Why CNC Wire Forming Machines Are Revolutionizing Manufacturing

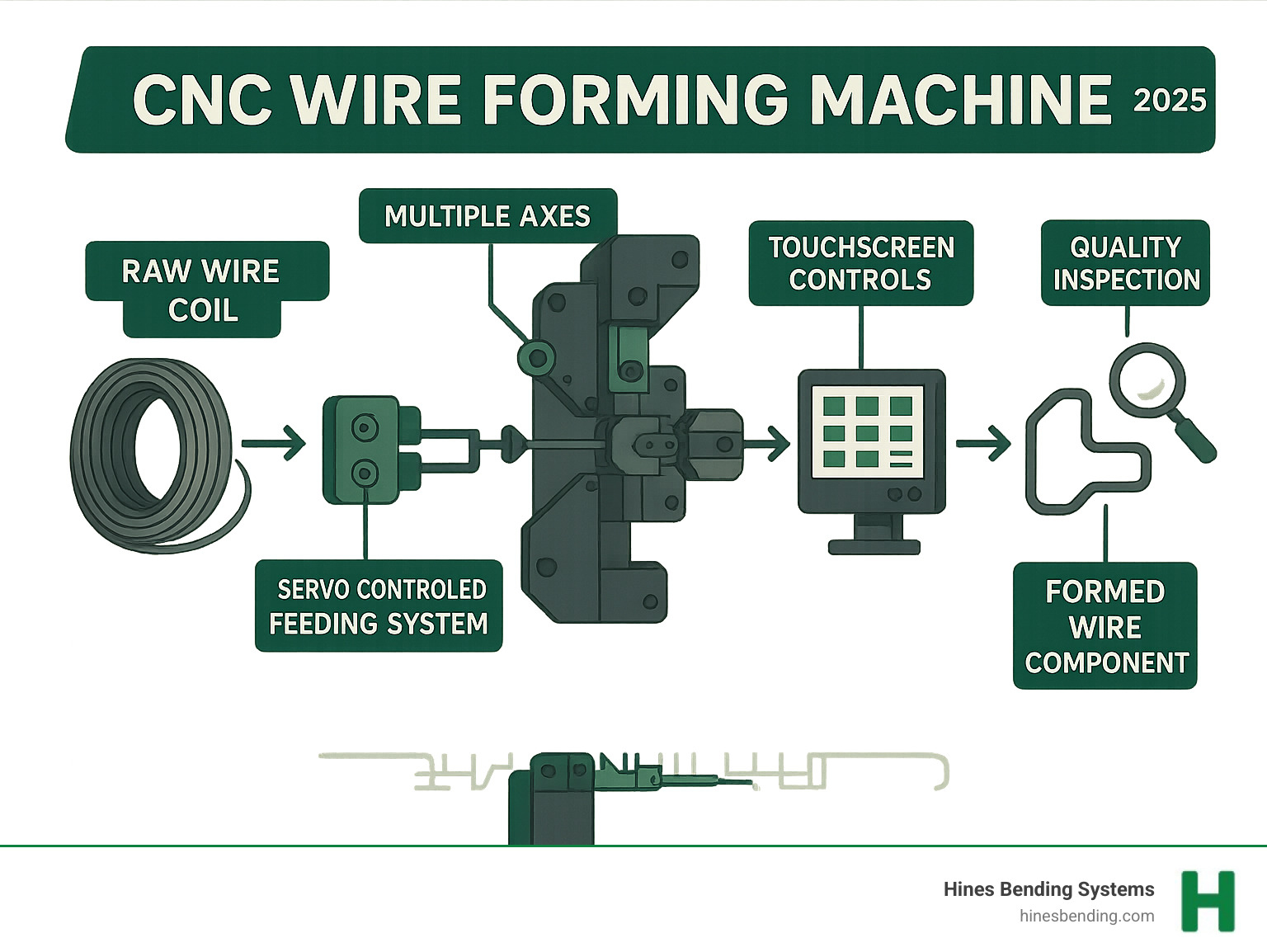

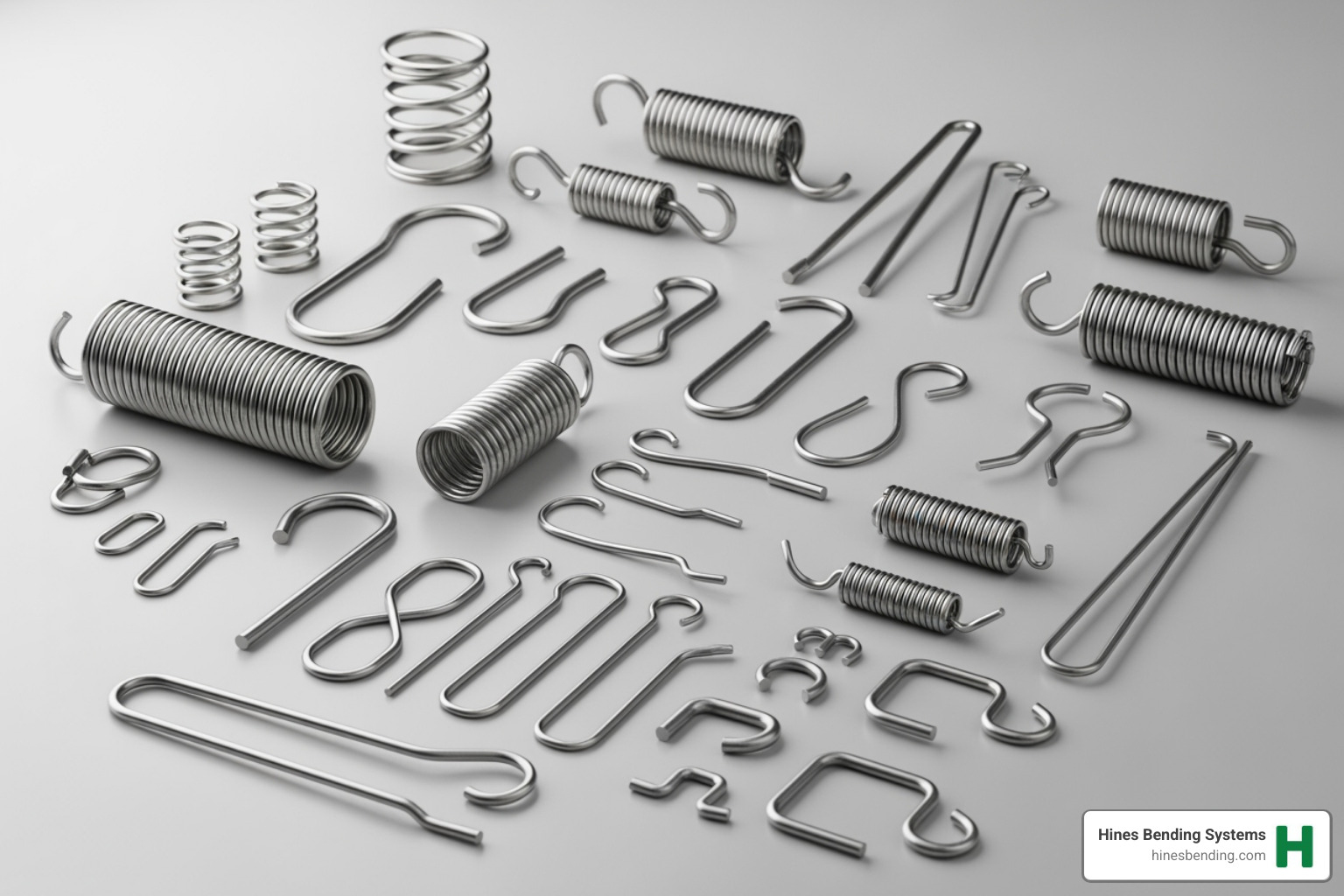

A CNC wire forming machine transforms raw wire into precise, complex components through computer-controlled automation. These machines use servo motors, programmable bending heads, and advanced software to create everything from simple 2D shapes to intricate 3D wire forms with exceptional accuracy and repeatability.

Key CNC Wire Forming Machine Capabilities:

- Wire Diameter Range: 0.4mm to 16mm (0.016″ to 0.625″) depending on model

- Bending Types: 2D shapes, 3D forms, springs, loops, and complex geometries

- Technology Options: Single-head, dual-head, turret tool changers, all-electric systems

- Applications: Automotive parts, medical devices, appliance components, display fixtures

- Production Speed: Up to 5,000mm/min feed rates with 5,000deg/min bending speeds

- Precision: ±0.1mm repeatability with ±0.05° angular precision

The wire forming industry has seen remarkable innovation, with machines now capable of storing over 10,000 processing programs and handling materials from soft copper to hardened stainless steel. As one manufacturer noted about their enameled copper processing: “The machine is doing really well bending our enamelled copper beautifully… it feeds and bends like a dream at 5000mm/min and 5000deg/min.”

Modern CNC wire forming machines offer significant advantages over traditional manual methods – increased productivity, consistent quality, reduced setup times, and the ability to create complex parts that would be impossible to form by hand. For manufacturing operations managers facing complex bending requirements and high production demands, these machines represent a critical investment in efficiency and precision.

Cnc wire forming machine vocabulary:

Understanding the Core of CNC Wire Forming

At its heart, a CNC wire forming machine represents the perfect marriage of precision engineering and computer intelligence. Think of it as having a master craftsman who never gets tired, never makes mistakes, and can work at lightning speed – that’s what Computer Numerical Control brings to wire forming.

The magic begins with the automated process that transforms a simple coil of wire into complex, precise components. The journey starts at the wire feeding system, where raw material gets pulled from its coil with mathematical precision. Modern systems use advanced servo motors that provide incredibly smooth acceleration and deceleration – no jerky movements that could distort your finished parts.

The real star of the show is the bending head mechanics. This sophisticated assembly moves with multiple axes of freedom, guided by computer programs that calculate every angle and curve down to fractions of degrees. When we talk about servo-driven precision, we’re talking about repeatability that’s measured in hundredths of millimeters – the kind of accuracy that makes engineers smile.

What makes this technology truly remarkable is how it eliminates the guesswork and inconsistencies of manual methods. While traditional wire forming relies on skilled operators who might have slightly different techniques or get fatigued during long production runs, a CNC wire forming machine delivers identical results whether it’s making the first part or the ten-thousandth.

The advantages over manual methods are game-changing for manufacturers. Speed increases dramatically – what once took minutes now happens in seconds. Quality becomes consistent across entire production runs. Complex geometries that would challenge even the most skilled craftsperson become routine. Plus, you can store thousands of different part programs, switching between products with just a few button presses.

At Hines Bending Systems, we understand these precision manufacturing principles intimately. While our expertise centers on tube, pipe, and induction bending machines – where we’ve earned recognition as the world’s leading manufacturer with installations everywhere from NASA facilities to major automotive plants – the fundamental engineering concepts of automated bending remain consistent across all applications. Our deep knowledge of servo control, precision mechanics, and custom automation solutions reflects the same technological excellence that drives innovation in wire forming.

For those wanting to dive deeper into the technical aspects, you can explore More about wire forming technology to understand the broader landscape of this fascinating field.

Types and Capabilities of the Modern CNC Wire Forming Machine

The world of CNC wire forming machines is diverse, with each type engineered for specific manufacturing challenges. Whether producing simple clips or complex automotive components, there’s a machine designed for the job.

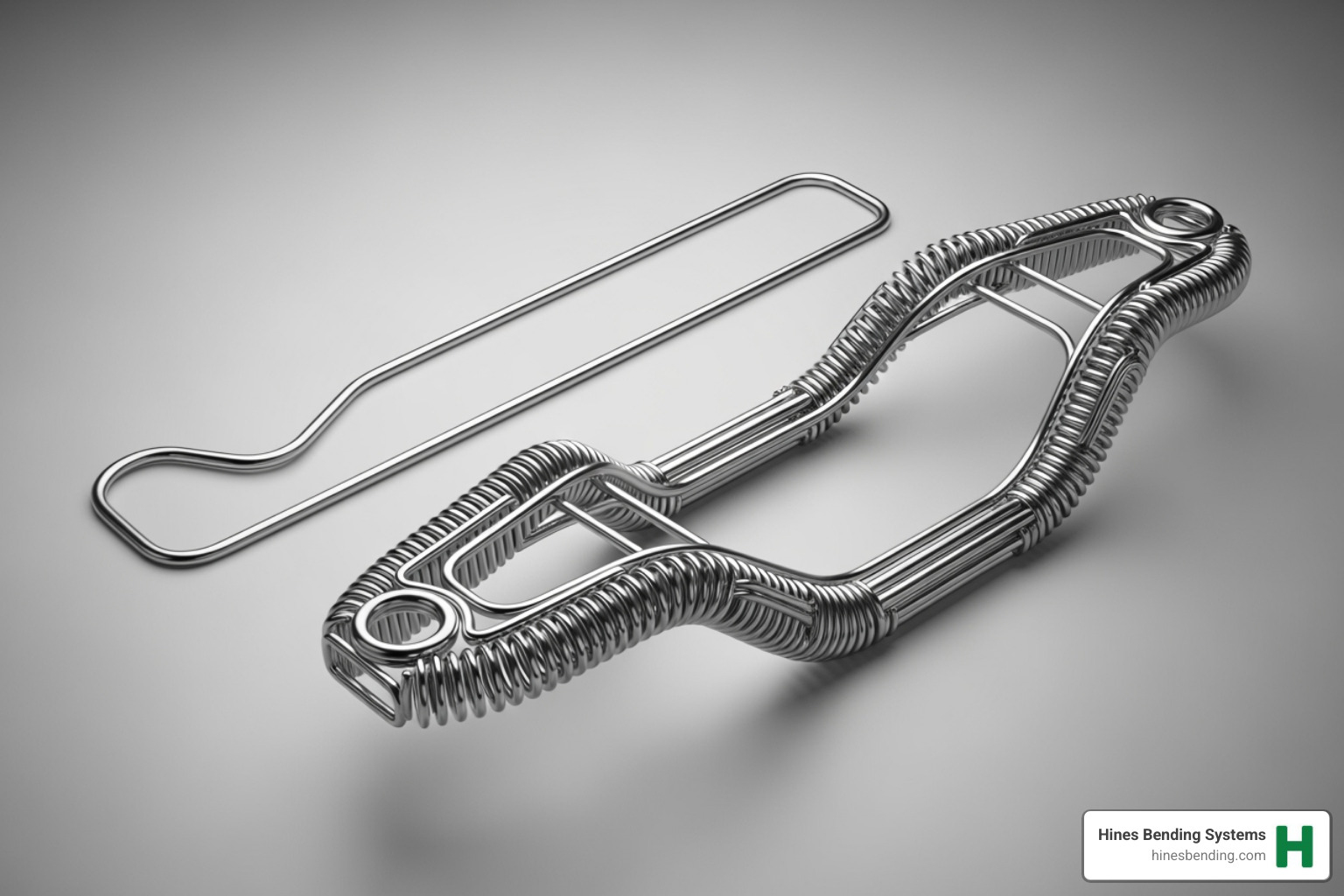

The most fundamental distinction is between 2D wire benders and 3D wire benders. 2D machines are workhorses for flat shapes, perfect for simple hooks, brackets, or clips. They work fast because their mechanics are straightforward.

3D wire benders are where things get exciting. These machines offer multi-axis movement, creating intricate three-dimensional shapes impossible with traditional methods. Picture an automotive seat frame or a sophisticated spring that bends in multiple directions—that’s 3D territory.

For production flexibility, multi-head machines shine in high-volume operations. While single-head machines are versatile, twin-head or four-head systems can work on multiple parts simultaneously or tackle longer components with impressive speed. Some advanced systems feature turret head benders that automatically change between up to 8 different bend radii without stopping production, like a tireless tool-changing robot.

The technology divide between camless and cam-operated machines is significant. Camless designs are the future, relying on servo motors for fast adjustments and rock-solid precision. Cam-operated machines, while still effective, require more hands-on mechanical adjustments when changing parts.

Wire diameter capabilities span an impressive range, from delicate 0.4mm wire up to robust 16mm stock for serious structural work. Some specialized machines push even further for unique applications.

Material compatibility shows their versatility. Modern systems handle everything from soft copper and aluminum to challenging materials like stainless steel, titanium, and specialized alloys. They can even work with flat stock and profiles.

At Hines Bending Systems, our deep expertise in precision bending across aerospace, automotive, and industrial applications gives us unique insights into what makes these machines effective. We understand the nuances of different bending technologies because we’ve spent decades perfecting them in our own world-class tube and pipe bending solutions.

Key Technologies in a CNC Wire Forming Machine

The precision and speed of modern CNC wire forming machines come from a blend of cutting-edge technologies that are foundational to their capabilities.

All-electric systems are a game-changer. Unlike hydraulic predecessors, these clean, quiet machines deliver up to 70% energy savings with incredibly consistent results. They are also highly reliable, with fewer moving parts and no hydraulic fluid. For operations focused on sustainability and cost control, this technology is a clear choice.

The heart of these systems is their advanced servo motors, often from leaders like Japan Panasonic or Sanyo Denki. Their S-curve positioning profiles create smooth acceleration and deceleration for faster production without sacrificing quality.

Integrated cutting mechanisms add efficiency. These powerful servo cutters slice wire with surgical precision, creating clean, burr-free cuts. The integration means a seamless workflow: the machine feeds, forms, cuts, and moves to the next part.

Automated tool changers are becoming standard where flexibility matters. These systems can swap tools automatically, holding multiple configurations ready for instant deployment. Changing a setup in seconds instead of minutes transforms a production line.

These technologies mirror the innovation in our own bending solutions at Hines. Our machines leverage similar components and engineering principles, which is why organizations like NASA trust us. When you need precision bending expertise, our experience with advanced manufacturing technologies makes us the natural choice. Explore our range of precision CNC Benders to see our technology leadership in action.

Common Applications for a CNC Wire Forming Machine

The versatility of CNC wire forming machines touches nearly every aspect of modern life, from cars to medical devices. Their ability to create precise, complex wire components efficiently has made them indispensable across many industries.

Automotive applications are a large market, where these machines create seating frames, headrests, exhaust hangers, and door lock mechanisms. The precision for safety-critical components demands the repeatability that only CNC technology delivers.

In the appliance world, wire forms are everywhere: refrigerator shelves, oven racks, and dishwasher components. The durability and consistency requirements in this industry make CNC wire forming essential.

Medical device manufacturing pushes precision to its limits. Surgical instruments, orthodontic wires, and specialized tools require extreme accuracy and material purity, where CNC technology excels.

The retail and display industry depends on wire forming for displays, hooks, hangers, and shopping carts, requiring both function and aesthetic appeal with consistent quality.

Construction and agricultural equipment need robust components like concrete reinforcing elements and machinery parts that can withstand stress and weather.

Spring manufacturing is a crucial application where torsion springs, compression springs, and custom forms are made with these machines.

Many of these industries—automotive, aerospace, construction, and appliance manufacturing—are sectors where our tube and pipe bending expertise at Hines has been proven. This deep industry knowledge means we understand the demands for precision, durability, and efficiency. Our experience supplying major companies and agencies like NASA demonstrates our commitment to meeting the highest standards.

How to Select the Right Machine for Your Application

Selecting the perfect CNC wire forming machine for your needs isn’t just about picking the most impressive model on the showroom floor. It’s about finding the right partner for your manufacturing goals—and that’s where decades of bending expertise truly matter.

The journey begins with a thorough application analysis. What are you actually making? A simple retail hook requires a completely different approach than a complex automotive seat frame or medical device component. Understanding your part’s geometry drives every other decision you’ll make.

Part complexity directly influences your machine requirements. Simple 2D shapes like clips or brackets work beautifully on straightforward benders, while intricate 3D components demand multi-axis machines with sophisticated tooling capabilities. If you’re working with multiple bend radii, consider machines with turret heads that can automatically switch tools without manual intervention.

Your production volume tells the rest of the story. High-volume operations need machines that can run at impressive speeds—some systems achieve 5,000mm/min feed rates with equally fast bending speeds. But if you’re in a high-mix, low-volume environment, flexibility and quick changeover capabilities become far more valuable than raw speed.

Required tolerances separate good machines from exceptional ones. Medical devices, aerospace components, and precision automotive parts demand repeatability within ±0.1mm and angular precision of ±0.05°. This level of accuracy requires robust machine construction, quality servo systems, and the kind of engineering expertise that goes into every component.

Don’t overlook your material specifications. The type of wire, its diameter range, tensile strength, and any special coatings all impact machine selection. Whether you’re working with delicate copper wire or robust stainless steel, your machine’s feeding system and tooling must handle your materials flawlessly.

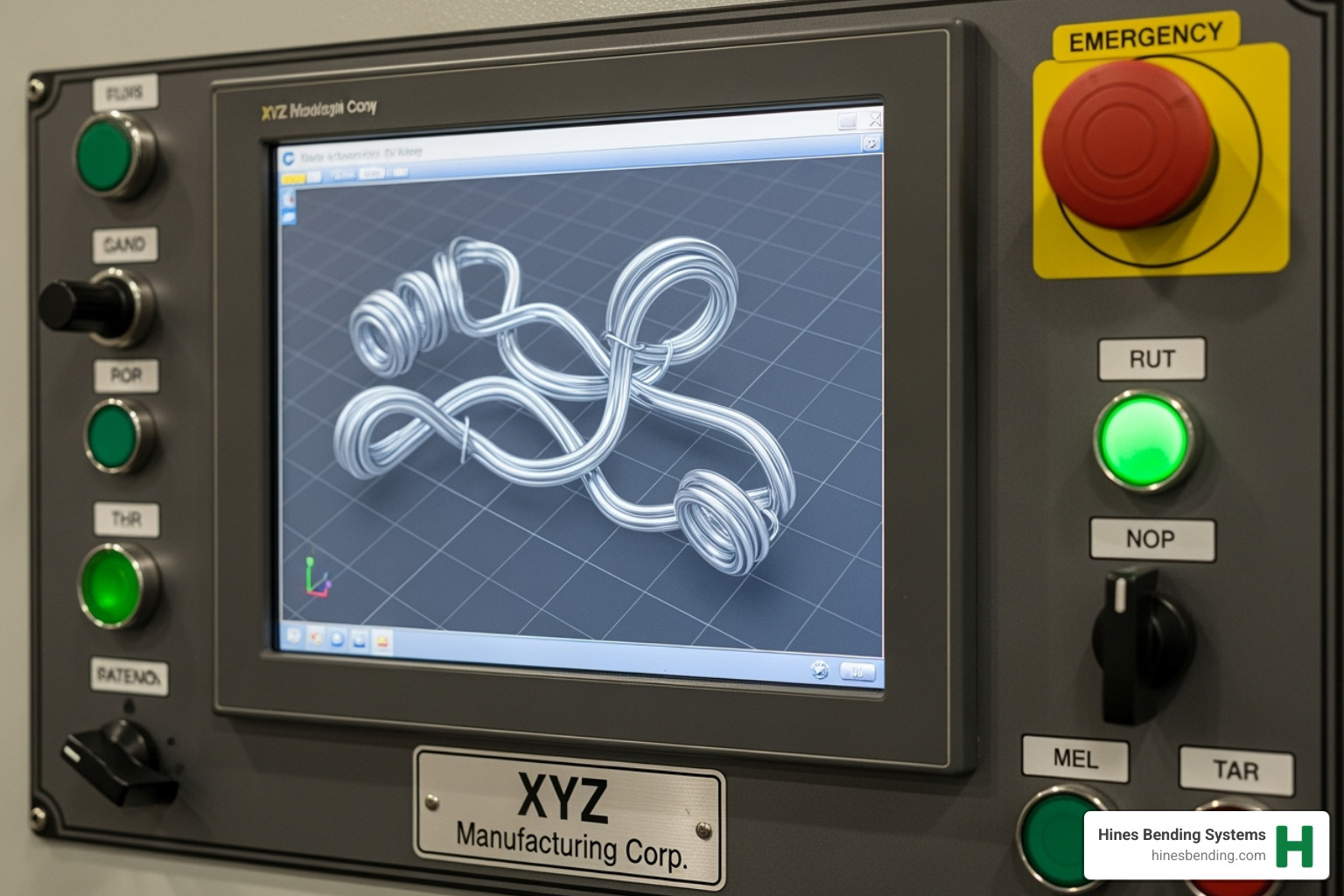

Software ease-of-use can make or break your daily operations. Look for intuitive programming interfaces that let operators input lengths and angles rather than wrestling with complex machine movements. Features like collision detection and offline simulation save both time and expensive materials during setup.

Perhaps most critically, consider your manufacturer support and training. A machine is only as good as the expertise behind it. At Hines Bending Systems, we understand this intimately. While our specialty lies in tube and pipe bending rather than wire forming, we’ve built our reputation on the same principles that matter in any bending application: engineering excellence, custom solutions, and unwavering support.

When NASA needs bending solutions, they turn to companies with proven expertise. The same careful analysis we apply to aerospace applications—understanding unique requirements, providing custom engineering, and delivering ongoing support—applies to any precision bending challenge. We don’t just manufacture machines; we solve problems and build lasting partnerships.

For guidance on making the right choice for your specific needs, explore our insights on What Type of Bending Machine is Best for Me?. While the specifics may differ between wire and tube forming, the fundamental approach to selecting the right bending solution remains the same: match the technology to your application, prioritize quality and precision, and partner with experts who understand your industry’s demands.

Industries Transformed by Precision Wire Forming

When you look at the incredible precision required in modern manufacturing, it’s clear that the CNC wire forming machine has become a game-changer across countless industries. These machines don’t just make parts—they enable entire sectors to push the boundaries of what’s possible, creating components that were once unimaginable or simply too expensive to produce.

Take aerospace components, for instance. This is where precision isn’t just preferred—it’s absolutely critical. Every wire harness, structural support bracket, and control linkage in an aircraft or spacecraft must meet exacting standards. The CNC wire forming machine excels here because it can work with high-strength aerospace alloys while maintaining tolerances that would make a Swiss watchmaker proud. At Hines Bending Systems, we understand this level of precision intimately. Our long-standing partnership with NASA, detailed in Hines working together with NASA, demonstrates our commitment to the same rigorous standards across all bending applications. When lives depend on precision, there’s no room for compromise.

The medical device industry presents equally demanding challenges. Think about the tiny guidewires that help surgeons steer through blood vessels, or the orthodontic wires that gradually straighten teeth over months. These components require not only incredible precision but also the ability to work with specialized biocompatible materials like medical-grade stainless steel and titanium. A CNC wire forming machine delivers the consistency and accuracy that patient safety demands—there’s simply no margin for error when human health is at stake.

Walk into any retail store, and you’ll see the handiwork of precision wire forming everywhere in point-of-sale displays. Those perfectly uniform hooks holding products, the neat wire racks showcasing merchandise, and the sturdy display frames that catch your eye—they’re all products of automated wire forming. The beauty here is in the volume and consistency. Retailers need thousands of identical components delivered quickly, especially during seasonal rushes, and that’s exactly what these machines provide.

Appliance manufacturing might not seem glamorous, but it’s where wire forming truly shines in everyday applications. The refrigerator shelves that hold your groceries, the oven racks that support your Sunday roast, and the internal mechanisms in your washing machine all rely on precisely formed wire components. These parts need to be durable enough to last for years while maintaining their shape and function under constant use.

The construction industry also benefits significantly, particularly when projects require custom wire components for concrete reinforcement or specialized structural supports. While larger construction elements might use tube or pipe bending solutions, intricate wire forms play crucial supporting roles in modern building techniques.

What ties all these industries together is their need for precision, reliability, and expertise—the same qualities that have made Hines Bending Systems the world’s leading manufacturer of tube, pipe, and induction benders. Our deep understanding of bending mechanics and our commitment to custom solutions means we bring the same level of engineering excellence to every project, whether it’s for aerospace, medical, or any other demanding application. When industries need precision bending solutions, they turn to the experts who have proven themselves time and again in the most challenging environments.

Frequently Asked Questions about CNC Wire Formers

When exploring CNC wire forming machines, manufacturers naturally have questions about cost, maintenance, and operation. Having helped countless clients with similar decisions for our tube and pipe benders, we understand these concerns. Let’s address the most common questions.

What is the typical cost range for these machines?

The investment in a CNC wire forming machine varies dramatically, from tens of thousands to several hundred thousand dollars. It’s like buying a car: a basic model works, but premium versions offer features that can transform your manufacturing operation.

Cost factors are crucial. Machine size and wire diameter capacity impact pricing, as larger machines need more robust construction and powerful motors. The number of axes is also significant; basic 2D benders cost less than sophisticated 3D multi-axis systems with turret capabilities.

Software features are another cost driver. Advanced interfaces with simulation, collision detection, and part libraries cost more but pay for themselves by reducing setup times and mistakes. Customization for specialized applications also affects pricing.

Here’s where manufacturer reputation is critical. At Hines Bending Systems, we know quality engineering and support require a higher initial investment but deliver superior reliability and performance. Cheaper alternatives often hide costs in maintenance and downtime. Our experience serving clients like NASA has taught us that true value comes from machines built to last and backed by expert support.

What are the maintenance requirements?

Modern CNC wire forming machines are designed for simple maintenance, much like our benders. The key is consistent routine checks for wear, loose connections, or unusual sounds.

Lubrication schedules are the backbone of preventive maintenance. Regular lubrication of moving parts per manufacturer specifications minimizes friction and extends component life.

Tooling inspection is vital since bending dies, cutting blades, and straighteners are wear items. These components should be made from hardened tool steels (Rockwell 55°-65°). Regular inspection and replacement maintain part quality.

Don’t overlook software updates to access the latest features. Operator training is your first line of defense; well-trained operators can address minor issues before they escalate, which is why we emphasize comprehensive training.

Regular cleaning prevents debris buildup that can affect precision. Our machines are engineered for durability and simple maintenance, reflecting our commitment to your production.

How complex is the programming and operation?

Programming and operating a CNC wire forming machine is now straightforward, thanks to user-friendly interfaces. Most modern machines feature color LCD touch screens and intuitive software like SmartEditor®, allowing operators to program parts by simply entering lengths and angles.

Simulation software is a game-changer. Operators can visualize the bending process on screen before cutting wire, verifying programs and detecting errors offline. This saves material and production time.

For advanced applications, G-code compatibility offers flexibility for custom programming or CAD/CAM integration. Many systems can import DXF or STEP files directly, streamlining design-to-production.

Collision detection provides a safety net, warning operators if components risk colliding. This prevents costly damage and builds operator confidence.

Some manufacturers offer remote diagnostics, allowing support teams to troubleshoot machines online, minimizing downtime.

At Hines Bending Systems, we prioritize user-friendly operation. Our comprehensive training programs, like our Tube and Pipe Bender Training, ensure your team becomes confident and capable quickly. We believe easy operation is essential to open uping a machine’s full potential.

Conclusion: Choosing a Partner for Manufacturing Success

When you invest in a CNC wire forming machine, you’re not just buying equipment—you’re investing in the future of your manufacturing operation. These remarkable machines deliver the precision, speed, and versatility that modern production demands, changing simple wire into complex components that drive industries forward.

But here’s what we’ve learned after decades in the bending business: the machine is only half the equation. The real difference between success and frustration lies in choosing the right partner to guide you through this journey.

At Hines Bending Systems, we’ve built our reputation as the #1 worldwide manufacturer of bending machines by understanding one fundamental truth: every bending challenge is unique, and every solution should be too. While our primary expertise lies in manufacturing the world’s highest quality tube, pipe, and induction benders, our deep understanding of bending mechanics, precision engineering, and custom solutions extends across the entire spectrum of metal forming.

Nobody understands bending better than we do. This isn’t just a bold claim—it’s backed by our work with major agencies like NASA, who trust us with their most critical bending applications. When space missions depend on precision, they turn to Hines. That same level of expertise and quality assurance flows into every recommendation we make, whether you’re forming automotive components or medical devices.

What sets us apart isn’t just our technical knowledge—it’s our commitment to working closely with each client to understand their specific challenges. We don’t believe in one-size-fits-all solutions. Instead, we take the time to analyze your application, production requirements, and long-term goals to recommend the bending solution that will truly serve your needs.

Quality matters, especially when your reputation depends on consistent, precise components. While cheaper alternatives might seem attractive initially, they often lead to costly downtime, quality issues, and frustrated operators. Our approach focuses on long-term value, reliability, and the kind of performance that keeps your production running smoothly year after year.

Whether you’re exploring wire forming technology or any other bending application, the right partner makes all the difference. Our comprehensive training programs, ongoing support, and custom engineering capabilities ensure that your investment delivers maximum returns.

When complex bending challenges arise—and they will—you want a partner with best expertise and experience standing behind you. Come to Hines Bending Systems, and let us help you shape your ideas into reality with the precision and reliability your business deserves.