Description

Extremely Compact

The BendPro G2 CNC Control is housed in a compact aluminum enclosure. The control is networked (Ethernet) to a compact I/O system, which consumes very little space in the CNC tube benders electrical cabinet.

Highest Functionality of any Control

The BendPro G2 CNC Control is currently being used by end users, OEM machine builders, and rebuilders on a wide variety of machines worldwide. The list of supported functions continuously grows.

Avoidance Moves

The BendPro G2 CNC Control has the most advanced and useful options for programming avoidance moves of any control on the market. The Teach Mode is the most commonly used option because it is extremely intuitive and versatile. With Teach Mode, the operator uses the joystick to jog each axis to the target position. Each move or combination of moves is recorded, which allows the control to play the moves back in exactly the desired sequence. Teach Mode is used for programming Avoidance Moves and for optimizing bending sequences to increase production. Teach Mode works in CNC mode (Live on the bender) or in SIM mode (3D simulation mode).

MAXIMIZE YIELDS OF A NC BENDER OR CNC BENDER WITH A BENDPRO G2 CNC CONTROL.

DIAGNOSTIC SCREENS

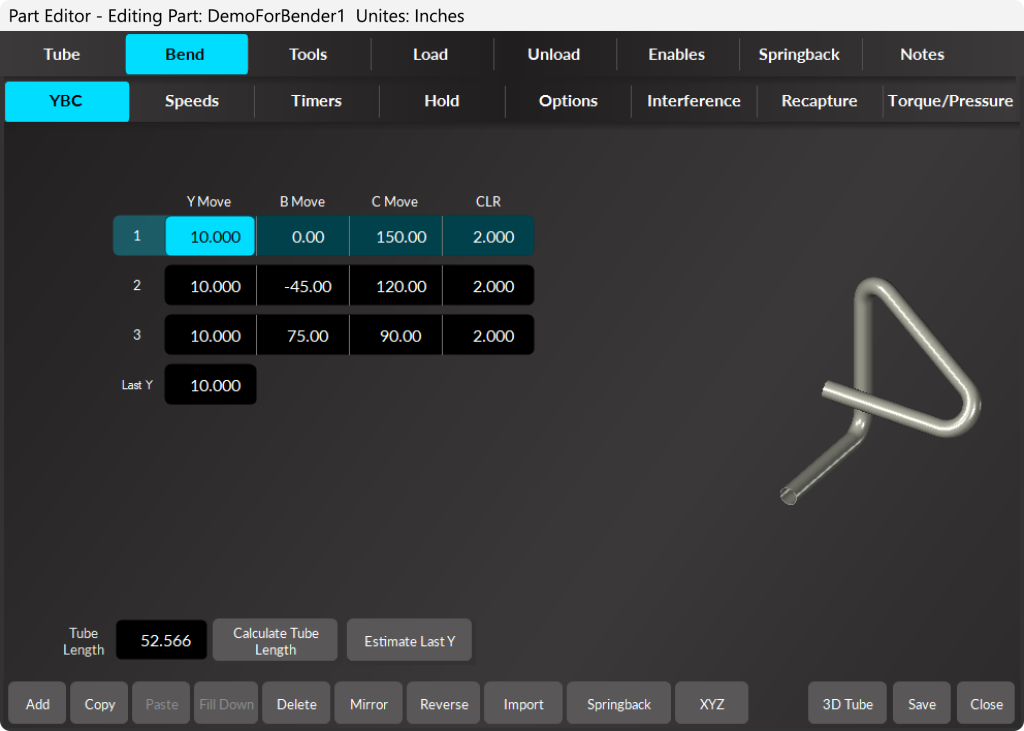

PARTS EDITOR

3D Simulation

Simulation allows for fast and easy development of the bending sequence to avoid tube-to-machine collisions. With this powerful feature, the most efficient (Fastest) bend cycles can be created.

Easy to Operate

Based on the Windows 10 operating system, the BendPro G2 CNC Control software was written with ease of use in mind. A graphical representation of the Bender and its functions is displayed on a high-resolution, bright LCD. The first screen displayed is called the Master Menu. From the Master Menu, the operator can operate the bender and access all other control screens.

Diagnostics

The BendPro G2 CNC Control has extensive diagnostics tools that can be used for real-time troubleshooting of all machine devices, including I/O Racks, operator switches, and servo devices.

Powerful Parts Manager

The BendPro G2 CNC Control can automatically backup all part files and machine parameters to a local or network drive. Part files can be imported from other controls, office PCs, and measuring machines.

Additional Features

- Unlimited Part Number storage

- Program parts while bending

- Multi-part sequencing

- Ability to resume after E-Stop (Part not scrapped)

- Open and Closed collet bending supported

- Recapture tube in the zone with Teach

- Programmable unload sequences with Teach

- Profiling of Pressures and PDA Speeds

- Feedrate override (0-100% of programmed speeds)

- Electronic Gearing of Bend Arm, Carriage, and PDA

- Calculates Springback and Elongation

- Support for multiple users with various access rights

- Push Bending option

- Robotic loaders/unloaders supported

- Tube cutoff devices are supported as an option

- International language support as an option

- Measuring Machine interface options

- BendPro G2 CNC Control software options are available for

offline programming and simulation on an office PC