Why Quality Tube Bender Dies Make All the Difference

Tube bender dies are the essential tooling components that prevent tubes from flattening or buckling during the bending process, ensuring precise radius formation and professional-quality results.

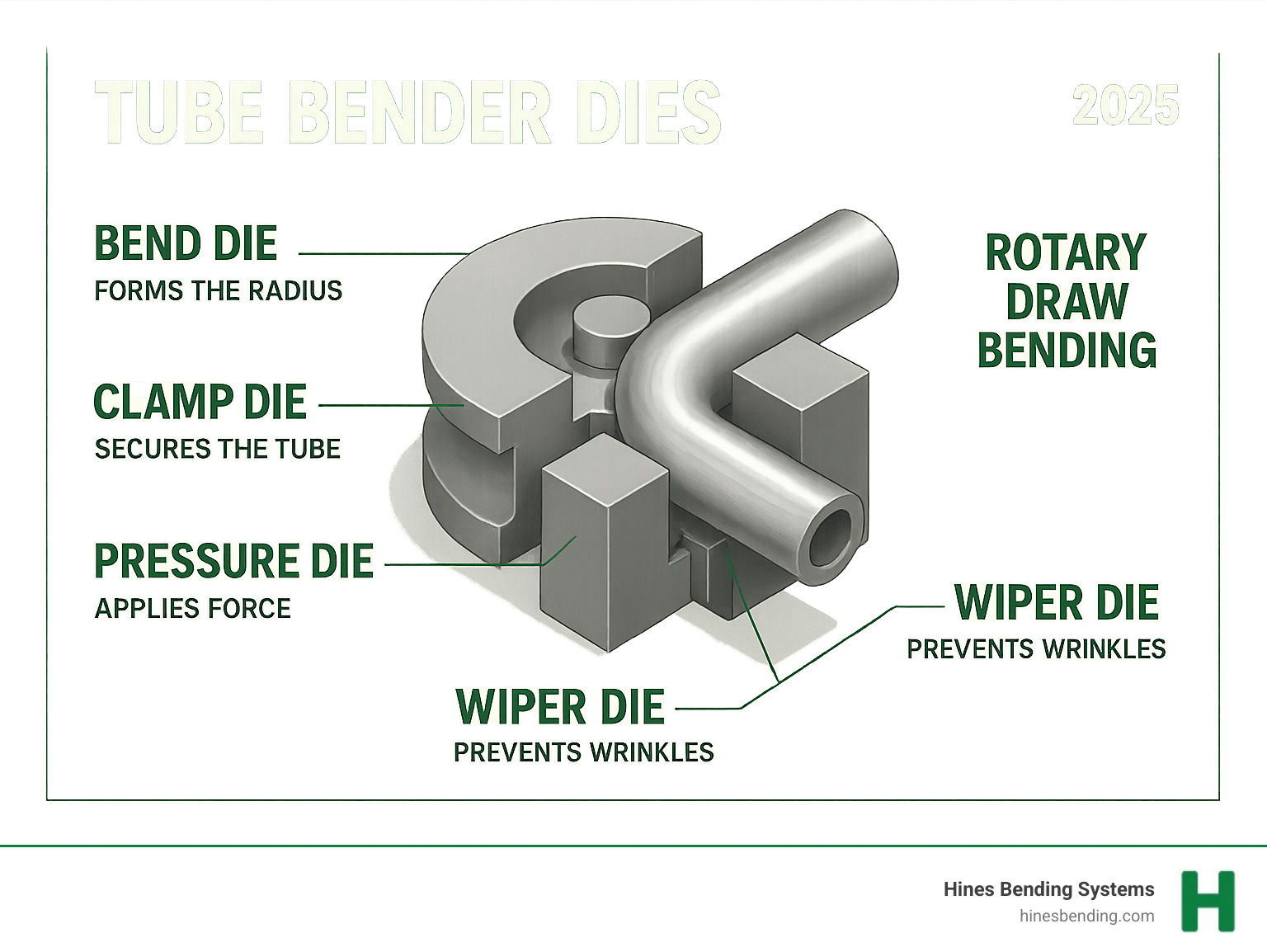

Key Types of Tube Bender Dies:

- Bend Die – Forms the radius and prevents tube flattening

- Clamp Die – Holds the tube securely in position during bending

- Pressure Die – Forces the tube into the bend die with controlled pressure

- Wiper Die – Prevents wrinkles on the inside surface of thin-wall tubing

Whether you’re fabricating exhaust systems, building roll cages, or creating precision aerospace components, the quality of your dies directly impacts the success of every bend. Poor tooling leads to costly defects like wrinkling, flattening, and material waste.

As one forum user finded when considering homemade alternatives: “In the time it takes to print a die, one could likely make a permanent steel die.” The reality is that professional-grade dies require precision machining and proper materials to withstand the significant forces involved in tube bending.

The challenge for manufacturing operations managers is finding dies that deliver consistent results while handling complex bending requirements. Wall thickness, center line radius (CLR), and material compatibility all play critical roles in die selection.

For mission-critical applications – like the projects Hines Bending Systems delivers for NASA – only the highest quality tooling will meet demanding specifications. As the #1 worldwide manufacturer of tube benders, Hines combines decades of expertise with custom solutions custom to your exact requirements.

Quick tube bender dies terms:

The Anatomy of a Perfect Bend: Key Die Components

When you watch a tube bend perfectly around a radius without a single wrinkle or flat spot, you’re witnessing the result of precision engineering at work. Behind every flawless bend is a carefully orchestrated team of tube bender dies working together in perfect harmony. At Hines Bending Systems, we’ve spent decades perfecting these tooling components because we know that the difference between a good bend and a great one lies in the details. These dies are the foundation of our comprehensive Tube and Pipe Bender Accessories collection.

Think of tube bender dies as a specialized surgical team, where each component has a specific role that’s absolutely critical to the success of the operation. When they work together seamlessly, you get results that meet the exacting standards we deliver to clients like NASA. When even one component is subpar, the entire bend suffers.

The Bend Die: The Heart of the Bend

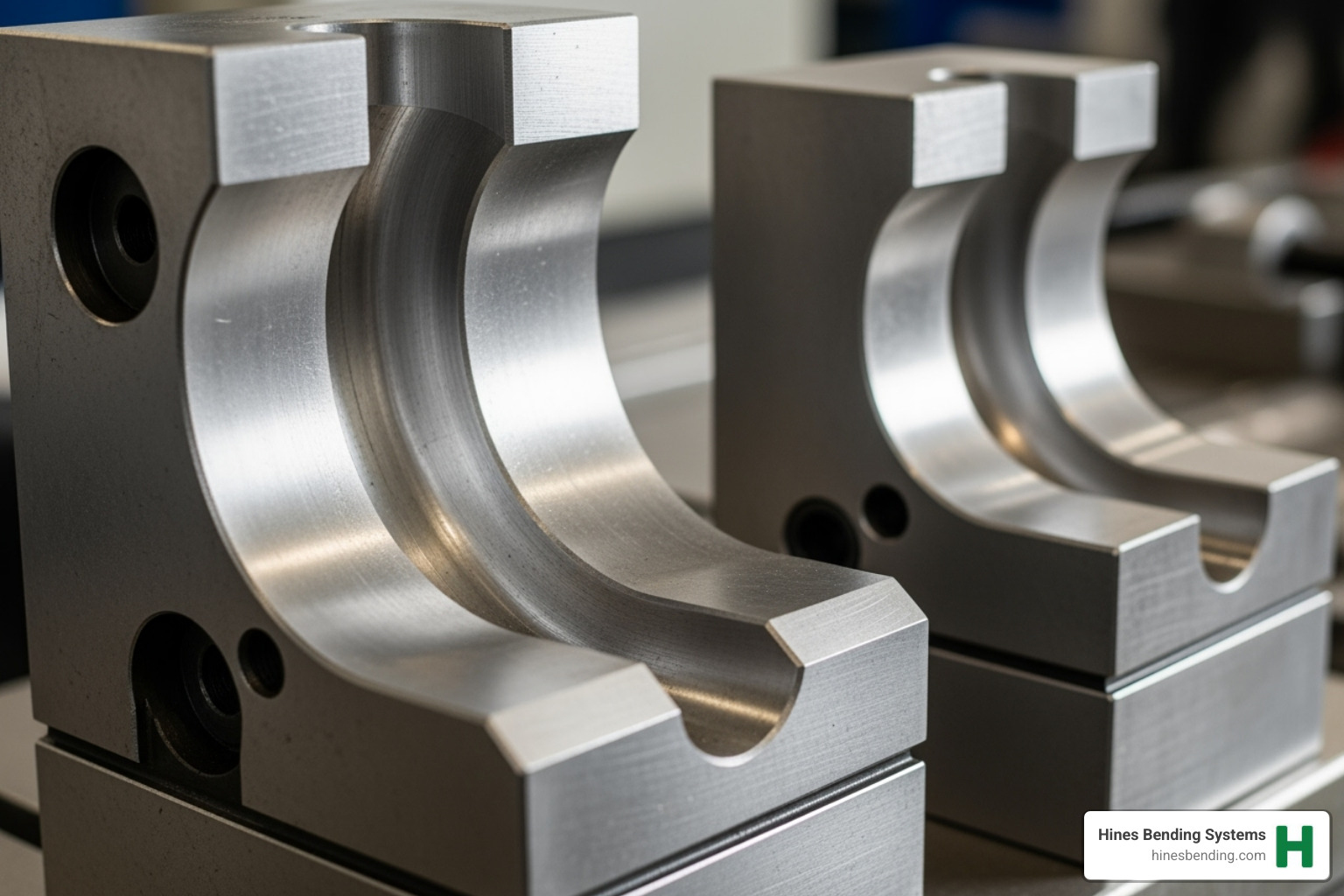

If there’s one component that truly earns the title “heart of the operation,” it’s the bend die. This isn’t just a piece of metal with a curve cut into it – it’s a precision-engineered tool that forms the radius while simultaneously preventing flattening of your tube.

The magic happens in the carefully designed groove that cradles your tube throughout the entire bending process. This grooved design provides essential material support right where it’s needed most. As your tube bends, the outside wall stretches and thins while the inside wall compresses and thickens. Without proper support, these natural material changes would lead to ugly deformation or complete failure.

The Center Line Radius (CLR) is where the science meets the art. This measurement – from the center of your bend to the centerline of the tube – determines just how tight you can make that curve. Get it wrong, and you’ll either have a bend that’s too gentle for your application or one that causes the tube to buckle under stress.

At Hines Bending Systems, our Tube and Pipe Bender Dies are machined to tolerances that ensure your CLR is exactly what you need, every single time. That’s the kind of precision that comes from being the #1 worldwide manufacturer with more installations than anyone else in the industry.

Essential Supporting Tooling

While the bend die gets most of the glory, it’s the supporting cast that makes the real magic happen. Without these essential components, even the most perfectly machined bend die would struggle to produce consistent results.

The clamp die might seem simple, but its job is absolutely crucial. It holds your tube firmly against the bend die, preventing any slippage or movement during the bending process. Think of it as the steady hand that keeps everything aligned while the real action happens.

Working alongside the clamp die, the pressure die applies controlled force to push the tube around the bend radius. This isn’t about brute strength – it’s about applying exactly the right amount of pressure at precisely the right moment. Too little pressure and your bend will be incomplete; too much and you risk damaging the tube or creating unwanted stress patterns.

When you’re working with thin-wall tubing, the wiper die becomes your best friend. This specialized tool prevents those unsightly wrinkles that can form on the inside of the bend where material compression occurs. It literally sweeps along with the bend, supporting the tube wall and ensuring a smooth, professional finish.

For the most demanding applications – the kind where failure isn’t an option – the mandrel provides internal support that prevents the tube from collapsing from the inside out. This internal support tool is essential for maintaining the tube’s cross-sectional integrity, especially when working with complex geometries or ultra-thin walls. Our Mandrel Bending Machine Sale options showcase just how sophisticated this tooling can be.

The beauty of working with Hines Bending Systems is that we don’t just sell you individual components – we engineer complete tooling systems that work together flawlessly. With our decades of experience and more expertise than anyone else in the bending industry, we know exactly how to configure these tools for your specific application. Whether you’re building aerospace components or fabricating exhaust systems, we’ll work closely with you to create the perfect custom solution.

How to Choose the Right Tube Bender Dies for Your Project

Choosing the right tube bender dies is like selecting the perfect tool for a delicate surgery – precision matters, and there’s no room for guesswork. At Hines Bending Systems, we’ve guided countless customers through this critical decision process, from small fabrication shops to major organizations like NASA. The key lies in understanding your project specifications, material compatibility, and bending calculations before you even touch a die. This expertise is exactly why we’ve become the go-to resource for answering What Type of Bending Machine is Best for Me?

The journey begins with a thorough understanding of your tube’s characteristics and your desired outcome. Skip this step, and you’re setting yourself up for costly mistakes, wasted material, and project delays. We’ve seen it happen too many times – that’s why our team at Hines takes the time to understand every detail of your application before recommending the perfect die solution.

Key Specifications for Your Tube Bender Dies

When selecting tube bender dies, several critical specifications demand your attention. Think of these as the DNA of your bending operation – get them wrong, and nothing else matters.

The Outside Diameter (OD) is your starting point. This precise measurement of your tube’s exterior must match your die set perfectly. Even a small mismatch can lead to slippage, deformation, or worse – damaged tooling that costs far more than getting it right the first time.

Your Center Line Radius (CLR) defines how tight your bend will be. Smaller CLRs create tighter bends but place greater stress on both your material and tooling. This is where Hines’ decades of experience become invaluable – we know exactly which CLR will work for your specific application without pushing your material beyond its limits.

Wall thickness is often overlooked, but it’s absolutely critical. Our research shows that most benders work best with mild steel square tubing between 0.065″ and 0.125″ wall thickness. Go outside these ranges, and you risk kinking, flattening, or die damage. For ERW (Electric Resistance Welded) tubing, which can have inconsistent wall thickness, we typically recommend going one increment thicker than you would for D.O.M. (Drawn Over Mandrel) mild steel or 4130 chromoly.

The tube material itself plays a huge role in die selection. Chromoly behaves differently than mild steel, which bends differently than aluminum. Each material requires specific die materials, finishes, and sometimes completely specialized tooling. This is where having the #1 worldwide manufacturer of tube benders on your side makes all the difference.

Don’t forget about tube shape either. While round tubes are common, we regularly create dies for square, rectangular, and even custom profiles. Your die must match your tube’s exact cross-sectional shape for optimal results.

| Application | Tube Shape | OD Range (in) | CLR Range (in) | Min. Wall Thickness (in) | Typical Material | Key Die Considerations |

|---|---|---|---|---|---|---|

| Roll Cage | Round | 1.5 – 2.0 | 4.0 – 7.0 | 0.095 – 0.120 | Chromoly, DOM | High strength, good surface finish, minimal distortion |

| Exhaust System | Round | 1.5 – 3.0 | 3.0 – 6.0 | 0.065 – 0.083 | Stainless Steel | Smooth interior for flow, anti-galling features |

| Aerospace Component | Round | 0.5 – 1.25 | 2.0 – 4.0 | 0.035 – 0.065 | Aluminum, Inconel | Precision, tight tolerances, no surface imperfections |

| Structural Frame | Square | 1.0 – 2.0 | 4.0 – 8.0 | 0.065 – 0.125 | Mild Steel | Consistent square corners, structural integrity |

| Boiler Tube | Round | 1.0 – 4.0 | 3.0 – 10.0 | 0.100 – 0.250 | Carbon Steel | Heavy-duty, high temperature resistance, smooth flow |

Understanding these specifications – which we detail thoroughly in our Tube and Pipe Bending Industry Terms guide – is essential for selecting the right tube bender dies. But knowing the specs is only half the battle; interpreting them correctly for your specific application is where Hines’ best expertise truly shines.

The Critical Difference: Tube Dies vs. Pipe Dies

Here’s where we see even experienced fabricators make costly mistakes. Tubes and pipes might look similar, but their sizing conventions are completely different – and using the wrong dies can ruin your entire project.

Tubes are always measured by their actual Outside Diameter (OD). When we say a 1.5″ tube, we mean it has an exact OD of 1.5 inches. This straightforward measurement system makes tube bender dies relatively easy to specify – what you see is what you get.

Pipes follow a completely different system called Nominal Pipe Size (NPS), which loosely relates to the inside diameter, not the outside. Here’s the kicker: a “1.5-inch pipe” actually has an outside diameter of approximately 1.90 inches! This historical sizing quirk trips up even seasoned professionals.

The consequences of mixing these up are severe. Try to bend a 1.5″ pipe with a 1.5″ tube die, and you’ll end up with flattened bends, excessive material stress, galling, or expensive die damage. We’ve helped countless customers recover from exactly this mistake.

This is why having Hines Bending Systems as your partner is so valuable. Our team has decades of experience navigating these nuances, and we’ll make sure you always have the right tooling for your specific material. When precision matters – like it does for our NASA projects – there’s simply no room for guesswork.

Common Bending Flaws and How Expert Tooling Prevents Them

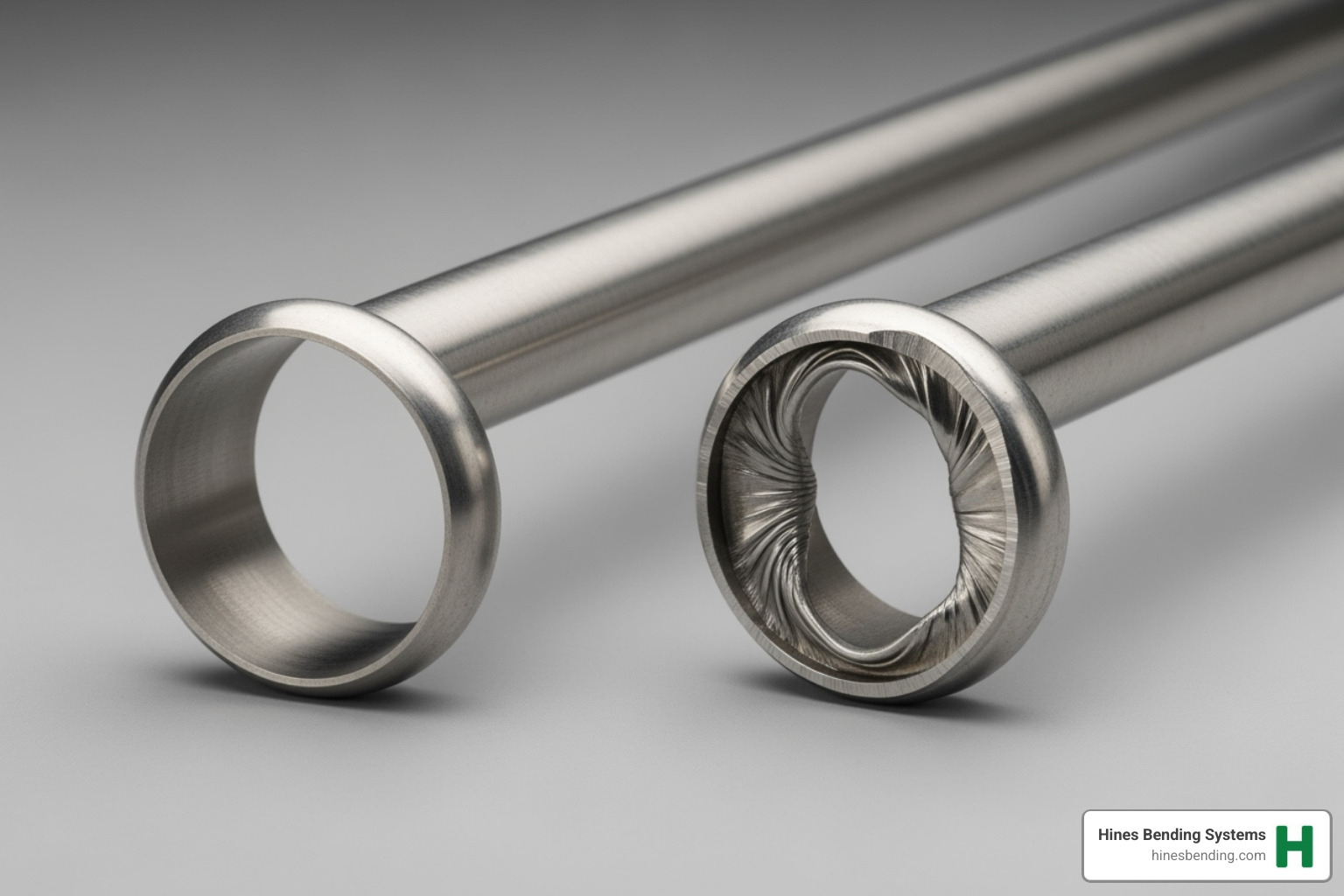

In tube bending, achieving a flawless curve is the goal, but the path is often riddled with potential pitfalls. Common bending issues like wrinkling, flattening, galling, and springback can turn a promising project into a pile of scrap. These challenges underscore why expert tooling, particularly high-quality tube bender dies, are not just an option but a necessity. The complexities of DIY tooling, as explored in discussions like this forum thread, highlight the significant challenges of achieving precision without professional-grade equipment.

Wrinkling occurs when the inside wall of the tube compresses too much, creating unsightly folds. Flattening, or ovalization, happens when the tube loses its circular (or square) cross-section, often due to insufficient internal or external support. Galling is the abrasive wear that occurs when the tube material adheres to and tears away from the die surface, leaving marks and potentially damaging both. Springback is the elastic recovery of the material after bending, where the tube partially returns to its original shape, requiring over-bending to compensate.

Quality control is paramount in preventing these flaws. It’s not just about aesthetics; these defects can compromise the structural integrity, flow characteristics, and overall performance of the bent component. This is where our unparalleled expertise at Hines Bending Systems truly shines.

Why Quality Tooling is Non-Negotiable

For us, quality tooling is the bedrock of successful bending. It is non-negotiable because it directly translates into preventing defects and ensuring the integrity of the material. The forces involved in tube bending are immense, and only precisely engineered tube bender dies can withstand them without deforming themselves or damaging the tube.

High-quality tooling is typically made from hardened steel or specialized aluminum alloys, chosen for their durability, wear resistance, and ability to maintain their shape under extreme pressure. Our dies are created through precision machining, ensuring exact tolerances that are critical for achieving consistent, repeatable bends. This meticulous manufacturing process ensures that the die’s CLR and groove perfectly match the tube’s OD, minimizing material stress and preventing issues like flattening or galling. Unlike cheaper alternatives that may compromise integrity, our commitment to superior quality means our dies are designed to meet, and exceed, industry standards and quality requirements. When you choose Hines, you choose precision. We invite you to explore our advanced CNC Bending Machine capabilities, where our dies play a central role.

Specialty Tube Bender Dies for Unique Applications

Not all bends are created equal, and some applications demand highly specialized tube bender dies. At Hines Bending Systems, we pride ourselves on providing custom solutions that cater to the most unique and challenging bending requirements.

- Dies for Thin-Wall Tubing: As mentioned earlier, thin-wall tubing is prone to wrinkling. Specialized wiper dies and mandrels are crucial here, providing the necessary internal and external support to maintain the tube’s integrity.

- Dies for Boiler Tubes: Bending boiler tubes often involves larger diameters and thicker walls, requiring robust dies that can withstand immense forces while maintaining precise flow characteristics. Our Dies for Boiler Tube Benders are engineered for this demanding environment.

- Dies for Exhaust Systems: These often require tight radii and smooth interiors to optimize gas flow. Dies for exhaust systems are designed to minimize distortion and surface imperfections, which could impede performance.

- Custom Profiles and Angle Iron: Beyond standard round or square tubes, we also create custom dies for unique profiles like rectangular tubing, angle iron, or even extra tight radius bending. Our ability to manufacture custom dies for specific material shapes and bending requirements sets us apart.

Our continuous innovation, including our Dual Stack CNC Push Bender and Roll Bender, addresses the growing demands of various industries, ensuring that we always have the right tooling solution, no matter how complex the application. We work closely with our clients to provide custom bender solutions, ensuring that their specific needs are met with unparalleled expertise.

Best Practices for Die Maintenance and Care

Your tube bender dies are precision instruments that deserve the same level of care you’d give to any valuable piece of equipment. Think of them as the heart of your bending operation – when they’re healthy, everything runs smoothly. But neglect them, and you’ll quickly find yourself dealing with poor bend quality, premature wear, and expensive replacements.

The good news? Proper die maintenance isn’t rocket science. It’s about developing consistent cleaning procedures, ensuring proper storage, and conducting regular inspections for wear. When you combine these practices with appropriate lubrication, you’re setting yourself up for years of reliable performance.

At Hines Bending Systems, we’ve seen how proper maintenance can extend die life by years – and we’ve also witnessed the costly consequences when maintenance is overlooked. Our decades of experience have taught us that a few minutes of care after each use can save thousands of dollars in replacement costs.

Extending the Life of Your Investment

Preventing rust should be your first priority, especially if you’re working in a humid environment. After each bending session, take a moment to clean your dies thoroughly. Remove any metal particles or residue that might have accumulated during the bending process. A simple wipe-down followed by a light coating of rust-preventative oil or spray will work wonders.

Avoiding damage during storage is equally important. Your dies should have a dedicated home – preferably on organized shelves or in purpose-built storage racks. We’ve seen too many expensive dies ruined by careless storage that led to drops, nicks, or scratches. Even minor surface damage can translate into visible marks on your finished bends.

When it comes to lubrication types, not all lubricants are created equal. The right tube bending lubricant reduces friction, prevents galling, and significantly extends die life. Different materials often require different lubrication approaches, so don’t hesitate to consult with material suppliers or our experts for specific recommendations.

Your inspection checklist should become second nature. Before and after significant bending jobs, take a few minutes to examine your dies carefully. Look for wear patterns – those telltale shiny spots or developing grooves in the die’s surface. Watch for cracks or chips, even hairline ones that might seem insignificant but can propagate under stress. Galling marks are red flags indicating insufficient lubrication or improper die selection. And always ensure cleanliness – debris lodged in grooves can cause serious problems.

Maximizing ROI from your tube bender dies comes down to consistency. When you follow these maintenance practices religiously, you’re not just extending die life – you’re ensuring consistent, high-quality output that minimizes scrap and keeps your operations running efficiently.

This is exactly why we emphasize training at Hines Bending Systems. Our Tube and Pipe Bender Training programs don’t just cover machine operation – they dive deep into maintenance best practices that keep your entire system performing at peak efficiency. Because when you’re working with the precision equipment that has earned the trust of agencies like NASA, every detail matters.

Conclusion: Achieving Unrivaled Precision with the Right Partner

Throughout this guide, we’ve explored how the right tube bender dies serve as the foundation of every successful bending operation. These aren’t just simple tools gathering dust in your shop – they’re precision-engineered components that make the difference between a flawless bend and costly scrap metal.

We’ve seen how proper die selection prevents common disasters like wrinkling and flattening, and why understanding the critical differences between tube and pipe dies can save you from expensive mistakes. The specifications we’ve discussed – from Center Line Radius (CLR) to wall thickness compatibility – aren’t just technical jargon. They’re the roadmap to achieving bends that meet your exact requirements every single time.

Precision equals safety and performance in every application. Whether you’re fabricating a roll cage that needs to protect a driver’s life or creating exhaust components that must withstand extreme temperatures, there’s no room for compromise. The integrity of your final product depends entirely on the quality of the tooling that shapes it.

For mission-critical projects, expertise is key for complex applications. When we work on projects for agencies like The National Aeronautics and Space Administration (NASA), we understand that failure isn’t an option. These demanding specifications require more than just good equipment – they require decades of experience, best expertise, and an unwavering commitment to excellence.

At Hines Bending Systems, we’ve earned our position as the #1 worldwide manufacturer through countless successful installations and satisfied customers across the globe. Our unparalleled experience in creating custom Tube and Pipe Benders and die sets means we understand the unique challenges you face, no matter how complex your application might be.

We don’t just sell you equipment and walk away. We work closely with you to develop customized solutions that meet your most demanding specifications. Our team brings more expertise and experience than anyone else in the bending machine industry, and we’re committed to ensuring your success.

When you choose Hines Bending Systems, you’re not just buying tube bender dies – you’re partnering with the industry leader who understands that your reputation depends on the quality of every bend you produce.