Finding the Perfect CNC Tube Bender for Sale: Your Guide to Smart Investment

When searching for a CNC tube bender for sale, you’re not just looking for a machine; you’re seeking a long-term investment that delivers precision, reliability, and a significant return. The market is filled with options, but a truly great investment is defined by its engineering, support, and the expertise behind it. This is where Hines Bending Systems stands apart.

With a Hines bender, you gain access to industry-leading technology capable of handling the most complex jobs. Our machines offer:

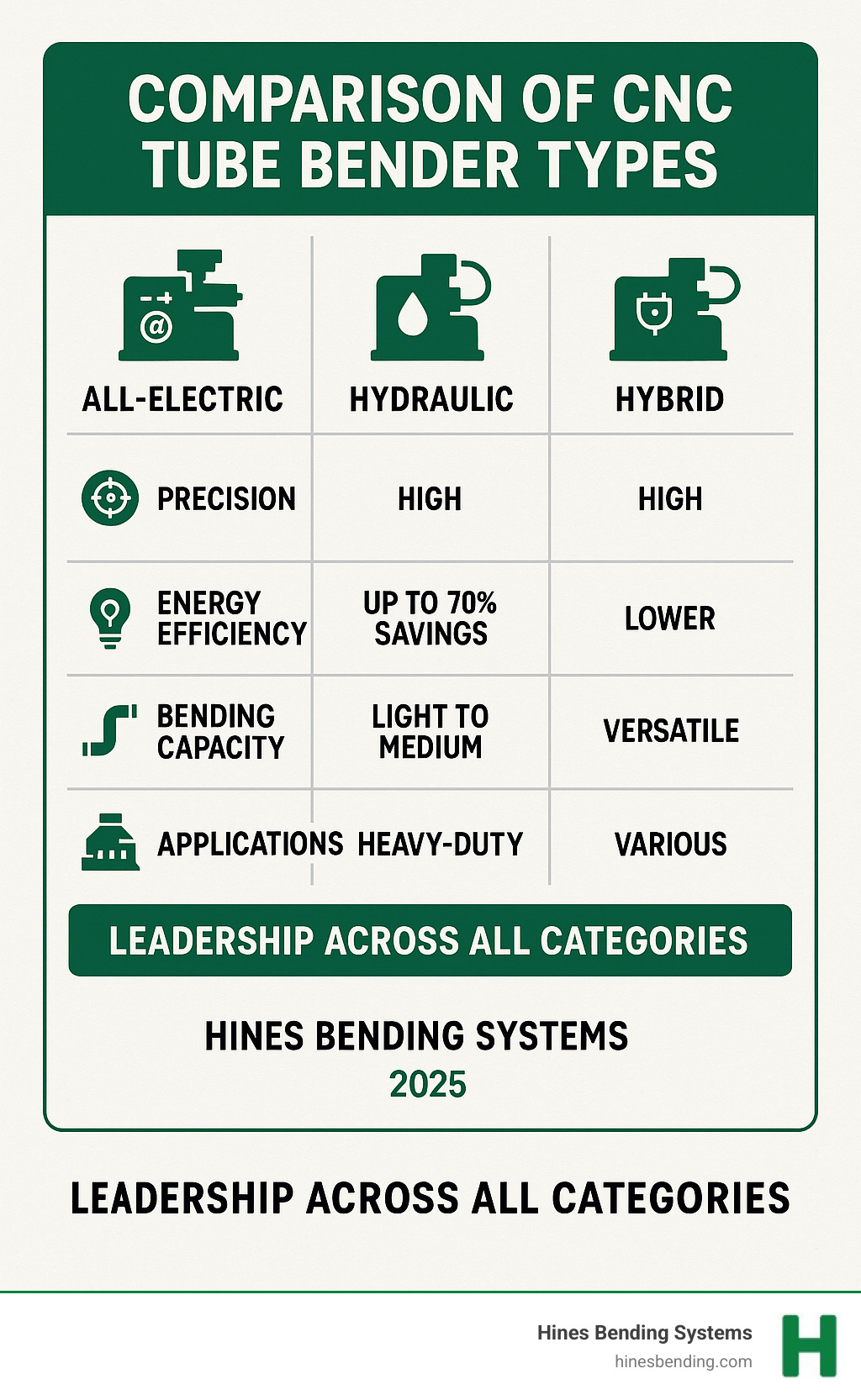

- Versatile Bending Solutions: From all-electric systems offering up to 70% energy savings to powerful hydraulic and hybrid benders, we have the right technology for any application.

- Advanced Capabilities: Our benders handle a wide range of tube diameters (from 0.87 to 6.0 inches) and lengths up to 16 meters, with high-speed operations and quick tooling changes to maximize your throughput.

- Best Precision: We specialize in mandrel bending for thin-wall tubing and complex geometries, ensuring flawless results every time.

The reality is, not all CNC benders are created equal. The difference between a good deal and a great investment is choosing a partner with proven expertise. As the #1 worldwide manufacturer of tube benders, Hines Bending Systems provides custom solutions for clients ranging from small fabrication shops to major government agencies like NASA. We don’t sell off-the-shelf equipment; we engineer a bending system specifically for your needs, ensuring you get the best possible performance and value.

This guide will help you steer the market to find not just a deal, but the right long-term investment for your fabrication needs. Learn more about what makes a superior bending machine by exploring the fundamentals of CNC metal bending and why Hines is the leading choice among tube bender manufacturers.

Why Investing in a High-Quality CNC Bender from Hines is a Game-Changer

When you’re searching for a CNC tube bender for sale, you’re not just buying equipment—you’re investing in a change that will revolutionize your entire production process. At Hines Bending Systems, we’ve seen how the right machine can turn manufacturing challenges into competitive advantages.

The best precision you’ll find in the industry comes standard with every Hines machine. While manual bending leaves room for human error and inconsistency, our CNC benders deliver micron-level accuracy that you can count on. Whether you’re producing your first part or your ten-thousandth, each bend maintains identical specifications with a minimum bend radius of 3 times the outer diameter.

This precision creates flawless repeatability that directly impacts your bottom line. No more scrapped parts due to operator error. No more time wasted on rework. Just consistent, high-quality results that meet your exact specifications every single time.

Increased throughput becomes a reality when you can operate at feed speeds reaching 200 mm/s—that’s 10 meters per minute of pure productivity. Add in tooling changes that take less than 5 minutes, and you’ll see why Hines customers consistently report dramatic improvements in their production cycles.

But here’s where it gets really exciting: reduced material waste means every tube you feed into a Hines machine has the best chance of becoming a perfect finished part. Our precision engineering minimizes scrap, and our advanced programming capabilities help you optimize material usage across your entire production run.

The ability to handle complex geometries opens doors to projects you might have turned down before. Multiple bends in different planes? Continuously changing radius bends? Our machines tackle these challenges with ease, allowing you to expand your capabilities and take on more sophisticated work.

Improved operator safety isn’t just a nice bonus—it’s built into every aspect of our design. Automated processes reduce manual handling of heavy materials, while robust safety protocols protect your team. Your operators can focus on quality control and optimization rather than wrestling with dangerous manual processes.

Perhaps most impressive is the energy efficiency of our all-electric technology. We’re talking about energy savings of up to 70% compared to traditional systems. Over your machine’s lifetime, these operational cost reductions add up to significant savings that improve your competitive position.

This is why major organizations like NASA trust Hines Bending Systems for their most critical applications. When precision, reliability, and performance matter most, they choose the #1 worldwide manufacturer of tube benders.

Ready to find how a Hines CNC bender can transform your operation? Learn more about the Advantages of CNC Tube Bending Machine For Sale and see why investing in Hines quality is always the smart choice.

Hines Bending: The Industry Leader in CNC Bender Technology

When you’re searching for a CNC tube bender for sale, you’re not just looking for equipment—you’re looking for a partner who understands your challenges and has the expertise to solve them. That’s exactly what you get with Hines Bending Systems, the #1 worldwide manufacturer of tube, pipe, and induction benders.

What makes Hines truly special isn’t just our impressive global reach—it’s our commitment to understanding your unique needs. We don’t believe in one-size-fits-all solutions. Instead, we work closely with each client to create custom bending systems that perfectly match their specific applications, materials, and complexity requirements.

Our comprehensive range of CNC Benders reflects this philosophy. Whether you need the precision and energy efficiency of our all-electric benders, the robust power of our hydraulic benders, or the balanced performance of our hybrid models, we have the right solution for you. Our roll benders excel at large radius work, while our push benders deliver the high-speed production that keeps your operations running smoothly.

This isn’t just about having options—it’s about having the expertise to guide you to the perfect choice. With decades of experience across every industry imaginable, from aerospace to furniture manufacturing, we understand the nuances that make each application unique. Our Advanced CNC Machines incorporate cutting-edge software integration and intuitive controls that make complex bending tasks surprisingly straightforward.

Mandrel Bending Expertise

When precision matters most—especially with thin-wall tubing or complex geometries—mandrel bending becomes essential. At Hines, we’ve perfected this specialized technique over decades of real-world applications.

Mandrel bending transforms challenging projects into achievable goals. By providing internal support during the bending process, we prevent wrinkles, maintain perfect ovality control, and ensure your finished parts meet the most demanding specifications. This expertise is particularly valuable in aerospace, medical device manufacturing, and other industries where component integrity is non-negotiable.

Our CNC Mandrel Tube Bender For Sale options represent the culmination of this specialized knowledge. When you choose Hines, you’re not just buying a machine—you’re accessing decades of mandrel bending expertise that ensures consistently high-quality results.

Innovative Bending Solutions by Hines

Innovation drives everything we do at Hines. We’re constantly pushing the boundaries of what’s possible in tube and pipe fabrication, developing solutions that didn’t exist before.

Take our induction bending technology, for example. This advanced approach revolutionizes how we handle large diameter pipes and thick wall materials. Instead of fighting against the material’s natural resistance, induction bending uses precisely controlled heating to make the bending process smoother and more accurate. The result? Superior material properties, reduced distortion, and the ability to tackle projects that were previously impossible. Our Induction Benders have become essential tools for shipbuilding, power generation, and structural fabrication applications.

But innovation isn’t just about individual technologies—it’s about reimagining entire production processes. Our dual stack benders and Stack Push Benders exemplify this approach. By allowing multiple tooling setups simultaneously, these machines dramatically reduce changeover times and boost productivity. It’s like having multiple benders in one compact footprint.

Similarly, our twin head benders tackle symmetrical parts and dual-end bending with remarkable efficiency. These advanced systems are engineered to meet the growing demands of specialized industries, providing our clients with competitive advantages through superior technology and performance.

At Hines, we don’t just follow industry trends—we create them. Our engineering team works tirelessly to develop solutions that address tomorrow’s challenges today, ensuring that when you invest in a Hines bender, you’re investing in technology that will serve you well into the future.

Key Industries and High-Value Applications Served by Hines

When you’re looking for a CNC tube bender for sale, you want to know it can handle the challenges your industry demands. At Hines Bending Systems, we’re proud to serve some of the most demanding sectors in the world—and we’ve earned their trust through decades of delivering precision when it matters most.

Nothing speaks to our quality quite like our partnership with NASA. When you’re building components for space exploration, there’s absolutely no room for error. Every bend must be perfect, every specification met to the micron. That’s why NASA trusts Hines Bending Systems for their critical bending needs. Our relationship with NASA isn’t just a business arrangement—it’s a testament to the highest levels of quality and reliability that our machines consistently deliver.

The aerospace industry presents some of the most challenging bending requirements imaginable. From hydraulic lines that must withstand extreme pressures to structural components that support entire aircraft, our machines bend titanium and exotic alloys with the precision these applications demand. When failure isn’t an option, aerospace manufacturers turn to us.

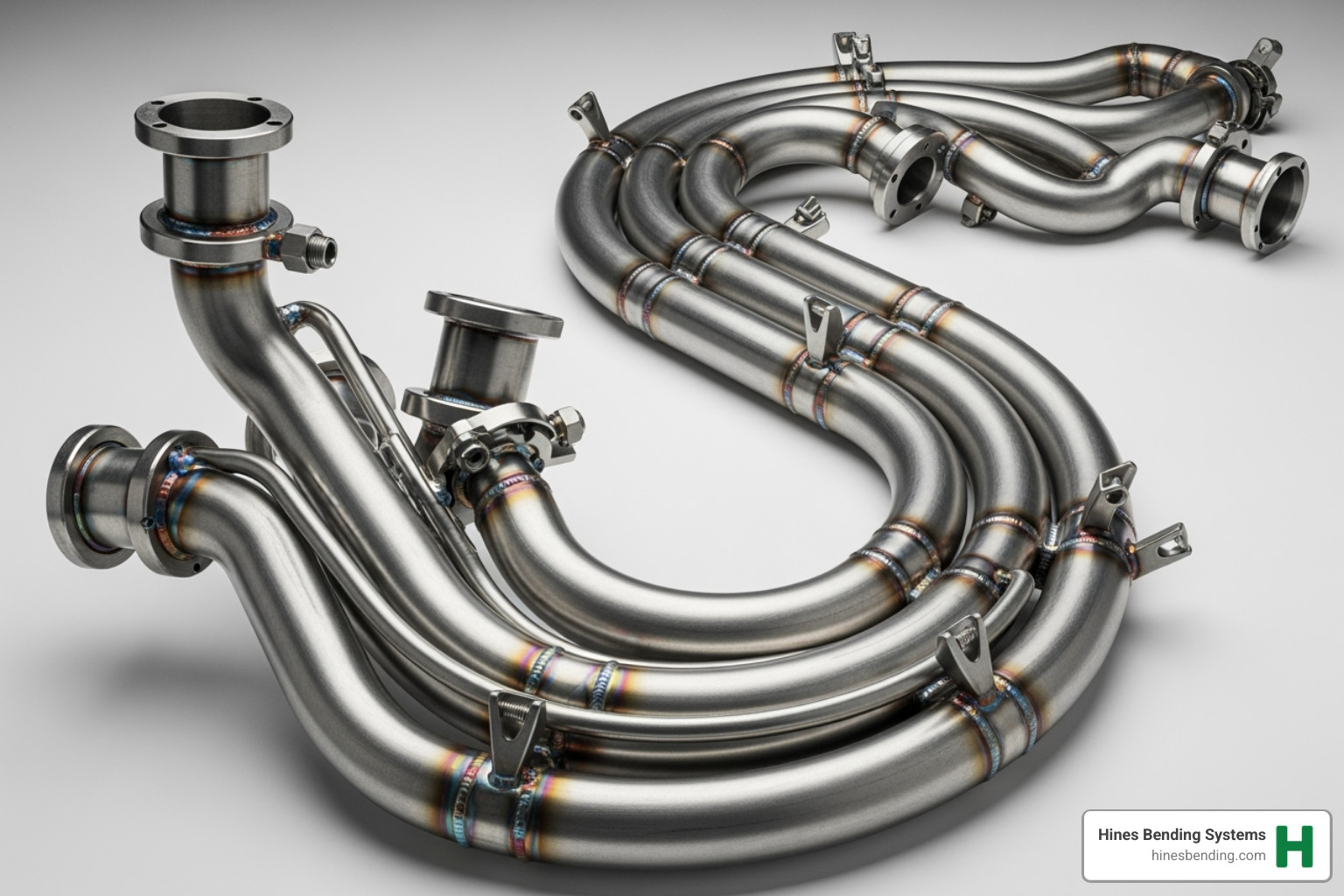

In the automotive sector, we’re the backbone of high-performance manufacturing. Whether it’s precision exhaust systems that need to fit perfectly in tight engine compartments, chassis components that must meet safety standards, or roll cages that protect drivers, our benders ensure consistent, high-volume production. The automotive industry doesn’t slow down, and neither do our machines.

Shipbuilding requires a different kind of strength entirely. We’re talking about large diameter piping systems, structural elements that withstand ocean forces, and intricate fluid transfer lines. Our robust benders handle the thick-walled materials that maritime safety demands, ensuring every component meets the rigorous standards of life at sea.

The military and defense sectors rely on us for everything from vehicle frames to specialized equipment. These applications require machines that can meet the most demanding specifications while maintaining the durability and precision that military standards require. Our expertise in working with government agencies means we understand these unique requirements inside and out.

For HVACR applications, precision takes on a different meaning. Seamless coils, refrigeration components, and precise ductwork are essential for energy-efficient systems. Our machines enable manufacturers to produce these critical components with the consistency and quality that modern heating, ventilation, air conditioning, and refrigeration systems demand.

Even in the furniture industry, where aesthetics meet functionality, our benders provide the flexibility and accuracy needed to create beautiful, durable designs. From neat chairs to sturdy bed frames, we help manufacturers achieve the perfect balance of form and function.

Structural fabrication brings its own set of challenges—architectural elements, playground equipment, and construction projects all require heavy-duty bending capabilities. Our machines handle these demanding applications with ease, providing the strength and precision that structural integrity requires.

What sets us apart isn’t just our ability to serve these diverse industries—it’s our commitment to providing custom solutions for each one. Whether you need a small, intricate bend for a medical device or a large, complex pipe for an industrial application, Hines Bending Systems has both the expertise and the machinery to deliver exactly what you need.

How to Find the Right CNC Tube Bender for Sale from Hines

Finding the perfect CNC tube bender for sale isn’t about grabbing the first machine you see—it’s about finding the right partner for your fabrication journey. At Hines Bending Systems, we believe that the best deals aren’t just about price tags; they’re about finding a machine that delivers exceptional value, performance, and reliability for years to come.

Think of it this way: you wouldn’t buy a car without knowing if it fits your driving needs, right? The same principle applies when you’re investing in a CNC tube bender. Our team doesn’t just sell you equipment—we guide you through every consideration to ensure you make the smartest choice for your specific applications.

Evaluating a New CNC Tube Bender for Sale

When you’re considering a new CNC tube bender for sale from Hines, you’re not just buying a machine—you’re investing in a solution that’s been engineered with decades of expertise. Our approach focuses on understanding your unique needs first, then matching you with the perfect technology.

Bending capacity is where we always start the conversation. Can the machine handle your material types and dimensions? Our extensive range covers everything from delicate instrument tubing to heavy-duty structural pipes. We’ll discuss your current projects and future growth plans to ensure your investment scales with your business.

The axis configuration determines how complex your bends can be. Whether you need a straightforward 3-axis system for simple bends or a sophisticated multi-axis setup for intricate, multi-plane geometries, we’ll explain exactly what each configuration means for your specific applications.

Our control systems are designed with real operators in mind. No confusing interfaces or steep learning curves—just intuitive controls that make complex programming feel natural. We’ll demonstrate how our software integration capabilities allow you to transfer 3D CAD drawings directly to the machine, eliminating guesswork and reducing setup time dramatically.

Tooling compatibility might sound technical, but it’s actually quite simple. Different jobs need different tools—mandrels for thin-wall tubing, wiper dies for smooth finishes, clamp dies for secure holding. We’ll walk you through exactly what tooling your applications require and ensure your chosen machine handles everything seamlessly.

Here’s where it gets exciting: automation potential. Many of our benders can integrate auto-loaders, weld-seam detectors, and unloaders to create fully automated fabrication cells. Imagine your machine running efficiently while your operators focus on higher-value tasks.

At Hines Bending Systems, we work directly with you to customize a machine to your exact specifications. This isn’t about selling you what we have in stock—it’s about engineering the perfect solution for your unique challenges. For detailed guidance on making the right choice, explore our comprehensive resource on Buying a Metal Tube Bender For Sale.

Considering a Used CNC Tube Bender for Sale

Sometimes the smartest investment is a quality used machine—especially when it comes from Hines Bending Systems. Our certified refurbished CNC tube benders for sale offer an excellent entry point into high-quality CNC bending without the full investment of a new unit.

Manufacturer refurbishment through Hines means something special. Our expert technicians don’t just clean and test—they restore machines to near-new condition. Critical components are inspected, repaired, or replaced using genuine Hines parts, ensuring the performance and reliability you’d expect from our brand.

Unlike buying from a general used equipment dealer, our refurbished machines come with warranty protection. You’re not gambling on an unknown machine history—you’re investing in equipment that’s been thoroughly vetted and backed by our commitment to quality.

The support advantage continues long after purchase. Whether your machine is new or used, you gain access to Hines’ legendary customer support. We don’t abandon our machines after sale—we support their entire lifecycle because we believe in building lasting relationships with our customers.

Parts availability is never a concern with Hines. We maintain comprehensive inventory of spare parts to ensure rapid repairs and minimal downtime. This means your used machine investment is protected for the long term, not just the immediate future.

Our certified refurbishment process and ongoing support ensure that even used machines deliver exceptional long-term value and reliability. It’s a smart way to expand your capabilities while maintaining the Hines quality standard you can trust. Explore our current inventory of professionally refurbished equipment at our Used CNC Bending Machine page.

Beyond the Purchase: The Hines Advantage in Support and Integration

At Hines Bending Systems, our relationship with you doesn’t end when you purchase a CNC tube bender for sale. In fact, that’s just the beginning of our partnership. We understand that maximizing your investment means ensuring your team is proficient, your machine runs optimally, and you have access to expert assistance whenever needed. This is the Hines Advantage – comprehensive support and seamless integration that transforms your production capabilities.

We believe that the best bending machines deserve the best operators, which is why operator training is at the heart of our service commitment. Our comprehensive training programs are designed to empower your team with the knowledge and skills needed to fully harness the capabilities of your Hines CNC bender. Whether it’s in-house training at our state-of-the-art facilities or on-site training at your location, our experienced instructors ensure your operators quickly become proficient in machine operation, programming, and troubleshooting.

This isn’t just about pushing buttons – it’s about understanding the nuances of precision bending, optimizing cycle times, and maintaining the highest quality standards. Our training significantly improves the efficiency of engineering and production for our clients, reducing the learning curve and getting you to full productivity faster. We’ve found that well-trained operators not only produce better parts but also take better care of their equipment, extending machine life and reducing maintenance costs. Learn more about our specialized programs at Tube and Pipe Bender Training.

Beyond initial training, we offer lifetime technical support that sets us apart from the competition. Our team of highly skilled engineers and technicians is available to provide expert guidance and troubleshooting assistance whenever you need it. Whether you’re facing a complex bending challenge, have a programming question, or encounter a technical issue, we’re just a phone call away. This commitment to long-term support ensures maximum uptime and productivity for your machine, year after year.

To keep your Hines CNC bender running at peak performance, we provide robust maintenance programs custom to your specific needs. Regular preventative maintenance helps identify and address potential issues before they become costly problems, extending the lifespan of your machine and ensuring consistent quality. Our team works closely with you to establish a maintenance schedule customized to your production demands, whether you’re running single shifts or around-the-clock operations.

One of the most critical aspects of our support is our comprehensive inventory of spare parts. When you need a replacement component, we can quickly supply the necessary part, minimizing downtime and getting your machine back into production swiftly. Our global reach and established logistics network ensure that parts are delivered efficiently, wherever you are in the world. This isn’t just about having parts in stock – it’s about having the right parts, manufactured to the same exacting standards as your original machine.

Hines Bending Systems provides support for the entire lifecycle of your machine, ensuring maximum uptime and productivity throughout its operational life. This holistic approach means that your investment continues to deliver value year after year, decade after decade. We work closely with clients to understand their specific needs, providing custom bender solutions that seamlessly integrate into their existing production or fabrication lines.

Our dedication to customer satisfaction means we don’t just sell you a machine – we partner with you for long-term success. As the #1 worldwide manufacturer with the most bender installations globally, we have the expertise and experience to support your operations no matter how complex or demanding they become. This is why major organizations like NASA trust us not just for their initial equipment needs, but for ongoing support that keeps their critical operations running smoothly.

Conclusion: Partner with the Global Leader for Your Bending Needs

Finding the right deal on a CNC tube bender for sale isn’t just about comparing price tags – it’s about recognizing true value. The smartest investment comes from partnering with a company that delivers quality, reliability, and comprehensive support that lasts for decades.

When you work with Hines Bending Systems, you’re choosing the #1 global manufacturer of tube benders, pipe benders, and induction benders. We’ve earned this position through years of innovation, countless successful installations, and an unwavering commitment to our customers’ success. From small fabrication shops to major government agencies like NASA, our clients trust us to deliver solutions that exceed expectations.

What sets us apart isn’t just our machines – it’s our people and our approach. We don’t believe in one-size-fits-all solutions. Instead, we work directly with you to understand your unique challenges, your production goals, and your specific requirements. This collaborative approach ensures that you’re not just buying equipment off the shelf; you’re investing in a custom bending solution engineered specifically for your applications.

Our superior quality machines are designed to meet the most stringent industry standards, delivering the precision and reliability that cheaper alternatives simply cannot match. Whether you need our innovative Dual Stack CNC Push Benders for high-volume production or our advanced Roll Benders for complex geometries, we continuously innovate to address the growing demands of various industries.

But here’s what really makes the difference: our commitment to your long-term success. When you partner with Hines, you gain access to comprehensive training programs, lifetime technical support, and maintenance services that keep your machine running at peak performance. We’re not just here for the sale – we’re here for the entire lifecycle of your investment.

Nobody in the bending machine industry has more expertise and experience than Hines Bending Systems. We’ve solved the most challenging bending problems, worked with the most demanding materials, and delivered solutions that others said were impossible. This depth of knowledge becomes your competitive advantage.

Ready to experience the Hines difference? We’re here to answer all your questions about what makes our bending machines superior and how our unique features and benefits will give you the edge you need in today’s competitive market.