What Are Hand Tubing Benders?

Hand tubing benders are portable, manual tools designed to create precise bends in soft metal tubing, such as copper and aluminum, without kinking or flattening. Because they are lever-operated and require no power source, they are essential for on-site work in HVAC, plumbing, and automotive applications where quick adjustments and repairs are needed.

These tools work by clamping a tube and using leverage to bend it around a die, typically achieving angles up to 180 degrees. While they excel at basic bending tasks for tubes from 1/4″ to 1/2″ OD, they have clear limitations. Wall thickness capacity is limited, and achieving consistent precision across multiple bends can be challenging.

As manufacturing operations managers know, choosing the right bending solution directly impacts productivity and quality. Hand benders are perfect for field repairs and simple fabrication, but when precision and repeatability matter most, industry leaders turn to advanced bending systems.

The Hines Bending Systems Advantage in Bending Solutions

When working with tubing, the right tool makes all the difference. Hand tubing benders, including lever, ratcheting, and spring types, are designed for specific situations, primarily with soft materials like copper and aluminum. They are the go-to for quick repairs by HVAC technicians or plumbers.

However, these manual tools are just the beginning of what’s possible. At Hines Bending Systems, we are the #1 worldwide manufacturer of bending solutions, providing the highest quality equipment for every need—from simple hand tools to cutting-edge CNC and induction benders. We don’t just make tools; we solve problems. When NASA needs bending solutions for spacecraft fluid systems, they turn to us. Our extensive expertise and the highest number of bender installations worldwide mean we understand exactly what works.

Key Specifications and Material Limitations

Understanding the limits of hand benders shows when it’s time to upgrade. Most hand tools handle common tube outer diameters (OD) like 1/4″, 3/8″, and 1/2″, but struggle with anything larger. Wall thickness capacity is another critical factor, maxing out around 0.12″ (3mm). Attempting to bend thicker or harder materials like stainless steel or titanium with a hand tool often results in kinked tubing and damaged equipment.

When you encounter these limitations, it’s an opportunity to upgrade to superior technology. This is where Hines Bending Systems excels. Our expertise in providing custom solutions for challenging materials and applications is the best in the industry. We work with clients to recommend the optimal equipment, whether it’s a hydraulic bender for heavy-duty work or a CNC system for high-volume production.

Ready to explore your options? Check out our guide: What Type of Bending Machine is Best for Me?

For additional support and accessories to improve your bending capabilities, explore: More info about Tube and Pipe Bender Accessories

Best Practices for Quality Bends

Creating kink-free bends with a hand tubing bender requires careful technique. Accurate measuring, securing the tube firmly, and applying steady, even pressure are crucial. It’s also important to account for springback—the tendency of metal to return to its original shape—by bending slightly past your target angle.

Even with perfect technique, common issues like kinking and flattening (ovality) can occur, especially when pushing the limits of the tool or material. Kinking often happens when a bend radius is too tight, while flattening occurs from a lack of support around the tube. This is where quality tooling makes all the difference. At Hines Bending Systems, our precision-machined dies are engineered to provide optimal support, minimizing these common issues.

For more advanced applications, our machinery uses features like roll dies to distribute bending forces evenly, reducing stress and ensuring structural integrity. Our commitment to quality assurance means our equipment is designed to deliver superior results consistently. When you work with Hines Bending Systems, you’re leveraging decades of engineering expertise refined through countless installations worldwide.

A well-maintained tool performs better and lasts longer. After use, clean your bender of debris, lubricate moving parts, and inspect it for wear. Proper storage in a dry place prevents rust and damage. We engineer our tools for durability, and simple maintenance ensures years of reliable service.

At Hines, we know quality tools are only half the equation. We provide comprehensive training and support to help customers achieve optimal results, transferring knowledge gained from working with everyone from small shops to NASA.

Learn how to use a hand tube bender to accurately and efficiently make bends

When to Upgrade to Professional Bending Machinery

Hand tubing benders are fantastic tools, but every tool has its limits. A time comes when a manual bender holds your business back rather than moving it forward. The signs are clear: high production volumes, the need for absolute repeatability, and working with larger diameters or thicker walls.

What takes minutes with a hand bender can be done in seconds with professional machinery. For hundreds or thousands of pieces, those seconds add up to real money. Professional CNC bending machines also eliminate the variability of manual work—every bend is identical to the last, down to fractions of a degree. Furthermore, some materials and tube sizes require more force than humanly possible to bend safely and effectively.

For critical applications in aerospace, automotive, or medical device manufacturing, precision is essential. Organizations like NASA trust their most demanding projects to our bending solutions because there is no room for the slight variations of manual tools.

This is where Hines Bending Systems shines. As the #1 worldwide manufacturer of tube, pipe, and induction benders, we solve the problems that hand tools can’t. Our CNC benders deliver automated precision for complex bends and efficient production runs. Our induction benders handle the largest diameters and heaviest walls by heating localized sections of the tube, allowing for large radii with minimal distortion.

We constantly innovate with technology like our Dual Stack CNC Push Bender and Roll Bender. When your projects demand more than a hand bender can deliver, you’re not just upgrading—you’re investing in your company’s capability and future growth.

See our Tube and Pipe Bender Gallery

Frequently Asked Questions about Bending

We hear the same thoughtful questions time and again. Whether you’re using a hand tubing bender or considering an upgrade to professional machinery, these answers will help guide your decision.

What are the primary advantages of using a hand tube bender?

Hand tubing benders shine due to their portability for on-site work, lower initial cost for small-scale projects, and simplicity for basic bends in soft materials. Since they require no power source, they are perfect for technicians in the field or work in remote locations. At Hines Bending Systems, we engineer our hand benders with the same commitment to reliability and quality that defines all our products.

How do different hand tube benders compare?

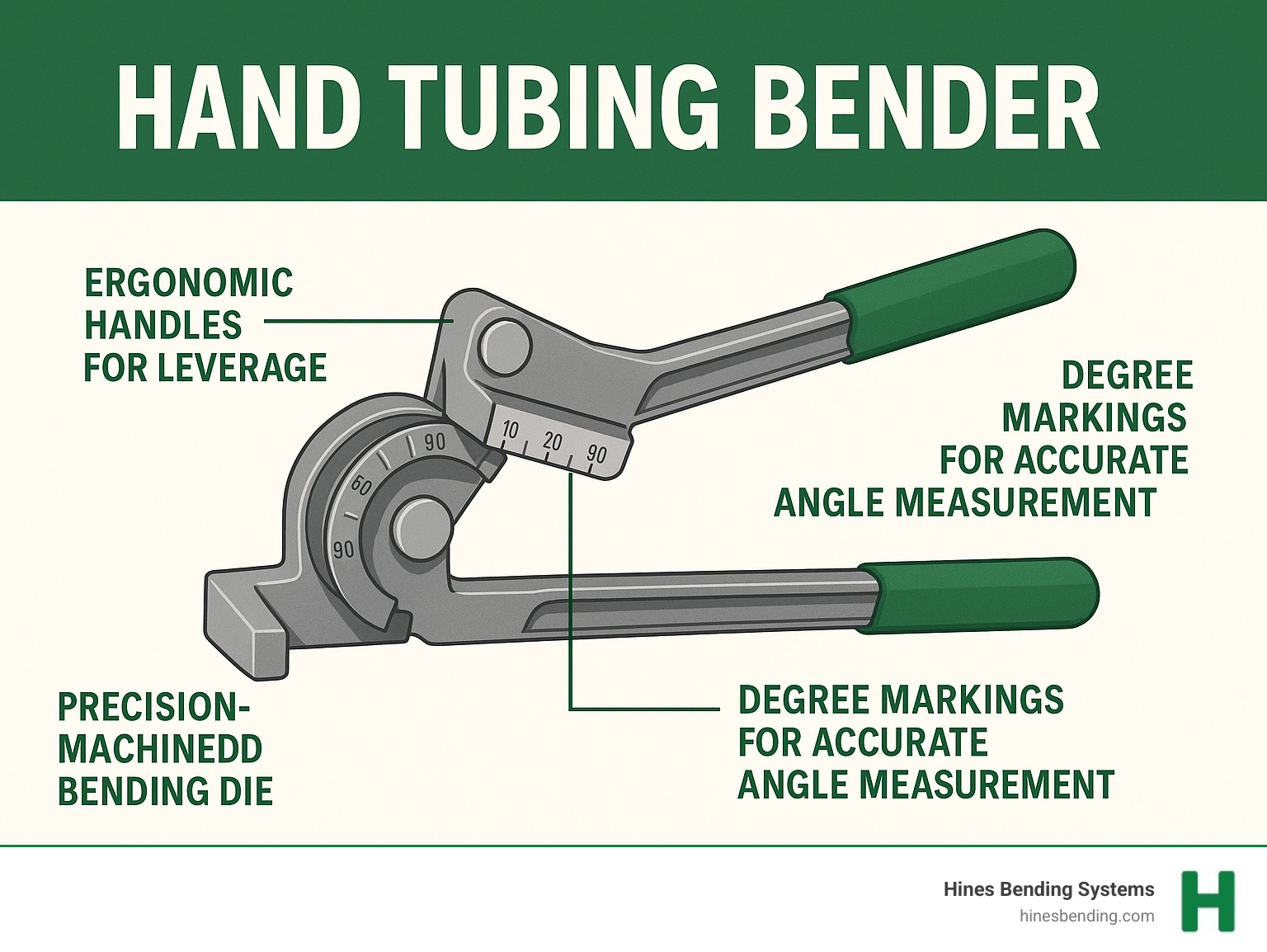

Not all hand tubing benders are created equal. Professional-grade tools are distinguished by high-strength steel construction that won’t deform under stress. Precision-machined dies are critical for clean, kink-free bends, while clear degree markings and ergonomic handles ensure accuracy and reduce fatigue. At Hines Bending Systems, our commitment to superior design and manufacturing ensures every tool we produce embodies these quality features, providing years of reliable service.

What makes Hines Bending Systems’ approach to complex projects superior?

When projects outgrow hand tools, Hines Bending Systems excels. Nobody in the bending machine industry has more expertise and experience than we do. As the #1 worldwide manufacturer of tube, pipe, and induction benders, our leadership reflects the trust that global industries place in our solutions. When massive agencies like NASA need bending equipment for critical projects, they turn to us. This proves that when precision and system integrity are non-negotiable, Hines delivers.

Our approach is built around custom solutions. We work with each client to design and build bending solutions optimized for their specific needs. Our superior quality assurance and continuous innovation, like our Dual Stack CNC Push Bender and Roll Bender, address the evolving demands for complex geometries and improved production capabilities. We don’t just sell machines; we provide complete bending solutions backed by unparalleled expertise.

Conclusion: Choosing the Right Bending Solution for Your Project

We’ve explored hand tubing benders, from their basic mechanics to the techniques for achieving perfect, kink-free bends. These portable manual tools offer convenience for field repairs, cost-effectiveness for small projects, and the reliability of simple engineering. For technicians working with soft materials like copper and aluminum, they are indispensable.

However, there is a clear threshold where the limitations of hand tools become restrictive. When projects demand higher production volumes, absolute repeatability, or involve larger, thicker, or harder materials, a hand bender can’t keep up. For critical applications in aerospace or medical fields, where precision is essential, the stakes are too high for manual tools. This is about using the right tool for the job to ensure quality and safety.

This is why partnering with an expert is crucial for industrial applications. It’s not just about buying a machine; it’s about gaining access to decades of knowledge and proven engineering. At Hines Bending Systems, we understand this progression intimately. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we’ve guided countless clients from simple hand-bending to sophisticated production. The trust organizations like NASA place in us is a testament to our commitment to providing optimal solutions for any challenge.

Whether you are mastering the basics or require a custom-engineered system, our team brings unparalleled expertise to the table. We provide the peace of mind that comes from knowing your projects will be completed with the utmost precision and efficiency, backed by industry-leading quality and innovation.

Ready to explore what’s possible for your specific bending challenges? Find our world-class Tube and Pipe Benders and let us build a custom solution for you.