Why Precision Matters in Modern Manufacturing

CNC machining and tube bending deliver the critical precision today’s industries demand. For aerospace components meeting NASA’s strict specifications or automotive parts ensuring high-speed safety, the margin for error is nonexistent.

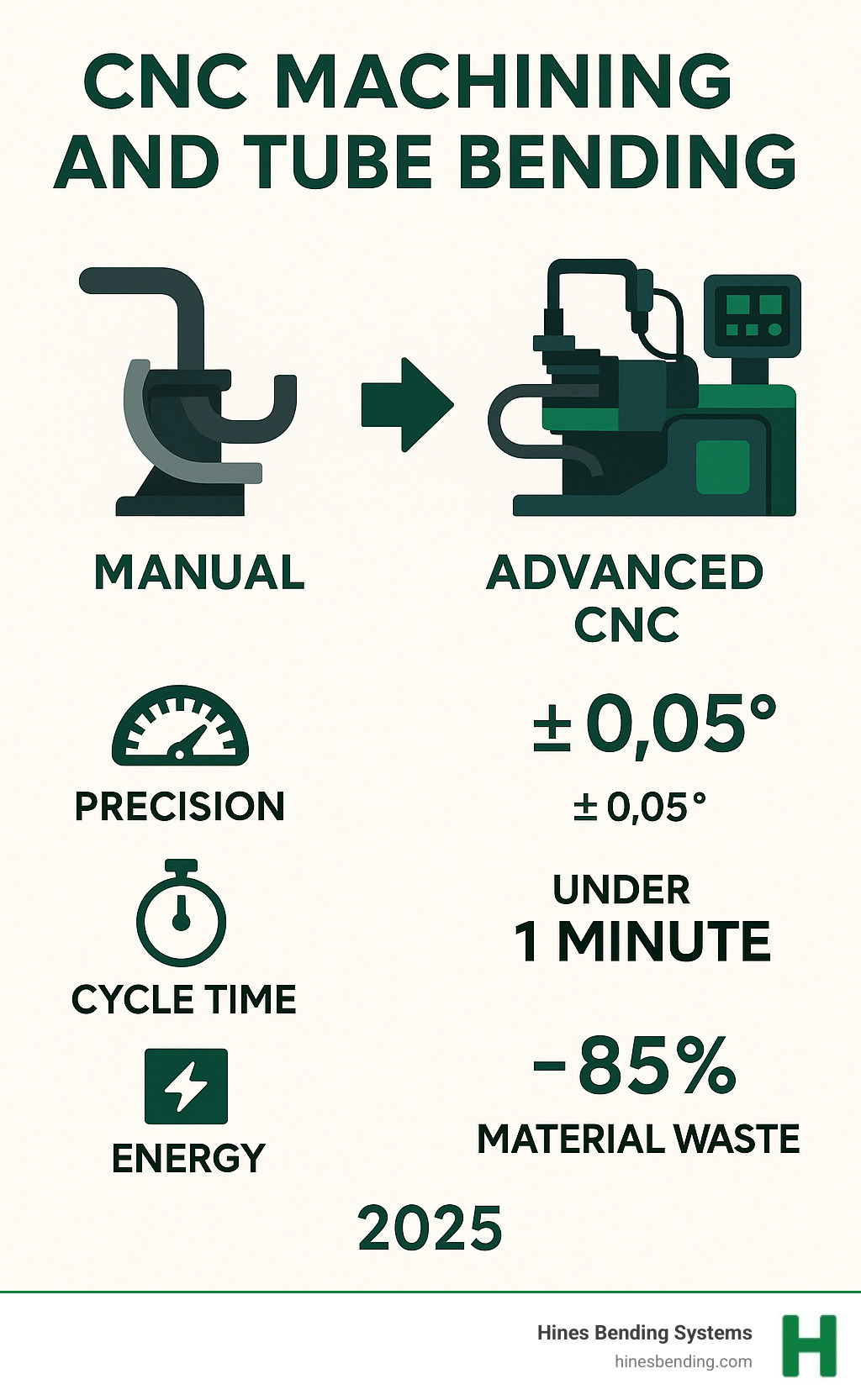

Quick Answer: CNC Machining and Tube Bending Integration

- Computer Control: CNC systems digitally control every aspect of the bending process.

- Precision: Achieve tolerances as tight as ±0.05 degrees consistently.

- Automation: Eliminate human error through programmed parameters.

- Efficiency: Complete complex bends in under one minute.

- Repeatability: Produce identical parts across thousands of units.

- Cost Savings: Reduce material waste and cycle times by up to 95%.

The integration of Computer Numerical Control (CNC) with tube bending has transformed manufacturing. Unlike manual methods, CNC machining and tube bending delivers repeatable precision that meets the strictest quality standards.

Industries like aerospace, automotive, and energy depend on this precision, as a single imperfect bend can lead to catastrophic failure. That’s why leading manufacturers trust advanced CNC tube bending solutions to ensure every component meets exact specifications.

This guide explores how CNC technology improves tube bending precision, from its core components to advanced applications. Find why precision tube pipe systems produced on CNC bending machines can allow for time savings of up to 95% compared to traditional methods.

Relevant articles related to cnc machining and tube bending:

The Core of Precision: What is CNC in Tube Bending?

The secret to perfectly shaped tubes lies in Computer Numerical Control (CNC), which gives the art of bending a digital brain. Every move, angle, and pressure is guided by a computer program, a massive leap from manual methods that enables incredible precision and consistency.

CNC facilitates digital-to-physical conversion, translating a CAD (Computer-Aided Design) model into exact instructions for the bending machine. The system executes each bend, rotation, and clamp with meticulous accuracy, creating a physical tube that flawlessly matches its digital twin.

This level of automation virtually eliminates human error. Once a program is perfected on a Hines CNC bender, it can be run thousands of times, delivering identical results. This repeatability is essential for modern mass production, from automotive parts to complex components for agencies like NASA. A Hines CNC bender delivers perfect quality, every time. To learn more about this technology, explore What is CNC Tube Bending?.

Essential Components for Flawless Bends

Flawless bends are the result of brilliant engineering and precisely made components working in harmony. Hines Bending Systems are experts in designing and manufacturing these essential tools for optimal results and the highest quality.

- Mandrel: This internal support prevents the tube from collapsing, wrinkling, or becoming oval-shaped during bending. This is critical for thin-walled tubes or tight bends. Hines manufactures the perfect mandrel for your specific needs.

- Bend Die: This core component determines the exact curve of the bend. The tube is clamped and wrapped around this die, taking on its precise radius. The quality of the bend die is key to achieving the exact bend radius.

- Clamp Die: This component holds the tube firmly at the start of the bend, preventing any slipping. This ensures the bend begins exactly as planned. A secure grip is essential for precision.

- Wiper Die: Positioned where the bend begins, its critical role is to prevent wrinkles from forming on the inside of the bend, ensuring a smooth, strong, and aesthetically pleasing result.

- Pressure Die: This tool applies controlled force to the outside of the tube, keeping it snug against the bend die. This assists material flow and prevents flattening on the outside of the bend.

Every one of these components is designed and manufactured by Hines Bending Systems with best precision. We know the quality of your bend reflects the quality of the tooling, and our commitment to excellence in every part ensures the highest quality bends. For more details, explore our guide to Tube and Pipe Bending Industry Terms.

Open uping Superior Performance with Hines CNC Machining and Tube Bending

Investing in CNC machining and tube bending with Hines Bending Systems means changing your manufacturing operations. As the #1 worldwide manufacturer of tube benders, we deliver results competitors can’t match.

Our systems provide immediate benefits:

- Best Precision: Achieve tolerances as tight as ±0.05 degrees. This is the level of accuracy trusted by NASA for mission-critical components.

- Increased Efficiency: Automated processes turn hours of manual work into minutes. A complex bend can be completed in under 60 seconds with perfect consistency.

- Significant Cost Savings: Achieving “first part right” minimizes material waste. Clients report time savings of up to 95% and energy savings of 70%, boosting your bottom line.

- Improved Product Quality: Our machines craft components with wrinkle-free surfaces and perfect cross-sectional integrity, ensuring structural reliability for applications from aerospace to automotive.

- Complex Geometries: Easily produce multi-plane bends, variable radii, and intricate curves that are impossible with traditional methods, opening up new design possibilities.

- Reduced Waste & Faster Cycles: Decades of engineering expertise are built into our machines to optimize resource use and maximize throughput.

To see how our technology can revolutionize your operations, explore the Advantages of CNC Tube Bending Machine for Sale.

Achieving Perfect Bends with Advanced Hines CNC Control

The heart of every Hines bender is our proprietary BendPro G2 CNC Control, a system that adapts in real-time. Its key features include:

- Automatic Springback Compensation: The system analyzes material properties and automatically adjusts the bend angle to counteract springback, eliminating trial-and-error and wasted material.

- Real-Time Adjustments: Integrated sensors monitor the bending process and instantly compensate for the slightest material variations, ensuring consistent quality.

- Programmable Logic: Complex bending sequences become simple, repeatable programs, dramatically reducing errors and boosting first-pass yield rates.

The Efficiency of Integrated Hines CNC Machining and Tube Bending

True efficiency comes from an integrated workflow. Hines solutions create lean manufacturing environments with features like automated tube loading, weld-seam detection, and robotic unloading. This seamless process allows a single operator to oversee a complete production line, from raw material to finished part. Our Advanced CNC Machines are engineered as complete solutions to maximize your productivity. Partnering with Hines means leveraging decades of experience to create a manufacturing system that delivers.

Applications Across Demanding Industries

The precision and versatility of CNC machining and tube bending are the backbone of demanding industries. Hines Bending Systems provides essential, custom solutions for sectors where quality, reliability, and intricate designs are paramount.

- Aerospace: There is no room for error in hydraulic lines or fuel systems. Our machines craft these critical parts to the highest standards, which is why agencies like NASA trust Hines for mission-critical components for space exploration and flight.

- Automotive: From intricate exhaust systems to vital brake lines, every bend must be exact and repeatable. Our machines enable mass production with the consistency and safety required for millions of vehicles.

- HVAC: These systems require precise tubing for efficient fluid transfer. Our benders create accurate lines and ducts, ensuring optimal performance and energy efficiency.

- Shipbuilding: We provide machines that handle the large diameters and tough materials needed for complex piping systems and structural elements in marine vessels.

- Energy Sector: Our benders produce vital components for oil and gas pipelines and power generation, where precision is critical for safety and efficiency.

Our long-standing relationship with NASA, detailed in Hines working together with NASA, cements our reputation as the trusted partner for projects where the stakes are highest.

Bending Diverse Materials with Hines Expertise

Hines Bending Systems provides solutions for an impressive range of metals, each with unique properties. This capability is crucial for industries requiring specific material features.

We have expertise in bending:

- Steel: Including carbon steel for structural applications and stainless steel for food processing and medical equipment.

- Aluminum: A lightweight, high-strength metal ideal for aerospace and automotive parts.

- Titanium: A top choice for aerospace and medical applications due to its strength and corrosion resistance.

- Inconel: A superalloy that withstands extreme heat and harsh conditions, used in aerospace and energy.

- Exotic Alloys: We create custom tooling and machine solutions for many other specialized alloys.

Our experience, including work on cutting-edge NASA projects, gives us unparalleled insight into material behavior. We understand the nuances of material properties, allowing us to engineer solutions for any application. Our innovative designs, like the Hines Bending Innovation: Dual Stack CNC Push Bender, demonstrate our commitment to delivering versatile, future-ready technology that outperforms any alternative.

Facebook | a0Youtube | a0Twitter

Why Choose Hines as Your Tube Bending Partner?

Choosing the right partner for CNC machining and tube bending is as critical as choosing the right machine. Hines Bending Systems offers a partnership built on unparalleled expertise, quality, and a dedication to your success.

With over 50 years of experience since 1972, we have mastered the art and science of tube bending. Nobody in the industry has more expertise than the Hines team. We have solved every type of bending challenge and are ready to put that knowledge to work for you.

We specialize in custom bender solutions, working closely with you to engineer machines that fit your exact requirements for any material, bend, or application. This dedication ensures your project achieves ultimate precision and efficiency.

Our Superior Machine Quality is an investment in durability, reliability, and precision. We use the highest quality components and rigorous manufacturing processes, so your Hines bender will perform for years. Learn more about Why Buy a Hines Bender?.

Our partnership extends beyond the sale with comprehensive training and robust after-sales support, including remote diagnostics and quick access to spare parts to minimize downtime.

As the #1 worldwide manufacturer of tube, pipe, and induction benders, our machines are at work globally. We are trusted by major companies and agencies like NASA, a testament to our credibility. This proven track record is why we are a leading Manufacturer of CNC Tube Benders.

Our customer-centric approach and industry leadership make us the ideal partner for your tube bending needs. We are an extension of your team, dedicated to helping you achieve your manufacturing goals.

Frequently Asked Questions about CNC Tube Bending

Over decades in the industry, we’ve helped manufacturers understand the advantages of our approach to CNC machining and tube bending.

How does Hines CNC technology improve bend repeatability compared to manual methods?

Manual bending relies on an operator’s skill, which can lead to inconsistencies due to fatigue or human error. Our CNC systems eliminate this variability through digital precision. A programmed bend sequence is executed identically every time, whether for the first part or the ten-thousandth. Every parameter is controlled by data that never wavers.

This consistent execution of programmed parameters allows us to achieve tight tolerances of ±0.05 degrees—a level of precision impossible with manual methods. Our advanced controls even make real-time micro-adjustments, ensuring every part is truly identical.

What makes a Hines CNC bender a better investment than simpler alternatives?

The true cost of equipment goes beyond the purchase price. A Hines CNC bender is an investment in superior capabilities. Our machines feature multi-axis control to create complex 3D geometries in a single setup, eliminating secondary operations. Seamless CAD/CAM software integration streamlines the workflow from design to production, boosting productivity.

When considering NC vs CNC: Which Bending Machine is Right for You?, our superior build quality, innovation, and support ensure your Hines bender will be a reliable asset for years, long after simpler alternatives fail.

Can Hines CNC benders handle both large-scale production and custom, one-off parts?

Yes, and this flexibility is a key advantage of our systems. For high-volume runs, our benders offer speed, automation, and repeatability. Quick programming and fast setup changes also make it easy to switch to custom work, from a single prototype to a one-off replacement part.

This versatility makes our CNC Benders ideal for both high-volume runs and prototyping. You are not just buying a machine; you are investing in the flexibility to handle any project, whether it’s a massive contract or a specialized component that no one else can produce.

Conclusion: Partnering with the Leader in Bending Technology

The future of manufacturing lies in advanced CNC machining and tube bending technology, and Hines Bending Systems is leading the way. We set the standard for manufacturing excellence.

Choosing Hines means partnering with a team that integrates cutting-edge CNC machining with robust tube bending mechanics. This combination allows manufacturers to achieve unparalleled precision and efficiency. Our commitment to quality, innovation, and customer satisfaction makes us a true ally for your success.

As the #1 worldwide manufacturer of tube, pipe, and induction benders, our expertise is trusted by industry leaders and agencies like NASA. Nobody in the bending industry has more experience. We are uniquely equipped to provide custom solutions for your specific needs.

When you partner with Hines, you gain access to the highest quality machines, best expertise, and a deep commitment to your success, including comprehensive training and support. Ready to transform your production? Explore our world-class CNC Bending Machine solutions today and achieve bending perfection.