The Critical Role of Dies in Precision Pipe Bending

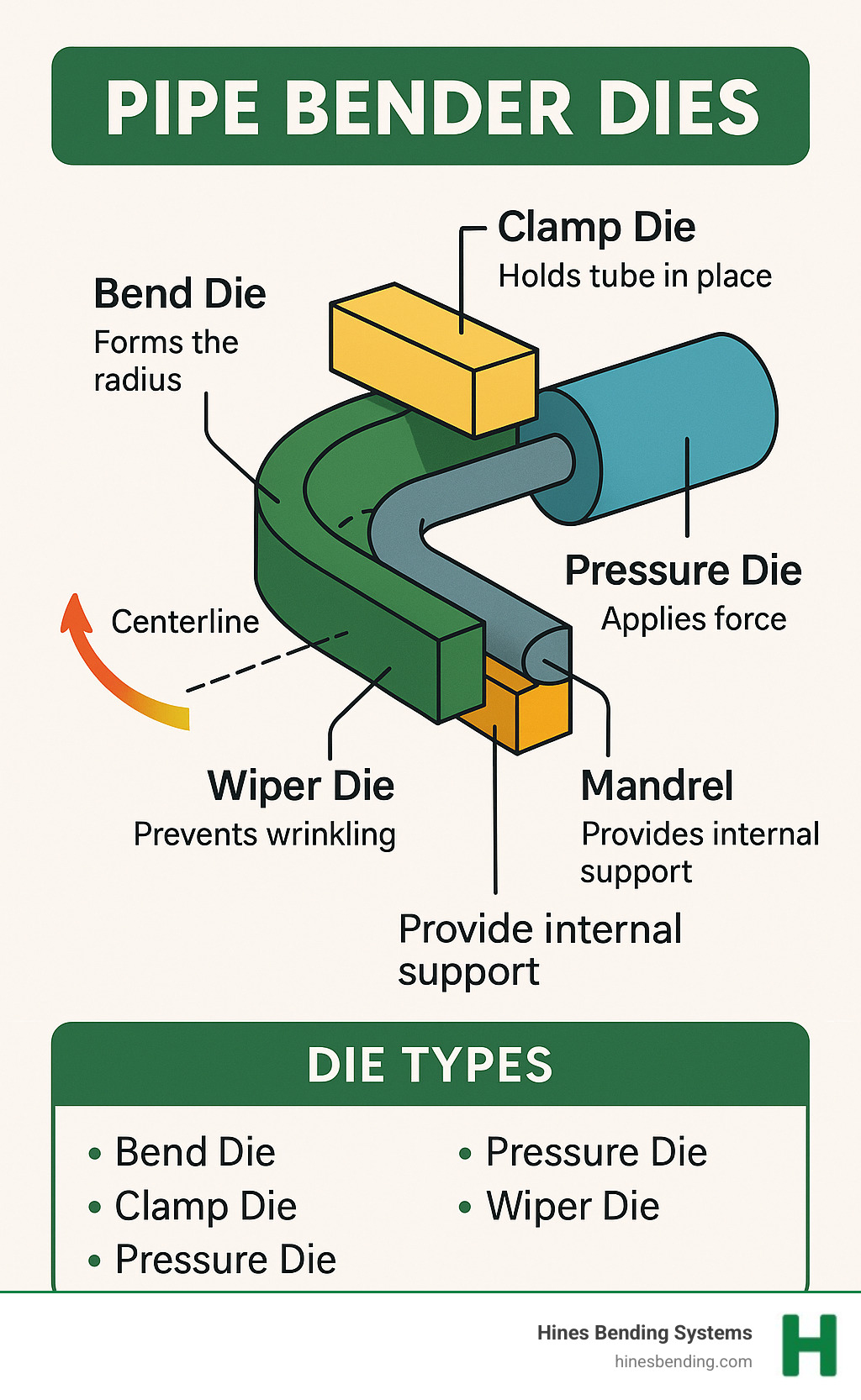

Pipe bender dies are specialized tools that form the backbone of any tube or pipe bending operation. If you’re searching for a quick understanding of pipe bender dies, here’s what you need to know:

| Die Type | Function | Common Applications |

|---|---|---|

| Bend Die | Forms the radius and prevents flattening | All bending operations |

| Clamp Die | Holds the tube in position during bending | All bending operations |

| Pressure Die | Applies force to push material into the bend | Rotary draw bending |

| Wiper Die | Prevents wrinkling on inside radius | Thin-walled tubing |

| Mandrel | Provides internal support | Tight radius bends |

In metal fabrication, achieving the perfect bend isn’t just about having a powerful machineit’s about pairing that machine with the right tooling.

The difference between a professional-looking bend and a kinked, flattened mess often comes down to one thing: your choice of dies.

For manufacturing operations managers, selecting the right pipe bender dies can mean:

- Lower material waste and scrap rates

- Consistent production quality

- Faster setup and changeover times

- Extended machine life

- Reduced post-bend finishing work

At Hines Bending Systems, we’ve seen how proper die selection transforms challenging bending operations into smooth, repeatable processes. Our expertise as the #1 worldwide manufacturer of tube and pipe benders ensures that we can guide you through the complexities of die selection.

Whether you’re bending schedule 40 pipe for industrial plumbing, forming precise DOM tubing for automotive roll cages, or creating architectural handrails with clean, consistent radiiyour success begins with understanding the humble yet critical pipe bender die.

Pipe Bender Dies 101

Ever wondered what actually shapes your metal during the bending process? Meet pipe bender dies the true workhorses of metal fabrication. Without these precision-engineered tools, even the most powerful bending machine would just be an expensive paperweight.

“The magic happens where the die meets the metal,” as our senior engineers at Hines Bending Systems often say. “When a tube bends, it’s undergoing dramatic changes the outside wall stretches thin while the inside wall compresses and thickens. A quality die controls this change with surgical precision.”

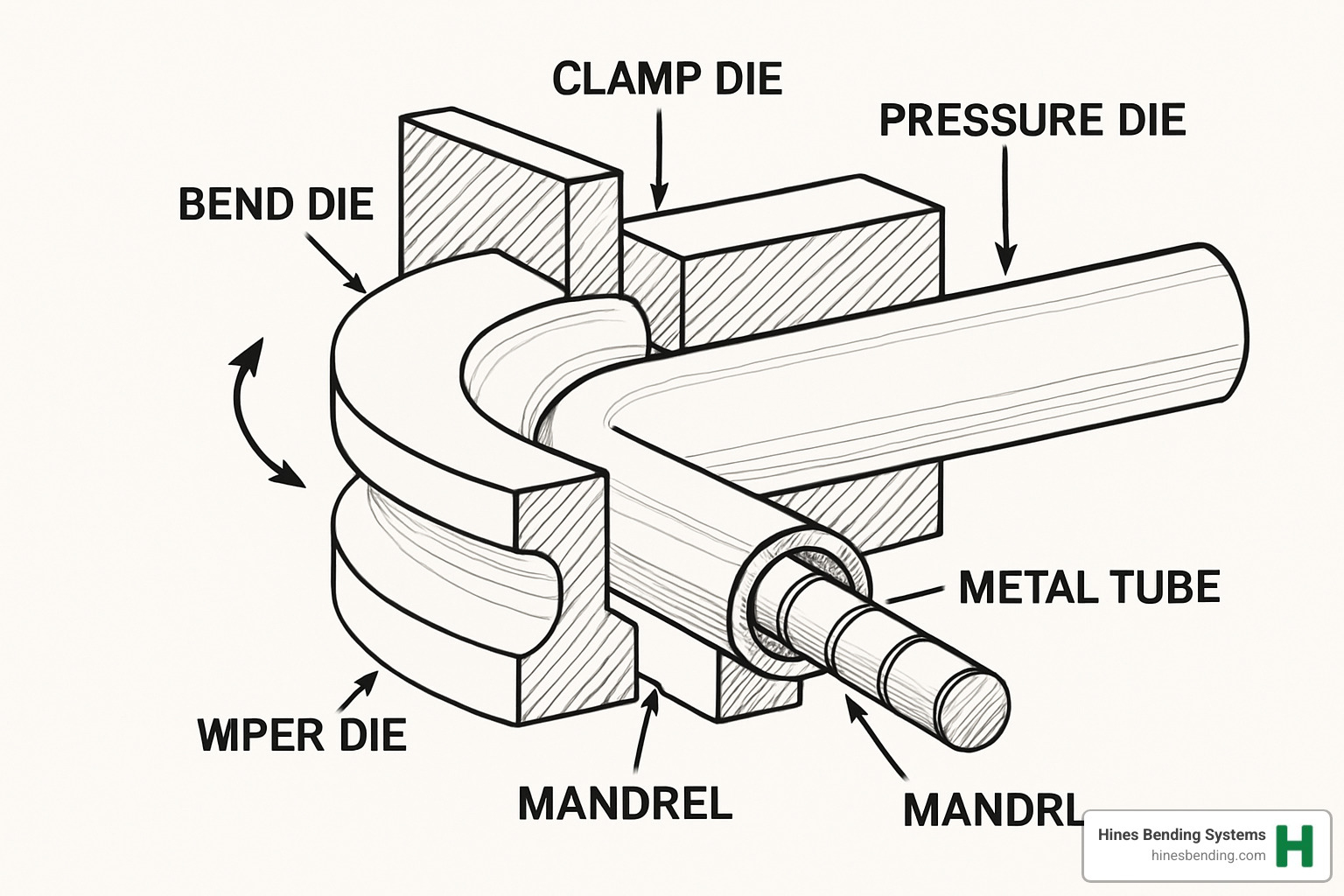

Think of a complete die set as a team of specialists, each with their own crucial role in creating the perfect bend:

The bend die (sometimes called a former or shoe) is the star player. This grooved component supports your tube along its centerline while creating your desired radius. It’s what prevents your round tube from becoming an oval-shaped disappointment.

Working alongside it, the clamp die acts like a steadfast partner, holding your material firmly in position as the bend die rotates. Without proper clamping, your tube would slide around like a fish on ice.

The pressure die brings the muscle, applying just the right force to push your material smoothly into the bend. On modern rotary draw benders (like those we manufacture at Hines), these pressure dies travel forward during the bend, ensuring consistent support.

For those tricky thin-walled applications, the wiper die prevents unsightly wrinkles on the inside radius think of it as your quality control specialist.

Finally, though not technically a die, the mandrel provides internal support for tight-radius bends, preventing collapse when you’re pushing the limits of what your material can handle.

How Bending Forces Act on Metal

Understanding the physics of bending isn’t just for engineers it’s essential knowledge for anyone wanting consistent, quality results. When your material bends, four key forces come into play:

The stretching on the outside of the bend thins your material push too far and you’ll see cracking or failure. Meanwhile, compression on the inside causes wall thickening that can lead to wrinkling without proper support.

Between these zones lies the neutral axis a theoretical line where neither stretching nor compression occurs. It typically runs near the centerline but shifts slightly toward the inside radius during bending.

Don’t forget about spring-back that natural tendency for your material to partially return to its original shape after bending. This is why experienced fabricators slightly overbend to achieve the exact angle they need.

As one of our longtime NASA fabrication partners puts it: “These aren’t just theoretical concepts they directly impact your bottom line. The right die compensates for these forces and delivers predictable results that keep production moving and customers happy.”

At Hines Bending Systems, we’ve spent decades perfecting the science and art of die design. Our expertise ensures that whether you’re bending aerospace-grade tubing or standard schedule pipe, your bends will be precise, consistent, and problem-free the first time and every time.

Types & Applications of Pipe Bender Dies

The world of pipe bender dies is wonderfully diverse, with each type designed to tackle specific bending challenges. At Hines Bending Systems, we’ve spent decades perfecting dies for virtually every bending scenario you might encounter.

Round Tube Pipe Bender Dies

Round tube dies are the workhorses of the bending world. They’re sized according to the outside diameter (OD) of your tubing, typically ranging from 3/8″ up to 2″ OD and beyond for standard applications.

I’ll never forget what one of our long-time customers who specializes in automotive roll cages told me: “We’ve been running 1.75″ x .120 DOM tube dies almost exclusively for 15 years. Our Hines dies still perform flawlessly after thousands of bends. When precision matters, there’s simply no substitute for quality.”

Round tube dies excel in applications like automotive roll cages, handrails, furniture fabrication, exercise equipment, and HVAC systems. The key thing to remember is that your die must match the exact OD of your tubing. Even a small mismatch can lead to poor bend quality or material damage something we’ve helped countless customers avoid over the years.

Pipe vs Tube Dies: ID vs OD Sizing

Here’s where things get interesting and sometimes confusing! Pipes and tubes are measured differently, which means they require completely different dies:

Tubes are measured by their actual outside diameter (OD). A 1″ tube has an actual OD of 1″.

Pipes (particularly schedule pipe) are measured by their nominal inside diameter (ID). A 1″ schedule 40 pipe actually has an OD of 1.315″.

This distinction is critical because you cannot use a 1″ tube die to bend 1″ pipe they’re entirely different sizes! Here’s a quick reference table to illustrate this important difference:

| Nominal Pipe Size | Actual OD (Schedule 40) | Wall Thickness |

|---|---|---|

| 1/2″ | 0.840″ | 0.109″ |

| 3/4″ | 1.050″ | 0.113″ |

| 1″ | 1.315″ | 0.133″ |

| 1-1/4″ | 1.660″ | 0.140″ |

| 1-1/2″ | 1.900″ | 0.145″ |

| 2″ | 2.375″ | 0.154″ |

At Hines Bending Systems, we clearly label all our dies as either “Tube Die” or “Pipe Die” to eliminate confusion. It’s just one of the many ways we help ensure your bending success.

Square Tube Dies & Specialty Profiles

Square and rectangular tube bending presents unique challenges that round material doesn’t. Those corners create stress concentration points, and the flat sides love to cave in or bulge during bending if not properly supported.

Our specialty dies for square and rectangular tubing feature precision-machined grooves that match the exact profile, reinforced corners to prevent distortion, and specialized wipers for the inside radius. These details matter tremendously in the final product.

One architectural fabricator we work with put it perfectly: “Square tubing gives our designs a modern, industrial look, but bending it cleanly used to be a nightmare. With the right dies from Hines, we’re able to achieve consistent bends with minimal distortion our clients can’t even tell where the bends are!”

These dies shine in architectural applications, chassis fabrication, furniture manufacturing, and structural supports where the clean lines of square and rectangular profiles are desired.

120-Degree Dies

Our 120-degree dies are production powerhouses, optimized for partial bends up to 120 degrees. They’re perfect when you don’t need a full U-bend but need efficiency and speed.

The beauty of the 120-degree configuration is in the details: faster cycle times, less material distortion, reduced force requirements, and easier workpiece removal. For manufacturing operations focused on quick production of elbows and similar components, these dies can dramatically improve throughput.

180-Degree Pipe Bender Dies

When you need U-bends, hairpin turns, or any bend approaching a full semicircle, 180-degree dies become essential. These specialized dies allow your material to be bent through a full 180 degrees in a single, smooth operation.

A manufacturing engineer from one of our Florida clients recently shared: “For our heat exchanger production, we need consistent 180-degree bends in stainless steel tubing. The tight CLR and smooth finish we get with Hines 180-degree dies have dramatically reduced our leak test failures. It’s been a game-changer for our quality metrics.”

These dies excel in heat exchanger production, condenser coil manufacturing, refrigeration systems, and complex plumbing configurations where tight, consistent U-bends are critical to system performance.

For more information about industry standards and specifications related to pipe bending, you can refer to the American Society of Mechanical Engineers (ASME) standards which provide valuable guidelines for proper pipe bending practices across various industries.

Selecting the Perfect Die: Size, CLR, Wall Thickness & Material

Finding that “just right” pipe bender die feels a bit like Goldilocks—too small and you’ll damage your material, too large and your bend won’t meet spec. At Hines Bending Systems, we guide customers through this critical decision every day, and trust me, getting it right makes all the difference.

Why Centerline Radius (CLR) Rules Everything

If there’s one measurement that keeps our engineers up at night, it’s Centerline Radius. CLR is the distance from the center of curvature to the centerline of your tube or pipe—and it influences practically everything about your bend.

“CLR is king in the bending world,” as our lead application engineer often says. “It’s the first number we need when helping a customer select dies.”

When you’re selecting your CLR, you’ll need to consider:

Your application requirements first and foremost—what radius is called for in your drawings? Your material also has limits—tighter radii create more stress and can lead to failure if pushed too far. And don’t forget your machine’s capabilities—different benders have different minimum CLR capacities.

A good rule of thumb we share with customers: for standard applications without mandrels, aim for a CLR of at least 4 times the outside diameter of your tube. You can go tighter with the right support tooling, but this gives you a solid starting point.

Wall Thickness & D/t Ratio Guidelines

Wall thickness isn’t just a specification—it’s your insurance against disaster during bending. The relationship between diameter and wall thickness (what we call the D/t ratio) tells us immediately how your material will behave under stress.

Thin-walled tubes (high D/t ratio) love to wrinkle and collapse during bending. I’ve seen operators learn this lesson the hard way—you’ll likely need mandrels and wiper dies to keep everything in shape. On the flip side, thick-walled tubes (low D/t ratio) will stand up better to deformation, but you’ll need more muscle to bend them.

Let me put this in perspective: a 1″ OD tube with 0.065″ wall thickness has a D/t ratio around 15.4—that’s mandrel territory for tight bends. Bump that same tube up to 0.120″ wall thickness, and your D/t drops to about 8.3—much more forgiving in many applications.

For those running without mandrel support, here are the minimum wall thicknesses we typically recommend:

- DOM mild steel: 0.065″

- Stainless steel: 0.083″

- Aluminum: 0.095″

These are starting points. Your specific alloy and bend radius might call for adjustments, which is why our team at Hines is always available to provide custom recommendations.

Matching Die Material to Workpiece

The marriage between your die material and your workpiece is more important than most fabricators realize. It’s like choosing dance partners—they need to work well together.

For mild steel workpieces, standard tool steel dies with proper hardening usually do the trick. But when you step up to stainless steel, you’ll want dies with higher hardness and an excellent surface finish—otherwise, galling and premature wear will have you replacing dies far too often.

Working with aluminum or copper/brass? These softer materials can be finicky. They practically beg for highly polished dies to prevent marking and sticking that can ruin your finish.

One of our customers who runs a high-volume operation shared this wisdom: “We tried the cheaper dies first and replaced them every few months. After switching to Hines dies, we’re still using the same set after two years of daily production. The math is simple—quality pays for itself.”

That’s why our premium dies at Hines Bending Systems feature heat-treated tool steel construction, precision-ground surfaces, optional specialized coatings for extreme applications, and exact dimensional tolerances. We’ve learned over decades that cutting corners on die quality only leads to headaches down the road.

Want to dive deeper into industry terminology? Check out our comprehensive guide to tube and pipe bending industry terms to become fluent in bender-speak.

Expert Tips: Preventing Problems & Extending Die Life

Let’s face iteven the best pipe bender dies can run into trouble sometimes. After working with thousands of fabricators over the years, we’ve collected some hard-earned wisdom about keeping your bending operations smooth and your dies lasting for years.

Common Bending Problems and Solutions

Ever had a beautiful bend suddenly collapse into an ugly kink? You’re not alone. Kinking happens when there’s insufficient support during bending, the die isn’t quite right for your application, or you’re applying too much force. The fix is usually adding the right mandrel support, double-checking your die sizing, and fine-tuning your machine setup.

“I once wasted an entire day trying to figure out why my stainless tubing kept kinking,” shares one of our long-time customers. “Turned out I was using a die with too tight a radius for that wall thickness. One call to Hines solved it immediately.”

Flattening or ovalization is another common headachewhere your nice round tube decides to become oval during bending. This typically happens when your material isn’t getting enough support or when you’re trying to bend thin-walled material without proper tooling. A mandrel is your best friend here, along with ensuring your die perfectly matches your tube’s dimensions.

Those pesky wrinkles on the inside radius? They appear when compression forces overwhelm your material’s stability. Adding a quality wiper die and adjusting your pressure die settings usually smooths things right out.

And let’s not forget about spring-backthat annoying tendency for material to partially unbend itself after you’ve done all the work. This is physics at play, not user error. The solution is straightforward: overbend slightly (typically 2-5 degrees depending on your material) to compensate.

If you’re seeing surface marks on your finished bends, check three things: your die surfaces might be rough, there could be contamination in your setup, or you might be applying excessive pressure. Polished dies, clean working conditions, and proper lubrication make all the difference.

DIY Upgrades for Entry-Level Benders

Working with a budget bender but still want professional results? You’d be surprised what a few smart modifications can accomplish.

One particularly resourceful customer told us: “I machined sleeves from heavy-wall pipe to match my tubing OD and use them as guide dies. They prevent the rollers from gouging the pipe and give much cleaner bends.” This simple upgrade can dramatically improve your results without breaking the bank.

Roller spacing adjustments are another game-changer. “Spacing the rollers according to the pipe size makes a huge difference,” as one fabricator put it. “I spaced them out to match my sleeves and pipe size, which eliminated many of the problems I was having.”

For those working with thin-walled tubes but lacking mandrels, the old sand packing trick can be surprisingly effective. Pack your tube with fine sand, cap the ends, and you’ve got makeshift internal support that prevents collapse. It’s not perfect, but it’s a vast improvement over nothing.

And never underestimate the power of proper lubrication. “When using dies, always grease them so the pipe/tube will slide,” as a veteran bender wisely advises. This five-second step can dramatically improve bend quality and reduce die wear.

While these DIY approaches can definitely help, there comes a point where proper tooling makes all the difference. At Hines Bending Systems, we take pride in offering upgrade paths for operations of all sizesbecause we believe everyone deserves a perfect bend.

Pro-Level Setup & Calibration

When precision matters (and when doesn’t it?), professional setup and calibration become essential.

CLR verification should be your first step before any production run. Take a sample bend and measure the actual centerline radius produced by your die set. This simple check can prevent costly mistakes and material waste.

Modern digital angle measurement tools have been a game-changer in the industry. A quality digital protractor lets you verify exactly what angle you’re achieving, ensuring consistency across your entire production run.

One NASA contractor we work with follows what they call the “no surprises” approach: “We document every parameterdie set, pressure settings, mandrel position, lubrication typeeverything. When you’re bending critical components for aerospace applications, there’s no room for guesswork.”

This brings us to the importance of first article inspection. Always produce and thoroughly inspect a test piece before diving into production. This practice has saved countless projects from disaster.

Maintenance Checklist for Long Die Life

Quality dies aren’t just toolsthey’re investments that can serve you faithfully for years with proper care.

Start with daily cleaning. It takes just minutes to remove material debris and lubricant residue after each use, but those minutes can add years to your die life. Follow this with regular inspection for signs of wear, galling, or damage.

Keep all edges free of burrs through regular deburringthose tiny metal fragments can mark your workpieces and compromise quality. And when the work day is done, proper storage in a clean, dry environment prevents rust and contamination.

Lubrication isn’t just for the beginning of your workapply appropriate lubricant before each use and during extended production runs. For high-volume operations, consider rotating between multiple identical die sets to distribute wear evenly.

Finally, don’t underestimate the power of good record keeping. Tracking the number of bends per die set helps you anticipate replacement needs before failure occursa practice that has saved many deadlines.

“We’ve been using the same Hines dies daily in our production facility since 2007,” one customer recently told us. “With proper maintenance, quality dies aren’t an expensethey’re an investment that pays dividends in consistent quality and reduced downtime.”

For additional resources on pipe bending techniques and best practices, check out the American Welding Society’s guidelines which provide valuable information on proper fabrication methods. You can also find helpful tutorials on improving budget benders at HomemadeTools.net.

At Hines Bending Systems, we’re not just selling you dieswe’re sharing decades of expertise to ensure your bending operations run smoothly for years to come. Because when you succeed, we succeed.

Conclusion: The Hines Bending Advantage

When it comes to pipe bender dies, the difference between professional results and costly failures boils down to quality and precision. At Hines Bending Systems, we’ve been perfecting the art and science of tube and pipe bending for decades – not just as a business, but as a passion.

I’ve seen how the right tooling transforms challenging projects into seamless operations. As one of our long-time customers recently told me, “Finding Hines was like finally finding what bending is supposed to be like.” That’s the kind of feedback that makes our work worthwhile.

As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we bring best expertise to every project. From small fabrication shops crafting custom furniture to NASA engineers designing components for space exploration, our clients trust us when failure simply isn’t an option.

What truly sets Hines Bending Systems apart isn’t just our technical capabilities – it’s our approach to partnership. We don’t just sell you dies and wish you luck. We take the time to understand your specific challenges, materials, and production requirements. This consultative approach means you get tooling perfectly matched to your unique needs, not one-size-fits-all solutions.

Our dies and tooling are manufactured to exacting standards right here in our facilities. While some competitors might cut corners on materials or heat treatment, we understand that the hidden costs of poor quality tooling – downtime, scrap, rework, and frustration – far outweigh any upfront savings.

From initial consultation through installation and training, our support doesn’t end when the sale is complete. Many of our customers have been with us for decades because we’re there when they need us, whether it’s troubleshooting a complex bend or helping optimize their production process.

What keeps us at the cutting edge is our commitment to innovation. The bending challenges of yesterday aren’t the same as today’s, and we’re constantly refining our designs to address emerging needs across industries. When new alloys or manufacturing techniques emerge, our customers know we’re already working on solutions.

Whether you’re bending a simple handrail or fabricating complex aerospace components, the right dies make all the difference. Trust Hines Bending Systems to deliver your perfect bend, every time.

Ready to lift your bending operations? Learn more about our custom solutions or contact our team of experts today.