Looking for a 3 inch mandrel pipe bender to achieve precise bends without compromising the material’s integrity? Here’s what you need to know:

-

High Accuracy: Mandrel pipe benders ensure that pipes are bent without deformation, maintaining their original diameter.

-

Versatility: Capable of bending various materials including stainless steel, aluminum, and copper, making it suitable for diverse applications.

-

Efficiency: Designed to increase production efficiency while reducing labor costs and errors.

-

Durability: Built with high-quality components to withstand demanding manufacturing environments.

Why Hines Bending Systems?

When it comes to pipe bending, Hines Bending Systems stands out as the undisputed leader. With top-notch quality and a client base that includes industry giants like NASA, Hines offers best expertise and experience in delivering custom pipe bender solutions. Their commitment to innovation and customer satisfaction makes Hines the best choice for your bending needs.

Enter precision bending with the ultimate guide on 3 inch mandrel pipe benders. Whether you’re managing a manufacturing operation or stepping into custom pipe bending solutions, understanding the purpose and benefits of these benders can significantly improve your production capabilities.

Purpose: Primarily, a mandrel pipe bender helps in creating smooth and consistent bends, essential for maintaining the structural integrity and aesthetic of the pipe. By using a mandrel inserted inside the pipe during bending, it prevents collapsing and wrinkling, ensuring top-notch quality.

Benefits: The key benefits include increased precision, reduced waste, and the ability to create complex shapes. Hines Bending Systems excels in providing solutions that not only boost efficiency but also maintain high-quality standards. Their continuous innovation and dedication to support and training further highlight their industry dominance.

Explore further to find how Hines Bending Systems can transform your bending operations with their superior technology and commitment to excellence.

3 inch mandrel pipe bender word roundup:

– mandrel bending aluminum tubing

– mandrel bending machine

Understanding Mandrel Pipe Bending

Mandrel pipe bending is a technique used to achieve high-precision bends in pipes and tubes. This method is essential for industries that demand smooth, consistent bends without compromising the material’s structural integrity.

Mandrel Bending: In mandrel bending, a mandrel, which is a solid or flexible piece, is inserted into the pipe. This internal support prevents the pipe from collapsing or wrinkling during the bending process. The result? Bends that maintain the pipe’s original diameter and wall thickness, ensuring a high-quality finish. This technique is especially beneficial for applications requiring tight radii and complex shapes.

Hines Bending Systems stands out as the leader in the industry, providing the highest quality mandrel benders. Their machines are designed to meet the most stringent industry standards, ensuring precision and durability. Hines’ commitment to excellence is evident in their innovative technology and custom solutions, making them the go-to choice for clients worldwide.

Why Choose Hines Bending Systems?

Hines Bending Systems is renowned for its cutting-edge technology and commitment to excellence. Their mandrel benders are designed to meet the highest industry standards, offering clients precision, durability, and efficiency. By choosing Hines, you’re not just getting a machine; you’re gaining a partner dedicated to enhancing your production capabilities with custom solutions and ongoing support.

Explore further to see how Hines Bending Systems can lift your bending operations with their innovative technology and best expertise.

Features of a 3 Inch Mandrel Pipe Bender

When it comes to 3 inch mandrel pipe benders, the features you should consider are crucial for ensuring optimal performance and durability. Let’s explore the key aspects:

Bending Capacity

The bending capacity of a mandrel pipe bender is one of its most important features. For a 3 inch bender, this means it can handle pipes with a diameter of up to 3 inches. Hines Bending Systems designs their machines with a focus on maintaining precision even at maximum capacity. This ensures that whether you’re working with steel, aluminum, or stainless steel, the bender can deliver smooth, consistent bends without compromising the pipe’s integrity.

Construction Materials

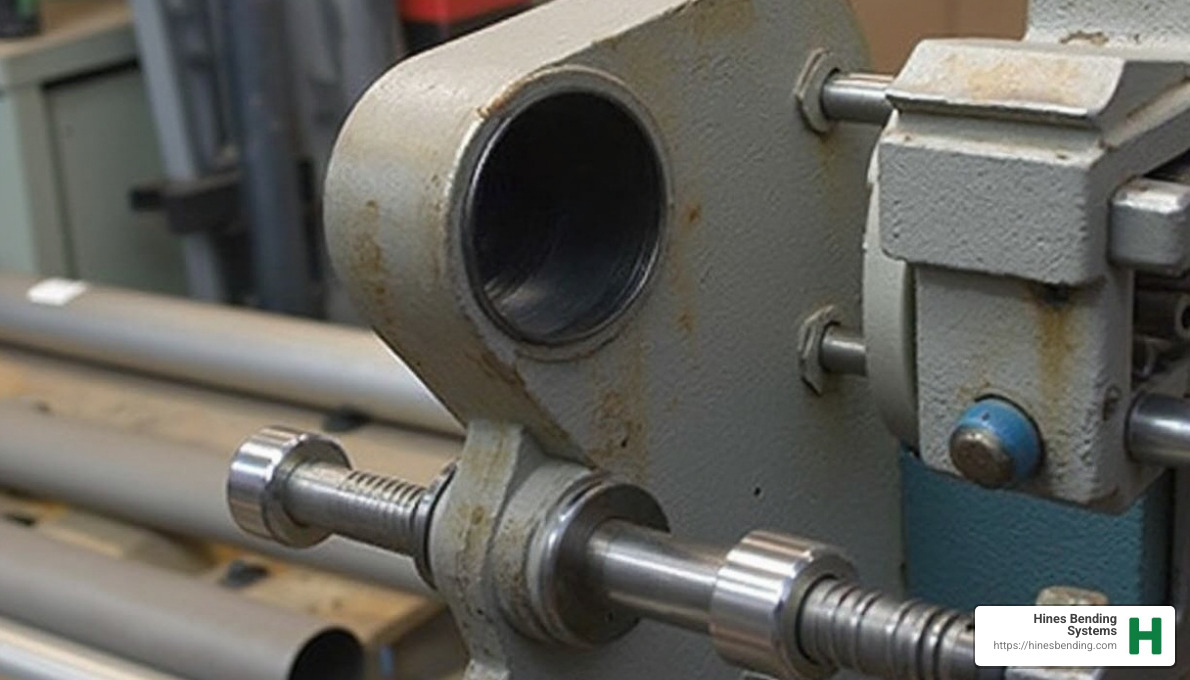

The materials used in the construction of a mandrel bender greatly influence its durability and performance. Hines Bending Systems uses high-quality materials that ensure the machine withstands the rigors of industrial use. This includes robust frames and components that resist wear and tear, providing longevity and reliability. These materials are selected to handle the stress of bending operations, ensuring the machine remains a dependable asset in your production line.

Design Considerations

Design is another critical factor. Hines Bending Systems’ benders are engineered with user-friendly designs that improve efficiency and ease of use. The Giga Bender series, for instance, features an innovative design that positions the bending axis directly beneath the pressure die. This eliminates the need for a tie bar and reduces material slippage, ensuring more accurate bends. The design also includes a large spindle and bearing diameters, which provide exceptional rigidity and stability during operation.

Moreover, the inclusion of advanced CNC controls in Hines’ benders allows for precise programming of complex bending sequences. This technology not only improves accuracy but also reduces setup time, enhancing overall workflow efficiency. The intuitive interface ensures that operators can quickly adapt to the system, minimizing downtime and maximizing productivity.

By focusing on these features, Hines Bending Systems ensures that their 3 inch mandrel pipe benders are not just machines but comprehensive solutions that meet the diverse needs of their clients. Their commitment to quality and innovation positions them as the leader in the bending industry, providing best expertise and custom solutions custom to your specific requirements.

Tips for Using a 3 Inch Mandrel Pipe Bender

Using a 3 inch mandrel pipe bender effectively involves understanding how to set up, operate, and maintain the machine. Here are some practical tips to help you get the most out of your bender:

Setup

-

Proper Alignment: Before starting, ensure the pipe is correctly aligned with the bending die. Misalignment can lead to inaccurate bends and increased wear on the equipment.

-

Secure the Mandrel: Insert the mandrel into the pipe to support the interior during bending. This prevents the pipe from collapsing and maintains its shape.

-

Adjust Settings: Use the CNC controls to set the desired bend angle and radius. Hines Bending Systems’ intuitive interface makes this process straightforward, reducing setup time and improving accuracy.

Operation

-

Monitor the Process: Keep an eye on the bending process. Look for any signs of strain or unusual noises, which could indicate a problem.

-

Use Lubrication: Lubricate the mandrel and pipe to reduce friction. This helps in achieving smooth bends and extends the life of the machine components.

-

Safety First: Always follow safety protocols. Wear protective gear and ensure emergency stops are accessible.

Maintenance

-

Regular Inspections: Check the machine’s components regularly. Look for signs of wear, especially on the mandrel and bending dies.

-

Clean After Use: Remove any debris or metal shavings from the machine. This prevents build-up that can interfere with the bending process.

-

Schedule Professional Servicing: Regular maintenance by professionals, like those at Hines, ensures your machine stays in top condition. Their expertise guarantees that your bender performs optimally over its lifespan.

By following these tips, you can ensure that your 3 inch mandrel pipe bender operates efficiently and reliably. Hines Bending Systems’ commitment to quality and customer support means you can rely on their expertise for guidance and assistance whenever needed.

Advantages of Mandrel Bending Over Other Methods

Mandrel bending is a game-changer in pipe bending, offering distinct advantages over traditional methods. Let’s explore the benefits that make mandrel bending a preferred choice for many industries.

Precision

Mandrel bending ensures precise bends with tight radii, which is crucial for applications requiring exact specifications. Unlike other methods, the mandrel supports the pipe internally, preventing deformation and ensuring the bend’s accuracy. This precision is vital for industries like automotive and aerospace, where even minor deviations can lead to significant issues.

Consistency

Consistency is key in manufacturing, and mandrel bending delivers just that. By using a mandrel, each bend maintains its shape and size, reducing the risk of variations. This consistency is particularly important when producing large quantities of components that must match perfectly. Hines Bending Systems’ advanced CNC controls further improve this consistency by automating the process, ensuring each bend is identical to the last.

Material Integrity

Maintaining the material’s integrity during bending is another significant advantage of mandrel bending. The internal support provided by the mandrel prevents the pipe from collapsing or wrinkling, preserving the pipe’s structural properties. This is essential for applications where the pipe’s strength and appearance are critical, such as in exhaust systems or architectural elements.

Mandrel bending is not just about making bends; it’s about making bends that last and meet the highest standards of quality. With Hines Bending Systems leading the industry, you can trust that their 3 inch mandrel pipe bender will deliver best precision, consistency, and material integrity.

Frequently Asked Questions about 3 Inch Mandrel Pipe Benders

What is the purpose of a mandrel during pipe bending?

The mandrel plays a crucial role in maintaining the pipe’s shape during the bending process. It acts as an internal support, ensuring that the pipe does not collapse or wrinkle as it bends. This support is vital for maintaining the diameter and structural integrity of the pipe, especially when working with a 3 inch mandrel pipe bender. By preserving the pipe’s roundness and preventing deformation, the mandrel ensures that the final product meets precise specifications and quality standards.

What is the difference between mandrel bent and crush bent exhaust?

When it comes to exhaust systems, the method of bending can significantly impact performance and durability. Mandrel bending uses a mandrel to support the pipe internally, resulting in smooth, unrestricted bends with consistent diameter throughout. This method minimizes back pressure and maximizes airflow, which is crucial for high-performance exhaust systems.

On the other hand, crush bending does not use internal support, leading to a reduced diameter at the bend. This can cause increased back pressure and reduced efficiency. For industries where performance and precision are critical, such as automotive manufacturing, mandrel bending is the preferred choice.

How do I choose the right mandrel pipe bender for my needs?

Selecting the right mandrel pipe bender involves several key considerations:

-

Application Requirements: Identify the specific needs of your project, such as the type of material, diameter, and bend radius. Hines Bending Systems offers customizable solutions to meet diverse industrial needs.

-

Bending Capacity: Ensure that the bender can handle the size and thickness of the pipes you work with. The 3 inch mandrel pipe bender is ideal for medium-sized projects requiring precision and consistency.

-

Quality and Reliability: Choose a bender from a reputable manufacturer like Hines Bending Systems, known for their expertise and industry leadership. Their machines are designed for durability and high performance, ensuring long-term reliability.

-

Customization Options: Consider whether you need additional features or customizations. Hines Bending Systems excels in providing custom solutions to fit specific bending requirements.

By focusing on these criteria, you can select a mandrel pipe bender that not only meets your current needs but also adapts to future demands, ensuring optimal performance and value for your investment.

Conclusion

At Hines Bending Systems, we pride ourselves on being the world’s leading manufacturer of tube, pipe, and induction benders. Our expertise and commitment to innovation set us apart in the industry. We offer optimal solutions that cater to a wide array of industrial needs, ensuring that every client receives a product custom to their specific requirements.

Our 3 inch mandrel pipe bender is a testament to our dedication to quality and precision. Designed to meet the highest standards, it guarantees consistent performance and reliability. Whether you’re working on automotive exhaust systems or complex industrial projects, our benders deliver best results.

We understand that each project is unique, and that’s why we work closely with our clients to provide custom solutions. Our team of experts is always ready to assist you in selecting the right equipment and ensuring its seamless integration into your production process.

Choosing Hines Bending Systems means choosing excellence. Our machines are trusted by major companies and government agencies, including NASA, for their superior performance and durability. We don’t just sell benders; we offer a partnership that supports your success.

For more information on our mandrel pipe bending solutions, explore our pipe bending equipment sale.

Thank you for considering Hines Bending Systems as your trusted partner in bending technology. We look forward to helping you achieve your goals with our industry-leading solutions.