Why Pipe Bending Machines Are Essential for Modern Manufacturing

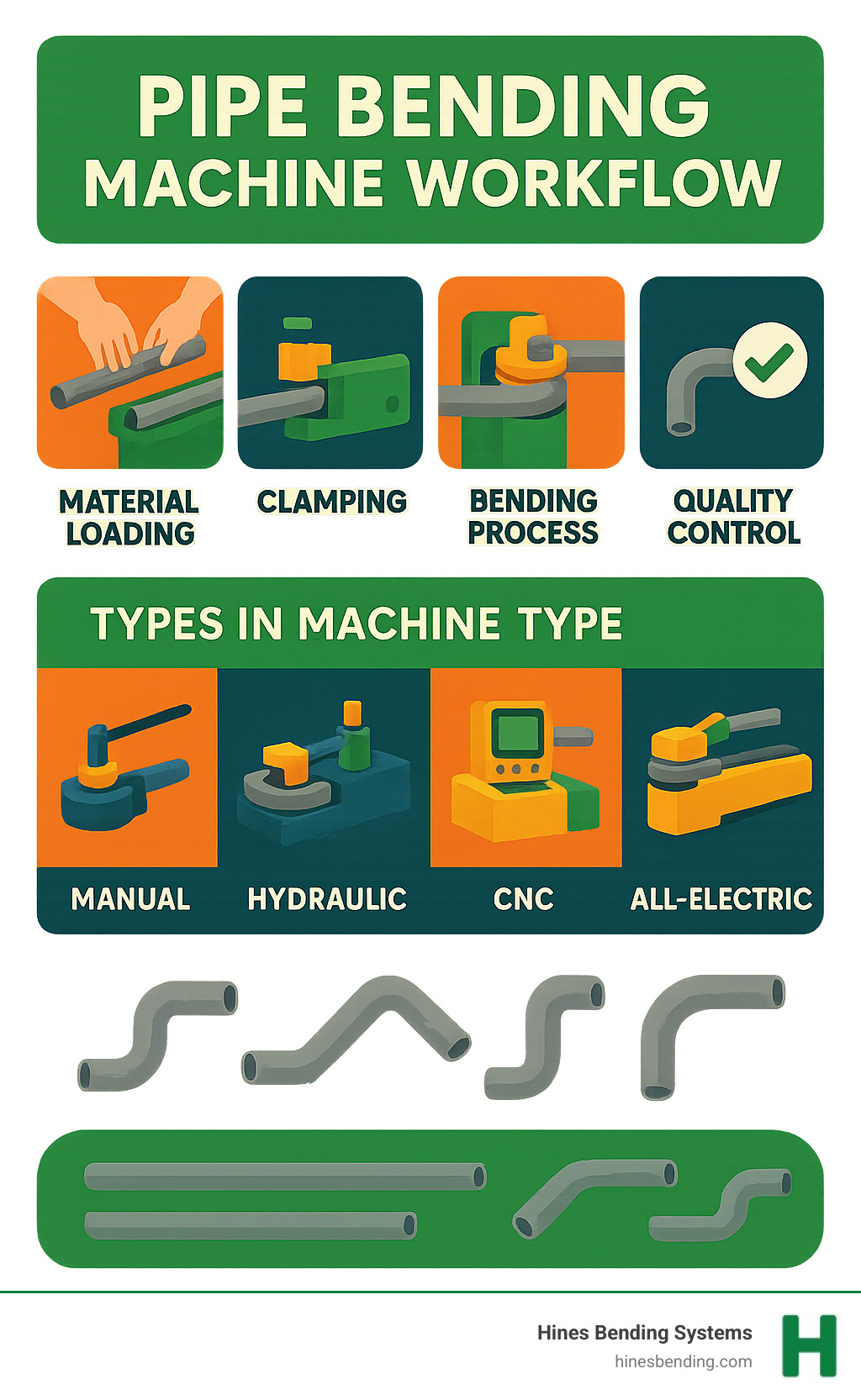

Pipe bending machines are specialized manufacturing equipment that shape tubes and pipes into precise angles and curves without compromising material integrity. These machines use various technologies – from manual hydraulic systems to advanced CNC automation – to bend materials like steel, aluminum, and stainless steel for industries ranging from automotive to aerospace.

Quick Overview: Types of Pipe Bending Machines

- Manual Benders: Hand-operated systems for simple bends and low-volume work

- Hydraulic Machines: High-force bending for thick-wall materials and heavy-duty applications

- CNC Systems: Computer-controlled precision for complex, repeatable bends

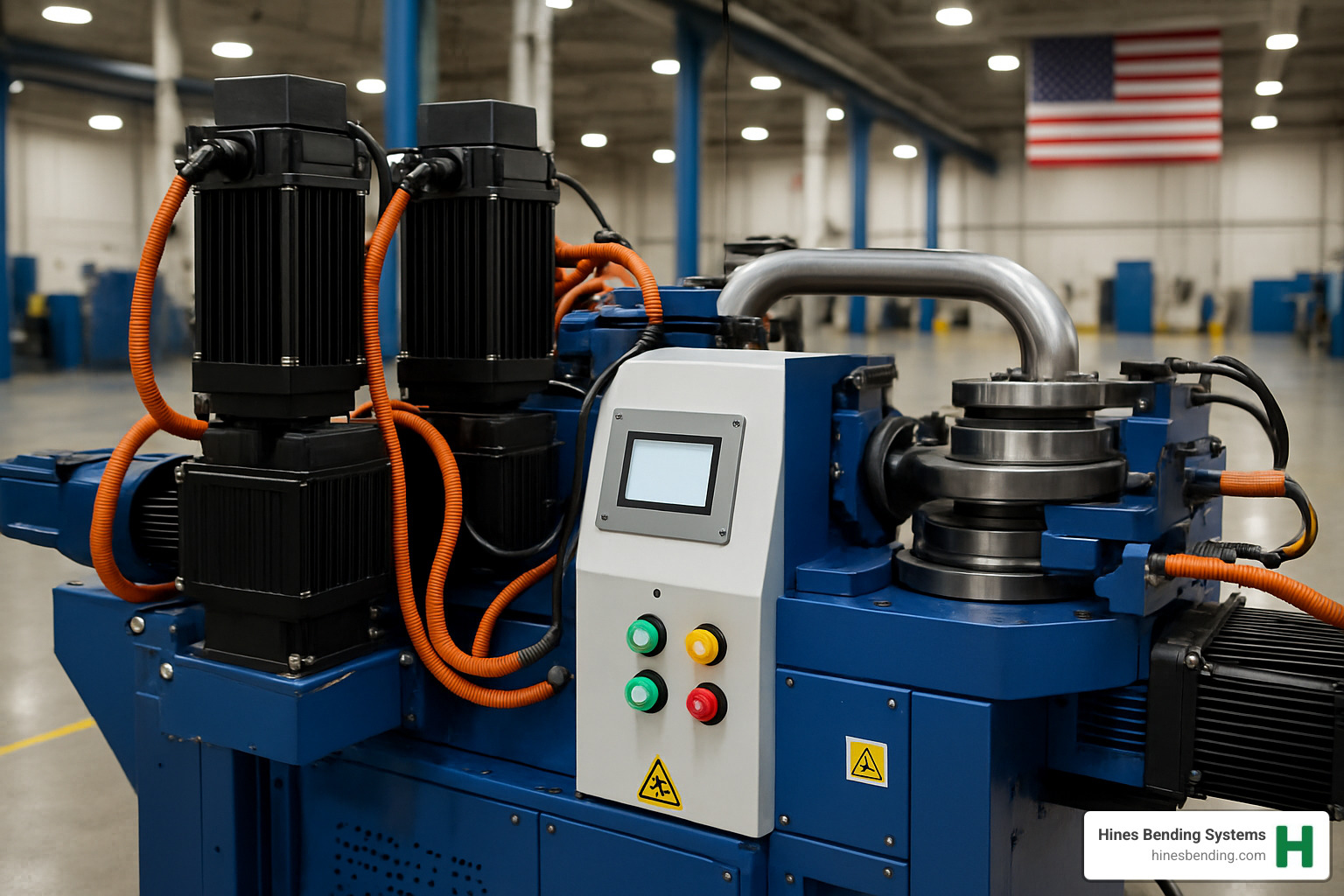

- All-Electric Models: Energy-efficient servo-driven machines with superior accuracy

- Induction Benders: Heat-assisted bending for large diameter and thick-wall pipes

The pipe bending industry has evolved dramatically from simple manual tools to sophisticated CNC systems that can achieve “first part right” production. Modern machines can handle tube diameters from 4mm up to 330mm, with some specialized systems processing pipes up to 12 3/4 inches in diameter.

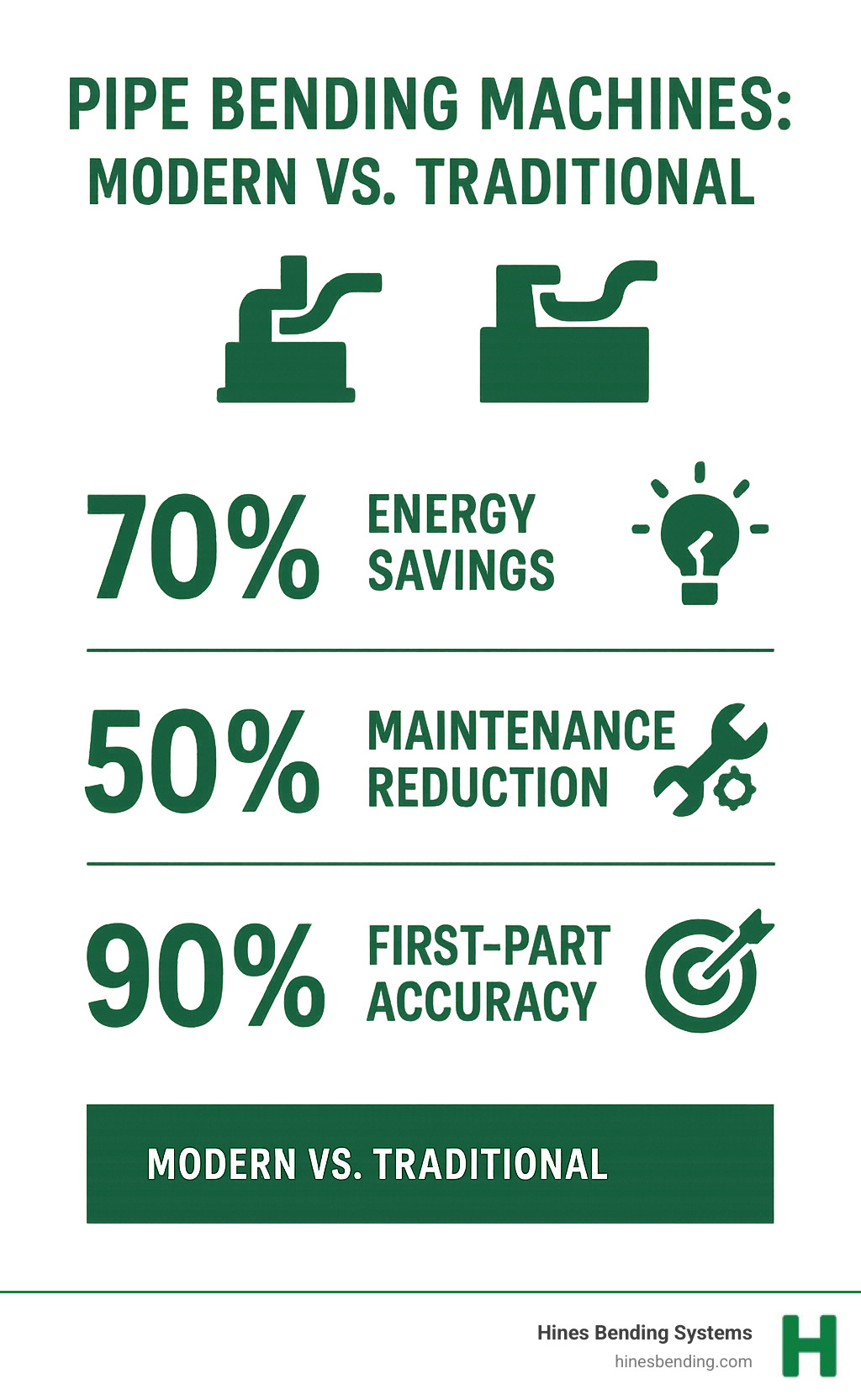

Energy efficiency has become a major advantage – all-electric tube bending machines can reduce energy consumption by up to 70% compared to traditional hydraulic systems.

As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, Hines Bending Systems has supplied advanced bending solutions to major organizations including NASA. With decades of expertise, Hines works closely with clients to provide custom bender solutions that meet specific production requirements and quality standards.

Why This Guide Matters

The global pipe bending market continues to expand as manufacturers seek more efficient production methods. Whether you’re exploring pipe bending machines for the first time or evaluating upgrades to existing equipment, understanding the available technologies and their capabilities is crucial for making informed decisions.

This guide provides the comprehensive information needed to steer the complex world of pipe bending technology, helping you identify the optimal solution for your specific manufacturing needs.

Understanding Pipe Bending Machines

The story of pipe bending machines is really a tale of human ingenuity. What started as simple manual tools has evolved into some of the most sophisticated manufacturing equipment you’ll find in modern factories. At Hines Bending Systems, we’ve been part of this incredible journey for decades, helping shape an industry that now serves everyone from NASA to your local HVAC contractor.

Modern pipe bending machines rely on three critical elements working in perfect harmony. First, you need rock-solid support for the material during the bending process. Second, you must have precise control over how the material deforms. And third – perhaps most importantly – you need to prevent defects like wall thinning or that dreaded ovality that can ruin an entire production run.

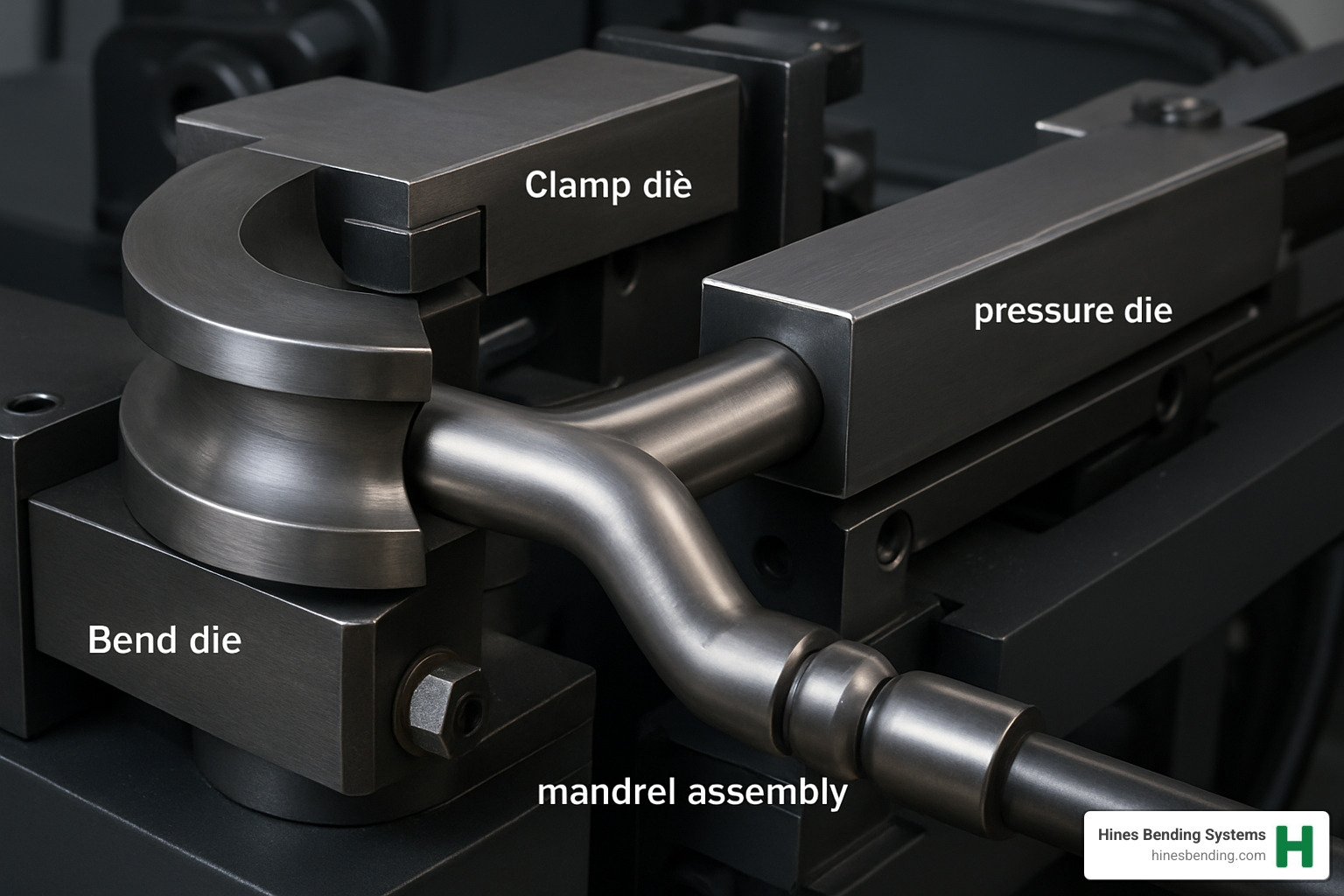

The rotary draw bending method has become the gold standard in our industry. This technique uses a fixed line of tangency at the point of bend, which gives you incredible control over material flow. It’s the kind of precision that has made Hines Bending Systems the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders.

How Pipe Bending Machines Work

The magic really happens when you watch a modern pipe bending machine in action. The process begins with the pipe being precisely clamped against a bend die that defines your desired radius. Meanwhile, a pressure die applies opposing force to control exactly how the material flows during the bend.

As the bend die rotates to form the curve, this coordinated dance ensures your material bends smoothly without buckling or distortion. For those tricky applications requiring tight radii or thin-wall materials, the mandrel becomes your best friend. This internal support system prevents the pipe from collapsing inward while maintaining that perfect cross-sectional shape you need.

The real sophistication shows up in the control systems. Today’s pipe bending machines can store multiple bend programs, automatically compensate for material springback, and adjust parameters on the fly based on material properties and bend requirements.

Mandrel vs. Non-Mandrel Bending

Non-mandrel bending works beautifully for larger diameter pipes with relatively thick walls. The material has enough inherent strength to resist collapse during bending, which means faster cycle times and lower tooling costs.

Mandrel bending becomes essential when you’re working with thin-wall materials, need to achieve tight bend radii, or must maintain precise cross-sectional dimensions. The mandrel provides that crucial internal support that prevents wall thinning and ovality.

The beauty of working with Hines Bending Systems is that we don’t just sell you a machine and walk away. We work closely with each client to determine the optimal approach for their specific applications. When you need more information about mandrel bending services, you’re tapping into best industry knowledge.

Main Types and Technologies

When you’re looking for the perfect pipe bending machines for your operation, understanding the different technologies helps you find exactly what you need.

Manual bending machines are still incredibly valuable for prototype work and custom jobs where you need that human touch. Hydraulic systems are the workhorses when you need serious force to bend thick-wall materials or large diameter pipes. Electric and servo-driven systems represent the cutting edge, offering incredible precision while using far less energy than traditional systems.

CNC and NC systems take automation to the next level, removing the guesswork from complex bends. This is where you see that “first part right” capability that manufacturers love.

At Hines Bending Systems, we’ve watched this evolution firsthand. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we’ve not only kept pace with these advances – we’ve helped drive them. Our experience with major clients like NASA has pushed us to perfect every type of bending technology available.

CNC vs. NC vs. Manual Pipe Bending Machines

CNC (Computer Numerical Control) systems are like having a master craftsman who never has a bad day. These machines store multiple bend programs, automatically adjust for material springback, and handle complex multi-axis bends without breaking a sweat. Our CNC Bending Machine solutions showcase exactly what this technology can achieve.

NC (Numerical Control) systems offer a sweet spot between automation and simplicity. They give you programmable precision without the complexity of full CNC systems.

Manual systems still have their place, especially when flexibility matters most. These machines shine in prototype development and small batch work where you might need to make adjustments on the fly.

Hydraulic vs. All-Electric Systems

Hydraulic systems are the powerhouses that built this industry. When you absolutely need maximum bending force for thick-wall materials or large diameter pipes, hydraulic power delivers without compromise.

All-electric systems represent the future we’re already living in. The energy savings alone are impressive – up to 70% less power consumption compared to hydraulic systems. These machines run quieter, cleaner, and with precision that surpasses traditional hydraulic systems.

Dual-Head & Induction Pipe Bending Machines

Dual-head systems are productivity game-changers. Imagine creating complex S-bends, U-bends, and intricate geometries in a single setup instead of multiple operations.

Induction bending takes a completely different approach to challenging applications. By precisely heating the material at the point of bend, we can handle pipe sizes and wall thicknesses that would be impossible with cold bending. We’re talking about pipes up to 12 3/4 inches in diameter.

Hines Bending Systems pioneered much of the induction bending technology used today. Our induction benders combine precision heating control with advanced bending mechanics in ways that our clients often tell us they didn’t think were possible.

Applications, Materials, and Industry Use Cases

The remarkable versatility of modern pipe bending machines has made them indispensable across virtually every manufacturing sector. At Hines Bending Systems, we’ve had the privilege of seeing our machines work across an incredible range of applications as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders.

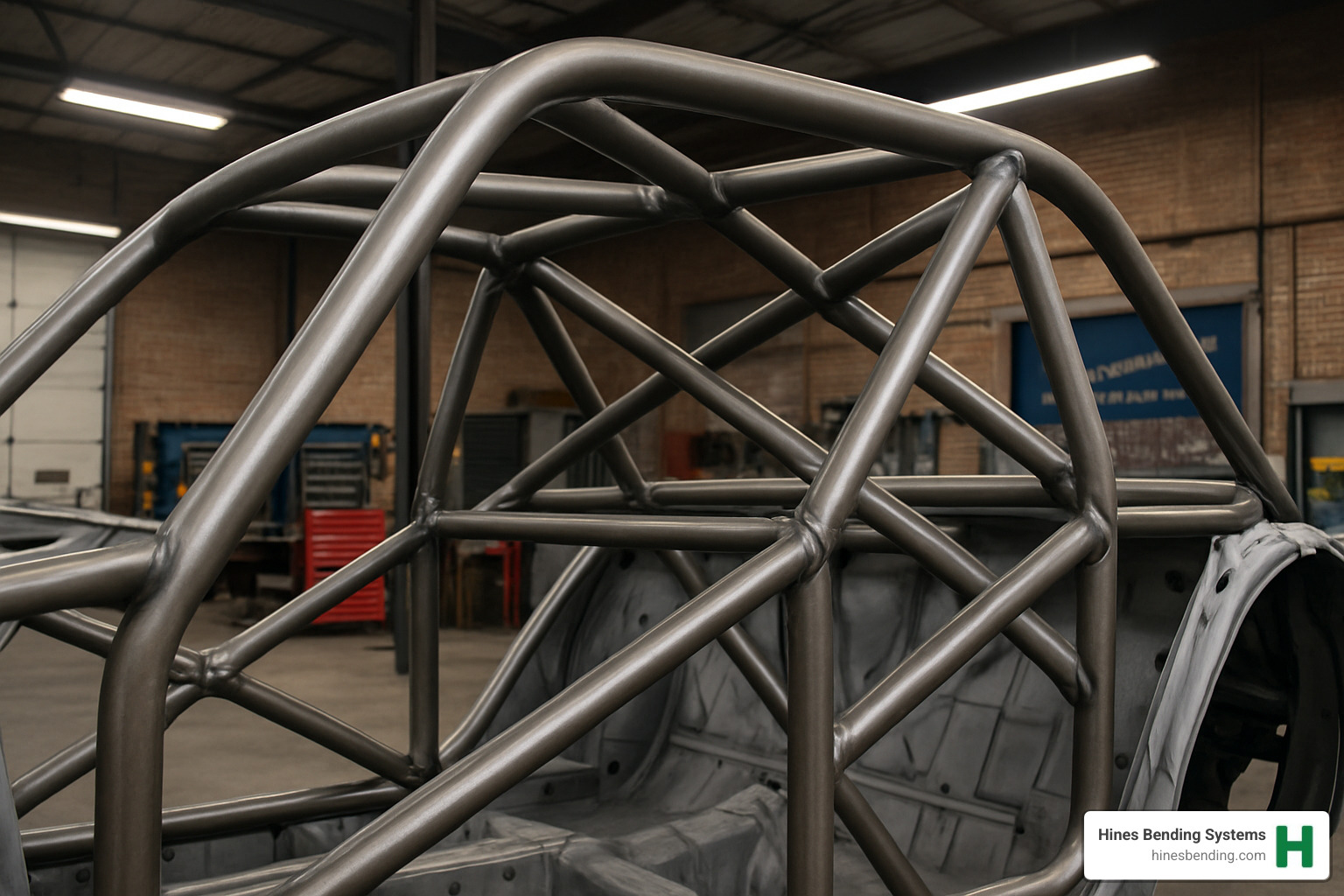

The automotive industry represents one of our most demanding markets. Every roll cage that protects a race car driver, every chassis component that provides structural integrity, and every exhaust system relies on precision bending. When NASA needs bending solutions for aerospace applications, they come to Hines – aerospace ducting, hydraulic lines, and fuel systems must meet specifications so tight they’d make your head spin.

The HVAC industry keeps us busy with precision-bent refrigerant lines and heat exchanger components that optimize fluid flow and heat transfer. Construction and infrastructure projects challenge our machines with large diameter pipes and heavy-wall materials. We’ve also found tremendous satisfaction working with the furniture and fitness equipment industries, creating components that people interact with daily.

Materials You Can Bend With Pipe Bending Machines

Steel remains our bread and butter – carbon steel offers that sweet spot of excellent formability, strength, and cost-effectiveness. Stainless steel is where things get interesting, as this material likes to work-harden, but our decades of experience have taught us exactly how to handle its quirks.

Aluminum is a joy to work with when you know what you’re doing. Its lightweight characteristics make it a favorite in aerospace and automotive applications. Copper and brass are highly formable materials we see frequently in plumbing and HVAC work.

Here’s where Hines really shines: exotic materials like titanium, Inconel, and duplex stainless steels. These materials offer exceptional performance characteristics, but they demand the kind of specialized expertise that only comes from years of experience. When other shops say “we can’t bend that,” clients come to Hines.

Automation Boosts in Pipe Bending Machines

The revolution in pipe bending machines automation has been nothing short of remarkable, and Hines has been leading this charge from the beginning. Our automated systems eliminate trial-and-error setups, delivering consistent results from the very first piece.

The energy savings alone make automation compelling – we’re talking about efficiency improvements of up to 70% compared to traditional systems. Labor reduction benefits extend far beyond simple cost savings, dramatically improving workplace safety.

The Keep reading Tube processing machines for HVACR systems shows how integration creates manufacturing cells that run with minimal intervention.

Selecting the Right Pipe Bending Machine

Finding the perfect pipe bending machine for your operation isn’t just about matching specifications – it’s about partnering with a company that understands your unique challenges. At Hines Bending Systems, we’ve learned that the best machine decisions come from understanding both your immediate needs and your long-term vision.

Capacity requirements form the cornerstone of any smart machine selection. Think beyond today’s production demands and consider where your business might be in five years. Bend radius capabilities can make or break your ability to win certain contracts. As the #1 worldwide manufacturer of bending machines, we’ve perfected the art of achieving tight radii without compromising quality.

Tooling considerations extend far beyond the initial purchase price. Smart buyers evaluate the availability, cost, and lead times for application-specific tooling. Modern software capabilities increasingly separate good machines from great ones. Advanced programming software, collision detection, and CAD integration can transform your productivity.

Budget planning requires balancing initial investment against long-term value. While premium machines like ours involve higher upfront costs, they deliver superior return on investment through improved productivity, consistent quality, and decades of reliable service. Our Used CNC Bending Machine for Sale options provide access to Hines quality for budget-conscious operations.

Key Features Checklist for Pipe Bending Machines

Diameter range flexibility should encompass your current requirements while providing room for growth. Stack height capabilities determine how complex your finished parts can be. Left and right bending capabilities eliminate the need for part repositioning during complex bending sequences.

Simulation software integration has become essential for competitive operations. Our advanced simulation capabilities model material behavior, predict springback, and optimize bend sequences before you commit to production. Safety system integration should protect operators without hampering productivity.

At Hines Bending Systems, we don’t just manufacture machines – we engineer solutions. Every feature we include has been proven in real-world applications, often in the most demanding environments imaginable.

Common Challenges & Expert Tips

Even with the most advanced pipe bending machines, certain challenges can impact quality and productivity. Our decades of experience have taught us that most problems are preventable when you understand the underlying causes and solutions.

Springback compensation becomes automatic with modern CNC systems. Wrinkling prevention requires understanding the delicate balance between material flow and compression forces. Collision avoidance becomes critical with complex multi-bend parts. Our simulation software identifies potential problems before they occur.

The truth is, most bending challenges aren’t really machine problems – they’re knowledge problems. That’s why choosing Hines means choosing not just superior equipment, but access to best expertise. Nobody in the bending machine industry has more experience solving real-world problems than Hines Bending Systems.

Integration, Maintenance, and Cost of Ownership

Today’s pipe bending machines aren’t just standalone equipment anymore – they’re becoming the heart of integrated manufacturing systems. At Hines Bending Systems, we’ve watched this evolution as our clients find how proper integration can multiply their bending investment’s value.

The magic happens when you connect bending operations with cell automation that handles everything from material feeding to finished part removal. MES integration connects your bending machines to production planning and quality control. Advanced robotic systems can handle complex part geometries and perform quality inspections automatically.

Preventive maintenance becomes much more sophisticated with modern systems. Instead of waiting for something to break, today’s machines tell you what they need and when they need it.

Integrating Pipe Bending Machines Into Production Lines

The future of manufacturing lies in seamless integration, and pipe bending machines are perfectly positioned to anchor these advanced production systems. Material handling systems eliminate bottlenecks that used to plague bending operations. The laser cut-bend workflow represents one of the most exciting developments – these integrated systems can produce complete assemblies from raw tube stock with virtually no work-in-process inventory.

Data feedback systems monitor every aspect of the bending process, enabling immediate corrections when parameters drift. The Keep reading A single MES software for tube and sheet metal processing demonstrates how sophisticated software integration can coordinate multiple manufacturing processes seamlessly.

At Hines Bending Systems, our expertise in integration goes beyond just connecting machines – we help clients reimagine their entire production workflow to maximize efficiency and quality.

Service, Support, and Total Cost

Understanding the true cost of owning pipe bending machines requires looking far beyond the initial purchase price. Training forms the foundation of successful bending operations. Our comprehensive training programs dive deep into programming techniques, tooling optimization, and advanced troubleshooting.

Remote diagnostics capabilities have revolutionized how we support our clients. Modern Hines machines can transmit diagnostic data instantly, enabling our experts to troubleshoot issues without setting foot in your facility. Energy costs vary dramatically between different bending technologies – all-electric systems typically consume 70% less energy than traditional hydraulic systems.

At Hines Bending Systems, our support doesn’t end when the machine ships. We’re committed to helping our clients achieve maximum value from their bending investments throughout the entire machine lifecycle.

Frequently Asked Questions about Pipe Bending Machines

What pipe diameters can modern pipe bending machines handle?

Most standard pipe bending machines work beautifully with diameters from 4mm up to 150mm (about 6 inches), which covers the majority of manufacturing applications. Specialized systems push these boundaries much further – some advanced machines can process pipes up to 330mm (roughly 13 inches) in diameter.

At Hines Bending Systems, we’ve built our reputation on handling the complete spectrum. Our induction bending systems can tackle pipes up to 12 3/4 inches in diameter, which is why organizations like NASA trust us with their most challenging applications.

How does CNC automation improve bend quality?

The change that CNC automation brings to bend quality is remarkable. Instead of relying on operator skill, CNC pipe bending machines deliver identical results every single time through precise digital control.

Automatic springback compensation represents one of the biggest quality breakthroughs. CNC systems calculate the exact overbend needed to achieve your target angle. The “first part right” capability of modern CNC systems saves both time and money, producing acceptable parts from the very first bend.

What factors influence the price of a pipe bending machine?

Machine capacity plays the biggest role in pricing. Larger diameter capabilities and higher force requirements naturally command premium prices. Technology level creates another major price distinction – CNC systems involve higher upfront investment but deliver superior quality and productivity.

Automation features add cost but frequently provide excellent returns through reduced labor and improved efficiency. At Hines Bending Systems, we work closely with every client to find the optimal balance of features and investment. Our decades of experience help identify which capabilities will deliver the best value for your specific applications.

Conclusion

The journey through pipe bending machines reveals incredible possibilities for manufacturers ready to transform their operations. Whether you’re starting with basic manual systems or looking to upgrade to cutting-edge CNC automation, the right technology can revolutionize your quality, boost productivity, and give you a real competitive edge.

Success isn’t just about picking any machine – it’s about finding the perfect match for your specific needs, getting proper training, and having rock-solid support when you need it most.

Hines Bending Systems stands alone as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. When organizations like NASA need bending solutions they can trust with their most critical missions, they turn to Hines. That’s the kind of proven expertise and reliability you want on your side.

What sets Hines apart isn’t just our decades of experience – it’s our commitment to custom solutions that work perfectly for your unique situation. We don’t believe in one-size-fits-all approaches. Instead, we work closely with you to understand exactly what you need, then engineer the optimal solution.

Our track record speaks volumes. With more bender installations worldwide than anyone else, we’ve seen every challenge the industry can throw at us. Hines Bending Systems has the expertise to make your project successful.

Ready to find what pipe bending machines can do for your operation? Our team of experts is standing by to discuss your specific requirements and show you exactly how Hines Bending Systems can provide the perfect solution for your manufacturing needs.

Contact Us today and take the first step toward bending excellence. Let’s talk about how we can help you achieve the quality, productivity, and reliability that only comes from working with the industry’s undisputed leader.