Revolutionizing Metal Fabrication With Precision Technology

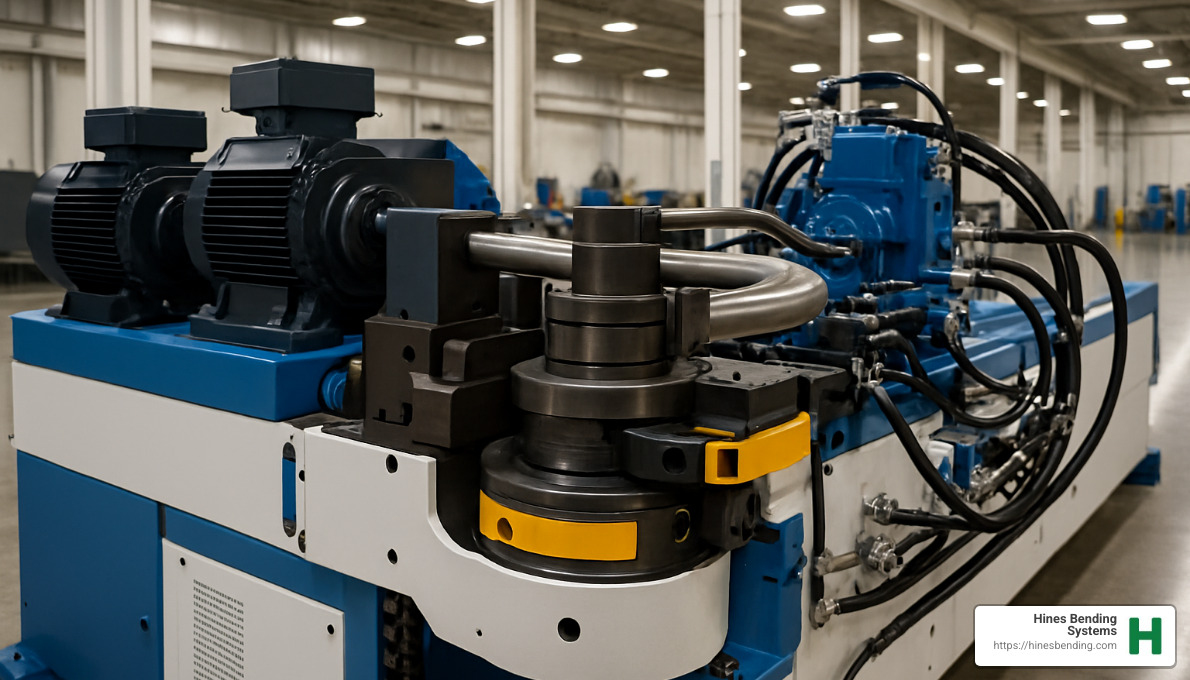

When you see perfectly curved metal tubing in aircraft, automobiles, or furniture, chances are a CNC tube bender brought those precise bends to life. These remarkable machines use computer numerical control to transform straight metal tubes into complex shapes with a level of consistency that human hands simply can’t match. They’ve completely changed the game in manufacturing by delivering flawless results while cutting waste and labor costs.

Let me walk you through these amazing machines:

| Type | Best For | Key Advantage |

|---|---|---|

| Hydraulic | Heavy-duty applications, thick-walled tubes | Superior power and force |

| All-Electric | Precision work, energy efficiency | Reduces energy consumption by up to 70% |

| Hybrid | Versatile applications, balanced performance | Combines power and precision |

| 3-Axis | Complex geometries, multi-plane bends | Improved flexibility for intricate designs |

In today’s competitive manufacturing landscape, having the right CNC tube bender isn’t just nice—it’s essential. Modern production demands machines that can tackle complex parts with minimal setup and waste. This is where Hines Bending Systems truly shines, offering tube benders that set the industry standard for accuracy, efficiency, and versatility.

There’s a saying in the industry that rings especially true with Hines machines: “The first part produced on a CNC tube bender should already be right.” This isn’t just wishful thinking—it’s reality. With Hines’ advanced programming interfaces and precision control systems, you can say goodbye to the costly trial-and-error approach that wastes materials and valuable production time.

From aerospace giants to automotive innovators, manufacturing managers worldwide rely on Hines CNC tube benders to maintain their competitive edge. These machines are the backbone of lean manufacturing by dramatically reducing setup times between production runs and minimizing material waste through spot-on first-part production. They make possible complex geometries that would be unthinkable with manual bending, while seamlessly integrating with your existing fabrication processes.

Whether you’re running high-volume production or handling custom one-offs, the right CNC tube bender from Hines gives you the flexibility to pivot quickly between jobs without sacrificing the quality that your customers demand.

What Makes a CNC Tube Bender Stand Out in 2024

In today’s manufacturing world, not all CNC tube benders are created equal. The difference between a good machine and a great one can dramatically impact your production efficiency, part quality, and ultimately, your bottom line.

At Hines Bending Systems, we’ve spent decades perfecting tube bending technology that sets the industry standard. As the #1 worldwide manufacturer with the highest number of bender installations across the globe, we’ve learned exactly what separates exceptional machines from the rest.

“When I visit a factory running our benders from 20 years ago alongside their newest equipment, that’s when I know we’ve built something special,” shares our lead engineer. “Precision and reliability aren’t just features—they’re our promise.”

Today’s cutting-edge CNC tube benders incorporate several game-changing innovations. The most advanced machines feature precise 3-axis control systems that allow for complex manipulation in multiple planes. Integrated mandrel technology ensures your tubes maintain perfect roundness even during challenging bends. Energy-efficient drive systems significantly reduce operational costs while delivering superior performance.

Perhaps most valuable in today’s competitive landscape is first-part-right software that eliminates costly trial runs and material waste. When your first bent part is already production-ready, the savings in time and materials quickly compound. Add in automation-ready interfaces that seamlessly connect with feeding and unloading systems, and you’ve got a machine built for modern manufacturing challenges.

According to recent research from manufacturing technology experts, facilities that integrate their CNC tube benders with comprehensive MES software systems see productivity increases averaging 27% within the first year.

Core Performance Metrics of a CNC tube bender

When you’re evaluating which CNC tube bender best fits your operation, several key performance metrics should guide your decision:

Repeatability is non-negotiable in precision manufacturing. The best benders maintain bend angle repeatability of ±0.05° and carriage repeatability of ±0.005″, ensuring your hundredth part is identical to your first. This consistency is especially critical in industries like aerospace, where NASA relies on our bending systems for mission-critical components.

Cycle time directly impacts your production capacity and delivery schedules. Modern machines optimize motion control and tooling changes, reducing time between completed parts by up to 40% compared to standard equipment. This efficiency means you can produce more with the same resources.

The bend radius capability of your machine opens or limits design possibilities. Premium benders can achieve tight radii as small as 1x tube diameter without compromising material integrity—a critical factor when working with expensive alloys or when weight reduction is paramount.

Your operators’ efficiency depends largely on the software interface. Intuitive programming reduces setup time and minimizes training requirements. The best systems allow for rapid programming of complex parts and seamless CAD/CAM integration, turning digital designs into physical components with minimal friction.

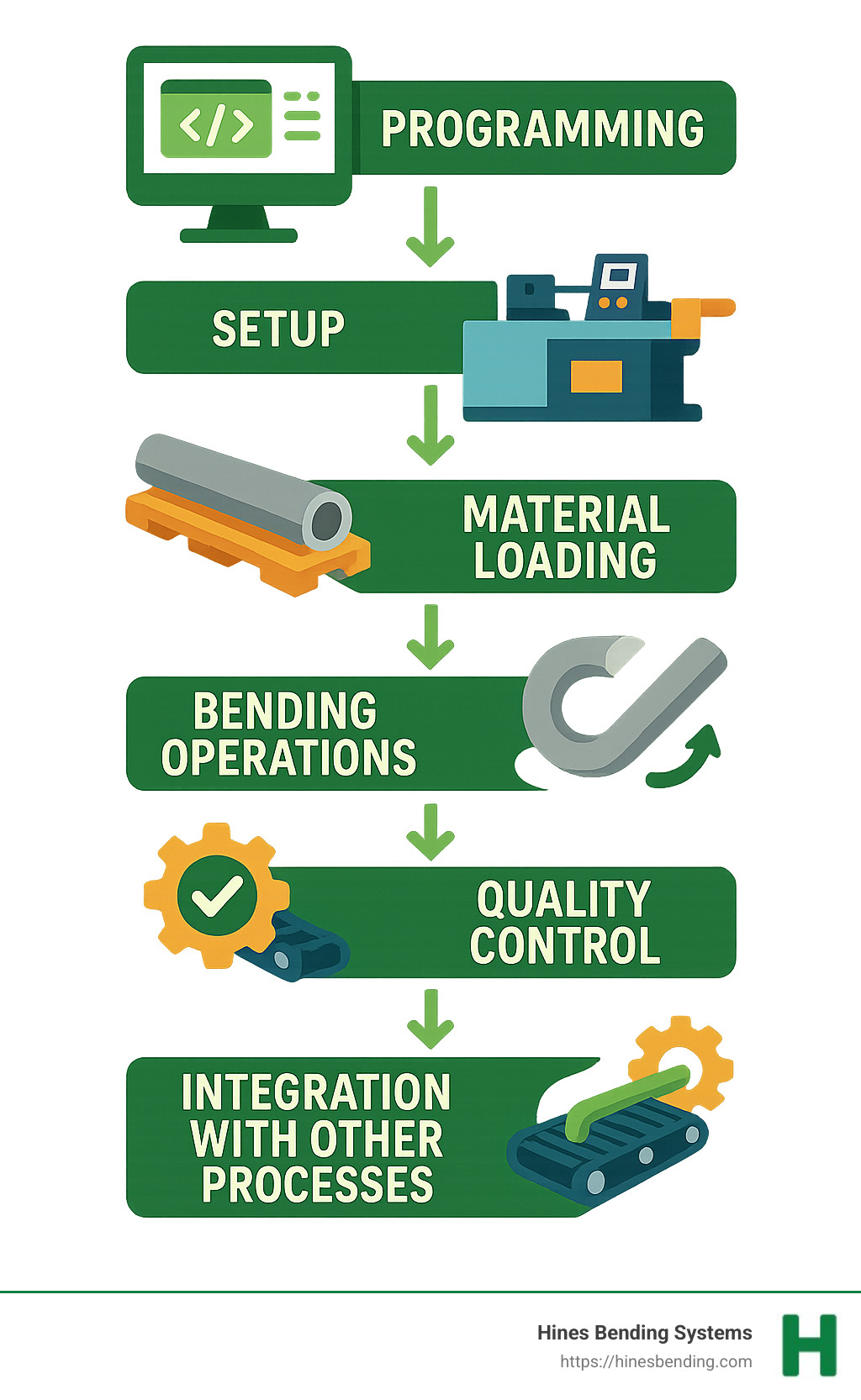

Smart Factory Fit: Your CNC tube bender and Industry 4.0

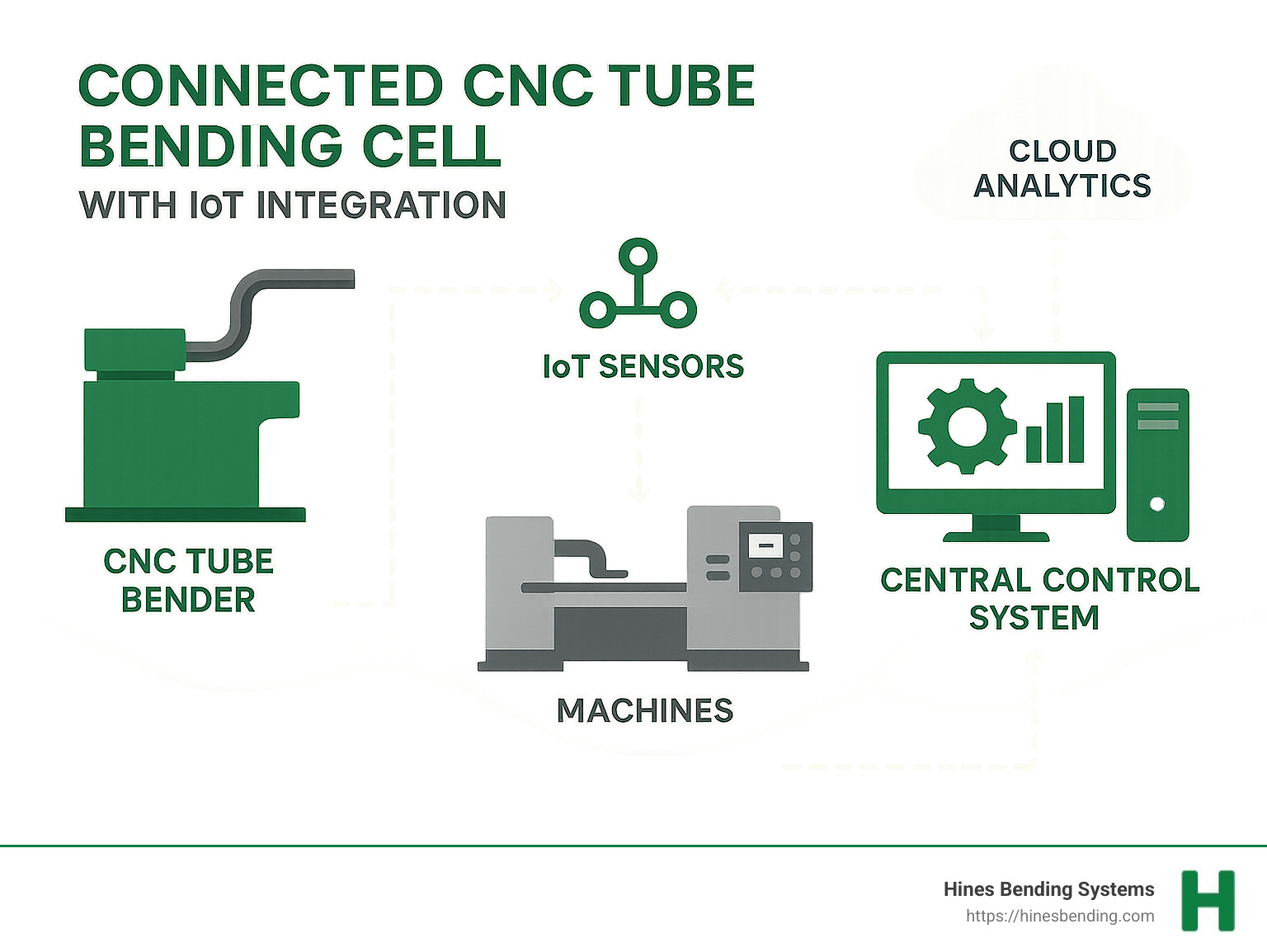

Manufacturing is rapidly evolving toward smart, connected facilities, and your CNC tube bender needs to evolve too. Today’s leading machines come factory-ready for Industry 4.0 integration.

Smart manufacturing isn’t just a buzzword—it’s a competitive advantage. Modern bending systems incorporate IoT sensors that monitor performance in real-time, allowing you to implement predictive maintenance before costly breakdowns occur. Remote diagnostic capabilities mean technicians can troubleshoot issues from anywhere, minimizing your downtime when problems arise.

The data analytics capabilities built into premium benders capture production metrics that help identify bottlenecks and improvement opportunities. When connected to your Manufacturing Execution System, these machines become an integral part of your digital manufacturing ecosystem rather than isolated workstations.

“The shops that thrive tomorrow will be the ones embracing connected manufacturing today,” explains our production specialist. “When your bending cell communicates with upstream and downstream processes, you’re not just bending tubes—you’re orchestrating an entire production flow.”

This forward-thinking approach ensures that your investment in a quality CNC tube bender continues delivering value as manufacturing technology evolves. The best machines aren’t just built for today’s requirements but designed with the flexibility to adapt to tomorrow’s challenges.

Hydraulic CNC Tube Bender – Power for Thick Walls

When your manufacturing challenges involve thick-walled tubes or massive pipes, you need serious muscle behind your bending operation. This is where Hines Bending Systems’ hydraulic CNC tube benders truly shine. These powerhouse machines marry brute force with digital precision to handle the toughest bending tasks with remarkable ease.

Think of hydraulic benders as the heavyweight champions of the tube bending world. They excel when you’re working with wall thicknesses beyond 0.250″, tackling stubborn materials like stainless steel and titanium, or managing pipes up to 8″ OD and beyond. For structural tubing with square or rectangular profiles, nothing else quite measures up to hydraulic power.

“We put our Hines hydraulic bender through absolute torture tests,” shares a production manager from a heavy equipment manufacturer. “It’s been bending 4″ square structural tubing with tight radii for years without breaking a sweat. The machine just keeps running, day in and day out.”

What makes these machines so impressive is the engineering beneath the surface. Hines hydraulic CNC tube benders feature high-pressure systems that generate tremendous bending force while maintaining precise control. The booster pressure capabilities provide crucial reinforcement during critical bend moments, while the rigid machine structure stands firm against deflection even under extreme loads.

The precision-controlled hydraulic valves might surprise you – they deliver movement accuracy that rivals electric systems but with substantially more power behind each action. It’s this combination of brawn and brains that makes Hines hydraulic benders the go-to solution for demanding applications.

When to pick a hydraulic CNC tube bender

Choosing a hydraulic CNC tube bender makes perfect sense when your production demands include high-torque applications where substantial force is non-negotiable. These machines excel with structural components for architecture, construction, or heavy equipment where integrity cannot be compromised.

Job shops particularly appreciate how hydraulic systems handle variable production runs across diverse materials and sizes. When your bending requirements venture into extreme territory – requiring push bending or compression techniques – hydraulic systems provide the necessary muscle.

What truly sets Hines apart is their consultative approach to matching machines with applications. Rather than selling you a standard solution, Hines engineers work alongside you to determine the perfect hydraulic configuration for your specific production challenges.

An aerospace contractor who went through this process noted, “The Hines team didn’t just sell us a machine – they sold us a solution. They asked questions nobody else bothered with, understanding our production challenges at a fundamental level. The hydraulic bender they configured has exceeded every expectation we had.”

This custom approach ensures your investment delivers maximum returns through perfect application matching – something particularly valuable with substantial investments like hydraulic bending systems.

Many Hines hydraulic CNC tube benders have remained in continuous production for decades – a testament to their extraordinary build quality and engineering excellence. When you need reliable power for your most demanding tube and pipe bending applications, Hines hydraulic systems deliver both immediate results and long-term value.

All-Electric CNC Tube Bender – Energy-Saving Champion

When it comes to modern manufacturing, the all-electric CNC tube bender from Hines Bending Systems represents a genuine breakthrough in both performance and sustainability. These remarkable machines don’t just bend metal – they transform how companies approach production efficiency.

“The day we installed our Hines all-electric bender was the day our energy bills took a nosedive,” shares a manufacturing engineer from a leading automotive supplier. “We’ve cut power consumption by nearly 40%, and the precision is actually better than our old hydraulic system.”

What makes these all-electric systems so special? For starters, they slash energy usage by up to 70% compared to traditional hydraulic alternatives – a game-changer for operations focused on reducing their carbon footprint and cutting costs. The servo motors that power these machines deliver pin-point positioning accuracy, making complex bends look effortless while maintaining tight tolerances.

Your shop floor benefits in other ways too. Gone are the days of hydraulic oil leaks and the maintenance headaches they bring. The all-electric CNC tube bender operates clean and runs whisper-quiet, dramatically improving the working environment. Operators notice the difference immediately – both in comfort and in the responsive performance of the machine.

Hines Bending Systems has pioneered advancements in electric drive technology that maintain impressive power while delivering these efficiency benefits. Their machines handle everything from delicate, small-diameter precision components all the way up to substantial 6″ tubes, covering virtually every industrial application with equal expertise.

The precise synchronization between axes enables these machines to produce complex, multi-radius bends with unprecedented accuracy – a capability particularly valuable in aerospace, medical device manufacturing, and performance automotive applications where tolerances leave no room for error.

Why an all-electric CNC tube bender excels in lean manufacturing

Lean manufacturing principles and all-electric CNC tube benders go together like peanut butter and jelly. These machines eliminate waste in multiple forms, starting with drastically reduced setup times. The electric drives position tooling with exceptional speed and accuracy, slashing changeover times between production runs.

Perhaps most impressively, the first-part accuracy of Hines electric benders often means the very first production piece meets specifications. This eliminates the frustrating and wasteful trial-and-error approach that plagues lesser machines.

“Our Hines electric bender has become the centerpiece of our lean initiative,” notes a production supervisor at a medical device manufacturer. “Setup times are down 60%, scrap is nearly eliminated, and the reliability means we can schedule with confidence.”

The maintenance advantages can’t be overstated. Without hydraulic components to service, downtime drops dramatically. The electric drives maintain their precision over time, ensuring consistent part quality throughout production runs. While the initial investment might be higher than hydraulic alternatives, the lower energy consumption and reduced maintenance costs result in a superior total cost of ownership over the machine’s lifetime.

This technology proves especially valuable for manufacturers in the HVACR sector. Scientific research on HVACR tube production confirms that all-electric bending technology delivers the precise, repeatable bends required in heat exchangers and similar applications – exactly the kind of reliability that has made Hines Bending Systems the supplier of choice for organizations like NASA.

When precision, efficiency, and environmental responsibility matter, the all-electric CNC tube bender from Hines stands alone as the industry’s true champion.

Scientific research on HVACR tube production

Hybrid CNC Tube Bender – Best of Both Worlds

Sometimes you don’t have to choose between power and precision – you can have both. That’s exactly what Hines Bending Systems delivers with their hybrid CNC tube benders, which brilliantly marry electric and hydraulic technologies in one smart package.

Think of these machines as the practical problem-solvers of the bending world. They take the precise positioning of electric servo drives for carriage movement and combine it with the raw muscle of hydraulic systems for bend operations where serious force is needed. The magic happens in the intelligent control systems that seamlessly coordinate these different components, using hydraulic power only when absolutely necessary to optimize energy consumption.

“We were stuck between needing precision for aerospace components one day and bending heavy structural tubing the next,” explains a fabrication shop manager who switched to a Hines hybrid bender. “Now we handle everything on one machine, with energy bills that are significantly lower than our old hydraulic system. It’s like getting the best of both worlds without compromise.”

The beauty of these hybrid systems lies in their thoughtful balance. They offer a lower acquisition cost than fully electric systems while retaining many of the same benefits. Their versatility is particularly valuable – handling everything from thin-walled precision tubing to robust structural components with equal confidence. For shops with experience in hydraulic bending, the familiar technology also creates a smoother transition to more advanced capabilities.

Manufacturing operations that process diverse materials and sizes find these machines especially valuable. Rather than purchasing multiple specialized benders, a single hybrid CNC tube bender from Hines can tackle an impressive range of projects, improving equipment utilization and delivering a stronger return on investment.

Balancing budget and performance with a hybrid CNC tube bender

When you’re weighing your options for tube bending equipment, the financial equation matters just as much as the technical specifications. Hybrid CNC tube benders shine in this department too.

On the initial investment front, hybrid machines typically cost less than their all-electric cousins while still delivering substantial performance improvements over traditional hydraulic benders. They strike an intelligent middle ground that makes advanced bending technology accessible to more operations.

The energy mix is another compelling advantage. By activating hydraulic systems only when needed for high-force operations, these machines significantly reduce power consumption compared to conventional hydraulic benders that run continuously. This translates directly to lower operating costs month after month.

Maintenance needs are also more manageable. While hybrid machines do require some hydraulic maintenance, the reduced oil volume and selective operation minimize these concerns compared to purely hydraulic systems. Many Hines customers report dramatically reduced maintenance downtime after switching to hybrid technology.

“What really impressed us about Hines was their honest assessment of our needs,” shares a manufacturing director who recently invested in a hybrid bender. “They took the time to analyze our production mix and recommended the hybrid solution that perfectly matched our requirements rather than pushing the most expensive option. Three years in, it’s proven to be exactly the right choice for our operation.”

The ROI calculation often tips in favor of hybrid machines due to their exceptional versatility. Higher utilization rates across diverse projects mean the equipment earns its keep more consistently than specialized machines that might sit idle between suitable jobs.

When considering your next CNC tube bender investment, let Hines Bending Systems guide you through an analysis of your specific production needs. Their best expertise ensures you’ll get the perfect balance of technology for your unique requirements – not just for today’s projects, but for tomorrow’s opportunities as well.

3-Axis CNC Tube Bender – Precision in Multi-Plane Bends

When manufacturing requirements include complex tube geometries with bends in multiple planes, 3-axis CNC tube benders from Hines Bending Systems provide the solution. These sophisticated machines enable the production of intricate parts that would be impossible or prohibitively expensive to produce with simpler equipment.

The 3-axis configuration controls:

- Y-axis: The bend angle (rotation of the bend arm)

- X-axis: The distance between bends (tube feed)

- Z-axis: The plane of bend (tube rotation)

This comprehensive control enables:

- Complex geometries: Production of parts with bends in multiple planes

- Precise positioning: Accurate distance between bends and orientation

- Coordinated mandrel extraction: Timed withdrawal of mandrels during bending to prevent tube collapse

- Automated sequences: Complete multi-bend parts in a single setup

A NASA contractor who relies on Hines equipment explains: “The aerospace components we produce have bends in multiple planes with extremely tight tolerances. The 3-axis Hines bender allows us to produce these complex parts consistently and efficiently.”

The ability to produce complex geometries in a single setup dramatically reduces production time and improves consistency. Parts that would traditionally require multiple setups or even manual adjustment between operations are completed in one automated sequence.

Hines Bending Systems has refined 3-axis control to achieve exceptional precision, with position repeatability measured in thousandths of an inch. This precision is critical in industries like aerospace, where component fit and performance depend on exact adherence to design specifications.

Programming a 3-axis CNC tube bender for flawless results

The power of a 3-axis CNC tube bender is fully realized through sophisticated programming capabilities. Hines Bending Systems provides intuitive software that simplifies the creation of complex bending sequences:

- CAD/CAM import: Direct import of 3D models and centerline data from design software

- Collision detection: Automatic checking for potential collisions during the bending sequence

- Simulation capabilities: Virtual testing of programs before committing to physical production

- Material spring-back compensation: Automatic adjustments based on material properties

“The simulation capability of our Hines bender has been a game-changer,” notes a production engineer. “We can verify programs offline, which has virtually eliminated crashes and dramatically reduced setup time.”

This advanced programming approach ensures that even the most complex parts are produced correctly on the first attempt, eliminating costly material waste and production delays. The software’s intuitive interface reduces the learning curve for operators, allowing manufacturing operations to quickly realize the full potential of their investment.

More info about CNC Bending Systems for Sale

Choosing the Right CNC Tube Bender for Your Business

Finding that perfect CNC tube bender for your operation isn’t just about buying equipment—it’s about investing in your company’s future. At Hines Bending Systems, we’ve guided countless manufacturers through this important decision, and we’ve learned that the right choice comes down to understanding your unique needs.

Let me walk you through the key differences between the main types of benders we offer:

| Feature | Hydraulic | All-Electric | Hybrid |

|---|---|---|---|

| Initial Investment | Lower | Higher | Moderate |

| Energy Efficiency | Basic | Excellent (70% savings) | Good (30-50% savings) |

| Maintenance Needs | Regular | Minimal | Moderate |

| Noise Level | Higher | Very Low | Moderate |

| Precision | Good | Excellent | Very Good |

| Power for Thick Walls | Excellent | Good | Very Good |

| Speed/Cycle Time | Good | Excellent | Very Good |

| Environmental Impact | Oil concerns | Minimal | Reduced oil volume |

But there’s more to consider than just the type of drive system. Your material challenges matter too. Different metals behave uniquely during bending—aluminum responds differently than stainless steel, and high-strength alloys have their own personalities. Our machines are designed to handle this entire spectrum, with settings and tooling optimized for your specific materials.

“When we came to Hines, we were bending three different alloys with varying wall thicknesses,” shares Maria, a production manager at an aerospace component manufacturer. “They didn’t just sell us a machine—they gave us a complete solution custom to our specific material challenges.”

Your production volume should influence your decision too. If you’re running high-volume jobs, we can integrate automated loading and unloading systems that keep your CNC tube bender humming along efficiently. For job shops handling varied work, we focus on quick-change tooling and intuitive programming to minimize setup times.

Space constraints? We get it. Our engineering team has designed compact footprint options that deliver impressive performance without hogging your valuable floor space. And if you’re planning for growth, our modular approach means your Hines bender can grow with you—adding capabilities as your business expands.

The future matters too. Many of our clients start with a basic configuration, knowing they can add automation, additional tooling, or improved control features down the road. This scalability protects your investment and ensures your CNC tube bender remains relevant as your business evolves.

Power requirements vary significantly between models. Our team will analyze your facility’s electrical capacity during the consultation process, ensuring your new bender integrates smoothly without requiring costly electrical upgrades. For hydraulic and hybrid models, we’ll also consider fluid handling and environmental factors.

Financing your CNC tube bender is another area where Hines stands apart. We offer flexible financing options that align with your cash flow and business goals. Many clients find that the productivity gains and material savings from a Hines bender mean the machine essentially pays for itself through improved efficiency.

“What really separated Hines from others was their commitment to understanding our specific needs,” explains Tom, a manufacturing director who recently invested in one of our benders. “They didn’t just sell us a machine; they provided a complete solution that addressed our current challenges and future growth plans.”

The right CNC tube bender isn’t just about today’s projects—it’s about building capacity for tomorrow’s opportunities. With Hines Bending Systems’ best expertise guiding your decision, you’ll find the perfect balance of performance, value, and growth potential.

More info about CNC Tube Bender for Sale

Frequently Asked Questions about CNC Tube Bender Selection

What is the difference between mandrel and non-mandrel bending?

The choice between mandrel and non-mandrel bending can make all the difference in your finished products. Think of a mandrel as your tube’s supportive best friend during the bending process – it’s a flexible steel rod inserted inside the tube that prevents it from collapsing or flattening where you need it to hold its shape.

Mandrel bending shines when you’re working with:

– Thin-walled tubing that might otherwise buckle under pressure

– Tight radius bends (typically less than 3× the tube’s diameter)

– Applications where the tube’s cross-section needs to maintain its original shape

– Systems carrying pressurized fluids or gases where wall integrity is non-negotiable

On the flip side, non-mandrel bending works perfectly well when:

– You’re bending thicker-walled tubes with natural resistance to collapse

– Your design calls for more generous bend radii

– Some minor flattening won’t affect the part’s functionality

– Production speed takes priority over absolute perfection in the bend

“We often see customers who aren’t sure which approach they need,” shares a Hines engineer with a smile. “That’s where our decades of experience come in handy. We’ll analyze your specific parts and help you choose the most efficient bending method that still meets your quality standards.”

Hines Bending Systems offers both mandrel and non-mandrel CNC tube benders, with many machines capable of switching between techniques as needed – giving you maximum flexibility for diverse production runs.

How does software make the first part right every time?

The days of “bend, check, adjust, repeat” are firmly behind us. Modern CNC tube benders from Hines achieve remarkable “first-part-right” accuracy thanks to sophisticated software that essentially creates a digital twin of your bending process before a single tube is touched.

This software magic works through several interconnected capabilities:

First, it precisely models how different materials behave – accounting for spring-back based on material type, tube dimensions, and specific bend parameters. The software then creates a virtual simulation of the entire bending sequence, letting you spot potential issues before production begins.

What truly sets Hines’ software apart is how it incorporates machine-specific calibration data and learns from your production history. “It’s like having an expert operator’s knowledge built right into the machine,” explains a production manager who switched to Hines. “We’re consistently achieving 98% first-part accuracy, even on our most complex parts. The material savings alone paid for our investment within the first year.”

Hines continues to invest heavily in software development, ensuring their control systems remain cutting-edge. Each software update brings incremental improvements to first-part accuracy – a commitment that translates directly to your bottom line through reduced waste and setup time.

What routine maintenance keeps a CNC tube bender running for decades?

It’s not unusual to find Hines CNC tube benders still performing flawlessly after 20+ years of service. This exceptional longevity isn’t accidental – it results from thoughtful engineering and a straightforward maintenance approach that any team can follow.

For hydraulic systems, the lifeblood is clean, quality hydraulic fluid. Schedule regular oil analysis and changes (typically every 2,000 operating hours), replace filters according to Hines’ recommendations, and make a habit of checking hydraulic pressure readings. A quick weekly inspection of seals and hoses can catch minor issues before they become production-stopping problems.

Electric systems require less intensive care but still benefit from periodic attention. Check servo motors and drives during scheduled downtime, verify that electrical connections remain tight (vibration can loosen them over time), and follow Hines’ lubrication schedules for moving components. Don’t forget to install software updates, which often include performance optimizations.

For all bending systems, daily cleaning of tooling contact surfaces takes just minutes but pays enormous dividends in part quality and tool life. Regularly inspect mandrels for wear, verify alignment and calibration quarterly, and maintain a reasonably clean, climate-controlled operating environment.

“We have several Hines benders that have been running continuously since the late 1990s,” shares a maintenance supervisor at an aerospace supplier. “Our secret? Nothing fancy – just following the maintenance schedules Hines provided and using genuine parts when replacements are needed.”

Every Hines CNC tube bender comes with comprehensive maintenance documentation and training, ensuring your team has the knowledge to maximize your machine’s performance and lifespan. It’s part of the complete partnership approach that has made Hines the trusted name in bending technology worldwide.

More info about CNC Bending Machine

Conclusion

Choosing the perfect CNC tube bender isn’t just a purchase—it’s a strategic decision that shapes your manufacturing future. Throughout this guide, we’ve explored how different bending technologies shine in specific applications, each offering unique advantages for your production needs.

When it comes to tube bending excellence, Hines Bending Systems stands alone at the summit. We’ve earned our position as the #1 worldwide manufacturer of tube, pipe, and induction benders through decades of innovation and an unwavering commitment to quality that competitors simply can’t match.

“We don’t believe in one-size-fits-all solutions,” shares a Hines executive with a warm smile. “Every manufacturing challenge is unique, which is why we take the time to understand your specific needs before recommending a bending solution. It’s more like a partnership than a transaction.”

This collaborative approach has made Hines the trusted choice for the most demanding clients in the world. When NASA needs precision tube bending for mission-critical applications, they turn to Hines. When automotive manufacturers need reliability at scale, they choose Hines. Our global installation base—the largest in the industry—tells the story of our success better than words ever could.

The manufacturing world continues to evolve, with smart factories, integrated systems, and increasingly complex part geometries becoming the norm. Through it all, Hines remains at the forefront of innovation, continually enhancing our machines and software to ensure our clients maintain their competitive edge.

What truly sets a Hines CNC tube bender apart isn’t just the precision engineering or robust construction—though these are certainly impressive. It’s the decades of expertise that inform every aspect of our machines, from the intuitive user interfaces to the thoughtfully designed maintenance access points. It’s the attention to details that others might overlook, but that make all the difference in daily operation.

Ready to experience the Hines difference? Our team of bending experts is eager to learn about your manufacturing challenges and help craft a custom solution that exceeds your expectations. Because when precision, reliability, and performance matter, the choice is clear: Hines Bending Systems delivers results that others can only promise.