Why Choosing the Right Tube Bender Is Critical for Manufacturing Success

Tube benders are specialized machines that shape metal tubing into precise angles and curves for countless industrial applications. These powerful tools are essential for manufacturing everything from aerospace components to HVAC systems, furniture frames, and automotive parts.

Quick Answer: What Are Tube Benders?

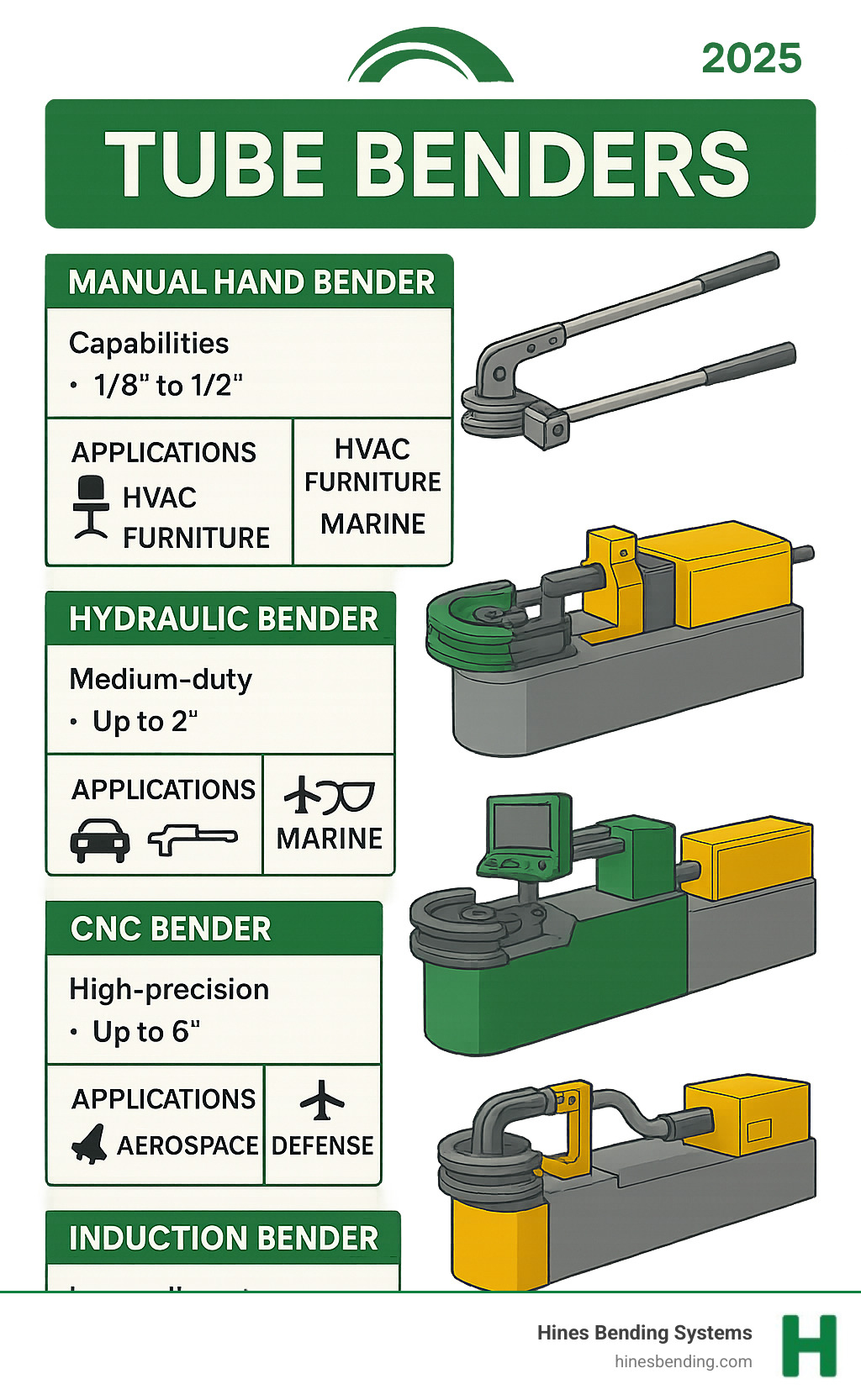

- Manual benders: Hand-operated tools for small-diameter tubing (1/8″ to 1/2″)

- Hydraulic benders: Powered machines for medium to heavy-duty applications

- CNC benders: Computer-controlled systems for high-precision, automated production

- Induction benders: Heat-based technology for large-diameter pipes and thick walls

- Applications: Aerospace, automotive, HVAC, furniture, marine, and defense industries

The choice of tube bender can make or break your manufacturing operation. Poor equipment selection leads to costly rework, material waste, and production delays. On the other hand, the right bending solution delivers consistent quality, reduces setup time, and maximizes profitability.

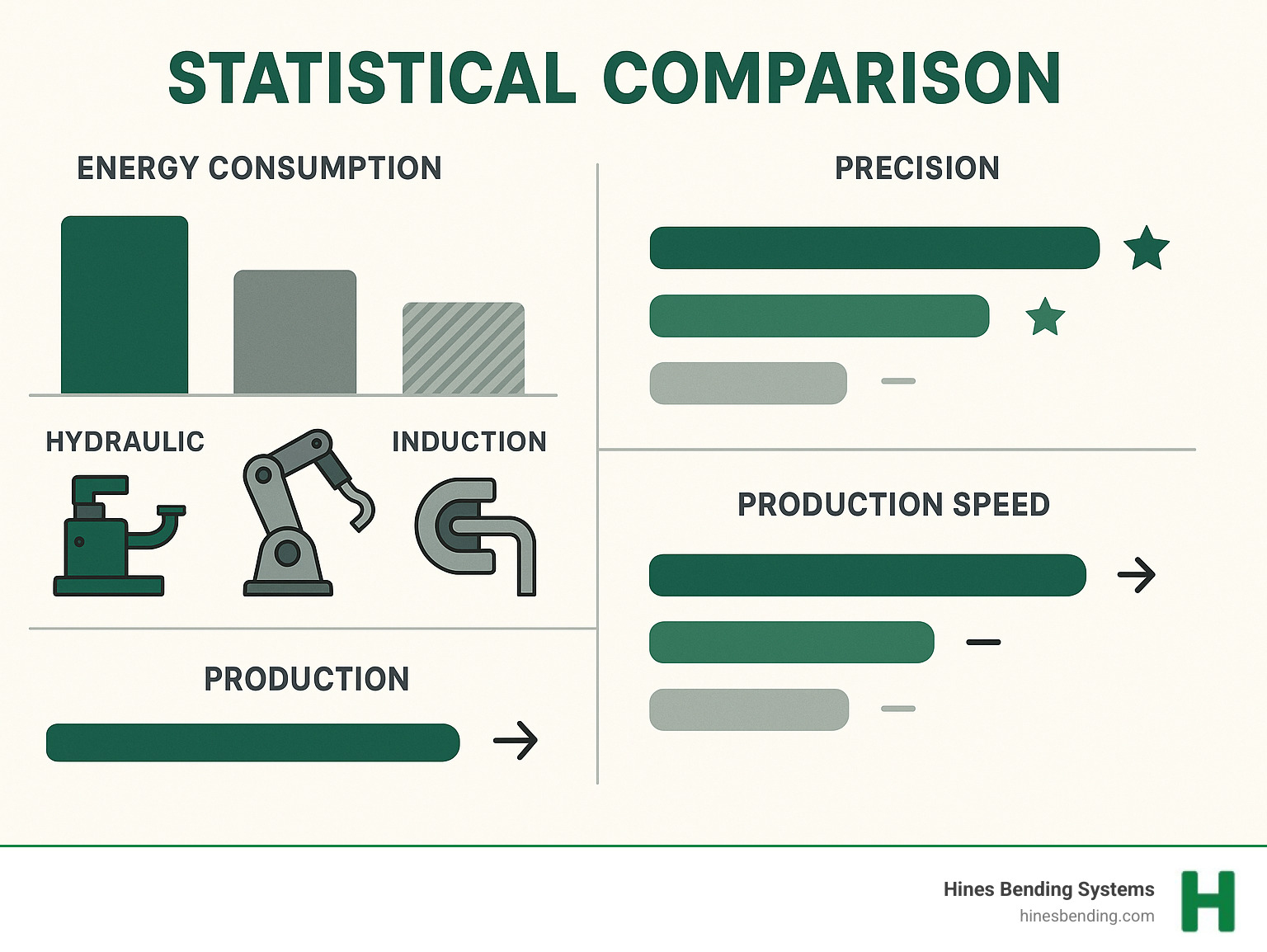

Modern manufacturing demands have pushed tube bending technology far beyond simple manual tools. Today’s advanced systems feature all-electric technology that saves up to 70% energy compared to traditional hydraulic machines, while CNC controls ensure repeatable precision down to fractions of a degree.

Industries like aerospace rely on tube benders to create critical components from exotic materials like titanium and Inconel. Major organizations including NASA trust specialized manufacturers to deliver custom bending solutions that meet the most demanding specifications.

Whether you’re bending 1/8″ copper tubing for refrigeration systems or 12″ steel pipe for structural applications, selecting the right tube bender requires understanding your specific needs, production volume, and quality requirements.

The Hallmarks of a Superior Bending Solution

Not all tube benders are created equal. After decades of manufacturing bending solutions for everyone from small fabrication shops to NASA, we’ve learned what separates truly exceptional equipment from the rest of the pack.

The difference isn’t just in the specs – it’s in the details that matter when you’re running production day after day. Superior bending solutions combine precision control systems, rock-solid construction, comprehensive training, and ongoing technical support that keeps your operation running smoothly.

At Hines Bending Systems, we’ve built our reputation as the #1 worldwide manufacturer by focusing on these critical elements. When organizations like NASA need bending solutions they can trust with their most demanding applications, they turn to us because we deliver on all fronts.

The Critical Role of Precision and Control

True precision goes way beyond just hitting the right angle. It’s about achieving consistent, repeatable results that meet tight tolerances every single time – whether it’s your first part or your thousandth.

Modern tube benders must deliver accuracy within fractions of a degree while maintaining consistent bend radius and minimizing springback. This level of precision simply isn’t possible with manual controls or outdated systems.

That’s where advanced CNC controls make all the difference. Our BendPro G2 CNC control system stores production setup data that can be recalled instantly, eliminating human error and ensuring perfect repeatability. This reduces skill requirements for operators while maintaining exceptional quality standards.

All-electric technology represents the future of tube bending, and for good reason. These systems offer dramatically improved repeatability compared to hydraulic machines while consuming up to 70% less energy. The power savings alone can justify the investment in many operations.

The integration of sophisticated software allows for virtual simulations and safe processes, enabling manufacturers to test bending sequences before committing materials. This capability minimizes waste and reduces the time needed to perfect new part geometries – a game-changer for complex projects.

Built to Last: Evaluating Machine Quality and Durability

Manufacturing standards separate premium bending equipment from budget alternatives that’ll leave you frustrated down the road. At Hines Bending Systems, we use heavy-duty construction with USA-made components designed for decades of reliable operation.

Our machines feature precision-machined components that maintain accuracy even under demanding production schedules. We’re talking about aircraft-grade materials and components that resist wear while maintaining precision – the kind of attention to detail that translates into reduced maintenance requirements and maximum uptime.

Reliability becomes especially critical in high-volume production environments. Our machines are engineered to handle continuous operation while maintaining consistent quality. This durability ensures that your investment continues delivering value year after year, rather than requiring frequent repairs or replacement.

We’re so confident in our build quality that we offer a lifetime warranty on critical components. This level of assurance provides peace of mind and protects your investment against unexpected failures – something you simply won’t find with cheaper alternatives.

When you’re evaluating bending solutions, the lowest price often comes with the highest long-term costs. Investing in superior equipment from an experienced manufacturer like Hines Bending Systems pays dividends through reduced downtime, lower maintenance costs, and consistent quality output.

Key Factors for Selecting the Right Tube Bender

Choosing the perfect tube bender isn’t just about picking the biggest or most expensive machine. It’s about finding the sweet spot where your specific needs meet the right technology. At Hines Bending Systems, we’ve helped countless manufacturers steer this decision by focusing on what matters most for their unique situation.

The beauty of working with industry leaders like us is that we understand every application is different. When NASA needs precision components for space missions, they require vastly different capabilities than a furniture manufacturer creating chair frames. That’s why we’ve become the #1 worldwide manufacturer – we listen first, then recommend solutions.

Your production volume sets the foundation for everything else. A shop making occasional prototypes has completely different needs than a facility churning out thousands of parts daily. Budget considerations go far beyond the sticker price – you need to think about energy costs, maintenance, and the hidden expenses of downtime.

Required accuracy can make or break your operation. Some applications demand precision down to fractions of a degree, while others have more forgiving tolerances. The material you’re working with, tube dimensions, and wall thickness all play crucial roles in determining which system delivers the best results.

What type of bending machine is best for you? The answer depends on balancing these factors while considering your long-term growth plans.

Matching the Machine to Your Materials and Dimensions

Every material has its own personality when it comes to bending. Steel behaves predictably with moderate springback, making it relatively straightforward to work with. Aluminum can be tricky – it’s lightweight and efficient, but prone to wrinkling if you’re not careful with speed control.

Titanium presents unique challenges that require specialized expertise. This aerospace-grade material demands precise handling and custom tooling solutions. That’s exactly the kind of challenge we excel at – our experience with organizations like NASA has taught us how to tame even the most demanding materials.

Copper offers excellent formability and minimal springback, making it ideal for tight radius bends in refrigeration and plumbing applications. Inconel brings high-temperature resistance but work-hardens during bending, requiring expert knowledge to achieve consistent results.

The dimensions of your tubing create another layer of complexity. Hand benders work well for small diameters from 1/8″ to 1/2″, while our heavy-duty systems can handle massive 12-3/4″ diameter applications. Wall thickness affects everything from machine selection to tooling requirements – thin-wall tubing needs gentle handling to prevent collapse, while thick-wall materials demand serious power.

Round tubing represents the most common application, but square, rectangular, and oval profiles each present unique challenges. Our decades of experience mean we’ve seen it all and developed solutions for every conceivable tube shape and size.

Production Volume and Required Accuracy

Prototype work and low-volume production often benefit from flexible systems that can adapt quickly to design changes. These applications prioritize versatility over raw speed, allowing engineers to iterate and refine their designs without major setup headaches.

Medium-volume production hits the sweet spot for hydraulic and semi-automatic CNC systems. These machines deliver improved consistency and speed while maintaining reasonable setup times for batch production. It’s where many of our customers find their perfect balance.

High-volume manufacturing demands the full power of automated CNC systems with advanced features like multi-stack capability and integrated quality control. These systems maximize throughput while ensuring every single part meets specifications – no exceptions.

Spring-back compensation becomes increasingly critical as accuracy requirements tighten. Our advanced systems automatically adjust for material springback, ensuring finished parts meet specifications without manual intervention. It’s the kind of precision that separates professional-grade equipment from basic alternatives.

Quality control integration allows real-time monitoring of bend angles and dimensions, catching deviations before they result in rejected parts. This capability proves especially valuable in high-volume production where consistency isn’t just preferred – it’s absolutely essential.

Exploring Advanced Tube Benders and Technologies

The world of tube benders has evolved dramatically, and nowhere is this more evident than in the advanced technologies that Hines Bending Systems has pioneered. After decades of innovation and thousands of installations worldwide, we’ve developed solutions that push the boundaries of what’s possible in tube bending.

At Hines Bending Systems, we’ve witnessed how advanced technologies transform manufacturing operations. Our customers – from NASA to major aerospace manufacturers – rely on our cutting-edge systems to achieve results that seemed impossible just a few years ago.

The shift from traditional hydraulic systems to all-electric technology represents one of the most significant advances in our industry. Our all-electric systems don’t just save energy – they fundamentally change how manufacturers approach tube bending by delivering precision that hydraulic systems simply cannot match.

CNC integration has revolutionized production capabilities, enabling manufacturers to create complex geometries with minimal operator intervention. These systems store unlimited part programs and execute them with perfect repeatability, ensuring consistent quality across thousands of parts.

For applications that push beyond conventional limits, our induction benders offer capabilities that no other technology can match. These specialized machines handle large-diameter pipes and thick-wall materials that would be impossible to bend using traditional methods.

How CNC and All-Electric Systems Revolutionize Bending

When we developed our advanced CNC tube benders, we had one goal: eliminate the limitations that held manufacturers back. The results speak for themselves – our customers now produce complex three-dimensional parts in a single setup that previously required multiple operations and extensive fixturing.

The speed advantages become immediately apparent in production environments. Our automated systems handle loading, bending, and unloading with precision that eliminates operator fatigue while dramatically reducing cycle times. Multi-stack systems can process multiple tubes simultaneously, multiplying throughput without compromising quality.

All-electric technology represents the future of tube bending, and Hines Bending Systems leads this revolution. Our all-electric machines consume up to 70% less energy than traditional hydraulic systems while delivering superior precision and repeatability. The elimination of hydraulic fluid also creates a cleaner, quieter working environment that operators appreciate.

Complex geometries that once seemed impossible become routine with our advanced systems. Parts requiring multiple bends in different planes can be completed in a single operation, reducing handling, eliminating potential errors, and dramatically shortening production times.

Our push bending technology enables the creation of parts with bends in close proximity without straight sections between them. This capability opens new design possibilities while reducing material waste – a combination that delivers both improved functionality and better economics.

The Power of Induction Bending for Heavy-Duty Applications

When conventional bending methods reach their limits, induction bending takes over. At Hines Bending Systems, we’ve perfected this specialized technology to address applications that would be impossible with traditional approaches.

The induction process uses controlled heating to soften material locally, enabling us to bend large-diameter pipes and thick-wall materials that would require enormous forces with conventional methods. This precision heating maintains material integrity throughout the bend – a critical requirement for structural applications.

Industries like shipbuilding and the energy sector depend on our induction bending capabilities for critical components. When you’re working with pipes several feet in diameter or structural components that form the backbone of major construction projects, there’s simply no substitute for induction technology.

Our 426 induction bender represents the pinnacle of this technology. This specialized equipment handles applications that extend far beyond conventional bending methods, maintaining material integrity while achieving bends that would be impossible through other means.

Thick-wall materials that would require enormous forces with conventional bending become manageable through our controlled induction heating process. This capability enables the processing of structural components for the most demanding applications, from military vessels to energy infrastructure.

The precision of our induction systems ensures that material properties remain consistent throughout the bend. This consistency proves essential for applications where structural integrity cannot be compromised – which is why organizations like NASA trust our induction bending solutions for their most critical projects.

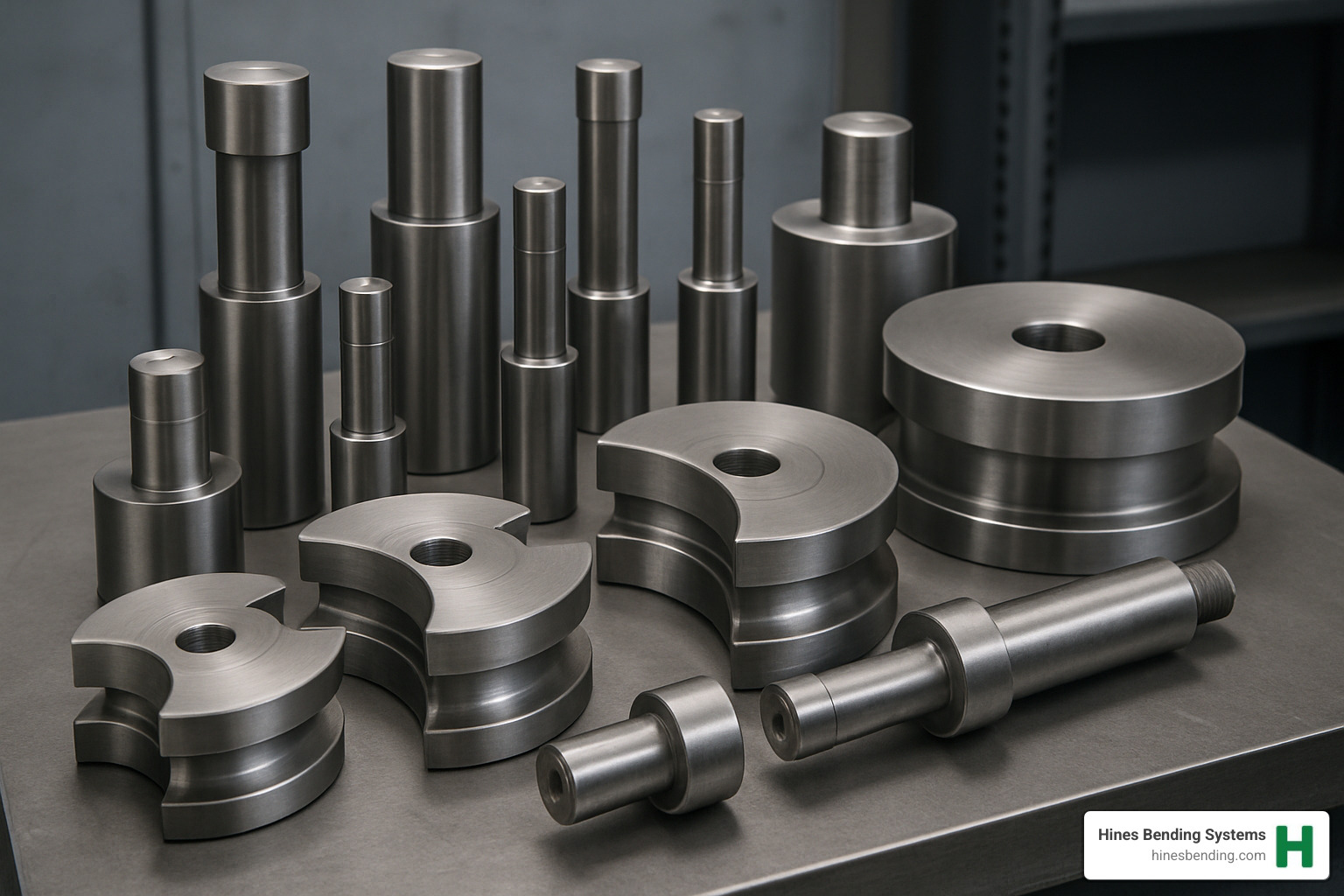

Essential Tooling and High-Stakes Industry Applications

The difference between exceptional and mediocre tube bending results often comes down to one critical factor: tooling quality. At Hines Bending Systems, we’ve learned through decades of experience that even the most advanced tube benders will underperform without precision tooling designed specifically for each application.

Think of tooling as the bridge between your machine’s capabilities and the final product quality. Bending dies, mandrels, wiper dies, and clamp dies work together as a precision team to shape metal exactly as intended. When one component falls short, the entire operation suffers.

Our expertise in tooling design and manufacturing has earned the trust of organizations that accept nothing less than perfection. When NASA needs components that must perform flawlessly in space, they rely on our comprehensive understanding of how tooling impacts every aspect of the bending process.

The relationship between machine performance and tooling quality cannot be overstated. Key insights from the FMA Annual Meeting consistently highlight that manufacturers who invest in premium tooling achieve dramatically better results than those who compromise on quality.

The Role of Tooling for High-Quality Tube Benders

Achieving smooth, wrinkle-free bends requires tooling that supports the tube throughout the entire bending process. Mandrels provide internal support to prevent collapse, while wiper dies eliminate unsightly wrinkles on the inside radius of each bend. These components must work in perfect harmony to deliver consistent results.

Clamp dies secure the tube during bending, ensuring consistent positioning and preventing movement that could result in dimensional variations. The precision of these components directly impacts the repeatability of your bending process – a critical factor when producing hundreds or thousands of identical parts.

Custom tooling becomes essential for specialized applications or unique part geometries. Our ability to design and manufacture custom tooling ensures that even the most challenging applications can be addressed effectively. This capability has made us the go-to choice for industries with demanding requirements.

The materials used in tooling construction significantly impact both performance and longevity. Premium tool steels and specialized coatings extend tool life while maintaining precision. This investment in quality tooling pays dividends through reduced replacement costs and consistent part quality over time.

Our innovative Empty-Bending® technology represents an advanced approach that eliminates the need for mandrels in many applications. This breakthrough reduces setup time, eliminates mandrel wear, and enables the bending of parts that would be impossible with traditional mandrel-based approaches.

When you choose Hines Bending Systems, you gain access to our comprehensive bender accessories that optimize every aspect of the bending process. From specialized dies to advanced measurement systems, we provide complete solutions rather than leaving you to piece together components from multiple suppliers.

Industries Reliant on Precision Tube Bending

The aerospace industry represents the pinnacle of demanding applications where failure simply isn’t an option. Components must meet stringent specifications while maintaining structural integrity under extreme conditions. Bending titanium and exotic alloys requires the specialized expertise that has made Hines Bending Systems the trusted partner for critical aerospace applications.

Automotive manufacturing relies on tube bending for everything from exhaust systems to structural components. High-volume production demands consistent quality and minimal setup time, making our advanced CNC systems essential for competitive manufacturing. The ability to maintain tight tolerances across thousands of parts separates successful operations from those struggling with quality issues.

The HVACR industry requires precise bending of copper and aluminum tubing for refrigeration and air conditioning applications. Our ability to create complex coil geometries in a single operation provides significant advantages in system design and manufacturing efficiency. This capability has made us the preferred choice for major HVAC manufacturers.

Military and defense applications often involve exotic materials and demanding specifications that push equipment to its limits. Security clearance requirements and uncompromising quality standards make manufacturer selection critical for these sensitive applications. Our long-standing relationships with defense contractors demonstrate our ability to meet these exacting requirements.

Shipbuilding demands the bending of large-diameter pipes and structural components that challenge conventional bending methods. Our induction bending technology enables the processing of materials that would be impossible with traditional approaches, making us essential partners for marine construction projects.

The furniture manufacturing industry has acceptd tube bending for both structural and aesthetic applications. Our ability to create smooth curves and complex geometries enables innovative designs while maintaining structural integrity. This versatility has opened new design possibilities for creative manufacturers.

Medical equipment applications require biocompatible materials and exceptional precision where the consequences of failure make quality and reliability paramount. Our understanding of these critical requirements has earned the trust of medical device manufacturers worldwide.

NASA and other space agencies represent the ultimate test of our capabilities. Our long-standing relationship with NASA demonstrates our ability to meet the most challenging requirements in the most critical applications. When failure is not an option, organizations trust Hines Bending Systems to deliver solutions that exceed expectations.

This breadth of industry experience – from furniture to spacecraft – showcases the versatility and reliability that has made us the #1 worldwide manufacturer of tube bending equipment. No other company in the industry possesses our depth of expertise across such diverse applications.

Conclusion

Choosing the right tube bender isn’t just about comparing specs on a spreadsheet – it’s about finding a partner who truly understands your manufacturing challenges and has the expertise to solve them. After decades in this industry, we’ve learned that the most successful projects happen when customers work with manufacturers who bring real-world experience to every conversation.

From our headquarters in Fort Myers, Florida, Hines Bending Systems has earned its position as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders by doing one thing consistently: delivering solutions that work. Our custom approach means we don’t just sell you a machine – we engineer a complete solution custom to your specific needs, materials, and production goals.

When organizations like NASA need bending equipment for their most critical applications, they turn to us. That level of trust doesn’t happen overnight. It’s built through years of delivering machines that perform flawlessly when failure simply isn’t an option. Our track record with major government agencies and Fortune 500 companies speaks to the reliability and precision that our equipment delivers day after day.

What sets us apart isn’t just our machines – it’s our people. Nobody in the bending industry has more hands-on experience solving complex bending challenges. Our team has seen it all, from exotic aerospace alloys to high-volume automotive production, and we bring that knowledge to every project. This depth of expertise means we can anticipate potential issues before they become problems and design solutions that exceed your expectations.

Our commitment goes far beyond the initial sale. We provide comprehensive training to ensure your operators can maximize the capabilities of their equipment. Our technical support team remains available throughout the life of your machine, helping you optimize performance and troubleshoot any challenges that arise.

The future of manufacturing demands equipment that can adapt to changing requirements while maintaining the highest quality standards. Our continuous innovation ensures that when you partner with Hines Bending Systems, you’re not just getting today’s best technology – you’re positioning yourself for tomorrow’s opportunities.

Whether you’re developing prototypes in a small shop or running high-volume production for critical applications, we have the expertise and equipment to help you succeed. Don’t settle for generic solutions when your application deserves the precision and reliability that only comes from working with the industry leader.

Ready to experience the Hines difference? Explore our complete range of tube and pipe benders and find how our custom solutions can transform your manufacturing capabilities.