerospace, medical device manufacturing, and automotive rely on their ability to maintain micron-level precision while handling the most demanding geometries.

Easy advanced CNC machines glossary:

What Are Advanced CNC Machines?

Advanced CNC machines bring unprecedented sophistication to modern manufacturing—a level that seemed impossible just a decade ago. These remarkable systems integrate multiple axes of movement—typically 5, 7, or even 12 axes—creating precision that can tackle complex geometries in a single setup with tolerances as tight as ±0.001 mm.

What makes them truly “advanced” isn’t just their extra axes. Modern systems feature hybrid additive/subtractive processes that combine 3D printing with precision machining, creating parts that were previously impossible to manufacture. AI-powered control systems continuously monitor and adjust every movement, while high-speed spindles spinning at up to 100,000 RPM deliver incredible surface finishes.

Key Differences vs. Standard Systems

The difference between standard and advanced CNC machines is like comparing a bicycle to a Formula 1 race car. Standard 3-axis machines rely on basic open-loop control systems, while advanced systems use sophisticated closed-loop feedback systems with multiple encoders constantly checking position and making micro-adjustments.

Adaptive control technology sets these machines apart. While standard machines cut at predetermined speeds regardless of conditions, advanced systems automatically adjust cutting parameters based on real-time feedback from cutting forces, vibration sensors, and thermal monitors.

Thermal compensation is another game-changer. Advanced systems monitor temperature throughout the machining process and automatically compensate for thermal expansion, maintaining tight tolerances even during marathon production runs.

The control systems represent perhaps the biggest leap forward. Advanced systems integrate seamlessly with sophisticated CAD/CAM software, allowing operators to simulate entire machining processes before cutting begins, optimizing toolpaths for maximum efficiency.

Types & Capabilities: From 5-Axis to Hybrid Systems

The world of advanced CNC machines offers specialized systems, each built to tackle specific manufacturing challenges with remarkable precision. 5-axis machining centers represent the sweet spot for most advanced manufacturing needs, moving simultaneously across five axes to create complex geometries without repositioning parts multiple times.

7-axis machines push boundaries further with additional rotational capabilities, while Swiss-type machines combine turning and milling operations with incredible precision on small components. Mill-turn centers integrate both milling and turning capabilities to complete entire parts in single setups.

High-speed machining centers feature spindle speeds exceeding 30,000 RPM and feed rates over 1,000 inches per minute, particularly valuable for aerospace applications where lightweight materials and complex geometries demand both speed and precision.

| Machine Type | Axes | Key Advantages | Typical Applications |

|---|---|---|---|

| 3-Axis Mill | 3 | Simple programming, cost-effective | Basic parts, prototyping |

| 5-Axis Center | 5 | Single-setup complex parts, 84% time reduction | Aerospace, medical, automotive |

| Hybrid AM/CNC | 5+ | Additive + subtractive, 40% waste reduction | Prototypes, complex assemblies |

5-Axis Powerhouses and Beyond – advanced CNC machines

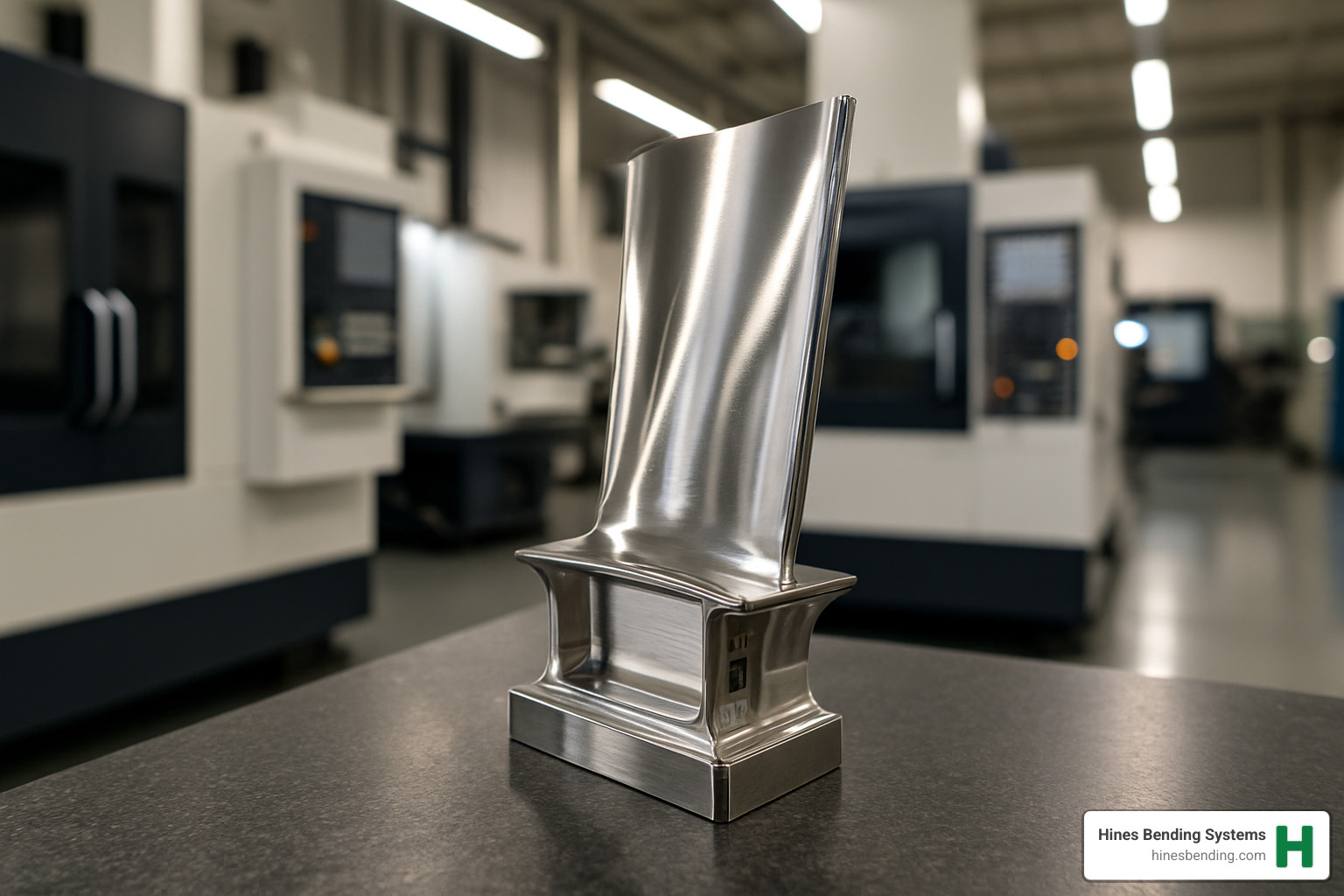

The magic of 5-axis machining lies in its ability to reach virtually any surface of a workpiece without manual repositioning. This simultaneous motion across five axes enables manufacturers to create incredibly complex geometries like turbine blades, impellers, and medical implants in single setups.

Research demonstrates that 5-axis systems can reduce machining time by up to 84% for complex parts compared to conventional 3-axis approaches. This improvement comes from eliminating multiple setups, reducing fixture requirements, and enabling more efficient toolpaths.

6-axis and 7-axis machines take this flexibility even further, handling parts with deep cavities, undercuts, and complex angular features that would challenge even advanced 5-axis machines.

Hybrid Additive/Subtractive Platforms – advanced CNC machines

Hybrid manufacturing represents one of the most exciting frontiers in advanced CNC machines. These systems combine additive manufacturing (3D printing) with traditional subtractive machining in single, integrated platforms.

The process typically begins with directed energy deposition (DED) or selective laser melting (SLM) to build up material layer by layer. Then, precision CNC machining achieves final tolerances and surface finishes. Scientific research on hybrid CNC systems shows these platforms can reduce material waste by 40% while improving production speed by 30%.

Hybrid systems excel at creating parts with internal cooling channels, complex lattice structures, and geometries impossible with traditional manufacturing alone. This approach has transformed turbine blade manufacturing, where internal cooling channels can now be printed directly into the part structure.

Technology Foundations That Drive Micron-Level Accuracy

Behind every advanced CNC machine achieving incredible precision lies sophisticated technologies working in perfect harmony. At the conductor’s podium sits the advanced controller, processing thousands of position calculations every second while coordinating movement across multiple axes with precise synchronization.

The mechanical foundation starts with premium ball screws and linear motors that deliver positioning accuracy within 0.005 mm, while linear motors eliminate backlash that plagues traditional drive systems. High-resolution encoders provide continuous feedback on actual position, creating closed-loop control that automatically corrects for any deviations.

The real game-changer is AI-driven error compensation. These intelligent systems continuously monitor machining conditions and automatically adjust parameters to maintain optimal performance, tracking spindle speed, temperature, vibration, and cutting forces in real-time. Research shows this technology reduces error rates by up to 50% compared to conventional control systems.

Thermal compensation monitors temperature throughout the entire machine structure and automatically adjusts for thermal expansion and contraction, keeping everything dimensionally stable during long production runs.

Smart Software & Programming Evolution

The software revolution has transformed how we program advanced CNC machines. Modern CAD/CAM systems integrate seamlessly with machine controls, enabling direct transfer of part geometry into optimized toolpaths.

Tool-path simulation creates digital twins that accurately model machine behavior, cutting forces, and material removal rates. Programmers can optimize entire processes in virtual environments, eliminating trial-and-error and minimizing material waste.

G-code optimization algorithms automatically adjust feeds, speeds, and toolpaths for maximum efficiency while maintaining quality requirements. AI-powered systems analyze part geometry, material properties, and quality requirements to automatically generate optimized machining strategies.

This sophistication extends beyond traditional machining. More info about CNC Bending Machine shows how advanced programming capabilities transform specialized applications like tube and pipe bending.

At Hines Bending Systems, we understand that precision manufacturing starts with the right technology. Our expertise in advanced CNC systems, combined with our track record of supplying NASA and other demanding customers, means we know what it takes to achieve impossible tolerances and complex geometries.

Material Mastery & Industry Applications

The world of manufacturing has been transformed by what advanced CNC machines can accomplish with materials that used to challenge engineers. Today’s sophisticated systems handle titanium alloys with finesse, maintaining precise control over cutting parameters to prevent work hardening that plagued earlier attempts.

Inconel and other superalloys present unique challenges, but advanced CNC machines maintain consistent cutting conditions through adaptive control systems that adjust parameters based on real-time feedback. Composite materials require gentle precision to avoid delamination or fiber pullout—exactly what advanced systems provide.

That 84% reduction in cycle time achieved by advanced 5-axis systems becomes even more valuable when working with expensive materials like titanium or Inconel. Single-setup machining means less material handling, minimal scrap, and consistent quality.

Tackling Hard & Brittle Materials

Polycrystalline diamond (PCD) and cubic boron nitride (CBN) tooling provide the hardness needed for challenging materials, but success requires the rock-solid stability that advanced machine control systems deliver.

Cryogenic cooling applies liquid nitrogen directly to the cutting zone, achieving surface finishes below 0.1 μm while dramatically extending tool life. Laser-assisted machining preheats material just ahead of the cutting tool, with advanced systems enabling perfect synchronization between laser and cutting tool.

Real-World Success Stories

Advanced CNC machines have impressive real-world applications. In aerospace manufacturing, turbine blades with complex internal cooling channels are now produced in single setups using 5-axis machines, achieving tolerances within ±0.001 mm.

Medical device manufacturing has been revolutionized by these precision capabilities. Hip implants machined from titanium achieve sub-micron accuracy with surface finishes below 0.1 μm, ensuring perfect anatomical fit and biocompatibility.

The automotive industry has acceptd these technologies for engine components, with some installations demonstrating 300% productivity improvements.

Just as advanced CNC machines have transformed manufacturing across industries, specialized applications like tube and pipe bending require their own precision solutions. At Hines Bending Systems, we’ve perfected precision bending, working with clients from NASA to major automotive manufacturers. Our expertise in advanced bending technologies ensures complex geometries can be achieved whether machining or bending components.

Smart Integrations & The Future of Advanced CNC Machines

The world of advanced CNC machines has become incredibly smart through Internet of Things (IoT) sensors that monitor everything from spindle temperature and vibration to cutting force and tool wear. This constant data flow enables predictive maintenance strategies that catch problems before expensive downtime occurs.

Robotic automation has created lights-out production cells that work around the clock, combining robotic systems for workpiece loading, tool changes, and quality inspection while CNC machines focus on precision machining. These systems connect globally through cloud-based networks, enabling real-time quality management across multiple locations.

GREENMODE technology has demonstrated potential for reducing energy consumption by over 30%, making these systems both smarter and more sustainable.

At Hines Bending Systems, we understand how smart integrations apply to specialized bending applications. Our CNC bending machines incorporate similar intelligent monitoring and control systems, ensuring the precision and reliability that clients like NASA depend on.

Emerging Trends to Watch

The future of advanced CNC machines is heading toward nanometer-level precision through advanced feedback systems and environmental control. Autonomous machining represents the ultimate goal—machines that can analyze part requirements, select optimal tooling and parameters, and execute complete operations without human programming.

The focus on sustainability is driving innovations across the board. Future systems will integrate environmental considerations directly into control algorithms, optimizing for both performance and environmental impact. Cloud-based CAM systems enable more sophisticated programming capabilities, while new superalloys continue to challenge conventional approaches.

This technological evolution mirrors what we’re seeing in specialized bending applications. At Hines Bending Systems, our continuous innovation in areas like Dual Stack CNC Push Benders and Roll Benders addresses growing industry demands. With our expertise serving clients like NASA and our position as the worldwide leader in bending machine installations, we’re uniquely positioned to help manufacturers steer these advancing technologies.

Maintenance, Programming & Operational Excellence

Keeping advanced CNC machines running at peak performance requires precision, expertise, and deep understanding of sophisticated systems. Predictive maintenance has revolutionized machine care—instead of waiting for failures, modern machines continuously monitor themselves through vibration analysis, temperature tracking, and performance data collection.

The lubrication systems use specialized lubricants applied at exact intervals to maintain incredible accuracy for micron-level tolerances. Calibration procedures have evolved into sophisticated routines that verify positioning accuracy across all axes simultaneously, with modern systems running automated sequences that check and adjust for positioning drift.

Tool management represents another critical aspect. These machines often operate with automatic tool changers containing 40, 80, or even 200+ specialized cutting tools. Advanced tool management systems track every tool’s usage history, predict remaining tool life, and automatically schedule tool changes to minimize production interruptions.

Software updates and system optimization require ongoing attention from skilled technicians who understand both mechanical and digital aspects. Regular calibration of feedback systems ensures machine accuracy matches actual performance.

At Hines Bending Systems, we understand this complexity intimately. While our expertise centers on the world’s most advanced bending systems, we work with clients who integrate our benders into comprehensive manufacturing cells alongside advanced CNC machines. Our experience supplying precision bending solutions to NASA has taught us the importance of comprehensive training and ongoing support.

More info about CNC Tube Benders shows how specialized CNC applications require custom maintenance approaches that account for unique stresses and operating conditions.

Operator training has transformed from basic machine operation to comprehensive system management. Today’s operators must understand data interpretation, predictive maintenance indicators, and system optimization principles. The most successful operations implement 24/7 monitoring systems that track machine performance continuously, detecting anomalies and optimizing cutting parameters automatically.

Frequently Asked Questions about advanced CNC machines

How do advanced CNC machines achieve such high precision?

The incredible precision of advanced CNC machines comes from technologies working together seamlessly. Feedback encoders provide position information accurate to fractions of a micron, monitoring where every axis is positioned thousands of times per second.

Closed-loop control systems continuously compare where the machine should be with where it actually is, making instant corrections. Thermal control monitors temperature throughout the machine structure and automatically compensates for thermal expansion, keeping everything dimensionally stable during long production runs.

AI tuning represents the latest breakthrough, with intelligent systems analyzing machining data patterns and automatically fine-tuning parameters to maintain optimal performance.

Which materials can I machine without excessive tool wear?

Aluminum alloys are the friendly materials of machining—they cut easily, produce excellent surface finishes, and are gentle on standard carbide tooling. Steel alloys require more finesse, with cutting parameters carefully custom to specific compositions.

Superalloys and composites represent the ultimate challenge. Materials like Inconel and titanium demand specialized tooling—ceramic or CBN inserts—along with precisely controlled cutting conditions. Advanced machines excel here because they maintain exact conditions throughout the entire process.

Ceramics need the gentlest touch, requiring diamond tooling and ultra-precise cutting strategies. The exceptional control available in advanced systems enables the delicate cutting action necessary to prevent chipping in these brittle materials.

How is IoT changing CNC shop floors?

IoT integration is revolutionizing advanced CNC machines, changing traditional shop floors into smart, connected manufacturing environments. Real-time data collection from sensors provides unprecedented visibility into production, monitoring everything from spindle temperature to tool wear.

Predictive maintenance analyzes data patterns to predict when maintenance is needed, preventing failures before they occur and dramatically reducing unplanned shutdowns. Remote dashboards allow managers to monitor entire operations from anywhere, enabling immediate response to issues.

The most exciting development is machine learning integration—smart systems that automatically adjust cutting parameters, schedule maintenance, and predict quality issues before parts are completed.

Just as Hines Bending Systems has revolutionized tube and pipe bending with advanced CNC-controlled systems, the broader manufacturing industry continues evolving through smart integrations and predictive technologies.

Conclusion

The revolution in advanced CNC machines has fundamentally changed what’s possible in precision manufacturing. We’ve seen how 5-axis systems can slash machining time by 84%, while hybrid additive/subtractive platforms reduce material waste by 40%. These aren’t just impressive numbers—they represent real solutions that are changing industries from aerospace to medical device manufacturing.

The integration of AI-driven control systems, IoT connectivity, and advanced materials processing has created manufacturing solutions that deliver precision within ±0.001 mm while handling the most challenging materials. From titanium turbine blades to complex medical implants, these technologies have made the impossible routine.

At Hines Bending Systems, we bring this same spirit of precision and innovation to the specialized world of tube and pipe bending. As the world’s #1 manufacturer of tube benders, pipe benders, and induction benders, we understand that advanced manufacturing extends far beyond traditional machining. Our expertise serves the most demanding applications—the same NASA-grade precision that defines advanced CNC technology drives every bending solution we create.

With the highest number of bender installations worldwide, we’ve developed best expertise in creating customized solutions that meet the exacting requirements of modern manufacturing. Whether you need precision tube bending for hydraulic systems, structural components for aerospace applications, or complex pipe assemblies for industrial processes, our team works closely with you to develop the optimal solution.

Just as advanced CNC machines have revolutionized traditional machining through their combination of precision, speed, and intelligence, our innovative bending solutions continue to push the boundaries of what’s possible in tube and pipe fabrication. We’ve built our reputation by supplying massive agencies and companies like NASA, where precision isn’t just preferred—it’s absolutely critical.

The future belongs to manufacturers who accept advanced technologies while maintaining an unwavering focus on precision, quality, and customer service. When your next project demands the highest levels of precision and reliability, partner with the industry leaders who understand both the technology and the application.

Contact Hines Bending Systems to find how our advanced bending solutions can transform your manufacturing capabilities. Let our decades of expertise work for your most challenging projects.

More info about CNC Bending Machine – Advantages of CNC Tube Bending Machine for Sale