Why Perfect Pipe Bends Matter More Than You Think

Learning how to bend pipe using a pipe bending machine is crucial for manufacturing success, but many operations struggle with kinking, inaccuracy, and costly material waste. The good news? Perfect bends aren’t magic – they’re science.

Quick Answer: How to Bend Pipe Using a Pipe Bending Machine

- Prepare your material – Clean pipe, mark bend locations, calculate springback

- Set up the machine – Choose correct die size, calibrate for material type

- Execute the bend – Secure pipe, align marks, apply steady controlled force

- Compensate for springback – Bend slightly past target angle, measure and adjust

- Quality check – Verify angle accuracy, check for defects like wrinkling or flattening

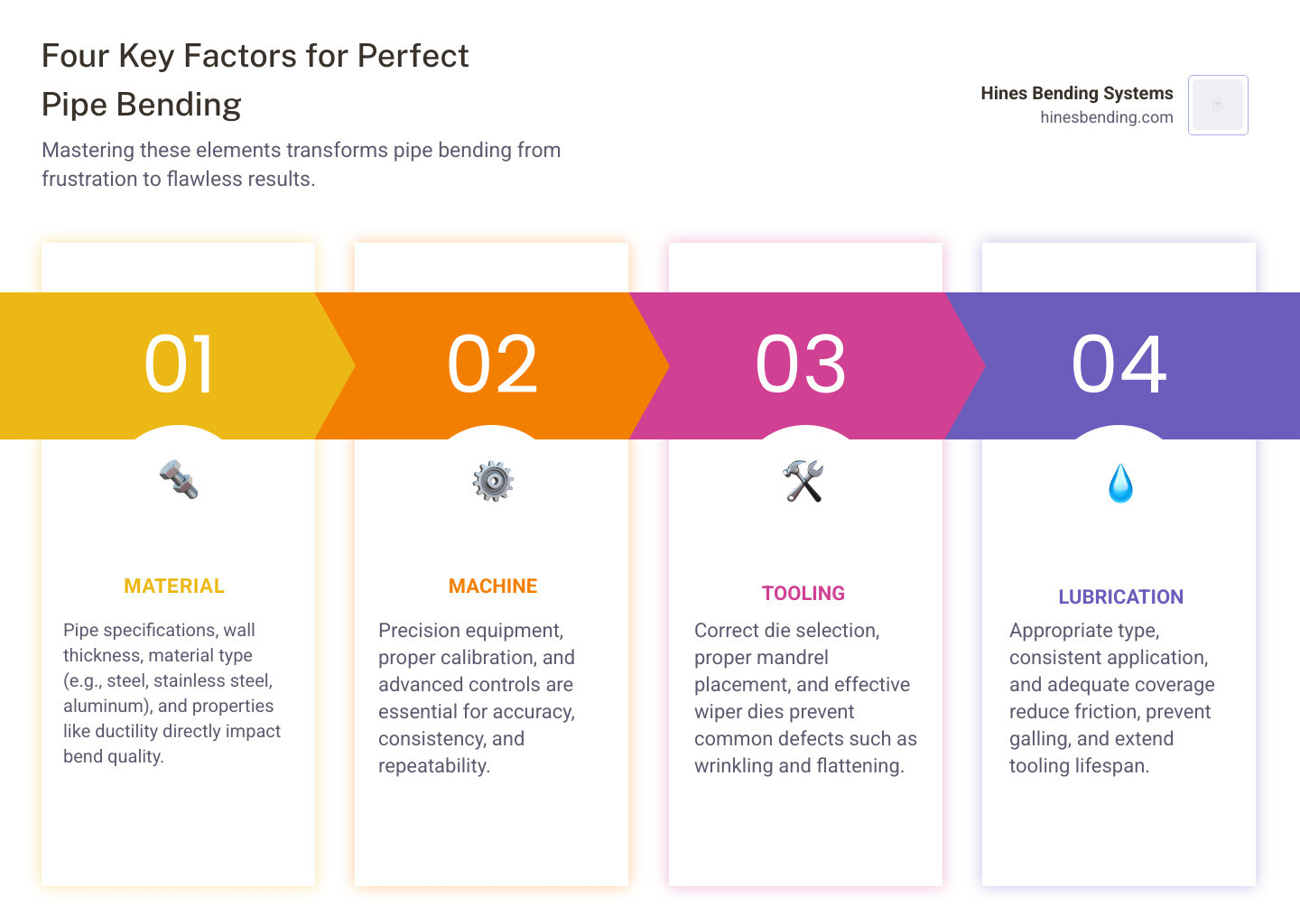

The difference between a nightmare bend and a perfect one comes down to four key factors: your material quality, the right machine, proper tooling, and correct lubrication.

Think of it this way – you wouldn’t build a house without understanding the foundation. The same applies to pipe bending. Understanding your material properties, choosing the right bending method, and having precision equipment makes all the difference.

Whether you’re dealing with stainless steel exhaust systems or large-diameter structural pipes, the principles remain the same. But here’s what most people get wrong: they focus on the bending technique instead of the quality of their equipment and expertise.

The best manufacturers know that consistent, high-quality bends require more than just following steps. They need precision machinery, expert knowledge, and proper training to avoid the costly mistakes that plague many operations.

How to bend pipe using a pipe bending machine terms to learn:

The Foundation of a Perfect Bend: Key Concepts and Considerations

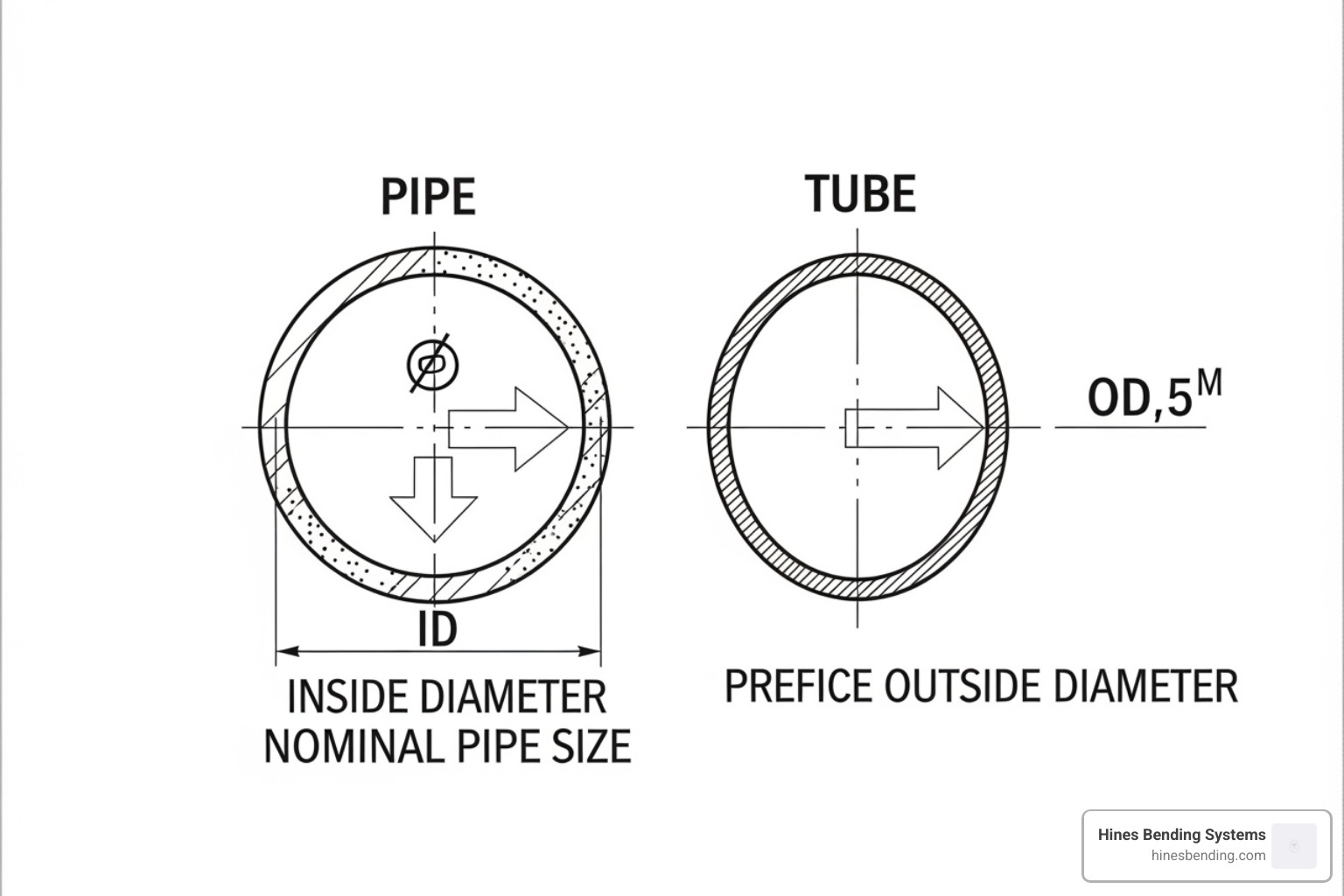

Before you even think about firing up a machine, let’s get comfortable with the language of bending. Here’s something that trips up many people: the difference between “pipe” and “tube.” While we use these words interchangeably at the coffee shop, they mean very different things when you’re learning how to bend pipe using a pipe bending machine.

Pipe is measured by its inside diameter (ID) and comes with a “nominal pipe size” – think of it as the plumbing in your building. Tube, on the other hand, is measured by its precise outside diameter (OD) and can be round, square, or oval. It’s more like the structural framework you see in modern architecture.

Why does this matter? Because your tooling and techniques must match exactly what you’re working with. At Hines Bending Systems, our machines handle both with the kind of precision that comes from being the #1 worldwide manufacturer – we’ve learned these distinctions matter a lot.

Now, let’s talk materials. Steel, stainless steel, and aluminum each have their own personality when it comes to bending. Steel might be straightforward, but stainless steel? It actually gets stronger as you bend it – which sounds great until you realize it also fights back harder.

Each material has what we call elongation – how much it can stretch before saying “enough!” Copper is generally more forgiving with less springback, while stainless steel requires the kind of expertise that comes from supplying companies like NASA. Trust me, when NASA needs perfect bends, there’s no room for guesswork.

Here are the essential terms that’ll become your bending vocabulary:

Centerline Radius (CLR) is your bend’s backbone – the radius measured down the center of your material. Smaller CLR means sharper bends, larger CLR means gentler curves. Springback is that sneaky tendency for your material to “remember” its original shape and try to return to it after bending. Every material does this differently, which is why you’ll need to bend slightly past your target.

The die is your shaping tool – think of it as the template your material follows. And the mandrel? That’s your internal support system, sliding inside the pipe to prevent collapse or wrinkling. It’s like having a steady hand inside, keeping everything smooth and uniform.

For deeper insights into these terms, check out more info about bending industry terms and tube and pipe basics from The Fabricator.

Why Material Choice and Quality Matter

Here’s where things get interesting – and where many operations run into trouble. Material type and wall thickness aren’t just specifications on a sheet; they’re the difference between a perfect bend and expensive scrap metal.

When you bend material, the outer wall stretches and thins while the inner wall compresses and thickens. If your wall is too thin for the bend radius, or your material lacks sufficient ductility, you’ll get oval-shaped disasters, wrinkles, or complete fractures.

Weld seam quality matters more than most people realize. An inconsistent weld creates weak points that show up exactly when you don’t want them to – right in the middle of an expensive bend. Our machines at Hines Bending Systems are engineered to handle even the most demanding specifications because we understand these critical details.

Hardness and ductility determine how your material responds to bending forces. Softer materials like copper bend easily with minimal springback. Harder materials like certain steels require precise control and the kind of expertise that comes from decades of experience working with the most challenging applications.

This is where our unparalleled expertise really shines. When you’re supplying bending solutions to NASA, you learn to handle materials that would make other manufacturers nervous.

Understanding Key Bending Measurements

Precision isn’t just nice to have in pipe bending – it’s everything. Getting these measurements right saves time, material, and the frustration that comes with parts that don’t fit.

Centerline Radius (CLR) and bend angle work together like dance partners. The CLR defines your curve, the bend angle (90 degrees, 45 degrees, etc.) defines how much of that curve you need. Calculating bend length becomes crucial for material planning – there’s actually a formula for this, but with our CNC machines, these calculations happen automatically with pinpoint accuracy.

Ovality and wrinkling are the enemies of good bends. Ovality flattens your round pipe into an egg shape, while wrinkling creates those unsightly ripples on the inside radius. Both are signs of improper technique or inadequate tooling.

Here’s the thing about precision measurements – every wasted bend costs real money. Every misfit part delays your project. Our superior quality machines, combined with expert guidance, are designed to eliminate these costly errors. This commitment to precision is why we’re trusted by the largest companies and government agencies worldwide.

When you’re learning how to bend pipe using a pipe bending machine, the foundation matters just as much as the technique. Get these concepts right, and you’re already ahead of most operations struggling with inconsistent results.

Choosing the Right Bending Method and Machine for Your Project

Here’s the truth about bending methods: choosing the wrong one is like trying to perform surgery with a butter knife. It might technically be possible, but the results won’t be pretty. At Hines Bending Systems, we’ve seen this scenario play out countless times, which is why we work closely with every client to match the perfect method to their specific needs.

Rotary draw bending stands out as the gold standard for precision work, especially when you need tight radii and absolutely cannot compromise on quality. Think aerospace components or automotive exhaust systems where every curve matters. This method gives you maximum control over wall thinning and ovality – exactly what our clients at NASA depend on for their critical applications.

For larger structural work like curved beams or architectural elements, roll bending uses three strategically positioned rolls to create smooth, large-radius curves. Meanwhile, compression bending offers a straightforward approach for simpler projects like handrails, while ram bending provides a cost-effective solution for basic applications, though with less precision control.

The key isn’t just knowing these methods exist – it’s understanding which one will deliver the results your project demands. This is where our decades of experience really shine. As the #1 worldwide manufacturer of bending equipment, we don’t just sell you a machine and wave goodbye. We analyze your specific requirements, consider your materials, evaluate your precision needs, and recommend the optimal solution.

When you’re learning how to bend pipe using a pipe bending machine, the machine itself is only part of the equation. The expertise behind it matters just as much. Our team has more hands-on experience than anyone else in the industry, and we use that knowledge to ensure you get exactly the right equipment for your applications. Explore our CNC Benders to see the precision and versatility we build into every machine.

The Advantage of Advanced Bending Technologies

While traditional methods have their place, advanced bending technologies represent a quantum leap in what’s possible. At Hines, we’ve pioneered innovations that tackle challenges other manufacturers can’t even approach.

Induction bending is where we really showcase our technological leadership. This sophisticated process uses precisely controlled heat induction to make localized sections of pipe pliable, allowing us to create smooth, gradual bends without any internal support tools. The advantages are remarkable – we can handle massive outside diameters and extremely thick wall materials with exceptional precision. This makes our induction systems perfect for heavy construction, oil and gas pipelines, and power generation facilities.

What sets our Induction Benders apart is the level of control we’ve achieved. The process maintains the pipe’s structural integrity throughout the entire bend, something that’s crucial when you’re working with critical infrastructure components.

CNC bending technology represents the pinnacle of automation and repeatability. Our computer-controlled systems execute complex bend sequences with extreme precision, eliminating human error and delivering consistent results every single time. These machines can perform multiple bends on a single piece with incredible accuracy, even handling complex parts with very short distances between bends.

Our continuous innovation drives us to develop solutions like our Dual Stack CNC Push Bender, which addresses the evolving demands of modern manufacturing. When you invest in a Hines CNC system, you’re getting a machine that will deliver flawless results for decades to come.

Selecting the Right Tooling

Even the most advanced bending machine needs the right tooling to perform at its best. Think of tooling as the difference between a master chef’s knife set and a dull blade from the discount store – both might cut, but only one delivers professional results.

The bend die forms the foundation of every bend, determining the radius with mathematical precision. It must be perfectly matched to your pipe’s outside diameter and desired centerline radius. Our clamp dies secure the pipe with just the right amount of pressure – too little and you get slippage, too much and you get deformation.

The wiper die prevents those unsightly wrinkles on the inside radius of your bend. Its positioning and sharpness are absolutely critical, especially when working with thin-walled tubing. Get this wrong, and your beautiful bend turns into scrap metal.

Mandrels provide internal support during the bending process, but their placement requires expertise. Position it too far back, and you’ll see ripples or buckles. Too far forward, and you get bumps at the end of your bend. Our decades of experience mean we know exactly how to set up each component for optimal results.

At Hines, we don’t just manufacture superior bending machines – we provide the complete tooling ecosystem needed for success. Our comprehensive support includes helping you select the perfect accessories for your specific applications. Browse our Bender Accessories to see the range of precision tooling we offer, all designed to work seamlessly with our machines and deliver consistent, professional results.

A Step-by-Step Guide: How to Bend Pipe Using a Pipe Bending Machine

Now comes the exciting part – actually making those perfect bends! While our Hines Bending Systems machines are engineered for precision and user-friendly operation, understanding the fundamental process is essential for success. And before we dive into the technical steps, let’s talk about something that’s non-negotiable: safety.

Safety isn’t just a checkbox – it’s the foundation of every successful bending operation. Always wear your protective gear: safety glasses to protect your eyes from metal shavings, sturdy gloves for grip and protection, and solid footwear that won’t slip. Your work area should be clean, well-lit, and free of clutter that could cause accidents. Take a moment to inspect your machine before starting – check that all guards are properly in place and everything looks ready to go. Our machines come with robust safety features built right in, but your vigilance is what keeps everything running smoothly.

Step 1: How to Prepare the Pipe and Your Machine for Bending

Great bends start with great preparation. Think of this as laying the groundwork for success – rush through this step, and you’ll likely pay for it later with wasted material and frustrating do-overs.

Measure twice, cut once – this old carpenter’s wisdom applies perfectly to pipe bending. Take your time with measurements and cut your pipe to the exact length needed. There’s nothing more frustrating than finding you’re an inch short after completing a complex bend sequence.

Marking your bend locations is where precision really matters. Use a quality measuring tool and a clear marker to indicate exactly where each bend should start and end. For complex multi-bend parts, consider drawing a longitudinal line on the exterior – this helps maintain proper alignment throughout the process. Bend offset (the distance between your bend start point and where the tube sits in the machine) varies by machine and tooling, so understanding your specific setup is crucial.

Setting up your machine properly can make or break your project. Choose the bend die that precisely matches your pipe’s outside diameter and desired centerline radius. Install your clamp die, wiper die, and mandrel according to your machine specifications. Here’s where Hines Bending Systems really shines – our machines feature intuitive setups that make this process straightforward, and our comprehensive training ensures you’ll master it quickly.

Calibrating for your specific material is often overlooked but absolutely critical. Different materials behave completely differently under bending forces. If you’re working with one of our advanced CNC benders, simply input your material type and wall thickness, and the machine handles the rest. For other setups, performing a test bend on scrap material helps you understand exactly how your specific material will respond.

Proper lubrication might seem like a small detail, but it’s absolutely vital for success. The right lubricant reduces friction, prevents material galling, and significantly extends your tooling life. Apply lubricant to all contact points between the pipe and tooling. Our experts work closely with customers to recommend the optimal lubrication approach for their specific materials and applications.

Step 2: How to Execute the Bend and Compensate for Springback

With everything properly prepared, it’s time for the main event. This is where how to bend pipe using a pipe bending machine transforms from theory to practice.

Securing your pipe in the machine requires attention to detail. Make sure the pipe sits properly in all dies and that your clamp die engages securely. Align your marked bend start point with the leading edge of the bend die (or according to your machine’s specific bend offset requirements). Take a moment to double-check everything – it’s much easier to adjust now than after you’ve started bending.

Applying steady, controlled force is where machine quality really matters. Whether you’re using a manual bender or one of our powerful hydraulic systems, smooth and consistent pressure is key. Jerky or uneven movements can cause kinking, wrinkling, or irregular bends that compromise both appearance and structural integrity. Our machines are specifically designed to deliver smooth, predictable power that gives you precise control throughout the entire bending process.

Here’s where experience really pays off: bending past your target angle to compensate for springback. Every material has a natural tendency to spring back toward its original shape after bending forces are released. This means if you want a perfect 90-degree bend, you’ll typically need to bend to 92 or 93 degrees, depending on your material and wall thickness.

Measuring springback accurately is crucial for consistent results. The best approach is performing a test bend on scrap material – bend it to your target angle, release the pressure, then measure the actual result. The difference tells you exactly how much to compensate on production parts. Our advanced CNC systems can learn these characteristics and automatically compensate, ensuring perfect angles every single time.

Making final adjustments when needed is part of the craft. If a bend isn’t quite perfect, you can often make small corrections by carefully re-seating the pipe and applying slight additional pressure. Precision bending is a skill that develops with experience, and with our machines and expert training support, you’ll achieve remarkable accuracy and consistency.

The most common mistakes we see can easily be avoided with proper technique: not compensating for springback leads to angles that are consistently off, while using incorrect tooling can cause kinking, ovality, or unsightly wrinkling. Inconsistent force application results in uneven bends, and improper lubrication causes excessive friction and premature tooling wear. Perhaps most importantly, ignoring material properties by treating all metals the same way leads to unpredictable results. Finally, never compromise on safety procedures – no bend is worth an injury.

At Hines Bending Systems, we don’t just sell you a machine and walk away. Our comprehensive training programs and ongoing support ensure you master these techniques quickly and maintain consistent, high-quality results. With our expertise backing you up, you’ll be producing professional-grade bends with confidence.

Why Bending is Often Superior to Traditional Fittings

When faced with routing pipes around obstacles or creating complex fluid systems, many professionals default to traditional fittings – elbows, tees, and couplings. But here’s something that might surprise you: how to bend pipe using a pipe bending machine often delivers far superior results than assembling multiple fittings together.

Think about it this way – every time you connect two pieces with a fitting, you’re creating a potential weak point in your system. Fewer leak points is perhaps the most compelling advantage of bent pipe. A single, continuous bent piece eliminates multiple connection points, dramatically reducing the risk of leaks, spills, and costly maintenance down the road. In industries where system integrity is critical, this advantage alone can justify the investment in quality bending equipment.

But the benefits extend far beyond just leak prevention. Improved fluid flow is another game-changer. When fluid travels through a smooth, continuous bend, it maintains better laminar flow compared to the turbulence created by multiple fittings. This means less turbulence, reduced pressure drops, and improved overall system efficiency. Your pumps don’t have to work as hard, and your system performs better.

From a practical standpoint, bent tubing delivers significant time and labor savings. Instead of measuring, cutting, deburring, and installing multiple fittings for every directional change, you can create complex routing with a single piece of bent pipe. This translates directly into reduced labor costs and faster project completion – something every project manager appreciates.

The structural integrity advantage is equally impressive. A continuous piece of bent pipe is inherently stronger than multiple short sections joined by fittings. This becomes especially important in high-pressure applications or structural uses where strength and reliability are non-negotiable. At Hines Bending Systems, we’ve seen this principle proven time and again in demanding applications for clients like NASA, where failure simply isn’t an option.

Space constraints? Bent tubing creates a more compact system footprint than traditional fitting assemblies. This is invaluable in tight spaces, allowing for more efficient use of available room while maintaining easier access for maintenance. Plus, let’s be honest about the aesthetic advantages – a beautifully bent piece of pipe looks far more professional and clean than a cluttered assembly of fittings. In applications where appearance matters, there’s simply no comparison.

These advantages explain why we’re so passionate about providing the highest quality bending machines to our clients. When you choose precision bending over traditional fittings, you’re not just changing your approach – you’re upgrading your entire system’s performance, reliability, and efficiency. This philosophy drives everything we do, from our advanced CNC benders to our comprehensive support, all backed by our Customers First Promise.

Conclusion: Achieving Bending Excellence with the Right Partner

Learning how to bend pipe using a pipe bending machine successfully comes down to understanding the fundamentals we’ve covered: material properties matter, precision measurements prevent costly errors, and the right equipment makes all the difference.

But here’s the truth – even with perfect technique, you’re only as good as your machinery and the expertise behind it. That’s where choosing the right partner becomes absolutely critical.

Precision bending requires expertise. It’s not just about following steps or having decent equipment. The most successful operations understand that consistent, high-quality bends demand deep knowledge of materials, advanced machinery, and ongoing support. This is exactly what sets Hines Bending Systems apart in the industry.

The right machinery is critical. We’ve seen too many operations struggle with inferior equipment that promises the world but delivers inconsistent results, costly downtime, and frustrated operators. At Hines Bending Systems, we don’t just manufacture bending machines – we engineer solutions that deliver superior quality and precision, day after day.

As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we bring best expertise to every project. When you consider that we supply industry leaders like NASA with our bending solutions, you understand the level of precision and reliability built into every machine we create.

Nobody in the bending machine industry has more expertise and experience than Hines. With the highest number of bender installations worldwide, we’ve seen every challenge, solved every problem, and refined our approach through decades of real-world application. This isn’t just about selling equipment – it’s about providing custom bending solutions custom specifically to your unique requirements.

We work closely with each client to understand their specific needs, then deliver machines designed to meet the most demanding industry standards. Our superior quality machines don’t compromise on integrity like cheaper alternatives might. Instead, they’re built to handle whatever your operation demands, backed by comprehensive training and support that ensures you maximize your investment.

Whether you need our innovative Dual Stack CNC Push Bender for complex applications or our precision induction benders for large-diameter work, we have the technology and expertise to deliver exactly what your operation requires.

Ready to experience the Hines difference? Explore our full range of Tube & Pipe Benders and find why professionals worldwide trust Hines Bending Systems for their most critical bending applications.