Why Precision Steel Pipe Bending Matters in Modern Manufacturing

A CNC steel pipe bending machine is an automated system using Computer Numerical Control (CNC) to bend steel pipes and tubes into complex shapes with exceptional accuracy. By translating digital designs into precise mechanical movements, these machines eliminate manual errors, achieve tolerances as tight as ±0.1°, and produce consistent results across thousands of parts. This technology is crucial for applications like automotive exhaust systems, aerospace hydraulic lines, and industrial piping.

In modern manufacturing, where precision is paramount, the quality of your bending equipment directly impacts your bottom line. Traditional manual methods are slow, inconsistent, and prone to costly errors, wasting expensive materials and delaying critical projects. CNC benders solve this by executing intricate bends with high repeatability, reducing scrap rates, and boosting efficiency by up to 95% over manual techniques.

However, not all CNC benders are created equal. The manufacturer’s expertise is critical. At Hines Bending Systems, we are the #1 worldwide leader in tube and pipe bending technology. Our machines are trusted by NASA, major aerospace manufacturers, and leading automotive companies—organizations that demand absolute precision and reliability. We understand the challenges of meeting complex requirements, controlling costs, and maintaining quality, and the right CNC bending partner solves all three.

What is a CNC Steel Pipe Bending Machine and How Does It Work?

A CNC steel pipe bending machine uses Computer Numerical Control to automate the bending process, changing straight pipes into complex parts with flawless precision. Unlike slow and error-prone manual methods, Hines CNC machines bring automation, incredible accuracy, and consistent quality to your production line. This leap in efficiency means faster production rates, lower costs, and a superior finished product every time.

How a Hines CNC Bender Operates

The process begins with a digital blueprint. Our advanced software translates CAD/CAM files into ‘YBC’ bending data—the precise instructions for the pipe’s length, bend angles, and rotation.

Once programmed, the machine’s servo motors and hydraulic systems execute the commands. The pipe is clamped, and a series of dies work in harmony to create the bend. This automated sequence is repeated for each bend, with our CNC system ensuring positioning accuracy of ±0.1mm and angular accuracy of ±0.1°. This control eliminates human error and guarantees consistency from the first part to the thousandth.

Core Advantages of Hines CNC Bending

Choosing a Hines CNC bender transforms your operation. The core advantages include:

- Best Precision: Our machines deliver angular accuracy as tight as ±0.1°, ensuring every part meets exact specifications.

- Increased Productivity: With speeds of 200-300 bends per hour, our machines can boost efficiency by over 50% compared to manual methods.

- Reduced Costs: Automation lowers labor costs and our machine’s accuracy drastically cuts material waste, saving you money, especially with expensive materials.

- Improved Safety & Versatility: Automated processes create a safer workspace. Our machines handle a wide range of materials (steel, aluminum, titanium) and profiles, excelling at the complex 3D bends that are impossible with older methods.

Want to dive deeper into how Hines CNC Benders can revolutionize your production? You can find More info about Hines CNC Benders here

The Hines Expert Advantage: Why Hines Bending Systems is the Industry Leader

When producing critical components for aerospace or automotive, “almost right” isn’t an option. The real question isn’t what is a CNC steel pipe bending machine, but who builds it.

That’s where Hines Bending Systems excels. We are the #1 worldwide leader in tube, pipe, and induction benders because the world’s most demanding organizations trust us.

We supply bending machines to NASA. When The National Aeronautics and Space Administration works with Hines, they rely on our decades of proven expertise and machines that perform flawlessly under the most rigorous standards. Major automotive manufacturers and government contractors do the same, because for critical parts like hydraulic lines or exhaust systems, “good enough” equipment is a liability.

Nobody in the bending machine industry has more expertise and experience than Hines. We’ve installed more benders worldwide than anyone, and that knowledge is built into every machine we make. We understand that every operation is unique, which is why we design custom bending solutions custom to your specific material, volume, and complexity needs.

While cheaper machines exist, they often cost more in downtime, scrap, and inconsistent results. Machine quality directly impacts your bottom line, and compromising on equipment compromises your products. Our commitment extends beyond the sale with our Customers-First Promise—a pledge of long-term reliability and responsive support.

Furthermore, we believe trained operators are as crucial as the machine itself. We offer comprehensive bender training programs to empower your team, maximizing productivity and ensuring you get the most from your investment.

Choosing Hines means gaining a partner with best expertise, proven reliability, and a genuine commitment to your success. That’s the Hines advantage.

Core Components and Innovative Bending Technologies from Hines

A Hines CNC steel pipe bending machine is a system of precision-engineered components working in unison. The CNC controller is the brain, translating designs into flawless movements. The tooling—including the bend die, clamp die, pressure die, wiper die, and mandrel—is engineered as a complete system. Our tooling solutions are matched to your specific materials and dimensions, preventing deformation and ensuring every bend maintains its structural integrity. This attention to detail is what sets Hines apart.

Hines’ Advanced Bending Technologies

Hines offers a comprehensive suite of bending technologies because we know different applications demand different approaches. We’ve mastered them all to provide the optimal solution for your project.

- Rotary Draw Bending: Our most precise method, this is the workhorse for creating high-quality, tight-radius bends for industries like automotive and aerospace.

- Roll Bending: Ideal for the large, sweeping curves needed in architectural structures and pressure vessels.

- Push Bending: A fast and efficient solution for larger radius bends where extreme precision is not the primary concern.

Our innovation truly shines with our advanced systems. Our Induction Benders are a quantum leap in capability, especially for large-diameter, thick-walled pipes. By heating a narrow band of the pipe, this technology allows for dramatic bends without compromising structural integrity, minimizing wall thinning and ovalization. It’s the only practical solution for many heavy-duty applications in energy and shipbuilding.

Furthermore, our Dual Stack Push Benders exemplify our commitment to innovation, offering improved capabilities for complex geometries and improved production efficiency. When you partner with Hines, you get access to the industry’s most advanced bending technologies, backed by the expertise to know exactly which one your project needs.

Key Applications Across Demanding Industries

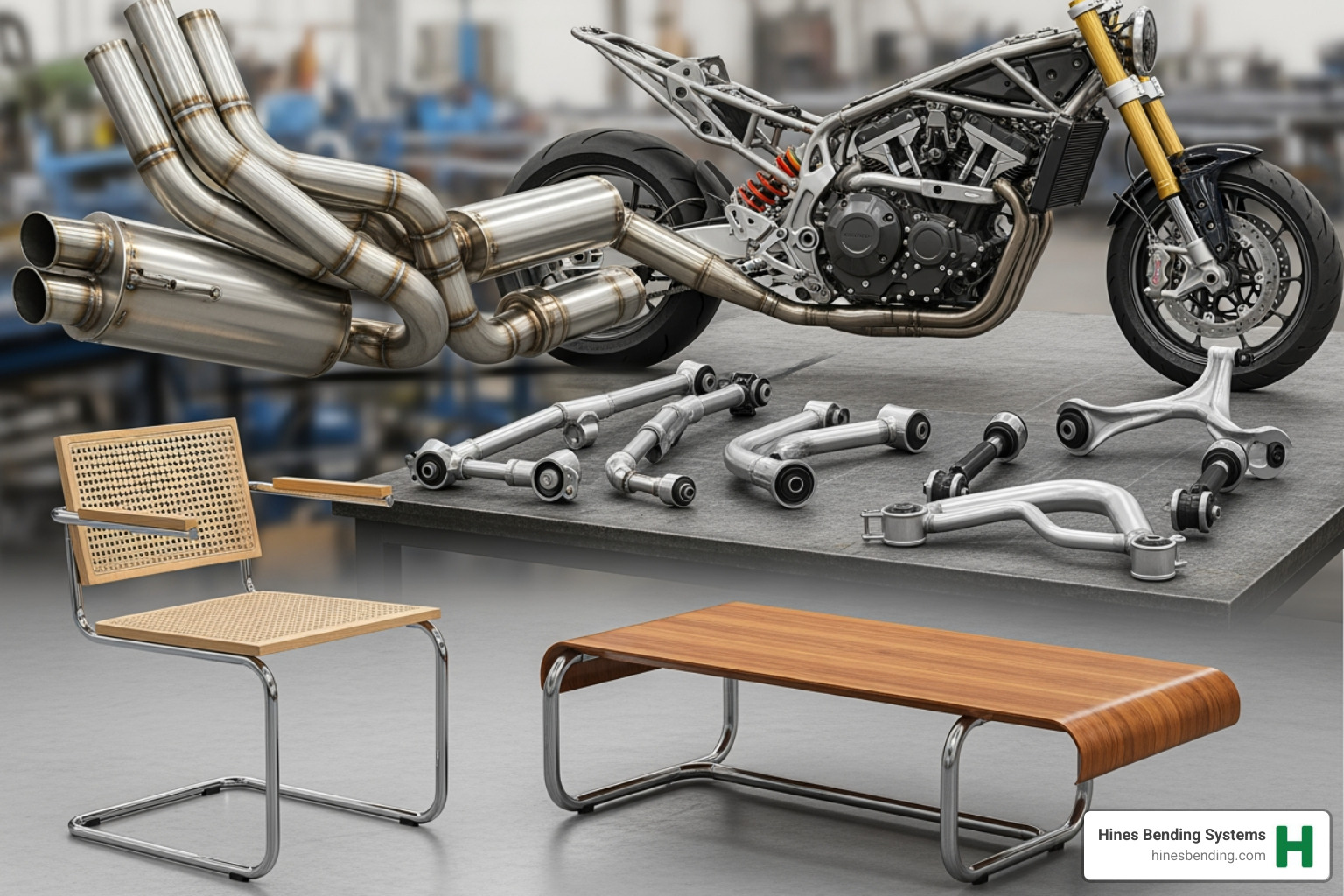

At Hines Bending Systems, our machines are the unseen backbone of countless products, shaping the world around us. Our CNC benders are versatile enough to handle a wide range of materials, including Carbon Steel, Stainless Steel, Aluminum, Titanium, and Copper, ensuring we can meet the specific demands of any industry.

The Role of Hines CNC Steel Pipe Bending Machines in Automotive and Aerospace

In the high-stakes automotive and aerospace sectors, there is no room for error. Our machines are trusted to produce critical components where failure is not an option.

- Automotive: We create everything from intricate exhaust systems and structural chassis components to life-saving roll cages and leak-proof fuel and brake lines. The precision of our benders ensures faster assembly and safer vehicles. Manufacturers rely on our technology for supporting steel machining operations.

- Aerospace: The fact that NASA calls Hines for bending machines says it all. We produce lightweight yet incredibly strong structural components, as well as hydraulic and fuel lines that must perform flawlessly under extreme pressures and temperatures. Our machines deliver the tight tolerances (down to ±0.1°) required to pass rigorous aerospace certification.

Applications in Construction, Shipbuilding, and Energy

Our CNC benders also shape the infrastructure of modern life.

- Construction: We bend pipes for architectural handrails, complex piping systems, and HVAC ductwork, meeting the growing demand for precision in modern building design.

- Shipbuilding: In harsh marine environments, our machines create robust piping systems, structural supports, and handrails that withstand the elements.

- Energy: For oil, gas, and power generation, we produce high-integrity pipeline components and boiler tubes that operate under extreme conditions where quality is paramount.

The common thread is the need for a partner who understands your industry’s specific demands. We’ve spent decades mastering these applications. If you’re new to the field, our guide on tube and pipe bending industry terms can help.

Frequently Asked Questions about Hines CNC Pipe Benders

When you’re considering a significant investment in bending technology, you naturally have questions. As the company that has installed more benders worldwide than anyone, we have the answers.

How accurate are Hines CNC bending machines?

Our machines deliver ±0.1 degree angular accuracy and ±0.1mm positional repeatability. This essential precision comes from our robust machine frames that resist vibration, the use of high-quality servo motors and control systems, and sophisticated software with 3D simulation to prevent errors before they happen. Consistent calibration, supported by our training, ensures this peak performance is maintained. Our 200 CNC Tube Bender exemplifies this commitment to high-precision manufacturing.

What factors should I consider when choosing a Hines CNC bender?

Finding the right bender means matching it to your operation. We partner with you to consider the key factors:

- Production Needs: Your volume and part complexity determine the right balance of speed and flexibility.

- Material & Size: The type, diameter, and wall thickness of your pipe dictate the required machine capacity and tooling.

- Manufacturer Expertise: Choosing Hines means gaining a partner with unparalleled industry knowledge to engineer the best solution.

- Support & TCO: We provide comprehensive training and support. While a Hines machine is an investment, its efficiency, reduced waste, and long lifespan result in a lower total cost of ownership compared to cheaper, less reliable alternatives. Explore why you should buy from an expert manufacturer to learn more.

Can one Hines machine handle different pipe sizes and shapes?

Absolutely. Versatility is a key feature. Our machines handle round, square, rectangular, and oval tubes, as well as solid bars. The secret is efficient tooling changeover, a process we’ve engineered to be straightforward. Many models feature quick-change die systems that reduce setup downtime by up to 70%. This adaptability allows you to diversify your offerings and respond quickly to customer needs without investing in multiple machines. Explore our Hines bender accessories to further expand your machine’s capabilities.

Conclusion: Hines Bending Systems—Your Partner for Unrivaled Bending Precision

We’ve explored what is a cnc steel pipe bending machine and how it delivers the precision, efficiency, and versatility modern manufacturing demands. But the most important truth is this: the machine is only as good as the company behind it.

At Hines Bending Systems, we are the #1 worldwide leader in tube, pipe, and induction benders because we partner with our customers for success. When NASA and major automotive manufacturers need to meet impossible tolerances, they trust Hines. This is the result of decades of expertise, relentless innovation, and an unwavering commitment to quality.

Investing in a CNC bender is a major decision. We don’t just sell equipment; we provide custom solutions custom to your specific needs, comprehensive training for your team, and dedicated after-sales support. Our customers choose Hines because they know superior equipment, backed by best expertise, delivers a lower total cost of ownership and the confidence that comes from working with true industry leaders.

Whether you’re bending carbon steel, titanium, or other materials, we have the technology and experience to help you succeed.

Ready to lift your bending capabilities? Explore our complete range of tube and pipe benders and find how partnering with Hines Bending Systems can transform your operations.

Additional Resources: