Mastering Mandrel Bending: Find Top Precision and Efficiency

Mandrel bending machine technology is a game-changer for the fabrication industry. It offers improved precision and efficiency. If you’re exploring mandrel bending, here’s what you need to know:

- Mandrel Bending Explained: This process involves a flexible mandrel inserted into a pipe or tube to prevent it from collapsing during bending.

- Key Benefits: Achieves precise bends, reduces deformation, and ensures consistent quality.

- Applications: Ideal for intricate pipe and tube shapes used in automotive, aerospace, and more.

Hines Bending Systems leads the industry in providing high-quality bending machines. Trusted by significant clients like NASA, Hines delivers innovative and reliable solutions custom to your bending needs. Their machines are not only the best available but also promise superior quality and long-term reliability. With a strong emphasis on client satisfaction and custom solutions, Hines stands out as the experts in precision bending.

What is a Mandrel Bending Machine?

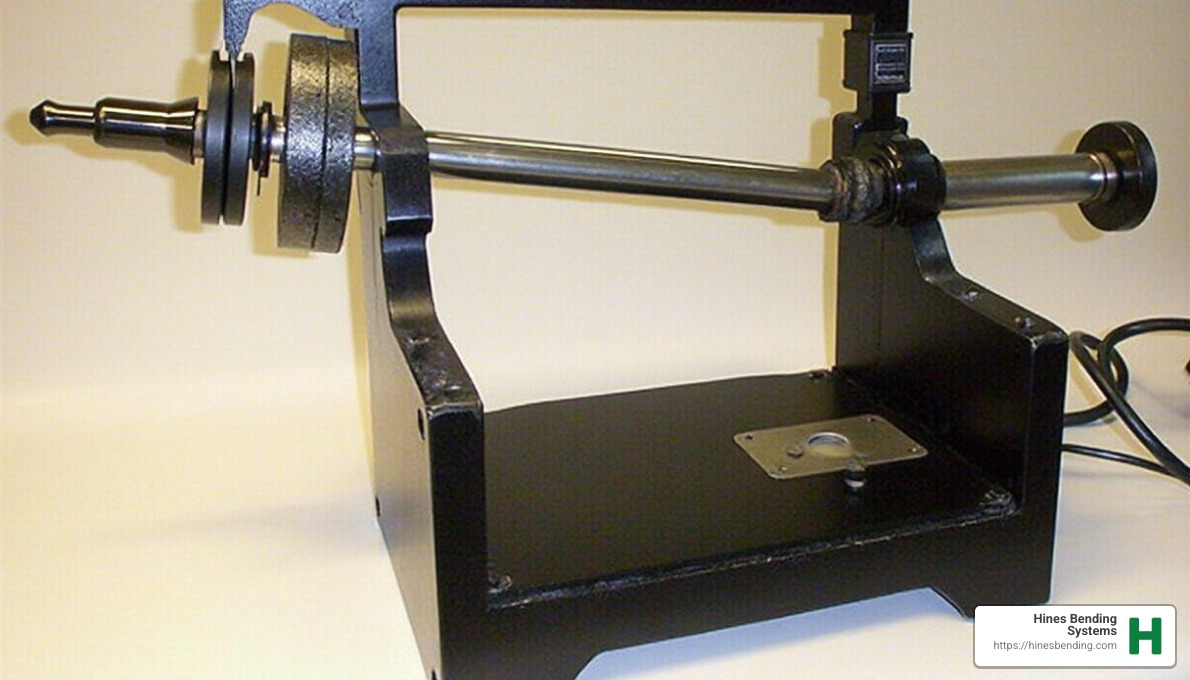

A mandrel bending machine is a specialized tool used to bend pipes and tubes with precision. Unlike other bending machines, it uses an internal support system to maintain the shape and integrity of the material being bent. This ensures that the bends are smooth, wrinkle-free, and accurate.

How Mandrel Bending Works

The magic of mandrel bending lies in its use of a mandrel shaft. This shaft is inserted into the pipe or tube before the bending process begins. The shaft often includes segmented balls or other forms of internal support, which help in maintaining the roundness of the pipe during bending.

Rotary draw bending is the technique most commonly used with mandrel bending machines. This method involves clamping the pipe or tube to a form or die, which rotates around a fixed axis to create the bend. The mandrel inside the pipe keeps it from collapsing or deforming, allowing for tight, precise bends.

The internal support provided by the mandrel is crucial. It prevents the material from flattening or wrinkling, which is especially important when working with thin-walled or flexible materials. This makes mandrel bending machines ideal for producing high-quality bends in complex geometries.

Hines Bending Systems is at the forefront of mandrel bending technology. Their machines are designed to handle a wide range of materials and shapes, ensuring that every bend is performed with the utmost precision and stability. By focusing on innovative solutions and customer-centric approaches, Hines delivers machines that are not only efficient but also reliable and long-lasting.

For more on how mandrel bending can benefit your industry, explore Hines Bending Systems’ offerings.

Advantages of Mandrel Bending Machines

Mandrel bending machines are game-changers in pipe and tube fabrication. Their design and technology offer quality bends, reduced deformation, and consistent results, making them indispensable in various industries.

Precision and Stability

One of the standout features of mandrel bending machines is their ability to deliver unparalleled precision and stability. By using an internal support system, these machines ensure that every bend is smooth and accurate. The mandrel shaft and segmented balls work together to maintain the material’s shape, preventing any unwanted flattening or wrinkling. This results in high-quality bends that meet exact specifications, a crucial requirement for industries like automotive and aerospace.

For example, Hines Bending Systems’ machines are equipped with advanced control systems that allow operators to achieve precise bending angles with ease. This means fewer errors and a significant reduction in material waste, ultimately saving time and resources.

Versatility and Capacity

Mandrel bending machines are not only precise but also incredibly versatile. They can handle a wide range of materials, from steel and aluminum to more exotic metals like titanium. This versatility is a testament to their robust design and engineering excellence.

These machines are capable of bending pipes and tubes with varying diameters and wall thicknesses, accommodating complex geometries with ease. Whether you’re working on simple bends or intricate designs, a mandrel bending machine can get the job done without compromising on quality.

Hines Bending Systems takes pride in offering machines that can tackle diverse bending tasks. Their focus on innovative technology ensures that their machines remain at the cutting edge of the industry, providing solutions that are both efficient and reliable.

By choosing Hines Bending Systems, you’re not just investing in a machine; you’re investing in a partner that prioritizes custom solutions and quality assurance. Their commitment to excellence has made them a leader in the bending industry, trusted by major organizations like NASA.

For more information on how Hines Bending Systems can meet your bending needs, explore their extensive range of tube and pipe benders.

Hines Bending Systems: Leading the Industry

When it comes to mandrel bending machines, Hines Bending Systems stands as an industry leader. Their commitment to quality and innovation is best, making them the go-to choice for businesses in need of reliable bending solutions.

Innovative Technology

Hines Bending Systems is renowned for its cutting-edge technology. Their dual stack CNC and roll bender models are at the forefront of innovation, designed to meet the growing demands of various industries. These advanced machines come equipped with features like programmable pressure die systems and booster features that improve performance and precision. This dedication to innovation ensures that Hines machines not only meet but exceed industry standards.

Clientele and Expertise

Hines Bending Systems isn’t just about machines; it’s about partnerships. With extensive installations around the globe, they’ve built a reputation for excellence. Their clientele includes prestigious organizations like NASA, showcasing the trust and confidence major players place in their capabilities. This extensive experience translates into a deep understanding of diverse industrial needs, allowing Hines to offer custom solutions custom to specific requirements.

The company’s customer-centric approach is a cornerstone of their success. By working closely with clients, Hines ensures that their machines are perfectly suited to each unique application. This commitment to customization, combined with rigorous quality assurance processes, guarantees that every machine delivers optimal performance.

Choosing Hines Bending Systems means choosing a partner dedicated to your success. Their expertise and industry leadership are evident in every machine they produce, making them the premier choice for those who demand the best.

For a closer look at how Hines’ innovative technology can transform your operations, explore their advanced bending solutions.

Frequently Asked Questions about Mandrel Bending Machines

What is the difference between mandrel and non-mandrel bending?

Mandrel bending and non-mandrel bending differ primarily in the use of internal support. In mandrel bending machines, a mandrel rod is inserted into the pipe or tube to provide internal support during the bending process. This prevents deformation, such as flattening or wrinkling, ensuring a smooth, high-quality bend. This method is ideal for applications requiring precision and consistency, like automotive exhaust systems and aerospace components.

Non-mandrel bending, on the other hand, does not use internal support. While this method can be faster and more cost-effective, it’s more prone to deformation, making it less suitable for applications demanding high precision. Explore how Hines Bending Systems’ solutions can address your specific bending needs by visiting their product offerings.

What materials can be bent using mandrel bending machines?

Mandrel bending machines are incredibly versatile and can handle a wide range of materials, ensuring they meet diverse industrial needs. Common materials include:

-

Steel: Known for its strength and durability, steel is a popular choice for various industrial applications. Mandrel bending machines can handle different grades of steel, maintaining their structural integrity during the bending process.

-

Aluminum: Lightweight and corrosion-resistant, aluminum is often used in aerospace and automotive industries. Mandrel bending ensures precise bends without compromising the material’s properties.

-

Titanium: This high-strength, lightweight material is used in high-performance applications. Mandrel bending machines provide the necessary precision to bend titanium without causing damage or deformation.

Hines Bending Systems’ machines are designed to accommodate these materials and more, offering custom solutions custom to your specific requirements.

What is the cheapest pipe bending method?

When cost is a primary concern, ram style bending is often the go-to method. This technique involves using a hydraulic ram to push the pipe against a die, bending it to the desired shape. While ram style bending is cost-effective and simple, it may not achieve the precision and smoothness of mandrel bending, particularly for complex or tight-radius bends.

For those seeking a balance between cost and quality, Hines Bending Systems offers a range of bending machines that cater to different needs and budgets. Their commitment to providing high-quality, efficient solutions ensures you get the most value for your investment. Learn more about their cost-effective options by visiting Hines Bending Systems.

Conclusion

In tube and pipe bending, Hines Bending Systems stands as a guide of excellence. Our commitment to superior quality and customer satisfaction is unmatched. We don’t just manufacture bending machines; we innovate solutions tailored to meet the unique needs of each client.\n\nOur machines, renowned for their precision and durability, have set the industry standard. This is why major organizations, including NASA, trust us to deliver the best bending solutions. Our extensive expertise and the highest number of bender installations worldwide underscore our leadership in the industry.\n\nAt Hines Bending Systems, we understand that every project is unique. That’s why we offer custom solutions, ensuring that our machines perfectly align with your specific requirements. Our dedication to innovation means you’re not just getting a machine; you’re getting the latest in bending technology.\n\nWe pride ourselves on a customer-centric approach. From the initial consultation to after-sales support, we ensure our clients receive the highest level of service. This dedication to customer satisfaction is what drives us to continually improve and adapt to the evolving needs of the industry.\n\nChoose Hines Bending Systems for your next project and experience the difference in quality and service. Explore our range of high-quality bending machines and find how we can help you achieve your bending goals. Visit our pipe bending equipment sale to learn more about our offerings and find the perfect solution for your needs.