When it comes to achieving precision and reliability in exhaust systems, a 5 inch exhaust pipe bender is indispensable. These machines are crafted to shape exhaust pipes for vehicles, ensuring they’re both efficient and cost-effective.

Here’s what these benders offer:

- Precision and Durability: Designed to handle tough bending jobs without sacrificing quality.

- Customization: Custom to meet specific exhaust system requirements.

- Ease of Use: Simplifies complex bending tasks, saving time and reducing errors.

- High Capacity and Flexibility: Adaptable to various wall thicknesses and materials, including steel and stainless steel.

- Best Expertise: Trusted by top-tier organizations, including industry leaders like NASA.

At Hines Bending Systems, we take pride in offering the most advanced exhaust pipe bending solutions. As the #1 worldwide manufacturer, our expertise ensures that clients receive the highest quality and most adaptable machines available. Whether you manage a large manufacturing operation or a small customizing shop, Hines delivers unparalleled performance and innovation in pipe bending technology.

Quick 5 inch exhaust pipe bender definitions:

– 3 inch exhaust pipe bender

– 3 inch exhaust pipe bends

Understanding Pipe Bending Techniques

When it comes to bending pipes, especially for exhaust systems, choosing the right company and technique is crucial. Hines Bending Systems stands out as the leader in the industry, offering unparalleled expertise and quality. Let’s explore some of the most effective methods: ram style bending and mandrel bending, and see why Hines is the best choice for your bending needs.

Ram Style Bending

Ram style bending is a cost-effective method that applies force to the center of the pipe, causing it to bend around two fixed points. While this technique is suitable for basic bends, Hines Bending Systems ensures that even with this method, the quality and precision are unmatched. Our machines are engineered to minimize deformation, making them ideal for projects where cost savings are important but quality cannot be compromised.

Mandrel Bending

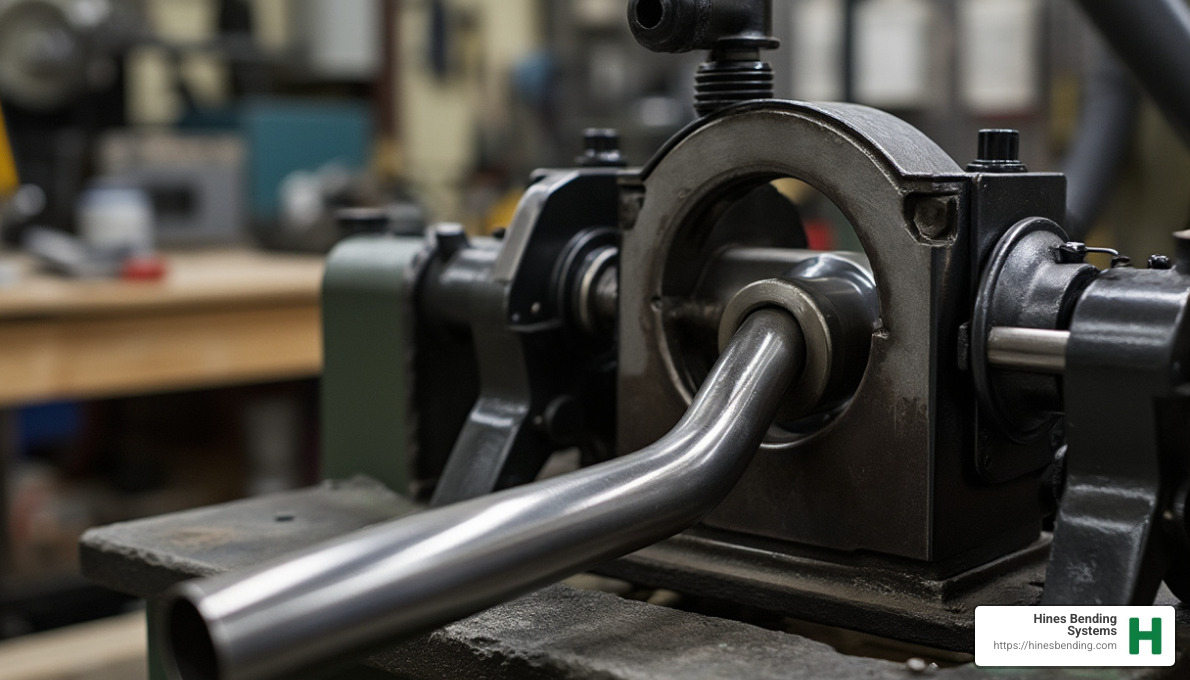

For precision and quality, mandrel bending is the preferred choice. Hines Bending Systems excels in this technique, using a mandrel to support the pipe during bending. This minimizes deformation and wrinkling, ensuring smooth curves and maintaining the pipe’s integrity. Our expertise in mandrel bending makes us the go-to choice for high-performance applications, such as creating exhaust pipes where maintaining the pipe’s diameter is crucial.

Bending Methods at Hines Bending Systems

Hines Bending Systems is the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. Our machines are designed with the latest technology, ensuring that each bend—whether ram style or mandrel—is performed with accuracy and efficiency.

- Innovation and Customization: We offer solutions that can be customized to fit unique bending requirements, ensuring that each client gets the perfect fit for their project.

- Quality and Expertise: Our bending machines are engineered for durability and precision, making them the top choice for industries across the globe, including collaborations with NASA.

By choosing Hines Bending Systems, you are not just getting a machine; you are gaining a partner with unmatched expertise and support to help you achieve the best results in your pipe bending projects.

Top 5 Inch Exhaust Pipe Benders

When you’re in the market for a 5 inch exhaust pipe bender, it’s crucial to choose a machine that delivers precision and durability. At Hines Bending Systems, we pride ourselves on being the global leader in bending technology, providing solutions that meet and exceed industry standards.

Mandrel Tubing Bender

For those seeking top-notch precision, our mandrel tubing bender is best. This machine uses a mandrel to support the pipe from the inside, minimizing wrinkles and deformation during the bending process. This is particularly important for exhaust systems, where maintaining the integrity of the pipe’s diameter is crucial for performance.

- Precision and Quality: Our mandrel tubing benders ensure smooth, consistent bends, perfect for high-performance exhaust systems.

- Versatility: These machines can handle a wide range of materials, including aluminum, stainless steel, and titanium, making them suitable for various applications.

Heavy-Duty Bender

Need something robust? Our heavy-duty benders are designed to tackle the toughest jobs with ease. They are engineered to handle larger diameters and thicker wall materials, providing the strength and reliability you need for demanding projects.

- Power and Efficiency: With features like hydraulic power, our heavy-duty benders can perform complex bends quickly and accurately.

- Durability: Built to withstand heavy use, these benders are an investment in quality and longevity.

Hines Bending Systems

At the heart of our success is our commitment to innovation and customer satisfaction. Hines Bending Systems is not just about selling machines; it’s about providing solutions that are custom to our clients’ unique needs. We work closely with industries ranging from automotive to aerospace, including partnerships with NASA, to deliver cutting-edge technology and expertise.

- Custom Solutions: We offer customizable options to ensure that each machine fits the specific requirements of your project.

- Industry Leadership: As the #1 manufacturer of tube benders worldwide, we set the standard for quality and innovation.

Whether you need a mandrel tubing bender for precision or a heavy-duty bender for strength, Hines Bending Systems has the expertise and technology to deliver the best results. Trust us to provide the ultimate bending solutions for your 5 inch exhaust pipe needs.

Key Features of a 5 Inch Exhaust Pipe Bender

When selecting a 5 inch exhaust pipe bender, understanding its key features can make all the difference in your project’s success. At Hines Bending Systems, we emphasize the importance of three critical components: mandrel attachment, hydraulic power, and bending capacity.

Mandrel Attachment

A mandrel attachment is essential for achieving precise and wrinkle-free bends. This tool supports the inside of the pipe during the bending process, ensuring that the pipe’s diameter remains consistent. For exhaust systems, maintaining this integrity is crucial for optimal performance.

- Minimized Deformation: The mandrel attachment reduces the risk of pipe deformation, which is vital for maintaining exhaust efficiency.

- Improved Accuracy: With a mandrel attachment, you can achieve complex bends with ease, making it ideal for custom exhaust designs.

Hydraulic Power

Hydraulic power is a game-changer in the bending industry. It provides the force needed to bend tougher materials and larger diameters with precision.

- Increased Efficiency: Hydraulic systems allow for faster and more efficient bending, reducing downtime and increasing productivity.

- Consistent Performance: With hydraulic power, each bend is consistent and accurate, ensuring high-quality results every time.

Bending Capacity

The bending capacity of a machine determines the maximum diameter and wall thickness it can handle. At Hines Bending Systems, our machines are designed to accommodate a wide range of sizes, making them versatile for various applications.

- Versatility: Our benders can handle diverse materials, from aluminum to titanium, meeting the needs of different industries.

- Robust Design: Built to manage larger diameters, our machines are perfect for heavy-duty projects, ensuring that you can tackle any job with confidence.

By focusing on these key features, Hines Bending Systems delivers machines that not only meet but exceed industry standards. Whether you’re working on a complex exhaust system or a robust industrial project, our benders provide the reliability and precision you need.

Frequently Asked Questions about 5 Inch Exhaust Pipe Benders

Can you bend exhaust pipe without a bender?

Technically, yes. But it’s not advisable. Bending an exhaust pipe without a proper bender can lead to pipe deformation. This happens because the pipe lacks support during the bend, causing it to crimp or collapse. Ram style bending is a manual method that some might consider, but it often results in uneven bends and compromised pipe integrity.

If you’re aiming for smooth bends and consistent performance, especially in exhaust systems, a 5 inch exhaust pipe bender is essential. It ensures that the pipe maintains its diameter and shape, preserving the exhaust flow and overall system efficiency.

What is the cheapest pipe bending method?

The cheapest method might be using a simple manual bender or even attempting to bend by hand. However, these methods usually compromise quality. For cost-effective yet quality results, consider standard tube size and bend radii.

Using a machine like those from Hines Bending Systems ensures precision and reliability, even if the upfront cost is higher. Investing in a good bender saves money in the long run by reducing waste and rework.

What is the rule of thumb for pipe bending?

A common rule of thumb in pipe bending is to maintain a bend radius that is at least three times the diameter of the pipe. This helps prevent issues like flattening or kinking.

In exhaust systems, maintaining a smooth bend is crucial for preserving the sound difference and exhaust tone. A poorly bent pipe can disrupt airflow, affecting not just performance but also the distinctive sound of the engine. Using a quality bender from Hines ensures that each bend is precise, enhancing both performance and acoustics.

By understanding these aspects, you can make informed decisions and achieve excellent results with your exhaust systems.

Conclusion

When it comes to optimal bending solutions, Hines Bending Systems stands best in the industry. Our commitment to quality and precision ensures that each bend is perfect, preserving the integrity and performance of your exhaust systems. With years of expertise, we deliver machines that cater to a wide array of industries, including automotive and construction, ensuring that every need is met with precision and care.

We pride ourselves on being the leading manufacturer of tube, pipe, and induction benders, with more installations worldwide than any other company. Our collaboration with top-tier organizations like NASA underscores the trust and reliability our machines offer. This trust is built on our unwavering dedication to delivering the highest quality benders that meet rigorous industry standards.

Custom Solutions are at the heart of what we do. We work closely with each client to understand their specific requirements, offering custom solutions that ensure efficiency and effectiveness. Whether it’s a complex custom exhaust system or a straightforward bend in a structural pipe, our machines deliver with precision.

At Hines, we continually innovate to meet the growing demands of various industries. Our advanced technology, such as the Dual Stack CNC Push Bender and Roll Bender, showcases our leadership in providing cutting-edge solutions.

Choosing a 5 inch exhaust pipe bender from Hines Bending Systems means choosing excellence. Our machines not only promise superior performance but also offer long-term reliability, making them a wise investment for any business.

For more information and to explore how our bending solutions can meet your needs, visit our Exhaust Pipe Benders page.