The Critical Role of Precision in Tube Fabrication

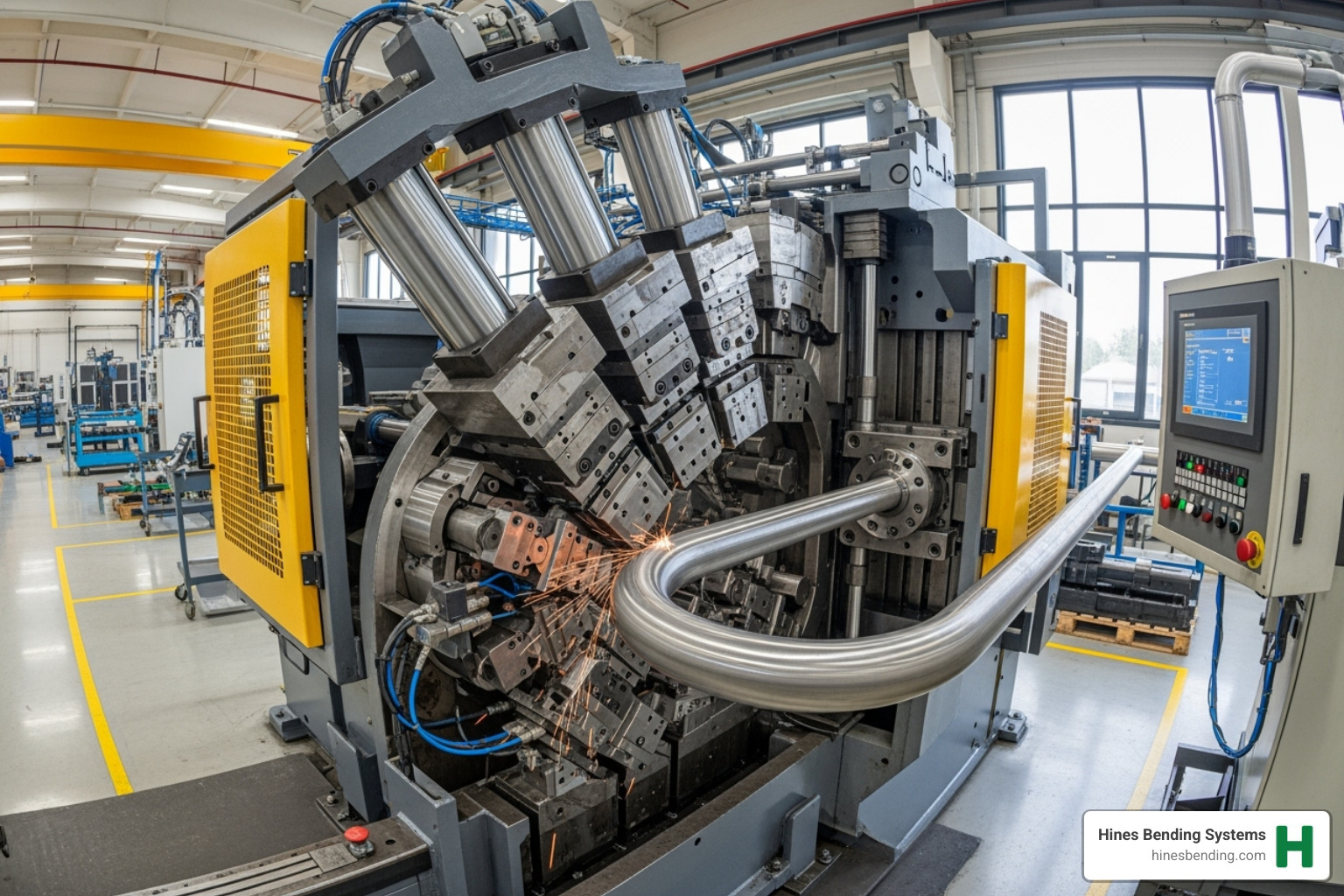

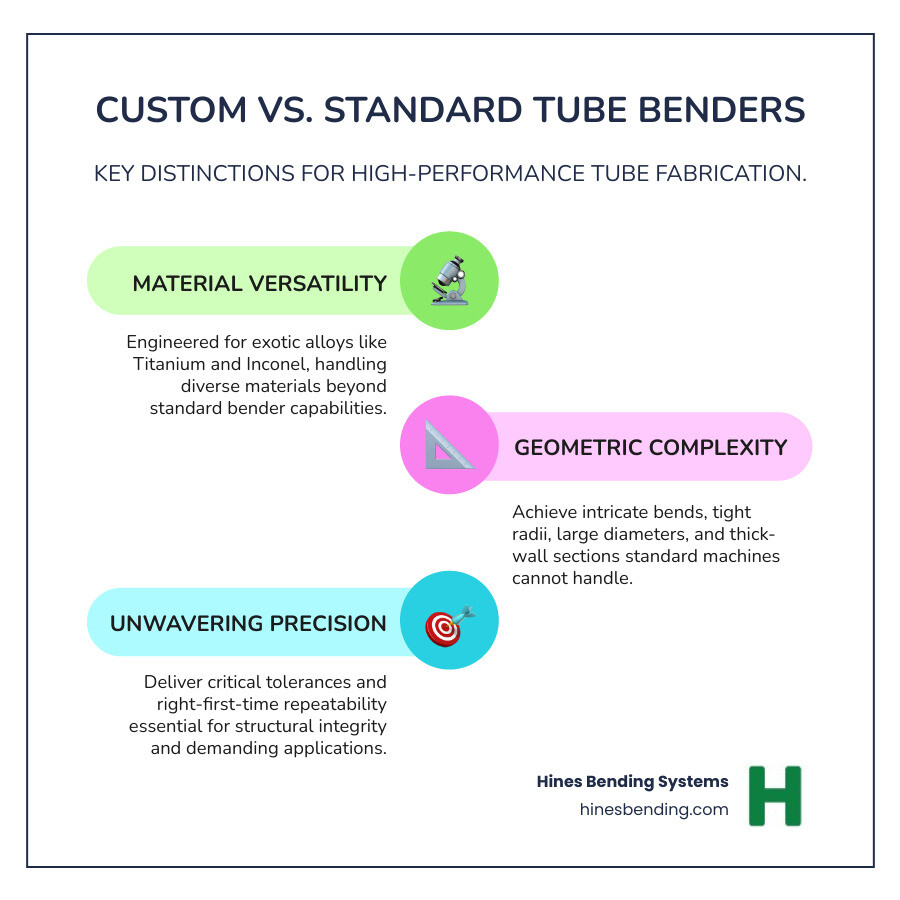

Custom tube benders are specialized manufacturing machines designed to bend tubes and pipes to exact specifications that standard equipment cannot achieve. Unlike off-the-shelf bending machines, these systems are engineered for unique applications requiring specific materials, complex geometries, or extreme precision tolerances.

Key characteristics of custom tube benders:

- Engineered solutions – Built to handle specific materials like titanium, Inconel, or exotic alloys

- Complex geometries – Can create tight radii, large diameters, and thick-wall applications

- Precision control – Achieve tolerances that standard machines cannot maintain

- Specialized tooling – Custom dies and mandrels designed for your exact requirements

- Industry-specific features – Built for aerospace, automotive, energy, and other demanding sectors

In today’s manufacturing landscape, precision isn’t optional – it’s critical. When NASA needs bent components for space missions, or when aerospace manufacturers require tubes that meet exact structural specifications, standard bending equipment simply won’t cut it.

The difference is clear: while standard benders work for basic applications, custom solutions handle the impossible. They bend materials others can’t touch, achieve tolerances others can’t reach, and create geometries others can’t imagine.

Hines Bending Systems stands as the #1 worldwide manufacturer of custom tube bending solutions. With decades of experience serving critical industries and agencies like NASA, no company has more expertise in solving complex bending challenges.

The stakes are too high for compromise. When structural integrity matters, when precision is non-negotiable, and when your reputation depends on flawless results, you need a partner with proven expertise and global experience.

Simple guide to custom tube benders terms:

Why Standard Benders Fall Short for Demanding Applications

Picture this: you’re trying to bend a piece of titanium tubing for an aerospace component using a standard bender. What should be a precise, smooth curve turns into a cracked, deformed mess. Sound familiar? This scenario plays out in manufacturing facilities every day when standard machines meet demanding applications.

Standard bending machines hit their limits fast when faced with real-world challenges. They’re built for basic applications – simple materials, straightforward geometries, and forgiving tolerances. But today’s manufacturing demands so much more.

Exotic alloys like titanium and Inconel are becoming the norm in aerospace, medical, and energy applications. These materials don’t behave like mild steel. They require precise heat control, specialized tooling, and exact pressure application. Standard machines simply weren’t designed for these challenges. When you try to force them, you get material failure, inconsistent results, and frustrated operators.

The geometry challenges are equally daunting. Complex geometries with tight radii push standard equipment beyond its breaking point. Try bending a large diameter tube with thick walls on a standard machine, and you’ll likely end up with an oval cross-section or complete crushing. That’s not just inconvenient – it’s catastrophic when structural integrity matters.

Here’s the real cost of compromise: when standard equipment fails, everything downstream suffers. Production failures mean scrapped parts, missed deadlines, and emergency redesigns. We’ve seen manufacturers lose entire contracts because their bending equipment couldn’t deliver the precision their customers demanded.

Compromised structural integrity is perhaps the most serious consequence. When a bent component fails in service – whether it’s in an aircraft, a medical device, or a power plant – the repercussions extend far beyond the immediate cost. Safety issues, recalls, and damaged reputations can cost millions.

That’s why specialized, engineered solutions aren’t luxury items – they’re necessities. Custom tube benders bridge the gap between what standard machines can do and what modern manufacturing demands. When NASA needs components for space missions, they don’t settle for “good enough.” They need precision, reliability, and performance that only engineered solutions can provide.

At Hines Bending Systems, we understand these challenges because we’ve been solving them for decades. Our tube and pipe benders are designed specifically for applications where standard equipment falls short. We’ve built our reputation on turning “impossible” bending challenges into routine manufacturing processes.

The choice is clear: settle for standard limitations or invest in engineered excellence. When your reputation depends on precision, there’s really only one option.

The Hallmarks of a World-Class Custom Tube Bender Manufacturer

When your project demands absolute precision and your reputation is on the line, you need more than just a machine supplier – you need a true partner with proven expertise. A world-class custom tube bender manufacturer stands apart through decades of hands-on experience, a global installation footprint that spans continents, and the kind of industry leadership that comes from solving the impossible, day after day.

At Hines Bending Systems, we’ve built our reputation one challenging project at a time. Our expertise isn’t just theoretical – it’s forged in the real world, where failure isn’t an option and precision is measured in thousandths of an inch. We’ve spent decades perfecting our craft, and that experience becomes your competitive advantage.

A Portfolio of Excellence

The true measure of a custom tube bender manufacturer lies in who trusts them with their most critical applications. We’re incredibly proud to serve industries where precision isn’t just preferred – it’s absolutely essential for success and safety.

Our work with NASA speaks volumes about our capabilities. When the space agency needs components for missions that literally reach for the stars, they turn to us. This partnership isn’t just business; it’s a testament to the best quality and reliability of our bending solutions. You can learn about our work with NASA to see exactly what this collaboration means.

Beyond aerospace, we’re trusted partners across government agencies that demand the highest standards. The automotive industry relies on our precision for everything from exhaust systems to chassis components. In shipbuilding, our machines create the complex pipework that keeps vessels running smoothly in the harshest marine environments. The oil & gas sector counts on our robust solutions for critical pipeline and processing equipment, while the broader energy sector uses our technology for power generation and renewable energy systems.

Comprehensive In-House Capabilities

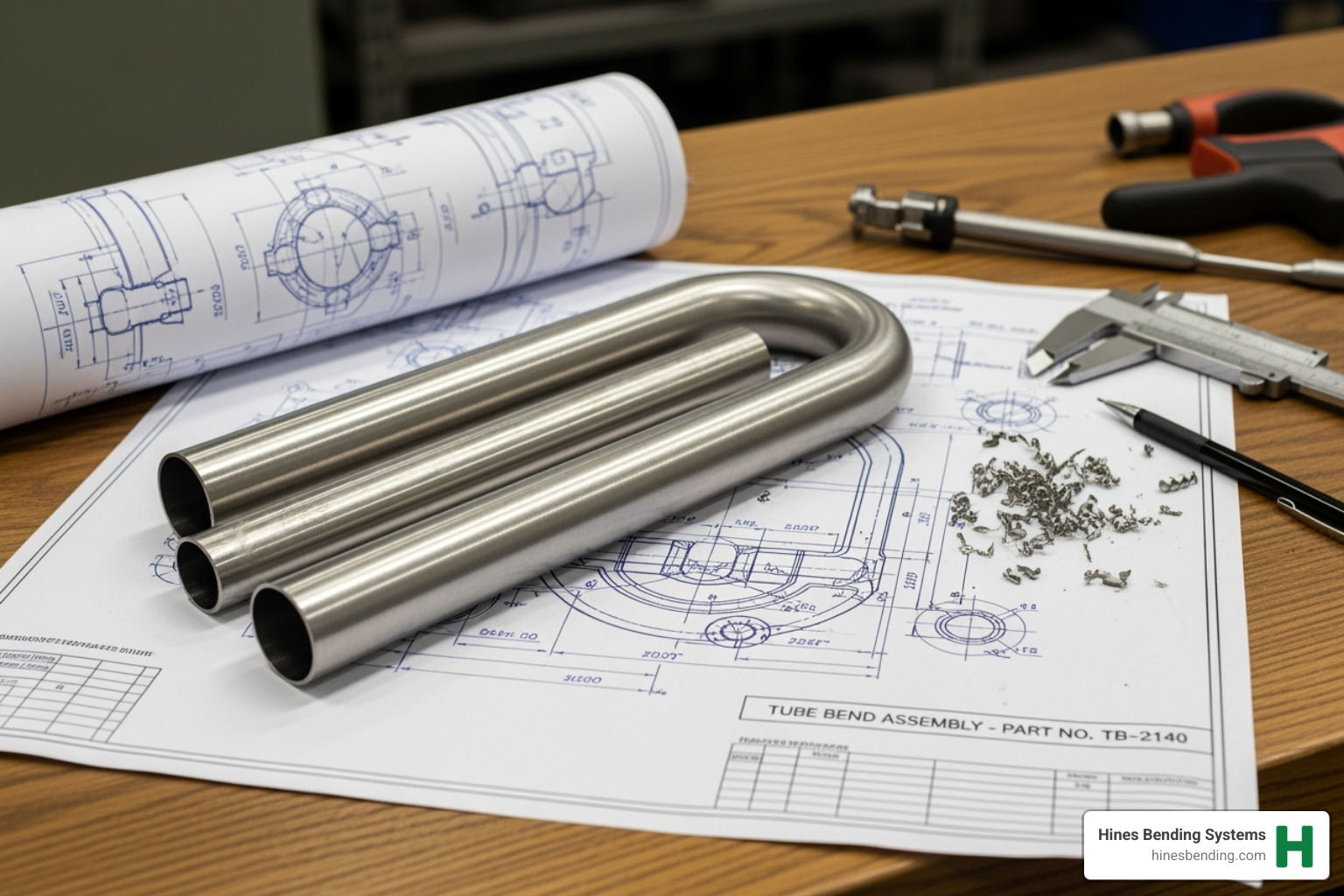

What sets us apart is our ability to handle every aspect of your project from concept to completion. Our dedicated in-house engineering teams don’t just build machines – they partner with you to solve your unique challenges. We speak your language, whether you’re dealing with complex blueprints or pushing the boundaries of what’s possible.

Our custom tooling design capabilities mean every die and mandrel is perfectly matched to your specific requirements. We offer a complete range of Tube and Pipe Bender Accessories designed to optimize every aspect of your bending process.

The heart of our machines beats with advanced software integration and our user-friendly CNC controls. Our BendPro G2 CNC Control system delivers exceptional accuracy and repeatability that you can count on, batch after batch. These sophisticated controls give you precise command over every aspect of the bend, minimizing errors and maximizing efficiency.

Quality isn’t an afterthought – it’s built into every step of our process. Our rigorous quality assurance systems ensure that every custom tube bender leaving our facility meets the highest industry standards. From initial material inspection to final product verification, we maintain the uncompromising standards that have made us the trusted choice for the world’s most demanding applications.

Commitment to Innovation and Support

Innovation drives everything we do. We’re constantly developing new technologies to stay ahead of industry demands. Our Dual Stack CNC Push Benders and Advanced Roll Benders offer unparalleled flexibility and precision for the most complex applications.

Our high-capacity Induction Bending solutions represent the cutting edge of bending technology. These Induction Benders can handle larger outside diameters and thicker wall materials while maintaining perfect material integrity – something that’s simply not possible with conventional methods.

We believe the best machines deserve the best operators. That’s why we offer comprehensive operator training through our detailed Tube and Pipe Bender Training programs. Your team will master every aspect of your new equipment, ensuring you get maximum value from day one.

Our commitment doesn’t end when your machine is installed. We provide dedicated after-sales customer support because we know that your success is our success. When you need us, we’re just a phone call away, ready to keep your operations running smoothly for years to come.

The Strategic Advantages of Investing in Custom Tube Benders

When you invest in custom tube benders from Hines Bending Systems, you’re not just buying a machine – you’re making a strategic decision that transforms your entire manufacturing operation. The benefits ripple through every aspect of your production process, delivering unwavering precision that hits the mark every single time.

Think about it: when was the last time you had to scrap a part because it didn’t meet specifications? With our custom tube benders, those frustrating moments become a thing of the past. Right-first-time repeatability isn’t just a nice-to-have feature – it’s the foundation of profitable manufacturing. Every bend comes out exactly as designed, which means dramatically reduced material waste and happier accountants.

But the real magic happens in your production efficiency. Our machines don’t just bend tubes; they revolutionize how you work. Faster cycle times mean you can take on more projects without expanding your floor space or hiring more operators. Even better, you can create complex, multi-bend parts in one seamless process, eliminating the headache of multiple setups and the risk of cumulative errors.

Expanding Your Manufacturing Capabilities

Here’s where things get exciting. Our custom tube benders open doors you didn’t even know existed. Suddenly, you can work with materials that used to send you scrambling to find subcontractors. We’re talking about carbon steel and stainless steel for your bread-and-butter work, but also exotic materials like titanium, Inconel, and chromoly that command premium prices.

The versatility doesn’t stop at materials. Our machines handle round, square, rectangular, and oval tubes with equal precision. Whether you’re bending delicate tubing with 0.010-inch walls or wrestling with solid bar up to 3 inches thick, we’ve got you covered. Some of our machines can bend round tubes from a tiny 1/16 inch O.D. up to 8 inches O.D., and square tubes from 1/2 inch x 1/2 inch up to 4 inches x 4 inches.

This expanded capability means you can say “yes” to projects that competitors have to turn away. When a customer needs oval tube bending – something few companies can handle properly – you’ll be ready with capabilities ranging from 1/2 inch up to 4 inches. That’s the kind of competitive advantage that builds long-term relationships and premium pricing power.

The Long-Term ROI of a custom tube bender

Let’s talk numbers – the kind that make CFOs smile. While a custom tube bender represents a significant upfront investment, the long-term return on investment is where the real story unfolds. Our machines are built like tanks, designed to run year after year with minimal downtime. That reliability translates directly to increased output and consistent delivery schedules that keep customers coming back.

The superior end-product quality you’ll achieve becomes your calling card in the marketplace. When your components are consistently precise and beautifully formed, word spreads. Premium quality commands premium pricing, and suddenly that initial investment starts looking like the bargain of the century.

We’ve seen it countless times: companies that try to save money with inferior equipment end up spending far more in the long run. Compromised structural integrity, frequent breakdowns, and constant rework eat away at profits faster than you can imagine. That’s why we always emphasize the question: Why Buy from an Industry Leader?

The confidence we have in our machines is so strong that we offer a lifetime warranty for bending certain heavy-duty tubing. When you’re dealing with the same company that supplies NASA, you know you’re investing in proven technology that will serve your business for decades to come.

Selecting Your Partner for Custom Bending Solutions

Finding the right manufacturer for your custom tube benders is one of the most important decisions you’ll make for your operation. This isn’t like buying office supplies online – you’re choosing a partner who will impact your production quality, efficiency, and bottom line for decades to come.

The truth is, not all bending machine manufacturers are created equal. When you’re evaluating potential partners, focus on the fundamentals that really matter: proven track record, extensive global experience, and undeniable industry leadership. At Hines Bending Systems, we’ve built our reputation one successful installation at a time, serving customers across every continent and earning their trust through consistent results.

Our decades of experience aren’t just numbers on a website – they represent thousands of solved problems, innovative solutions, and satisfied customers who continue to rely on us for their most challenging bending applications.

Questions to Ask a Potential custom tube bender Manufacturer

Before you make your decision, ask the tough questions that separate the real experts from the pretenders. What is your experience with my specific industry and application? This matters more than you might think. Bending tubes for medical devices requires different expertise than creating components for oil rigs. We’ve worked extensively across aerospace, automotive, energy, and government sectors – including our ongoing partnership with NASA.

Can you provide examples of similar projects? Anyone can make promises, but results speak louder than sales pitches. We’re proud to share detailed case studies showing how we’ve solved complex bending challenges for clients just like you. When NASA trusts us with components for space missions, you know we can handle your project.

What level of customization and tooling support do you offer? This is where many manufacturers fall short. True customization means designing specialized tooling, engineering unique solutions, and adapting our machines to your exact needs. Our in-house engineering teams don’t just modify existing designs – they create entirely new solutions when necessary.

What does your training and after-sales service include? A custom tube bender is only as good as the team operating it. We provide comprehensive Tube and Pipe Bender Training and ongoing support that keeps your operation running smoothly long after installation.

How do you ensure quality and precision? Ask about their quality control processes, certifications, and the specific technologies they use to maintain tight tolerances. Our rigorous quality assurance systems and advanced CNC controls like the BendPro G2 CNC Control ensure every bend meets your specifications.

These questions, highlighted by experts at The Fabricator, help you identify manufacturers who truly understand what it takes to deliver exceptional results.

The Importance of a True Partnership

Here’s what separates us from other manufacturers: we don’t just sell machines and walk away. We believe in building long-term manufacturing partnerships that grow stronger over time. This starts with our collaborative approach – we listen carefully to understand your unique requirements, challenges, and goals.

Our dedicated engineering support doesn’t end when your machine ships. We stay involved, providing ongoing technical assistance, helping optimize your processes, and ensuring you’re getting maximum value from your investment. This commitment is formalized in our Customers First Promise, which puts your success at the center of everything we do.

When you choose Hines Bending Systems, you’re not just buying a custom tube bender – you’re gaining access to the industry’s deepest expertise, most innovative technologies, and most responsive support team. We become an extension of your engineering department, ready to tackle whatever challenges come next.

That’s the difference between a transaction and a true partnership. We’re here for the long haul, committed to helping you succeed today and grow tomorrow.

Conclusion: Achieve Unparalleled Precision with a Custom Bending Solution

When you look at the landscape of modern manufacturing, one thing becomes crystal clear: precision isn’t just nice to have anymore – it’s absolutely essential. Throughout our exploration of custom tube benders, we’ve seen how these specialized machines deliver the precision, efficiency, and capability that today’s demanding applications require. From the tight tolerances needed for aerospace components to the exotic materials used in energy applications, standard bending solutions simply can’t keep up.

The difference between success and failure often comes down to choosing the right partner. When you’re dealing with applications where every bend matters, where structural integrity is non-negotiable, and where your reputation depends on flawless results, you need more than just a machine supplier. You need a manufacturer with decades of experience, proven expertise, and the kind of global support network that ensures you’re never left hanging.

That’s exactly what sets Hines Bending Systems apart as the #1 global leader in bending technology. Our track record speaks for itself – from our trusted partnership with NASA to installations across the globe, we’ve consistently delivered solutions that exceed expectations. We don’t just manufacture machines; we engineer solutions that transform challenges into opportunities.

The importance of innovation and comprehensive support cannot be overstated in this industry. Technology evolves rapidly, materials become more sophisticated, and applications grow more complex every day. That’s why our commitment to continuous innovation and unparalleled customer support ensures that your investment today will continue paying dividends for years to come.

Whether you’re bending titanium for aerospace applications, creating complex multi-bend assemblies for automotive systems, or handling large-diameter pipes for energy infrastructure, we’re ready to engineer the perfect solution for your most demanding needs. Don’t settle for compromise when excellence is within reach.

Ready to find what true precision looks like? Contact us to learn more about our CNC Bending Machines and see how we can lift your manufacturing processes to achieve unparalleled precision and efficiency.