Why Copper Pipe Bending Machines Are Essential for Professional Results

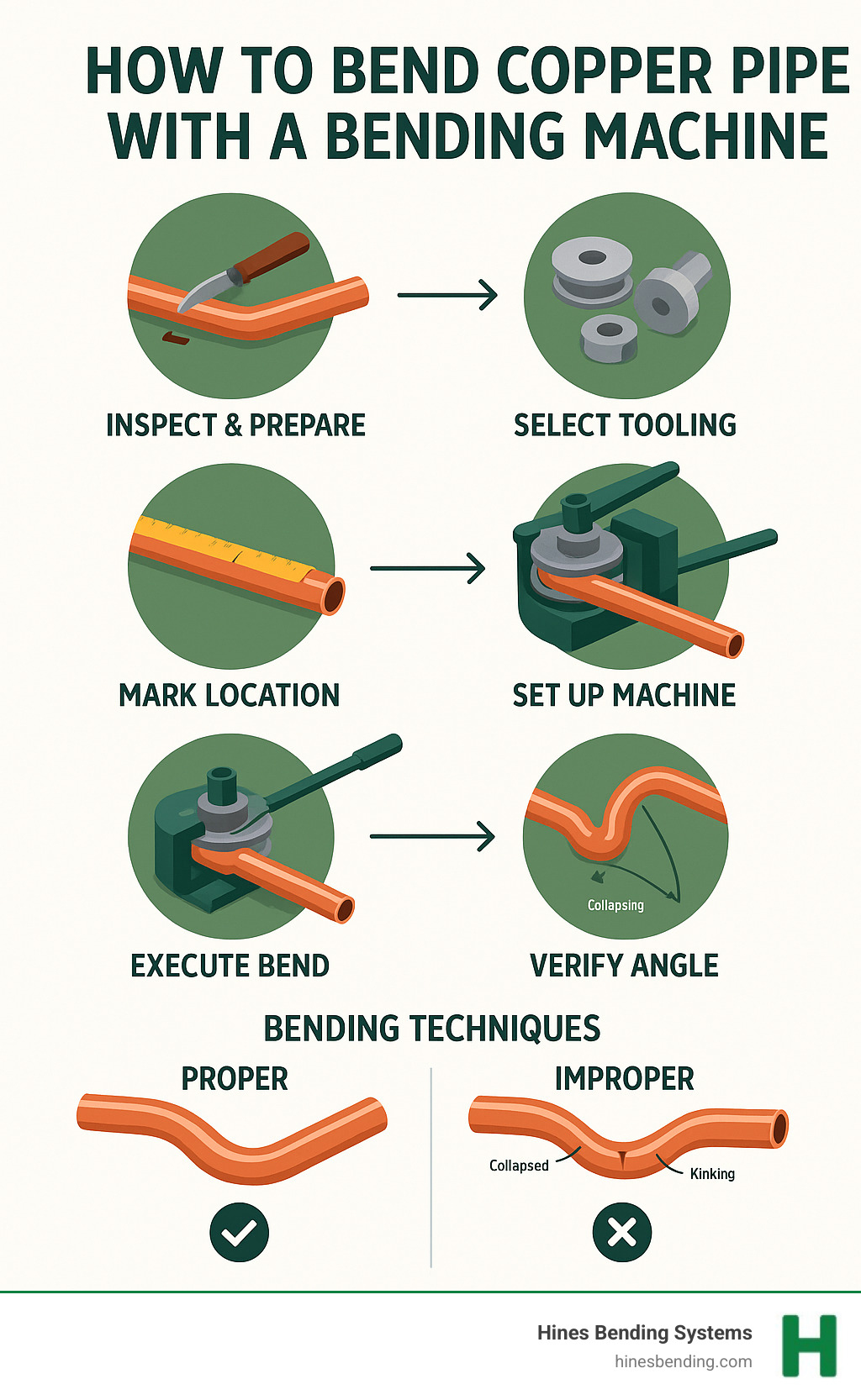

Learning how to bend copper pipe with a bending machine is crucial for any operation demanding precision and quality. Here’s the essential process:

Quick Steps for Machine Bending Copper Pipe:

- Inspect and prepare the copper pipe by cutting to length and deburring edges

- Mark the bend location accurately using proper measurement techniques

- Select the correct die size and insert mandrel for internal support

- Set up the bending machine with appropriate angle and radius settings

- Execute the bend using steady, consistent pressure

- Verify the angle with measuring tools for accuracy

Copper is ideal for bending due to its formability. Research even shows that properly bent copper tube can have greater bursting strength than before bending. This property makes machine bending a critical skill for plumbing, HVAC, and refrigeration systems.

Machine bending offers significant advantages over traditional fitting methods. It eliminates potential leak points, improves flow dynamics with sweeping bends, and provides cost savings by reducing the number of fittings required.

However, achieving professional results requires understanding factors like copper type, wall thickness, and proper machine setup to prevent common issues like kinking or flattening. For high-volume or complex jobs, the choice of equipment is critical. Hines Bending Systems, the #1 worldwide manufacturer of tube benders, has supplied precision solutions to major organizations including NASA, demonstrating the level of expertise required for demanding applications.

Related content about how to bend copper pipe with a bending machine:

Why Professional Bending is Crucial for Copper Pipe

Copper is the gold standard in plumbing, HVAC, and refrigeration due to its exceptional formability. What’s remarkable is that, when bent correctly, copper tube can have greater bursting strength than before bending, a key factor for system integrity detailed by the Copper Development Association.

This is where knowing how to bend copper pipe with a bending machine provides a competitive edge. Professional machine bending improves your entire system by:

- Eliminating leak points: Continuous bends are inherently more reliable than fitted joints.

- Boosting flow efficiency: Sweeping curves reduce turbulence and energy costs compared to sharp elbows.

- Improving aesthetics: Clean, continuous runs look professional and polished.

- Increasing cost-effectiveness: Fewer fittings reduce material and labor costs and minimize future repairs.

At Hines Bending Systems, we’ve spent over 50 years perfecting these advantages. As the #1 worldwide manufacturer of tube benders, our machines deliver the precision and reliability that organizations like NASA depend on. For guidance on finding your ideal bending solution, explore more about our bender solutions.

Understanding Key Bending Terminology

Achieving professional results requires understanding key terms. Hines Bending Systems’ machines and training ensure these factors are perfectly controlled:

- Center Line Radius (CLR): The radius to the pipe’s centerline, which defines the bend’s sharpness.

- Wall Thickness & Outside Diameter (OD): These dimensions determine the required machine power and tooling.

- Springback: The material’s tendency to partially straighten after bending, which our CNC machines automatically compensate for.

- Mandrel Support: An internal tool that prevents the pipe from collapsing, ensuring a smooth, round bend.

For a complete glossary, visit our Tube and Pipe Bending Industry Terms resource.

Choosing the Right Copper for the Job

The type of copper—from flexible soft tubing to rigid hard-drawn (Type L or M)—dictates the bending requirements. Harder tempers and thinner walls are more challenging and prone to kinking or cracking with inferior equipment.

This is where professional machinery is non-negotiable. Hines Bending Systems has extensive experience with every copper type. We provide the powerful, precise machines and custom tooling required to bend even the most challenging materials flawlessly. Our experts will help you select the perfect machine and setup for your specific copper, ensuring you avoid costly material failure and achieve perfect results every time.

How to Bend Copper Pipe with a Bending Machine: A Professional Guide

Mastering how to bend copper pipe with a bending machine transforms your manufacturing capabilities. Whether using our manual benders or industry-leading CNC systems, the principles are the same: meticulous preparation, precise setup, and controlled execution.

At Hines Bending Systems, we’ve perfected this process with clients from small shops to NASA. Our approach focuses on achieving professional results every time.

Step 1: Preparation and Measurement for a Perfect Bend

A perfect bend starts with meticulous preparation. This foundational step eliminates most bending problems before they happen.

- Inspect and Prepare: Check the copper pipe for any flaws. Ensure it is cut cleanly to the correct length and that all edges are deburred to prevent damage to tooling.

- Mark and Measure: Accurately mark the bend location. For complex parts, calculating the “take-up” (material consumed in the bend) is critical for precision. Hines Bending CNC machines can automate these calculations, ensuring your finished part matches the design specifications perfectly.

- Verify: Use a digital angle gauge to confirm measurements. This simple check ensures consistency and helps with quality control.

Great bends start with great setup, and our selection of tube and pipe bender accessories provides the tools you need for proper preparation.

Step 2: Setting Up Your Bending Machine

Proper machine setup is what separates good bends from exceptional ones. The experts at Hines Bending Systems ensure your machine is perfectly configured for your application.

- Select the Right Machine and Tooling: Your bender must match the pipe’s diameter, wall thickness, and material. The die set must match the pipe’s OD perfectly. Hines offers a range from manual benders to industrial CNC systems, and our team helps you select the right machine and precision-engineered tooling for your job.

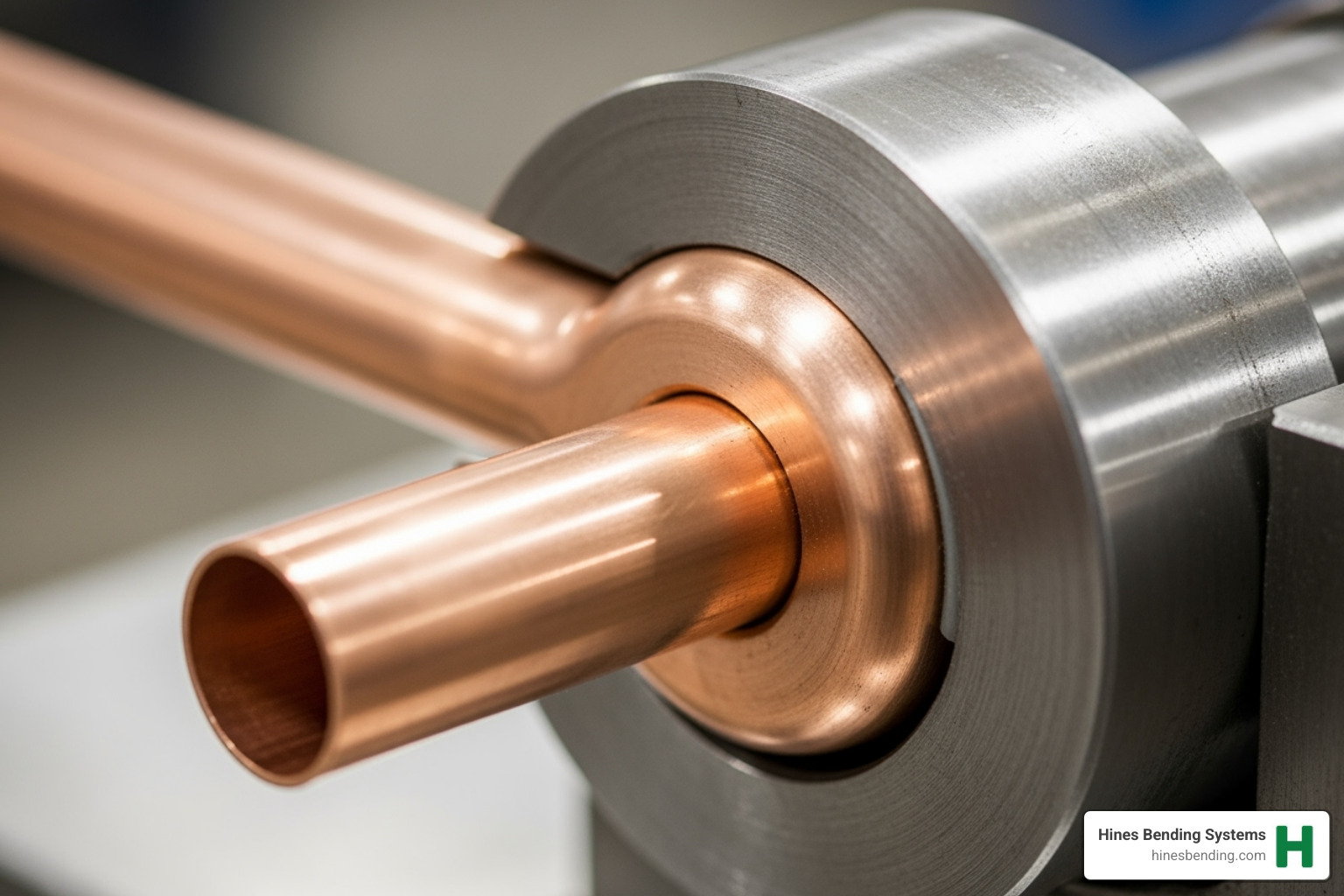

- Position the Mandrel: Correct mandrel placement is critical to prevent internal ripples or collapse. Our expert training ensures your operators master this skill.

- Program the Bend: Set the desired bend angle and radius. While manual benders rely on operator skill, our CNC systems allow you to program exact specifications for perfect repeatability, eliminating guesswork.

Quality tooling is non-negotiable for quality results. Our dies and mandrels meet the same exacting standards as our machines, ensuring every component works together for superior performance.

Step 3: Executing the Bend and Ensuring Accuracy

This is where Hines Bending machines demonstrate their superiority, providing controlled precision that manual methods can’t match.

- Apply Controlled Force: Our hydraulic and servo-electric machines apply steady, consistent pressure, eliminating the jerky movements that cause imperfections.

- Maintain Pipe Profile: The machine’s forming dies and support tooling work in concert to prevent kinks and flattening, maintaining the pipe’s round profile throughout the bend.

- Verify Accuracy: After bending, immediately check the angle with a digital gauge. Our CNC systems deliver angles with incredible accuracy, making precise 90-degree bends and other complex angles routine.

Having the right equipment makes all the difference. Our tube and pipe bender videos demonstrate the precision and efficiency that comes from choosing quality equipment backed by decades of expertise.

Advanced Bending Machines and Custom Solutions

For high-volume production, complex geometries, or large-scale industrial copper installations, manual benders lack the necessary precision and consistency. Modern manufacturing in aerospace, automotive, and sophisticated HVAC systems requires machines that handle intricate designs with absolute reliability.

This is where Hines Bending Systems has established itself as the worldwide leader. We engineer complete solutions customized to your most challenging requirements. Our partnership with organizations like NASA speaks volumes about our capabilities. When you’re Working Together with NASA on mission-critical components, there is no room for compromise.

We understand that how to bend copper pipe with a bending machine becomes more complex with tight tolerances or high-volume production. That’s why we’ve perfected advanced solutions that deliver best results.

CNC Benders for Best Precision and Repeatability

CNC (Computer Numerical Control) technology has revolutionized bending. A CNC bender’s computer program controls every variable—bend angle, radius, and rotation—with mathematical precision. This eliminates human error and guarantees perfect repeatability.

Our T BEND series offers servo-electric and servo-hydraulic options. Servo-electric systems are ideal for speed and precision on copper pipe from 1/4″ to 6″. For larger diameters (up to 12 3/4″) or thick-walled materials, our servo-hydraulic systems provide the necessary power while maintaining Hines’ legendary precision.

Multi-stack tooling is another game-changer, allowing multiple die setups on one machine. This dramatically increases productivity by reducing setup time for parts with different bend radii.

Our advanced software makes programming complex geometries intuitive, allowing you to simulate and verify bends before production. This is crucial in aerospace and medical applications where failure is not an option.

For detailed specifications, explore our complete CNC Tube Benders lineup.

Induction Bending for Large Diameter Copper Pipe

For massive copper installations, induction bending is essential. This method uses a controlled heat application to warm only the specific area being bent. As the pipe moves through an induction coil, the heated section is rapidly cooled, locking in the bend.

This approach offers tremendous advantages for thick-walled copper pipes and larger diameters, preventing distortion and ensuring structural integrity. Our Induction Benders deliver the precision and reliability these critical industrial applications demand.

The Importance of Custom Tooling and Expert Training

Even the best machine is only as effective as its tooling and operator. We’ve learned that standard solutions are rarely sufficient.

Custom die sets are often essential for unique copper alloys or extremely tight bend radii. We design and manufacture tooling to your exact specifications. Mandrel design is equally critical, with different styles required for thin-walled copper or specific alloys to prevent collapse and contamination.

Most importantly, operating advanced equipment requires expertise. Our comprehensive Tube and Pipe Bender Training covers everything from setup to advanced programming. Proper training maximizes your equipment’s capabilities, improves quality, and reduces downtime.

Frequently Asked Questions about Bending Copper Pipe

When clients ask us about how to bend copper pipe with a bending machine, we hear the same concerns repeatedly. After decades of helping manufacturers achieve perfect bends, we know that understanding these fundamentals is key to success.

How do you prevent kinks and flattening when bending copper pipe?

Preventing kinks and flattening requires a combination of proper support, correct tooling, and controlled force—all of which are hallmarks of a Hines Bending machine.

- Internal Support: A correctly positioned mandrel is essential to prevent the pipe from collapsing inward during the bend.

- Correct Tooling: The forming die must perfectly match the pipe’s outside diameter. Our precision-engineered tooling eliminates the guesswork that leads to deformation.

- Consistent Force: Our hydraulic and servo-electric machines apply smooth, gradual pressure throughout the bend, which is critical for preventing defects.

Our experts also help you account for material properties like wall thickness and temper to ensure a perfect bend every time.

What is the ideal bend radius for copper pipe?

While a general rule of thumb is a radius four to five times the pipe’s outside diameter, the ideal radius truly depends on your application, material, and flow requirements. A larger radius is often better for flow efficiency, while some installations require a tighter bend.

This is where Hines Bending Systems’ expertise is invaluable. Our advanced CNC benders can achieve remarkably tight radii without compromising the pipe’s integrity. We work with you to determine the optimal bend geometry for your project, ensuring it meets all functional and performance standards. Our custom solutions are designed to deliver the exact results you need.

Can you bend hard-drawn (Type L or M) copper pipe?

Yes, but it requires a powerful, high-quality machine. Hard-drawn copper is rigid and will kink, flatten, or crack if bent with inadequate equipment. While annealing (heating to soften) is an option, it adds an extra step and requires careful control.

A far better solution is using a machine designed for the challenge. Hines Bending Systems’ heavy-duty benders are engineered to handle hard-drawn copper with ease. They deliver the significant, controlled force needed to create a perfect bend without damaging the material. As the #1 worldwide manufacturer trusted by organizations like NASA, we have the expertise to provide a machine that turns this difficult task into a routine success. Our team can help you determine what type of bending machine is best for your needs.

Conclusion: Partnering with an Expert for Flawless Results

Mastering how to bend copper pipe with a bending machine is about embracing precision engineering to create components that perform flawlessly for decades. This guide has covered every aspect of professional copper bending, from material properties to the detailed steps that ensure superior results.

We’ve shown why machine bending delivers superior results over fittings and how quality machinery serves as the cornerstone of consistent outcomes. Whether executing simple 90-degree bends or complex geometries, the right equipment makes the difference between struggling with imperfections and achieving flawless parts every time.

For advanced needs, CNC benders and induction systems enable manufacturers to tackle projects that were previously impossible. The common challenges—preventing kinks, selecting optimal radii, and working with hard-drawn copper—underscore a fundamental truth: experience and proper equipment eliminate the guesswork that leads to costly mistakes.

At Hines Bending Systems, we understand that choosing the right bending solution is about partnering with a team that brings best expertise to every project. For over 50 years, we have earned our position as the worldwide leader by consistently delivering the highest quality Tube and Pipe Benders and supporting our customers with deep knowledge.

Our work with organizations like NASA demonstrates our capability to meet the most demanding requirements, while our commitment to custom solutions ensures every customer receives exactly what they need to succeed. When you choose Hines Bending Systems, you’re not just purchasing equipment; you’re gaining access to the industry’s most experienced team and a partnership dedicated to turning your most challenging bending requirements into routine successes.