The Art and Science of Bending Copper Pipe

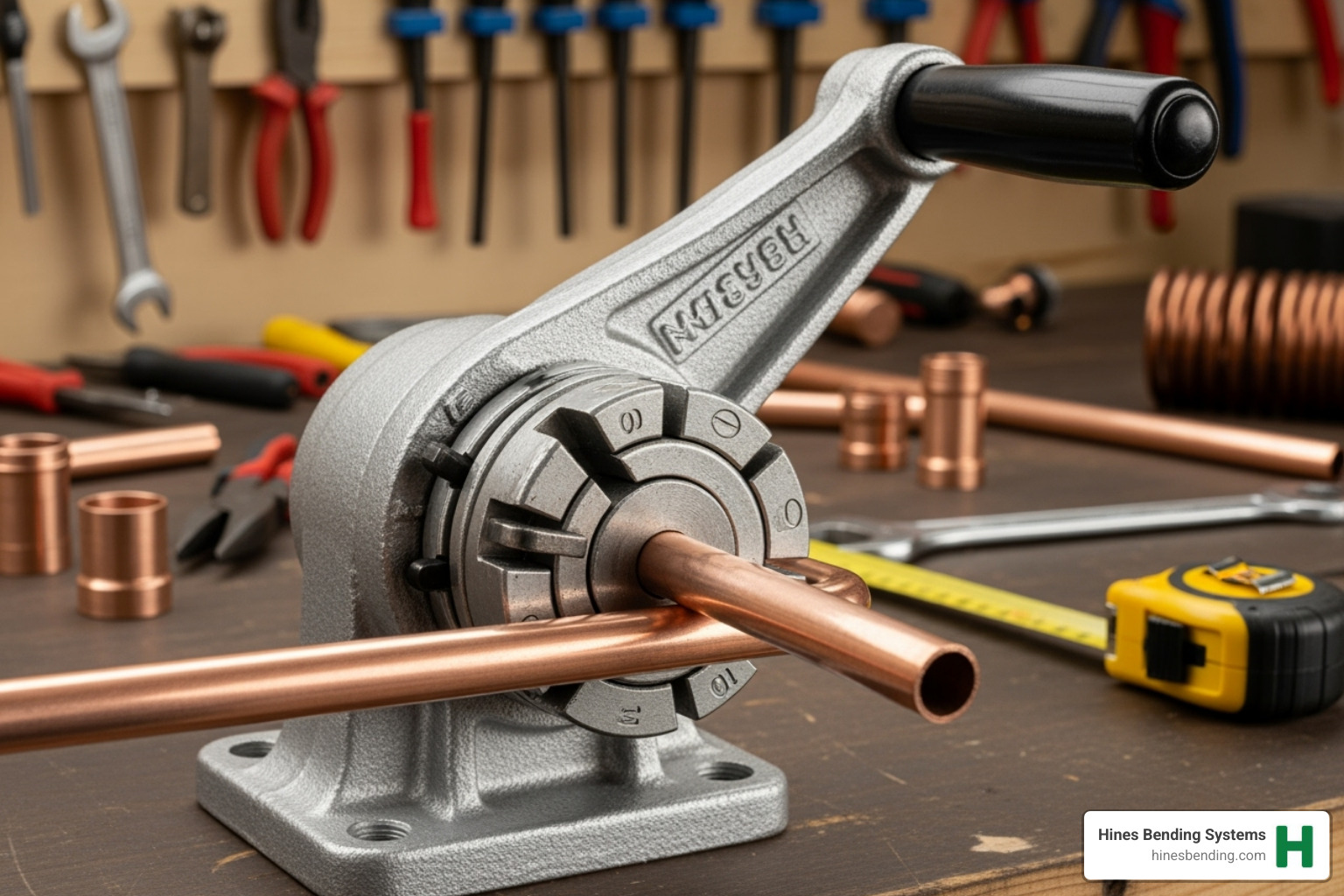

A copper pipe tube bender is a specialized tool for creating smooth, precise curves in copper tubing without kinking or damage. These machines range from simple manual benders for small jobs to advanced CNC and induction systems for industrial applications.

Copper’s unique properties make it ideal for bending. It’s soft enough to form without breaking, yet strong enough to maintain structural integrity. In fact, a properly bent copper tube can have greater bursting strength than before bending.

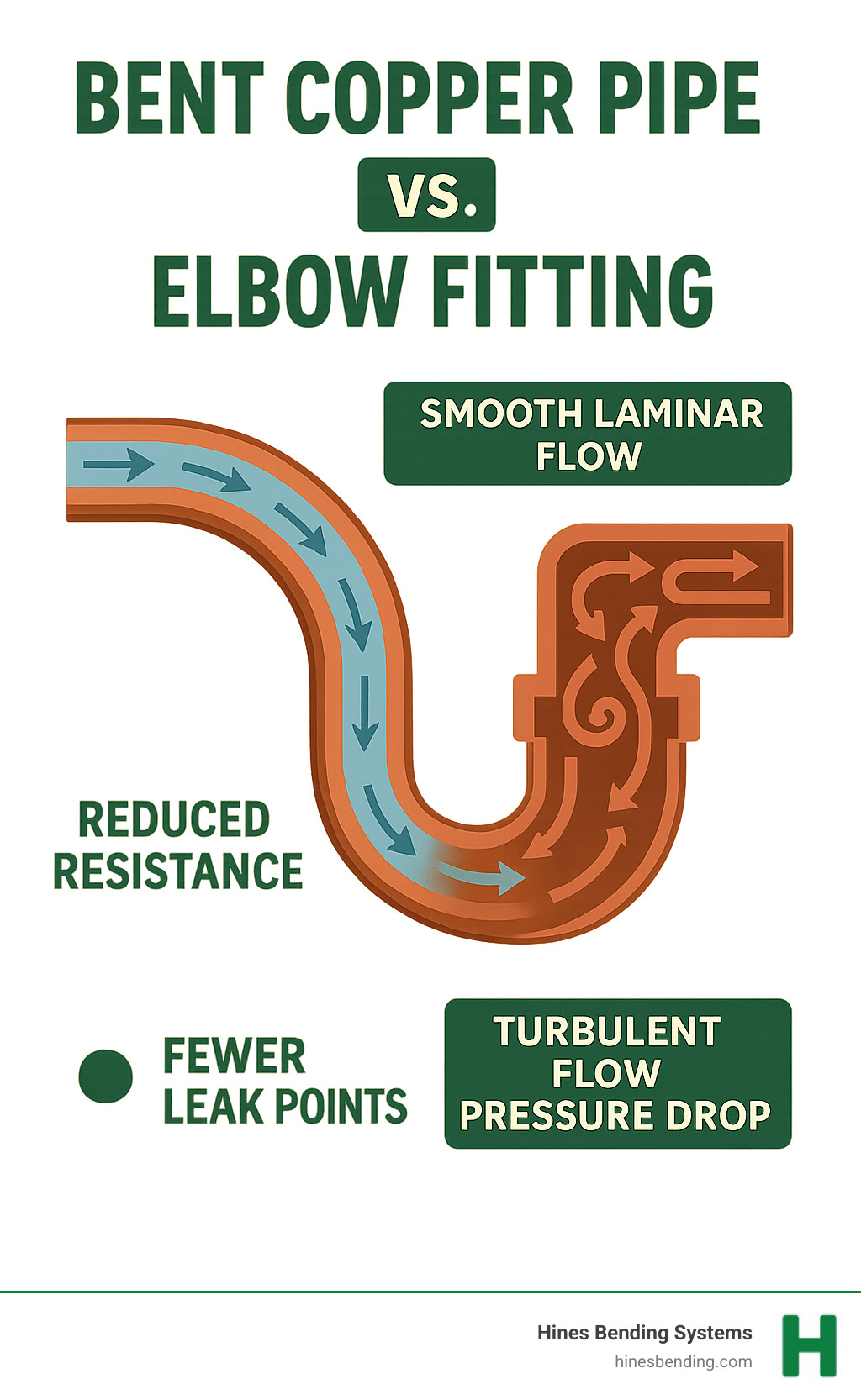

Choosing to bend pipes instead of using fittings offers significant advantages, including fewer leak points, improved flow dynamics, cost savings, and a cleaner, more professional appearance. From plumbing and HVAC to mission-critical aerospace applications, bent copper is essential. Achieving the best results requires equipment and expertise custom to copper’s specific needs.

That’s where Hines Bending Systems stands apart. As the world’s #1 manufacturer of tube and pipe benders, Hines has supplied precision bending solutions to organizations like NASA and countless manufacturing operations worldwide. Our decades of experience ensure every bend meets the highest standards of quality and precision.

Relevant articles related to copper pipe tube bender:

The Hines Advantage: Best Expertise in Copper Pipe Tube Bending

When you need precision copper pipe tube bending, experience is paramount. And nobody in the industry has more experience than Hines Bending Systems. For decades, we’ve perfected the art of bending, growing into the #1 worldwide manufacturer of tube, pipe, and induction benders, backed by the most installations across the globe.

What truly sets us apart is the trust placed in us by organizations like NASA. When the space agency requires mission-critical precision, they turn to Hines. This same level of quality is applied to every project, from small HVAC jobs to complex aerospace applications. If our machines are good enough for rocket science, they are ready for your project.

We don’t believe in one-size-fits-all solutions. We work closely with every client to create custom bender solutions that match your unique requirements, handling unusual dimensions and tight tolerances with ease. Our engineering team thrives on solving the bending challenges others avoid.

Our commitment to continuous innovation and superior quality is built into every machine. While cheaper alternatives exist, they often compromise long-term integrity. Our benders are designed to exceed industry standards, ensuring flawless performance for years. Partnering with Hines means gaining access to decades of expertise and a team invested in your success. Learn more about our story at our About Hines Bending Systems page.

Understanding the Impact of Bending on Copper Tubing

It may be surprising, but bending copper tubing correctly actually makes it stronger. This is due to a process called work hardening, where the material’s molecular structure becomes denser and more resistant to pressure. A properly bent copper pipe can handle higher bursting pressures than a straight one, a key advantage in demanding applications.

However, this benefit is only achieved with the right technique and equipment. The science of bending requires understanding your material, whether it’s soft annealed copper or more rigid hard-drawn copper. Improper methods lead to kinking, flattening, or wrinkling, which compromise structural integrity and flow capacity.

This is where Hines Bending Systems’ expertise is invaluable. Our precision-engineered copper pipe tube bender machines are designed to maintain the pipe’s cross-sectional integrity, regardless of the copper temper. We ensure you have the right equipment and knowledge to achieve optimal results every time. The structural soundness achieved with Hines technology maximizes copper’s natural advantages, a standard of quality trusted by clients like NASA for their mission-critical applications.

For a deeper dive into the technical terminology that defines our industry, check out our comprehensive Tube and Pipe Bending Industry Terms guide.

Hines Bending Systems: The Full Range of Copper Pipe Tube Benders

At Hines Bending Systems, we offer a comprehensive spectrum of copper pipe tube bender solutions for every scale of operation, from small workshops to large industrial facilities. Our lineup is designed for precision, durability, and the superior quality our clients, including NASA, expect.

Hines Manual and Semi-Automatic Benders for Small to Medium Jobs

For projects requiring portability, quick setups, or smaller production volumes, our manual and semi-automatic benders are ideal. Perfect for prototyping, repair work, and specialized applications, these robust and reliable tools provide consistent, controlled results that reduce the risk of kinking. Our superior build quality and expert engineering support ensure you can overcome any challenge.

Hines Advanced CNC and Induction Bending Solutions for Industry

When precision, repeatability, and high-volume production are paramount, Hines leads the way with advanced CNC and induction bending solutions. Our CNC benders offer best automation, ensuring identical bends across thousands of parts for pipe diameters from 1/4″ up to 12 3/4″. For the largest diameters and thickest walls, our induction benders are the superior choice, allowing for large-radius bends with minimal material distortion.

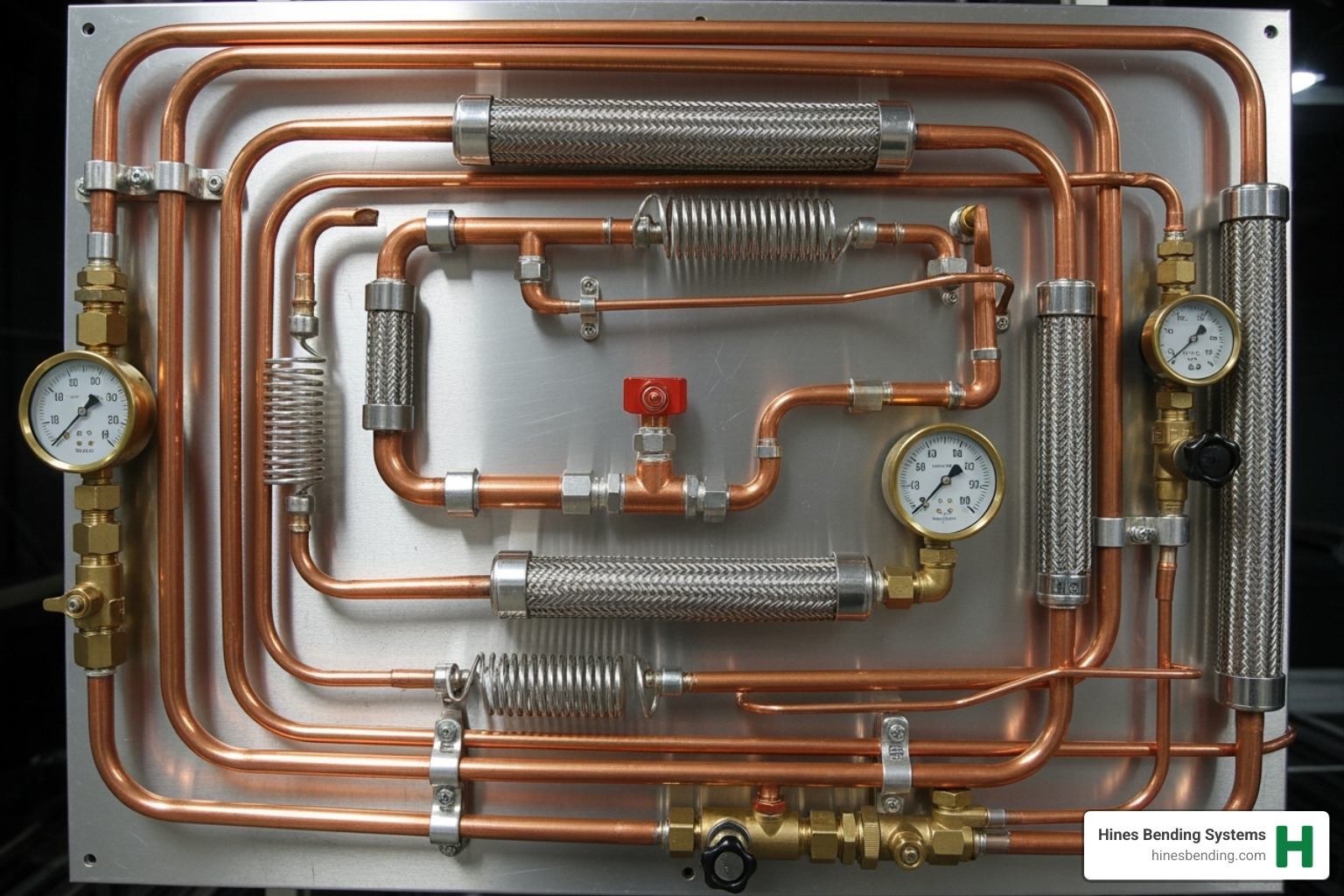

Hines’ innovation extends to specialized solutions like our Dual Stack CNC Push Bender and Roll Bender, engineered for maximum flexibility and efficiency in mission-critical applications. We also provide comprehensive training on machine maintenance to ensure the longevity and optimal performance of your Hines equipment.

Find the full capabilities of our automated solutions at CNC Bending Machine and NC Metal Bender.

How to Achieve a Flawless Bend Every Time with Hines

Creating perfect bends in copper pipe is an art and a science. While a superior copper pipe tube bender from Hines is the foundation, proper technique ensures exceptional results. At Hines, we partner with you to ensure every bend meets the highest standards.

Preparation and Measurement

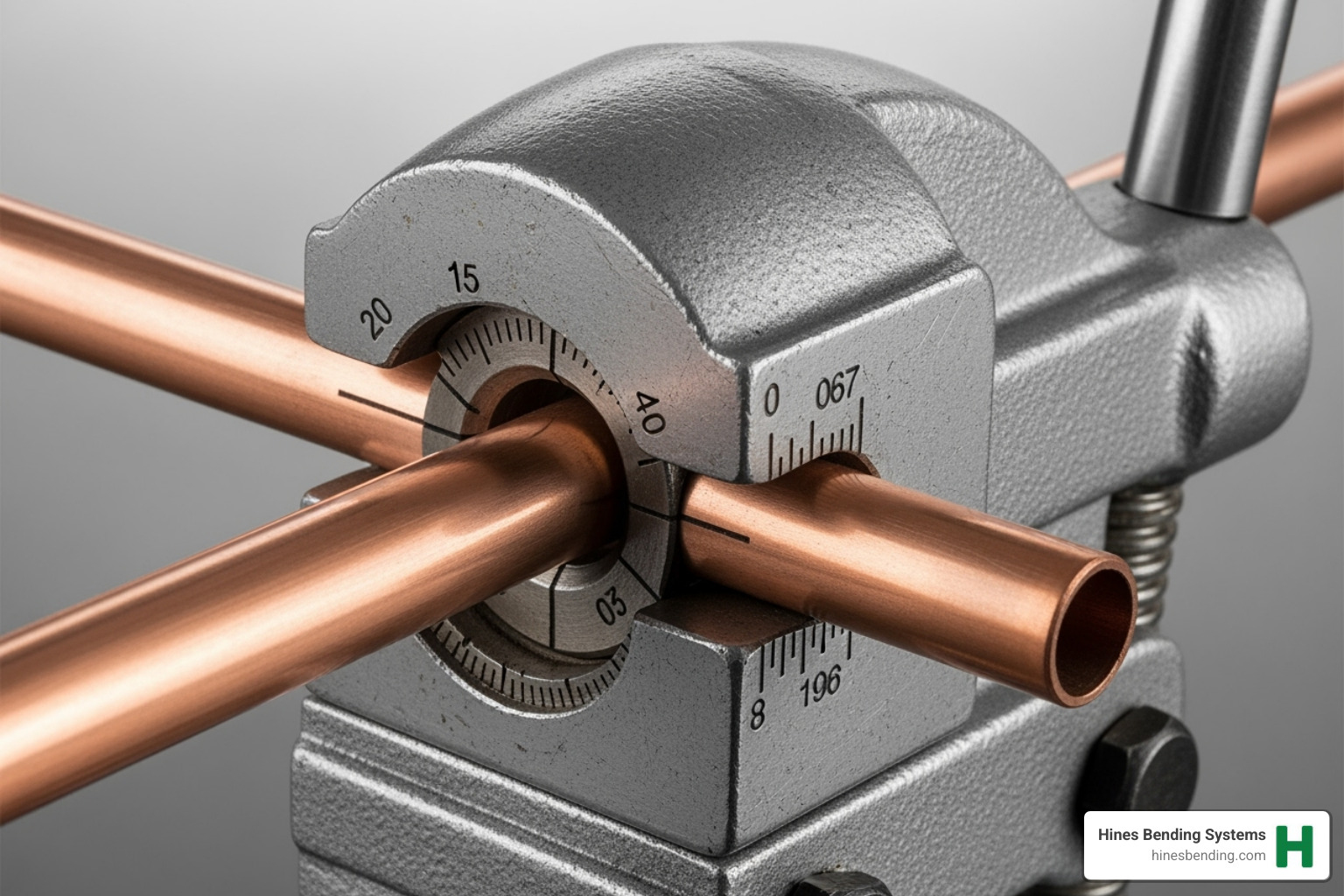

Every flawless bend starts with proper preparation. This includes inspecting the pipe for damage, making clean cuts, deburring edges, and marking accurately. Understanding concepts like “bend gain” and optimal bend radius is crucial. Hines machines are engineered for consistency, and our expert team guides you on the perfect settings for your application. Our comprehensive Tube and Pipe Bender Training programs ensure your team masters these fundamentals.

Avoiding Common Mistakes with Hines Solutions

Common bending mistakes like kinking, flattening, and wrinkling can ruin a project and compromise system performance. These issues are typically caused by improper support or inconsistent pressure.

The superior engineering of a Hines copper pipe tube bender virtually eliminates these problems. Our machines feature precision dies and mandrels that provide optimal support throughout the bend. The smooth, consistent pressure application prevents the uneven compression that causes wrinkling, while our calibrated and programmable systems ensure accurate angles every time. This meticulous attention to detail is why organizations like NASA trust Hines for quality assurance.

Selecting the Right Hines Bending Solution for Your Project

Choosing the perfect copper pipe tube bender is a critical decision. At Hines Bending Systems, we partner with you to understand your unique challenges and match you with the ideal solution.

Key Technical Considerations

Our consultative approach ensures you get the right machine. Our team considers all key factors: pipe outside diameter (OD), wall thickness, material temper, Center Line Radius (CLR), production volume, and required precision. Whether you need a portable manual bender or a high-speed automated system, we recommend the solution that will serve you best for years. Get started with our guide on What type of bending machine is best for me?.

Meeting the Toughest Requirements

For complex geometries, unusual configurations, or mission-critical applications where failure is not an option, Hines Bending Systems truly shines. Our reputation is built on solving challenges others can’t. When NASA needs bending machines for space exploration, they come to us.

Complex geometries and intricate assemblies are our specialty. Our quality assurance process is embedded in every machine, ensuring your components perform flawlessly under the most demanding conditions. This commitment to excellence is why the world’s most demanding industries choose Hines. Learn more about our work with NASA at Hines Working Together with NASA.

Frequently Asked Questions about the Copper Pipe Tube Bender

From decades of experience, we’ve answered some of the most common questions about bending copper.

Does bending weaken a copper pipe?

No, properly bending copper pipe actually makes it stronger through a process called work hardening. A kinked bend will weaken the pipe, but a precision-engineered Hines copper pipe tube bender uses controlled pressure and support to improve the pipe’s structural integrity and bursting strength.

What is the difference between a pipe and a tube?

The main difference is measurement: pipes are measured by their inside diameter (ID), while tubes are measured by their exact outside diameter (OD). This distinction affects tooling selection. Our experts at Hines will ensure you have the right setup for either pipes or tubes.

How do you prevent kinking when bending copper?

Kinking is prevented by using the correct equipment and technique. A Hines copper pipe tube bender is engineered to prevent kinking by ensuring a perfect fit for your pipe’s diameter, providing internal support with integrated mandrels, and applying smooth, steady pressure. Investing in a Hines system makes kink-free bends routine. For additional tools, check out our Tube and Pipe Bender Accessories.

What makes Hines Bending Systems superior to other options?

Our superiority comes from a combination of best expertise, continuous innovation, and a commitment to quality. We provide custom solutions custom to each client’s needs, backed by comprehensive support. The trust placed in us by organizations like NASA for their critical applications speaks to our credibility and precision. When failure isn’t an option, professionals choose Hines.

Conclusion: Your Partner for Precision Bending

Bending copper pipe offers undeniable advantages over using fittings: fewer leaks, better flow, cost savings, and a professional finish. However, achieving these benefits depends entirely on the quality of your copper pipe tube bender.

This is where Hines Bending Systems truly shines. We are the industry leader, with decades of experience and the trust of organizations like NASA. We don’t just sell equipment; we provide custom solutions and personalized support to solve your specific challenges. From portable manual benders to advanced CNC and induction systems, our commitment to quality is best.

For the most demanding projects where precision is non-negotiable, Hines Bending Systems is your trusted partner. We combine world-class expertise with superior equipment to ensure your success.

Ready to experience the Hines difference? Explore our industry-leading Tube and Pipe Benders and find how we can lift your bending capabilities.