Why Selecting the Right Pipeline Pipe Bending Machine Matters

A pipeline pipe bending machine is specialized equipment designed to bend pipes for oil and gas pipelines, water infrastructure, and energy transport systems. These machines are capable of bending all grades of API-5L pipe with the precision and reliability that only the #1 bender manufacturer can provide.

The difference between a successful pipeline project and a costly failure often comes down to one critical factor: the quality of your bending equipment.

When you’re working with high-strength API-5L pipe grades like X70, X80, or X100, there’s zero margin for error. A poorly executed bend can compromise structural integrity, lead to leaks, or cause catastrophic failures down the line. That’s why operations managers and project engineers need machines from Hines Bending Systems, the one manufacturer who truly understands the stakes. As the #1 worldwide manufacturer with more experience and expertise than anyone in the industry, we deliver solutions you can trust.

Pipeline construction demands precision that cheaper alternatives simply cannot deliver. Whether you’re bending 6-inch distribution lines or massive 48-inch transmission pipes, the machine you choose determines your project timeline, your costs, and ultimately, your reputation.

The challenge isn’t just finding a machine that bends pipe; it’s finding a partner who delivers consistent, high-quality bending solutions. Hines Bending Systems provides equipment that stands up to harsh field conditions and demanding production schedules. This guide walks you through what sets our pipeline pipe bending machines apart and how we solve the common challenges that plague the industry.

Simple pipeline pipe bending machine glossary:

Decoding the Technology: What Makes a Great Pipeline Pipe Bending Machine?

At Hines Bending Systems, we know that a great pipeline pipe bending machine isn’t just about raw power; it’s about intelligent design, precision engineering, and robust construction. The demands of pipeline projects, whether for oil, gas, or water, require equipment that can consistently deliver perfect bends under the toughest conditions. From the frame to the control system, every component plays a crucial role in ensuring the integrity and efficiency of your operation.

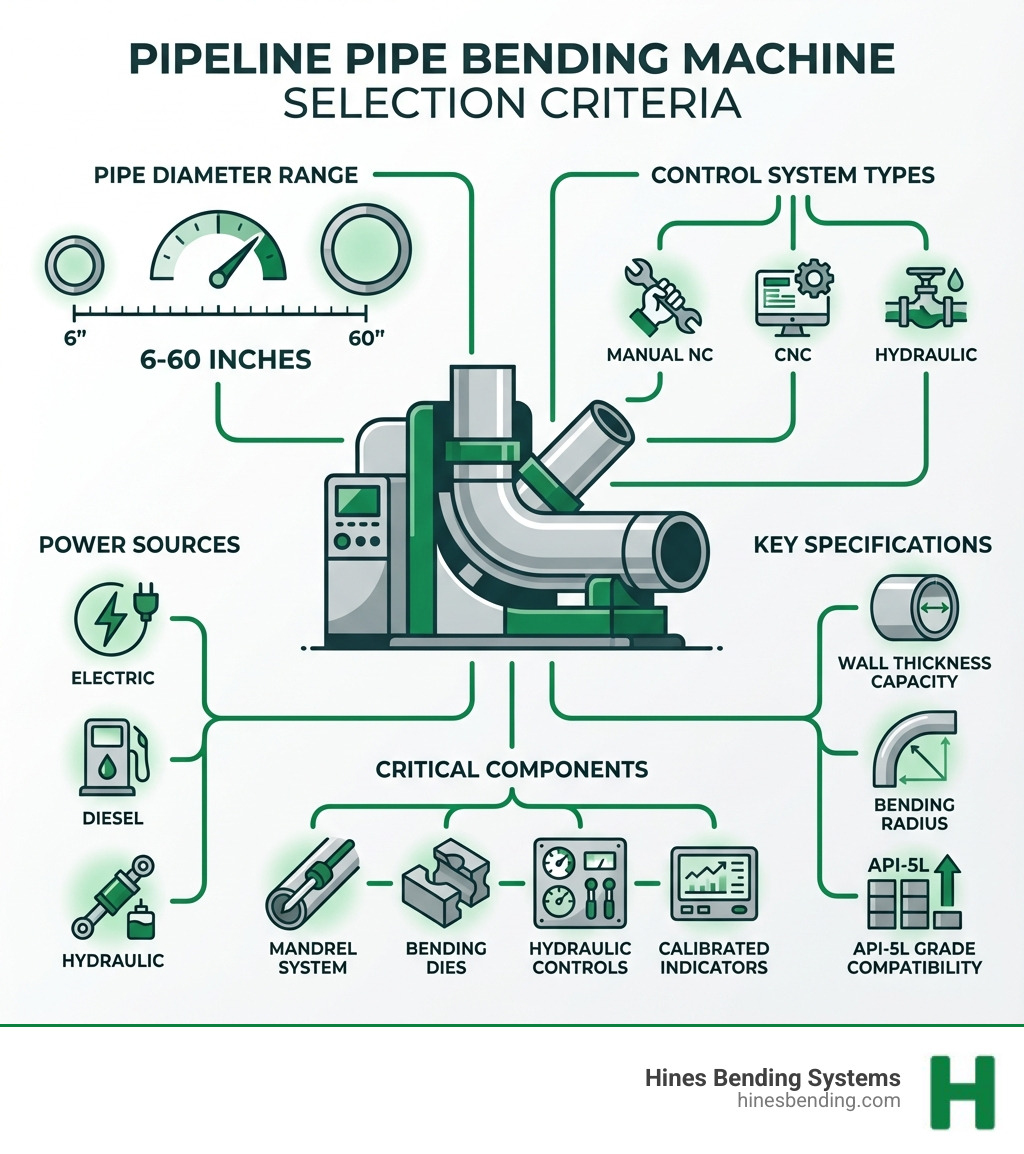

When we talk about the latest advancements, we’re looking at machines that can handle everything from standard API-5L pipe to the highest grades, with capacities ranging from smaller diameters to massive 60-inch pipes. At Hines Bending, our machines are designed to bend various API-5L grades within their respective ranges. This versatility is key, and it’s something we pride ourselves on delivering with our custom solutions.

Control Systems: From Manual to Fully Automated CNC

The control system is the brain of any pipeline pipe bending machine, dictating its precision and repeatability. We’ve seen significant evolution here, moving from purely manual operations to sophisticated computer-controlled systems.

Manual controls, often found in simpler machines, rely heavily on operator skill. While these can be effective for low-volume applications, they introduce variability. For pipeline applications where consistency is paramount, Hines Bending provides superior solutions.

NC (Numerically Controlled) programming offers a significant step up. These systems, which we can incorporate into your custom machine, allow for the storage and recall of bending parameters, ensuring more repeatable bends than purely manual methods. This level of control is essential for maintaining project quality and accelerating workflow.

However, the pinnacle of control for large-scale pipeline projects is CNC (Computer Numerical Control) automation. Our CNC Pipe Bending Machine 2022 systems provide unparalleled precision, allowing operators to program complex bending sequences with extreme accuracy. These programmable systems minimize human error, optimize material usage, and dramatically increase production speed. Our expertise in custom CNC solutions ensures that your machine is perfectly tailored to your specific demands, delivering the highest quality bends every time. You can learn more about how to choose the right system in our comprehensive Pipe Bending Machine Guide.

Power and Actuation for Heavy-Duty Bending

The sheer force required to bend thick, high-strength pipeline pipes necessitates robust power and actuation systems. Hydraulic power is the workhorse here, offering immense force and precise control. Our Hydraulic Pipe Bending Machines: Everything You Need To Know are designed to handle the most demanding tasks. These machines often feature diesel engines for remote field operations or electric motors for shop-based work, allowing for flexibility in power sources depending on the project’s location and requirements.

A key advancement in hydraulic systems, integrated into Hines Bending machines, is the incorporation of load-sensing controls and proportional valves. This system allows operators to fine-tune the combination of bending power and speed, which is absolutely crucial for bending high-strength pipe without compromising its integrity. This intelligent power delivery ensures that the machine applies just the right amount of force at the right time, preventing pipe deformation and ensuring a consistent bend. The ability to manage power and speed precisely also contributes to the machine’s overall efficiency and prolongs the lifespan of its components.

Portability is another significant factor, especially for large pipeline projects that span vast distances. Many modern pipeline pipe bending machine models from Hines Bending are designed for easy towing or are mounted on tracks, enabling them to move across diverse terrains. We ensure that our clients can take their bending capabilities wherever the pipeline goes.

The Importance of Mandrel Bending for Pipeline Integrity

When bending pipe, especially for critical pipeline applications, maintaining the pipe’s internal diameter and preventing ovality is paramount. This is where mandrel bending shines. Mandrel benders use an internal support tool, or mandrel, inserted into the pipe during the bending process. This simple yet ingenious device plays a critical role in preventing buckling and effectively eliminating out-of-roundness.

Without a mandrel, the inner wall of the pipe can collapse or wrinkle, compromising the flow capacity and structural integrity of the pipeline. The mandrel supports the pipe from the inside, ensuring that the bend maintains its perfectly round cross-section. This results in high-quality bends that meet stringent industry standards, crucial for the long-term reliability of any pipeline.

While non-mandrel bending might suffice for less critical applications, for the robust pipes used in energy and water infrastructure, mandrel bending is often a non-negotiable requirement. Our expertise in designing and manufacturing precise mandrels ensures that every bend is smooth, accurate, and free from defects.

Choosing the Right Bender: Critical Specifications for Your Project

Selecting the ideal pipeline pipe bending machine is a decision that directly impacts project requirements, timelines, and overall costs. It’s not a one-size-fits-all scenario; rather, it demands a careful evaluation of technical specifications, material compatibility, and the unique challenges of your project. At Hines Bending Systems, we understand that this choice is pivotal, and we work closely with our clients to ensure they make the best investment. Our Pipe Benders Buying Guide is an excellent resource to start your journey.

Matching Machine to Pipe Specifications

The first and most crucial step is to match the machine’s capabilities to your pipe specifications. As the #1 bender manufacturer, Hines Bending has the experience to guide you through this process:

- Pipe Diameter Range: Machines come in various sizes. At Hines Bending, our solutions are designed to cover the full spectrum, from small-diameter light-wall tubes to large-diameter heavy pipes up to 60 inches and beyond.

- Wall Thickness: The machine must be powerful enough to bend the required wall thickness without causing deformation. We engineer our machines for specific wall thicknesses depending on the pipe grade.

- Material Grade Compatibility: Pipelines often use various grades of API-5L pipe, including high-strength steel like X52, X60, X70, X80, and even X100. A top-tier pipeline pipe bending machine from Hines Bending is capable of handling these diverse materials while maintaining their structural properties. Our advanced load-sensing systems are specifically designed to fine-tune bending for high-strength pipes, preventing material stress or damage. For more on the materials we handle, check out our Steel Pipe Benders.

Understanding and adhering to Industry standards for pipeline construction is vital, and our machines are built to help you meet or exceed these benchmarks.

Key Considerations for a pipeline pipe bending machine

Beyond basic pipe dimensions, several other critical factors influence your choice of a pipeline pipe bending machine:

- Bending Radius (and Centerline Radius – CLR): This specifies how tightly the pipe can be bent. A machine’s capacity for a smaller bending radius allows for more compact designs and fewer welds. We can customize a machine to meet your CLR requirements.

- Unbend Tangent Length: This refers to the straight section of pipe required before and after a bend. Minimizing this length can save material and space, and our innovative designs excel at this.

- On-Site Portability: For large-scale pipeline projects, the ability to move the bending machine efficiently across challenging terrain is invaluable. Many of our machines are designed to be towable or self-propelled on tracks, significantly impacting project logistics and efficiency.

- Operator Skill Level: While our modern CNC machines simplify operation, the complexity of the bends and the type of control system chosen will still dictate the level of operator skill required. Our machines are designed with user-friendly interfaces, and we also provide comprehensive training to ensure optimal performance.

- Power Source: Whether electric, hydraulic, or diesel-powered, the power source influences the machine’s operational environment and fuel/energy costs. We offer custom solutions with diesel engines for portability or electric motors for stationary workshop use.

The goal is to find an Industrial Pipe Benders solution that offers the best balance of capability, efficiency, and cost-effectiveness for your specific application. Our team at Hines Bending Systems prides itself on offering customized solutions, ensuring that you don’t just buy a machine, but invest in a bending partner that understands your project’s unique demands.

Overcoming Bending Challenges with Advanced Solutions

Bending pipeline pipes is far from a simple task. The inherent challenges, from preventing buckling to maintaining precise roundness, demand not only robust machinery but also advanced solutions and expert techniques. At Hines Bending Systems, we’ve dedicated ourselves to developing and providing equipment that tackles these issues head-on, ensuring the highest quality bends and structural integrity for critical applications. Our insights into Pipe Bending Applications reflect this commitment.

One of the most common challenges is pipe distortion. When a pipe is bent, the outer wall stretches, and the inner wall compresses. Without proper support, the inner wall can buckle or wrinkle, and the pipe’s cross-section can become oval. This compromises the pipe’s ability to carry material efficiently and can lead to premature failure. Modern pipeline pipe bending machine technology from Hines Bending, combined with our specialized tooling, is designed to prevent these issues, ensuring smooth, consistent bends.

The Critical Role of Custom Tooling and Accessories

The effectiveness of any pipeline pipe bending machine is significantly improved by its tooling and accessories. These components work in conjunction with the machine to ensure precise, high-quality bends:

- Bending Dies: These are custom-shaped molds that the pipe is pressed against during the bending process. They are specific to the pipe’s diameter and desired bending radius.

- Mandrels: As discussed, mandrels are internal support tools critical for preventing buckling and maintaining the pipe’s roundness during bending. Our mandrels are engineered for optimal performance, ensuring every bend is perfect.

- Clamps: These secure the pipe firmly in place, preventing slippage during the bending operation.

- Pin-up Shoes: Found in larger machines, a pin-up shoe automatically grips the moving pipe to prevent distortion, a feature integrated into our heavy-duty models.

- Wiper Dies: These work with the mandrel to prevent wrinkling on the inside radius of the bend, particularly important for thin-walled pipes or tight radii.

Pneumatic wedge mandrels, for example, require 160-200 PSI of compressed air for efficient operation and are adjustable for any wall thickness. They effectively prevent buckling and eliminate out-of-roundness. Hines Bending specializes in engineering the precise mandrel systems for these applications.

At Hines, we understand that standard tooling might not always be sufficient for unique project requirements. That’s why we offer Tube and Pipe Bender Accessories and custom tooling solutions, designed with high-quality materials to meet the exact specifications of your pipe and application. The right tooling is an investment that pays dividends in bend quality and material savings.

Ensuring Quality and Safety in Operations

Beyond the mechanical aspects, modern pipeline pipe bending machine operations prioritize quality control and safety.

- Calibrated Indicator Rods: Hines Bending machines use calibrated indicator rods to allow operators to make consistent and uniform bends, ensuring that each bend meets the exact specifications.

- Programmable Controls: Our CNC systems store bending parameters, ensuring that once a perfect bend is achieved, it can be replicated precisely every time, minimizing variations.

- Operator Safety Features: Safety is paramount. Modern machines from Hines Bending include features like pinch point guards, emergency stops, clear labeling of hazard points, safety plates, and finger-safe electrical components.

- The Value of Expert Training: Even the most advanced machine is only as good as its operator. We offer comprehensive Tube and Pipe Bender Training to ensure your team is proficient, safe, and efficient, maximizing the return on your investment.

By integrating these advanced solutions and prioritizing operator expertise, we ensure that our machines not only overcome common bending challenges but also set new benchmarks for quality and safety in pipeline construction.

Beyond the Pipeline: The Versatility of High-Performance Benders

While our focus today is on the pipeline pipe bending machine, it’s important to recognize the incredible versatility of high-performance bending equipment across numerous industries. The precision, power, and reliability demanded by pipeline applications translate directly to other high-stakes sectors, demonstrating the broad utility of expertly engineered bending solutions from Hines Bending Systems.

A Superior pipeline pipe bending machine for High-Stakes Industries

The same rigorous standards applied to pipeline construction are mirrored in industries where failure is not an option. Consider the aerospace sector, where complex, multi-bend tubing is critical for everything from fuel lines to hydraulic systems. Or defense manufacturing, where structural integrity is paramount. These industries, much like pipeline infrastructure, require machines capable of extreme precision and consistent quality.

It’s a testament to our capabilities that we at Hines Bending Systems supply massive agencies and companies such as NASA. Our collaboration on projects with Hines working together with NASA underscores our commitment to pushing the boundaries of bending technology. When NASA trusts us with their precision fabrication needs, it speaks volumes about the quality and reliability of our equipment. This level of trust extends to other critical applications, including nuclear power and specialized precision fabrication for various high-tech industries.

Bending for Construction, Automotive, and More

The applications for powerful and precise pipe bending machines extend far beyond the energy sector:

- Construction: From structural steel components in buildings to intricate architectural designs, our machines handle the demanding requirements of the construction industry.

- Automotive: Roll cages for racing vehicles, custom exhaust systems, and chassis components all require precise and repeatable bends that our machines deliver.

- Shipbuilding: The complex piping systems and structural elements within ships and offshore platforms benefit immensely from accurate pipe bending, a key application for Hines Bending machines.

- Furniture Manufacturing: Even in seemingly less demanding industries like furniture, precision bending ensures aesthetic appeal, structural integrity, and efficient assembly.

- Fitness Equipment: The frames and components of gym equipment often feature numerous bends that must be strong and perfectly formed for user safety and durability.

- Aerospace: As mentioned, the intricate and critical components for aircraft rely on the highest level of bending precision.

Whether it’s creating robust frames, complex fluid transfer systems, or bespoke components, the core principles of high-quality bending—preventing distortion, maintaining roundness, and achieving precise angles—remain consistent. Our Steel Pipe Bending Machine solutions are designed to cater to this vast array of needs, demonstrating our expertise across the board. Our Industrial Pipe Benders offer the versatility and power required for these diverse applications.

The ability to deliver custom bending solutions across such a wide range of industries is a testament to our innovative technology and our commitment to working closely with clients. We ensure that, no matter the application, our machines provide the optimal bending solution.

Conclusion: Partner with the #1 Bender Manufacturer for Guaranteed Success

Choosing the right pipeline pipe bending machine is not merely a purchase; it’s a strategic investment in the success, safety, and longevity of your projects. As we’ve explored, the technology, specifications, and operational challenges in pipeline bending demand nothing short of excellence. From the precision of CNC controls and the power of hydraulic systems to the critical role of mandrels and custom tooling, every detail matters.

At Hines Bending Systems, we don’t just sell machines; we offer unparalleled expertise, innovative technology, and a commitment to quality that is best in the industry. We are proud to be the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, a testament to our continuous innovation and dedication. Our global leadership is built on providing customized solutions that meet and exceed the most stringent industry standards.

Our clientele, including prestigious organizations like NASA, speaks volumes about our credibility and the exceptional quality of our equipment. When you partner with us, you’re not just getting a machine; you’re gaining access to a team with the highest number of bender installations worldwide and an unrivaled depth of experience. Nobody in the bending machine industry has more expertise and experience than Hines.

We understand that every project has unique requirements. That’s why we work closely with our clients, from the initial consultation to post-sale support and Tube and Pipe Bender Training, to provide custom bender solutions. Our superior quality bending machines are designed to meet all industry standards and quality requirements, ensuring that your investment is sound and your projects are successful. We believe in building solutions that last, unlike cheaper alternatives that may compromise integrity and lead to costly failures.

Investing in a machine that guarantees project quality, reduces costs, and ensures long-term reliability is the smartest decision for any serious operation. For a custom solution engineered by the world’s most experienced team, explore our range of Tube and Pipe Benders. Choose Hines Bending Systems for a partnership that ensures success.