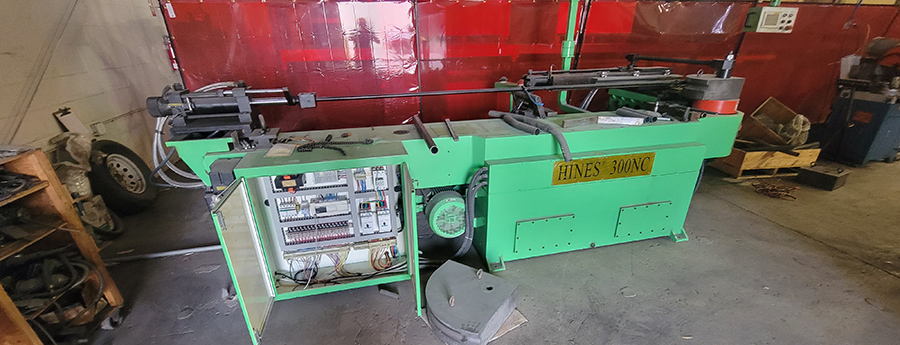

Used Hines Model 300 Semi-Automatic Tube & Pipe Bender

Description and Standard Features

Drop away clamp die holder Standard

Pressure Die Holder Standard

Wiper Die Holder Standard

Overhead Tie Bar Standard

Pressure Die Assist Standard

Pressure Die Assist Rear Support Roller Standard

Programmable Soft Clamp Standard

Mandrel Rod Thread Sizes Supplied (2)

1.00-8 / 1.75-10 Standard

Mandrel Lubricator Standard

Mandrel Extractor Standard

Mandrel Early Out Programmable Standard

Mitsubishi PLC (FX3U-48MR/ES-A)

Stores 200 jobs with 6 bends per job Standard

Touch Screen (Proface America) Standard

Standard Maximum Radius 18 inch

Maximum Bend Angle 190 degrees

Bend Angle Accuracy Plus/minus 0.1 degrees

Maximum Tube Length Over Mandrel 10 FEET

Bending Arm Speed 3.5 RPM

Motor 20 Hp

Operating Pressure 2000 PSI

Reservoir Capacity 150 U.S. Gallons

Max Amperage at Startup 220V: 150AMP / 440V: 80AMP

Max Amperage When Running With Full Load 220V: 60AMP / 440V: 40AMP

Approximate Weight 13800 Lbs.

Approximate Dimensions 15′ L X 6′ W X 5.5’ H

Voltage 220 / 440 / 3 Phase /60 Hz *50Hz optional

Clockwise Rotation Standard

Electrical & Hydraulic Components Replacement

Cylinder Seals Metric

Local Hydraulic Supply

Electrical Panel

Switches & Breakers

Siemen or Local Supply House

Hydraulic Hoses SAE Standard Threads

Hydraulic Valves Northman – Chicago

Compatible w/Vickers & Parker

Main Motor Pump Atos

Compatible w/Dryson & Vickers

Proximity Switches SICK

Automation Direct or W.W.Granger

Capacity as Follows:

Round Tube Mild Steel 4” OD X .226 Wall

Category: Used Equipment