NC pipe bending machine for sale is a phrase that resonates with those seeking efficiency and precision in tube and pipe bending tasks. If this caught your eye, you’re likely in search of machinery that merges automation with reliability, especially for small to medium production environments. Here’s what you need to know:

- Efficiency: NC machines offer a semi-automatic solution, making them ideal for operations that demand accurate, repetitive bending.

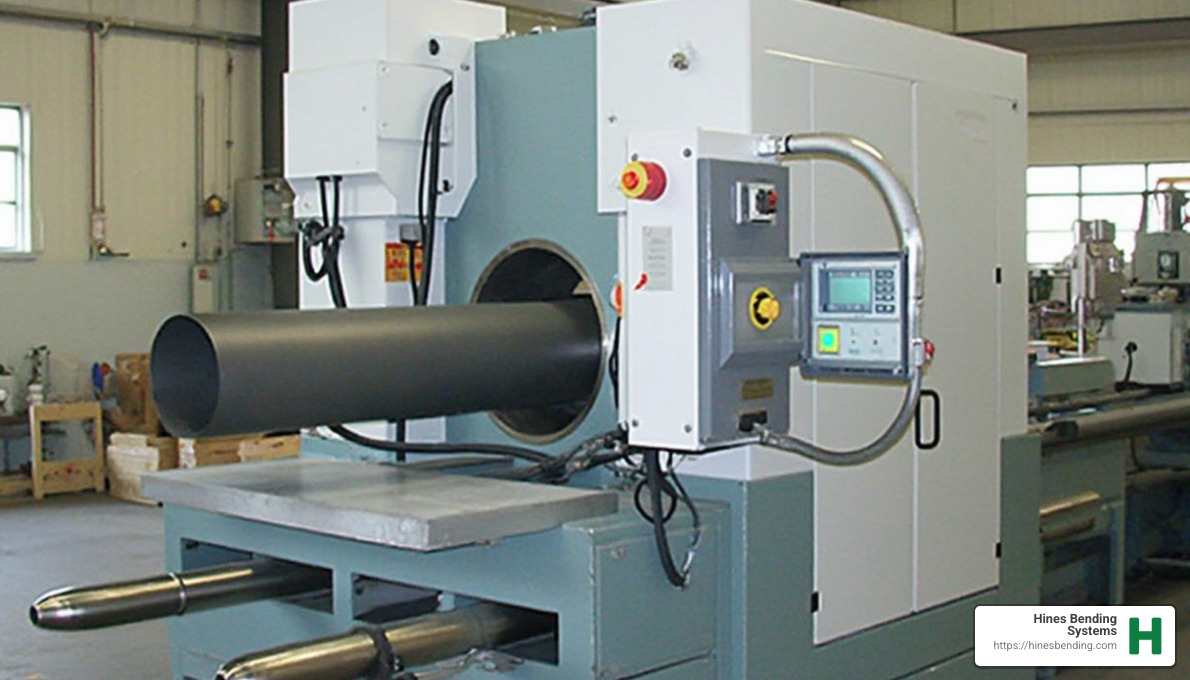

- Technology: These machines feature a blend of electric and hydraulic systems, ensuring precise and powerful bending.

- Custom Solutions: Hines Bending Systems provides custom machines that cater to specific industrial needs, standing out as a leader in innovation and reliability.

- Support and Training: Comprehensive support and employee training ensure you get the most out of your investment.

As the world’s #1 tube bender manufacturer, Hines Bending Systems brings unparalleled experience and expertise to the table. Their dedication to quality assurance, customer-centric solutions, and cutting-edge technology makes them the go-to choice for anyone in need of robust bending machinery.

Why Choose Hines Bending Systems?:

- Industry Leader: Trusted by major agencies like NASA for top-tier bending solutions.

- Custom Solutions: Machines that meet exact specifications and unique industry needs.

- Innovative Technology: State-of-the-art equipment like the Dual Stack CNC Push Bender.

- Customer Satisfaction: Consistently providing stellar support and training programs.

For more information on how a Hines NC pipe bending machine can revolutionize your production line, consider reaching out today. With a blend of superior craftsmanship and dedicated support, your production needs are in experienced hands.

Know your nc pipe bending machine for sale terms:

– electric nc tube bending machine

– nc bending machine

Understanding NC Pipe Bending Machines

When it comes to achieving precision in pipe and tube bending, NC pipe bending machines stand out as a crucial tool in the industry. These machines, known for their semi-automatic capabilities, offer a perfect balance between manual operation and automation, making them ideal for small to medium-sized production environments.

NC Tube Bending: A Closer Look

NC, or numerically controlled, pipe bending machines are designed to provide consistent and accurate bends with minimal manual intervention. Unlike fully manual machines, NC benders allow operators to input specific bend angles and sequences into the machine’s control unit. This results in precise bends that are repeatable, reducing the risk of human error and material wastage.

The Semi-Automatic Advantage

The semi-automatic nature of NC machines means that while the bending process is automated, the loading and unloading of pipes are typically done manually. This setup offers several advantages:

-

Cost-Effectiveness: NC machines are generally more affordable than fully automated CNC machines, making them a great choice for businesses looking to optimize their budget without sacrificing quality.

-

Ease of Use: With a straightforward interface and programmable settings, operators can quickly learn to use NC machines, reducing training time and increasing productivity.

Precision in Bending

Precision is a hallmark of NC pipe bending machines. The combination of hydraulic and electric systems ensures that each bend is executed with accuracy, maintaining the integrity of the pipe or tube. This precision is crucial for industries where exact specifications are non-negotiable, such as automotive, aerospace, and construction.

In summary, NC pipe bending machines from Hines Bending Systems offer a reliable, efficient, and cost-effective solution for businesses seeking high-quality bending capabilities. With their semi-automatic operation, these machines provide the perfect blend of precision and practicality, making them an indispensable tool in the manufacturing world.

Key Features of NC Pipe Bending Machines

When considering an NC pipe bending machine for sale, understanding the key features that set them apart is essential. Hines Bending Systems’ NC machines are designed to provide exceptional performance and precision, making them a top choice for industries requiring tight tolerances and efficient production.

Tight Radius Bending

One of the standout features of Hines’ NC pipe bending machines is their ability to achieve tight radius bends. This capability is crucial for applications where space is limited or specific design requirements must be met. By utilizing advanced hydraulic technology and precise control systems, these machines can bend pipes and tubes to a tight radius without compromising the material’s integrity. This is particularly important in industries such as automotive and aerospace, where precision and compact design are critical.

Thin Wall Bending

Another significant feature of Hines’ NC machines is their proficiency in handling thin wall materials. Thin-walled pipes and tubes are often used in applications where weight reduction is a priority. Hines Bending Systems ensures that their NC machines can bend these materials without causing deformation or wrinkling. This is achieved through a combination of innovative design and robust engineering, allowing businesses to maintain high-quality standards while meeting specific design criteria.

Hydraulic Motor Power

The hydraulic motor power in Hines’ NC pipe bending machines provides the necessary force to bend a wide range of materials, including steel, stainless steel, aluminum, and brass. The powerful hydraulic system ensures consistent performance, even with thicker materials or larger diameters. This versatility makes Hines’ machines a valuable asset for any production line, capable of adapting to various materials and bending requirements.

In conclusion, Hines Bending Systems’ NC pipe bending machines offer best precision and versatility, thanks to their ability to handle tight radius and thin wall bending effectively. Combined with their robust hydraulic motor power, these machines are designed to meet the demanding needs of modern manufacturing, ensuring high-quality results every time.

Benefits of Using NC Pipe Bending Machines

When it comes to fulfilling your production needs, Hines Bending Systems stands out as the industry leader. Their NC pipe bending machines are designed with precision and efficiency in mind, making them an ideal choice for businesses looking to improve their production capabilities.

Customization

One of the key benefits of using Hines’ NC machines is their adaptability to different production requirements. These machines are engineered to accommodate a wide range of materials, including steel, stainless steel, aluminum, and brass. This flexibility ensures that businesses can customize their bending processes to suit specific project needs, whether it’s for automotive, aerospace, or any other industry requiring precise bends.

Quality Assurance

Hines Bending Systems places a strong emphasis on quality assurance, ensuring that every machine meets the highest industry standards. The robust construction and advanced technology of their NC pipe bending machines guarantee consistent, high-quality results. This commitment to quality means that businesses can trust Hines’ machines to deliver reliable performance, reducing the need for costly rework and ensuring customer satisfaction.

By choosing Hines Bending Systems, you’re not just investing in a machine; you’re investing in a partner dedicated to helping you achieve your production goals with custom solutions custom to your needs. With their expertise and experience, Hines provides the assurance that your investment will yield the precision and efficiency required in today’s competitive market.

NC Pipe Bending Machine for Sale: What to Consider

When exploring an NC pipe bending machine for sale, several key factors will help you make an informed decision. These factors include the machine’s maximum diameter, bending radius, and feeding speed. Let’s break these down for clarity.

Maximum Diameter

The maximum diameter a machine can handle is crucial. It determines the size of pipes you can bend. Hines Bending Systems offers machines capable of bending large diameters, making them suitable for various industries, from construction to automotive. Ensure the machine you choose can accommodate the largest pipe size you anticipate using in your production.

Bending Radius

The bending radius is another critical consideration. It affects the tightness of the bends you can achieve. Hines’ NC machines provide a range of bending radii, allowing for both tight and wide bends. This flexibility is essential for projects that require specific curvature, ensuring that your final product meets exact specifications.

Feeding Speed

Feeding speed impacts the efficiency of your production process. A faster feeding speed means quicker production times, which can significantly improve productivity. Hines Bending Systems’ machines are designed with optimal feeding speeds, balancing speed and precision to ensure high-quality bends without sacrificing efficiency.

Choosing the right NC pipe bending machine involves assessing these factors in the context of your specific production needs. By considering the maximum diameter, bending radius, and feeding speed, you can select a machine that not only meets but exceeds your expectations, ensuring that your investment is both strategic and beneficial.

Frequently Asked Questions about NC Pipe Bending Machines

What is the difference between NC and CNC pipe bending machines?

The difference between NC (Numerically Controlled) and CNC (Computer Numerically Controlled) pipe bending machines mainly lies in their control systems and level of automation.

NC Machines are semi-automatic. They allow operators to program specific bend angles, but require manual repositioning of the pipe between bends. This makes them ideal for projects that don’t require complex bending sequences but still demand precision and reliability. NC machines are cost-effective for small to medium productions.

CNC Machines, on the other hand, are fully automated. They use computer controls to manage multiple axes, allowing for intricate bending sequences without manual intervention. This automation leads to higher efficiency and precision, especially for complex projects with numerous bends.

How do I choose the right NC pipe bending machine for my needs?

Selecting the right NC pipe bending machine requires careful consideration of your production requirements, the material type, and the bending capacity you need.

-

Production Requirements: Evaluate the volume and complexity of your bending projects. For straightforward tasks with moderate production volumes, an NC machine offers a good balance of cost and functionality.

-

Material Type: Consider the materials you’ll be working with. Hines Bending Systems’ NC machines can handle various materials, including steel, aluminum, and brass, ensuring versatility for different projects.

-

Bending Capacity: Match the machine’s bending capacity with your requirements. This includes the maximum pipe diameter and the bending radius you need. Hines offers machines that cater to a wide range of specifications, ensuring you find a perfect fit for your needs.

What maintenance is required for NC pipe bending machines?

Routine maintenance is vital to keep your NC pipe bending machine running smoothly and efficiently.

-

Regular Checks: Perform regular inspections to identify and address wear and tear. This includes checking hydraulic systems, electrical connections, and mechanical components.

-

Replacement Parts: Keep a stock of essential replacement parts. Hines Bending Systems provides high-quality parts and support to ensure minimal downtime.

-

Technical Support: Use technical support for troubleshooting and repairs. Hines offers robust support services, ensuring any issues are promptly resolved, keeping your production line moving.

By understanding these aspects of NC pipe bending machines, you can make informed decisions that improve your production capabilities and ensure long-term operational success.

Conclusion

At Hines Bending Systems, we pride ourselves on delivering the highest quality NC pipe bending machines that meet the diverse needs of our clients. Our expertise and experience in the industry are best, making us the go-to choice for businesses looking for reliable and efficient bending solutions.

Our commitment to custom solutions ensures that each machine is custom to the specific requirements of your production line. Whether you’re dealing with simple bends or complex sequences, our machines are designed to handle a variety of materials and dimensions with precision.

Quality assurance is at the core of our operations. Each machine undergoes rigorous quality checks to ensure it meets industry standards and delivers consistent performance. This focus on quality, combined with our innovative technology and comprehensive support, ensures that you receive the best possible solution for your bending needs.

We understand that investing in a bending machine is a significant decision. That’s why we offer robust training and support services to help you maximize the efficiency and lifespan of your machine. Our team of experts is always ready to provide assistance, ensuring that your operations run smoothly with minimal downtime.

Choosing Hines Bending Systems means choosing a partner dedicated to your success. With our extensive expertise, innovative solutions, and customer-centric approach, we are here to help you achieve optimal results in your bending operations.

Find how our NC pipe bending machines can transform your production process. Visit our NC Bending Machine page to learn more and get started with the best in the industry.