Why CNC Tube Bender Price Matters for Your Bottom Line

The CNC tube bender price you pay today shapes your production capacity—and profits—for years to come. Knowing the basic ranges keeps you from overspending or buying too little machine.

Quick CNC Tube Bender Price Guide:

- Entry-Level: $5,000 – $20,000 (basic 2-axis, small diameters)

- Mid-Range: $20,000 – $75,000 (multi-axis, production features)

- High-End: $75,000 – $350,000+ (all-electric, large diameters, aerospace grade)

- Used Options: 30-60 % less than new

From a neighborhood fab shop to NASA, buyers trust Hines Bending Systems to match capability and budget. As the #1 worldwide manufacturer of tube benders, Hines delivers custom solutions that slash scrap, boost throughput, and protect your investment.

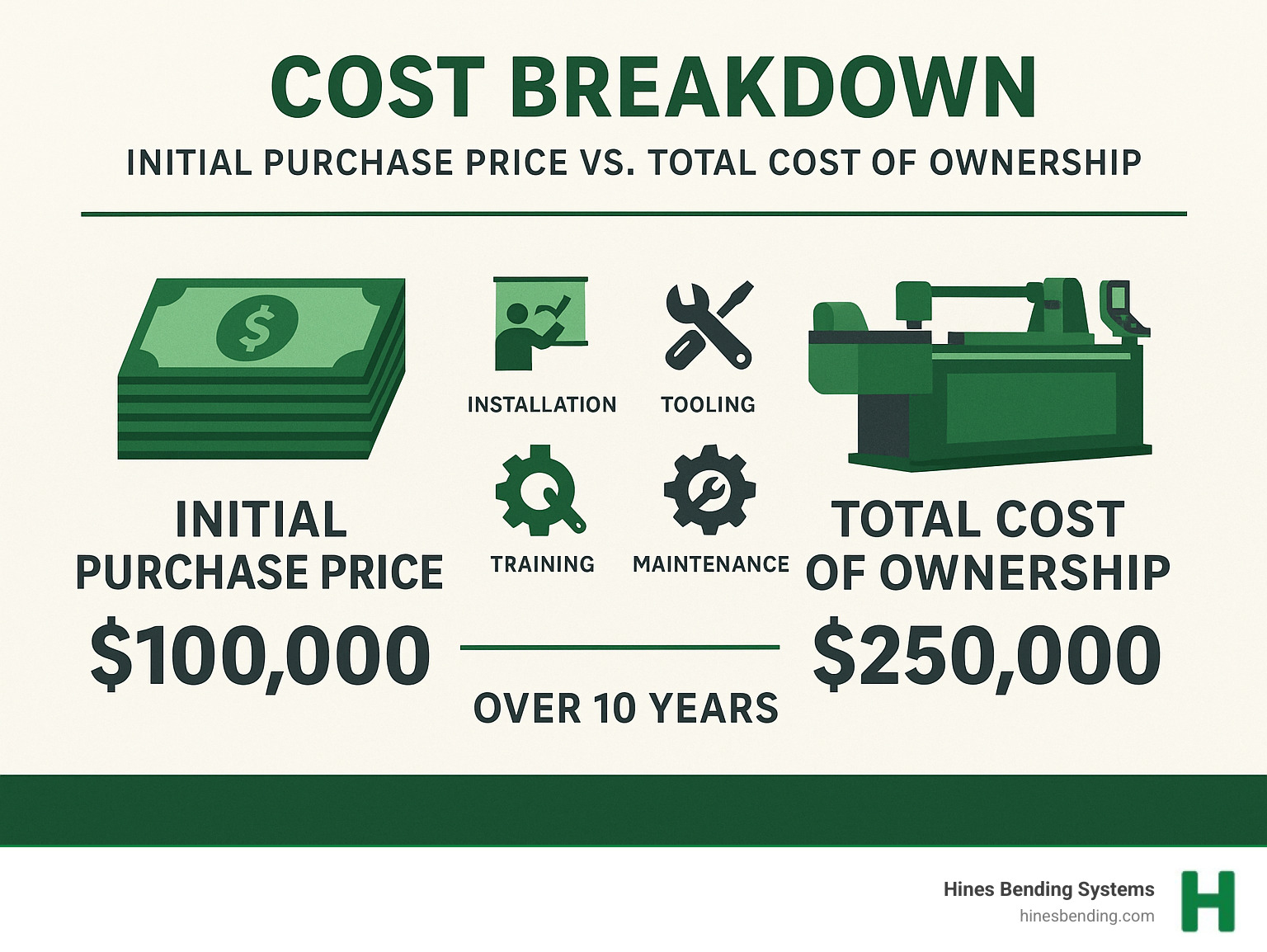

Sticker price is only part of the calculation. Shipping, installation, training, and maintenance can add 20-30 %. With Hines, those extras turn into value-adds thanks to expert setup and world-class support.

How CNC Tube Benders Work & Which Type Fits Your Budget

Finding the right CNC tube bender for your budget starts with understanding how these sophisticated machines work. The CNC tube bender price you’ll pay depends heavily on the type of technology and level of automation you choose – and that’s where Hines Bending Systems’ expertise becomes invaluable.

As the #1 worldwide manufacturer of tube benders, Hines has perfected every aspect of CNC bending technology. Their machines combine precision engineering with user-friendly operation, delivering the kind of reliability that keeps NASA and other major clients coming back for more equipment.

Core Bending Process Explained

The magic happens through draw-bending technology that’s been refined over decades of innovation. Your tube gets clamped securely, then a rotating bend die shapes it around a precise radius while servo motors control every micro-movement. It’s like having a master craftsman’s steady hand, but with computer-perfect repeatability every single time.

What makes Hines machines special is how their advanced software coordinates multiple servo motors working in perfect harmony. Each axis moves independently yet synchronously, allowing complex multi-plane bends that would be impossible with manual methods. This level of precision justifies the investment – especially when you consider the scrap reduction and consistency you’ll achieve.

The repeatability factor alone can transform your production line. Once you’ve programmed a bend sequence, Hines machines will reproduce it flawlessly whether you’re making ten parts or ten thousand. That’s the kind of reliability that pays for itself quickly in reduced waste and increased throughput.

Popular Machine Configurations

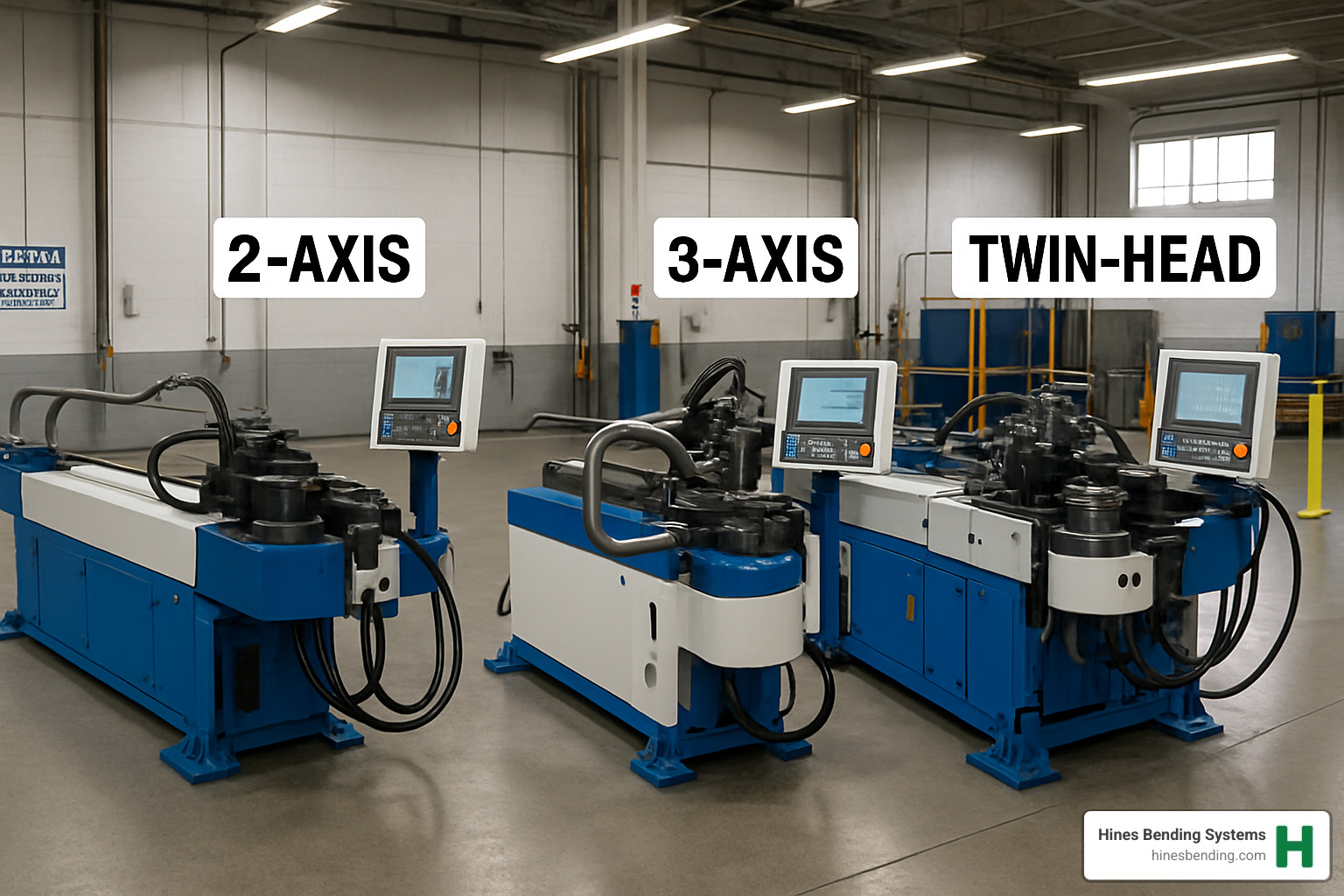

When evaluating options, the configuration you choose dramatically impacts both capability and cost. 2-axis systems handle straightforward bends beautifully and keep your initial investment lower – perfect for shops just getting started with CNC bending. 3-axis machines add rotational capability for complex shapes, opening up entirely new product possibilities.

The choice between electric and hydraulic drive systems often comes down to your specific needs. All-electric servo systems offer superior precision and energy efficiency, while hydraulic systems provide the raw power needed for heavy-duty applications. Hines engineers can help you determine which approach delivers the best value for your particular production requirements.

Right and left bending capability might seem like a luxury, but it’s actually a major productivity booster. Machines that can bend in both directions without repositioning save tremendous setup time. The push-roll and twin-head configurations excel at specialized applications – twin-head systems are fantastic for symmetrical parts, while push-roll setups handle long, continuous bends with ease.

The beauty of working with Hines is their commitment to custom solutions. Rather than forcing you to adapt your processes to a standard machine, they’ll work with you to configure equipment that fits your specific production needs and budget constraints. That’s the kind of expertise that comes from decades of experience and thousands of successful installations worldwide.

CNC Tube Bender Price Breakdown: Entry-Level vs Mid-Range vs High-End

When you’re shopping for a CNC tube bender, understanding the price tiers is like having a roadmap to the perfect machine for your needs. The CNC tube bender price landscape breaks down into three distinct categories, each serving different production requirements and budgets.

| Price Tier | Cost Range | Diameter Capacity | Key Features | Best For |

|---|---|---|---|---|

| Entry-Level | $5,000-$20,000 | 6-38mm | 2-axis, basic CNC | Small shops, simple parts |

| Mid-Range | $20,000-$75,000 | 25-76mm | Multi-axis, production features | SME manufacturers |

| High-End | $75,000-$350,000+ | 76-275mm | All-electric, advanced automation | Industrial production |

The beauty of this pricing structure is that there’s genuinely something for everyone. Whether you’re just starting out or running a major production facility, the key is matching your actual needs with the right capability level.

Entry-Level CNC Tube Bender Price: What to Expect

Starting your CNC bending journey doesn’t have to break the bank. Entry-level machines in the $5,000 to $20,000 range offer a fantastic introduction to automated tube bending, especially for smaller operations working with tubes up to 38mm in diameter.

These starter-friendly machines typically feature 2-axis control and hydraulic drive systems that keep costs manageable while delivering consistent results. They’re perfect for small fabrication shops where space is tight and budgets are even tighter. Don’t let the lower price fool you though – these machines can still produce quality work that far exceeds what you’d achieve with manual methods.

The space-saving designs common in this category make them ideal for shops where every square foot counts. While they may not have all the bells and whistles of their pricier cousins, they represent a solid investment for businesses ready to step up from manual bending without making a massive financial commitment.

Mid-Range CNC Tube Bender Price: Sweet Spot for SMEs

Here’s where things get really interesting. The $20,000 to $75,000 price range represents the sweet spot for most small-to-medium enterprises, offering the perfect balance of capability, reliability, and value.

These machines handle multi-axis operations with ease, typically working with tube diameters from 25mm to 76mm. What really sets them apart is their production-ready reliability – they’re built to run day after day without missing a beat. The programmable controls can store hundreds of bend programs, making them incredibly versatile for job shops handling diverse customer requirements.

At Hines Bending Systems, we’ve seen countless businesses transform their operations with machines in this category. The reliability factor becomes crucial here because downtime directly impacts your bottom line. These machines are engineered for continuous production use, with robust construction that minimizes maintenance headaches and maximizes uptime.

More info about CNC tube benders for sale

High-End CNC Tube Bender Price: Premium Performance, Premium Cost

When precision is non-negotiable and production demands are extreme, high-end CNC tube benders deliver best performance. Starting at $75,000 and extending well beyond $350,000, these machines represent the pinnacle of bending technology.

All-electric servo systems dominate this category, providing aerospace-grade precision and energy efficiency that pays dividends over time. These machines handle large diameter tubes up to 275mm with accuracy that meets the most stringent industry standards. Advanced software packages include simulation capabilities, allowing operators to test bend sequences before committing expensive material.

The premium pricing reflects more than just advanced technology – it represents extensive testing, certification, and the kind of reliability that companies like NASA depend on. When Hines Bending Systems supplies bending machines to major government agencies and aerospace manufacturers, they’re choosing equipment that simply cannot fail.

These machines often include remote diagnostics and support capabilities, ensuring that even the most complex issues can be resolved quickly. The investment may seem substantial, but for operations where quality and reliability are paramount, these machines deliver value that far exceeds their cost.

New vs Used CNC Tube Bender Cost Comparison

The used equipment market can be a goldmine for smart buyers looking to maximize their CNC tube bender price budget. Here’s something that might surprise you: used CNC tube benders typically cost 30-60% less than new equivalents, depending on age, condition, and market demand.

Depreciation works in your favor when buying used equipment. CNC tube benders follow predictable depreciation curves, with the steepest drop happening in the first 3-5 years. After that initial hit, values tend to stabilize, creating excellent opportunities for buyers who know what to look for.

Warranty considerations become crucial when comparing new versus used options. New machines come with comprehensive warranties – typically 1-2 years on major components – giving you peace of mind. Used machines may have limited or no warranty coverage, which makes thorough inspection absolutely essential.

Lifecycle hours tell the real story of a machine’s remaining value. Industrial CNC benders are built like tanks – designed for decades of service. A well-maintained machine with 50,000+ operating hours can still deliver outstanding performance if it’s been properly cared for. However, machines approaching 100,000+ hours may need significant overhaul investments down the road.

The key is understanding what you’re getting into. At Hines Bending Systems, we’ve seen customers make excellent decisions with both new and used equipment. Our expertise helps you evaluate whether a used machine will truly meet your production needs or if investing in new equipment makes more financial sense for your specific situation.

Evaluating a Pre-Owned Deal

When you’re considering used equipment, becoming a detective pays off. Control system condition should be your first checkpoint. Older machines may have obsolete control systems that are difficult to service or upgrade. Factor in potential upgrade costs when evaluating used equipment – they can add thousands to your total investment.

Mechanical wear inspection separates smart buyers from those who end up with expensive problems. Look carefully at bend dies, clamps, and drive systems for excessive wear. Replacement tooling can cost thousands of dollars and should be factored into your total investment calculation.

Service records are like a machine’s medical history – they reveal everything. Complete maintenance records indicate proper care and help predict future service needs. Machines with gaps in service history may be hiding problems that could cost you dearly later.

The bottom line? Used equipment can offer tremendous value, but only when you know what you’re buying. Working with experienced professionals who understand the intricacies of CNC tube bending equipment can save you from costly mistakes and help you find the perfect balance of capability and cost.

More info about Used CNC options

Support listings for used machines

Hidden Costs & ROI: Don’t Let Extras Bust Your Budget

Here’s the reality that catches many buyers off guard: the CNC tube bender price you see advertised is just the starting point. Smart manufacturers know that hidden costs can easily balloon your total investment by 20-30%, sometimes more. Let’s break down what you’re really looking at.

Shipping costs hit harder than most people expect. We’re talking about moving several tons of precision machinery, not a package from Amazon. For smaller machines, you might get away with $500-$1,500 in shipping costs. But when you’re dealing with industrial-grade systems, those numbers can jump to $5,000-$10,000 or more, especially if you’re importing equipment internationally.

Installation and setup represent another significant expense that’s often overlooked. You could try to figure it out yourself, but professional installation ensures your machine performs optimally from day one. More importantly, many manufacturers require professional installation to maintain warranty coverage. Budget anywhere from $2,000 for basic machines up to $15,000 for complex multi-axis systems with specialized site requirements.

Training costs might seem optional, but they’re actually one of your best investments. Proper operator training dramatically reduces scrap rates and maximizes your machine’s potential. Comprehensive training programs typically run $1,000-$5,000, but they pay for themselves quickly through improved efficiency and reduced waste.

Then there’s tooling and accessories – the ongoing reality of CNC tube bending. Bend dies, mandrels, and clamps are consumable items that need regular replacement. Your initial tooling package alone can cost $5,000-$25,000, depending on your production requirements. Factor in ongoing replacement costs based on your production volume.

Maintenance contracts and energy costs add to your operational expenses. While modern CNC benders are remarkably reliable, preventive maintenance keeps them running smoothly. Energy costs vary significantly between hydraulic and all-electric systems, with electric systems offering better long-term efficiency despite higher upfront costs.

Crunching the Numbers

The good news? When you run the numbers properly, CNC tube benders typically deliver impressive returns on investment. Most systems pay for themselves within 12-36 months through increased productivity and reduced labor costs. The key is understanding how your specific production requirements affect the payback calculation.

Production volume plays the biggest role in ROI calculations. High-volume operations can justify premium equipment through economies of scale. If you’re bending thousands of parts monthly, the efficiency gains from a higher-end machine quickly offset the additional investment. Lower-volume applications might be better served by more modest equipment that still delivers significant improvements over manual methods.

Scrap reduction often provides the most dramatic cost savings. Manual bending typically results in 5-10% scrap rates, while CNC precision can reduce this to under 2%. Even a modest 3% reduction in scrap can save thousands of dollars annually in material costs, especially when working with expensive alloys or large-diameter tubing.

Labor efficiency improvements compound over time. A single operator can often manage multiple CNC machines, compared to the one-to-one ratio typical with manual bending. This labor efficiency becomes increasingly valuable as skilled operators become harder to find and more expensive to retain.

Working with an experienced manufacturer like Hines Bending Systems helps optimize these calculations. With more installations worldwide than any other manufacturer, Hines has the expertise to help you identify the right balance of capability and cost for your specific applications. Their custom solutions ensure you’re not paying for features you don’t need while guaranteeing you have the capacity for future growth.

Tips to Score the Best Deal Without Sacrificing Quality

Getting the best CNC tube bender price doesn’t mean settling for inferior quality. Smart buyers know how to negotiate effectively while ensuring they get equipment that delivers long-term value.

Timing makes all the difference when it comes to equipment purchases. Manufacturers like Hines Bending Systems often offer year-end incentives to meet sales targets, and trade show periods present excellent opportunities for special pricing and package deals. The key is being ready to move when these opportunities arise.

Demo bends are your secret weapon in negotiations. Request demonstration bends using your actual materials and specifications. This proves the machine’s capability and gives you solid negotiating leverage if performance doesn’t meet expectations. At Hines Bending Systems, we encourage customers to test our equipment thoroughly because we’re confident in our superior quality and precision.

Don’t overlook trade-in opportunities if you have existing equipment. Even older machines may have value for their raw materials or components. This can significantly reduce your net investment and make upgrading to a higher-quality system more affordable.

Financing options often provide better terms than traditional business loans. Many manufacturers offer specialized equipment financing, and some even provide 0% financing promotions that can dramatically reduce your total cost of ownership. These programs make it easier to invest in premium equipment that delivers better long-term value.

Grant and incentive programs shouldn’t be ignored either. Manufacturing equipment purchases may qualify for tax incentives, depreciation benefits, or economic development grants. Research available programs in your area – they can make the difference between settling for basic equipment and investing in a premium solution.

Checklist Before You Sign

Before finalizing any purchase, you need to verify these critical points to protect your investment:

Specification matching ensures the machine meets all your current and anticipated future requirements. Service network availability confirms local service and response times – crucial for minimizing downtime. Software licenses need clarification on what’s included and ongoing costs. Warranty coverage should be reviewed carefully for terms and exclusions. Training inclusion varies by manufacturer, so clarify what’s included versus what costs extra. Delivery timeline confirmation helps you plan production schedules around equipment arrival.

When you work with Hines Bending Systems, you’re partnering with the #1 worldwide manufacturer of tube benders. Our extensive expertise and record number of installations worldwide mean we understand exactly what you need to succeed. We’ve supplied everyone from NASA to local fabrication shops, and our custom solutions approach ensures you get equipment that fits your specific requirements perfectly.

The difference between a good deal and a great investment often comes down to the manufacturer’s commitment to your success. At Hines Bending Systems, we don’t just sell equipment – we provide comprehensive solutions that include training, ongoing support, and the peace of mind that comes from working with industry leaders.

Frequently Asked Questions about CNC Tube Bender Price

Why do prices vary so much?

The CNC tube bender price landscape can feel like a maze, but there’s solid reasoning behind the wide variations you’ll encounter. Think of it like comparing a basic pickup truck to a NASA-grade rover – both move things from point A to point B, but the engineering and capabilities are worlds apart.

Entry-level machines keep costs down by using simpler components and streamlined designs. These work great for basic applications, but they’re not built for the precision and durability that demanding industries require. At the other end of the spectrum, premium systems like those from Hines Bending Systems incorporate aerospace-grade components, advanced software, and extensive testing protocols that justify their higher investment.

The manufacturing origin plays a huge role too. Established manufacturers with decades of experience and worldwide service networks naturally command higher prices than budget alternatives with limited support. But here’s the thing – when you’re dealing with companies like Hines, who supply bending machines to NASA and other critical applications, you’re paying for expertise that simply can’t be replicated overnight.

Quality costs more upfront but saves money over time. Cheaper machines might seem attractive initially, but they often require more frequent repairs, produce more scrap, and lack the precision needed for demanding applications. When your production depends on reliability, investing in proven technology makes financial sense.

What size bender do I really need?

This is where many buyers either overspend or paint themselves into a corner. The sweet spot is sizing your machine for your largest current tube diameter plus 20-30% for future growth. Going much beyond that often means paying for capacity you’ll never use, while undersizing limits your business opportunities.

But diameter is just one piece of the puzzle. Wall thickness, material type, and bend radius requirements all factor into machine selection. Stainless steel behaves differently than aluminum, and tight radius bends require different tooling than gentle curves. These details matter more than you might think.

This is exactly why working with experienced manufacturers like Hines Bending Systems becomes invaluable. With more bender installations worldwide than anyone else, they’ve seen every possible application scenario. Their engineers can analyze your specific requirements and recommend the right machine configuration – not the most expensive one, but the one that delivers optimal results for your applications.

Don’t guess on capacity requirements. A quick consultation with Hines’ technical team can save you thousands of dollars and prevent costly mistakes. They’ll consider factors you might not even think about, ensuring your chosen machine handles all your current and anticipated future needs efficiently.

Is it cheaper to finance or buy outright?

The financing versus cash decision depends on your specific situation, but there are some clear guidelines that can help you decide. Equipment financing often provides tax advantages through depreciation schedules and may preserve working capital for other critical business needs.

Cash purchases eliminate interest costs and provide immediate ownership, which appeals to many business owners. However, you need to consider the opportunity cost – could that cash generate better returns if invested elsewhere in your business? Sometimes paying interest on equipment financing makes sense if it frees up capital for high-return opportunities.

Many manufacturers, including Hines Bending Systems, offer promotional financing rates that can make financing more attractive than cash purchases. These special programs often feature low or zero-interest terms that essentially give you free money to invest in productivity improvements.

The key is calculating total cost of ownership rather than just focusing on monthly payments. A slightly higher-priced machine from a quality manufacturer like Hines might cost more initially but deliver better long-term value through superior reliability, lower maintenance costs, and better resale value. Their machines are built to last decades, not just years, which changes the financial equation significantly.

Consider your cash flow patterns too. Financing can smooth out the investment over time, making it easier to budget for other business needs. Just make sure you understand all terms and conditions before signing any agreements.

Conclusion

Making the right CNC tube bender price decision isn’t just about finding the lowest number on a quote sheet. It’s about understanding the total value equation – balancing upfront costs with long-term productivity, reliability, and support. The machine you choose today will shape your manufacturing capabilities for the next decade or more.

Here’s what we’ve learned: entry-level machines serve their purpose for basic applications, but growing businesses quickly outgrow their limitations. Mid-range systems offer the sweet spot for most manufacturers, while high-end machines deliver the precision and capacity that demanding applications require. The key is matching your investment to your actual needs, not just your current budget.

The difference between a good purchase and a great one often comes down to your partner. At Hines Bending Systems, we’ve built our reputation as the #1 worldwide manufacturer of tube benders by understanding that every customer faces unique challenges. When NASA needs precision bending solutions, they turn to us. When small fabrication shops need reliable equipment that won’t break the bank, they call us too.

What sets us apart isn’t just our machines – it’s our approach. We don’t believe in one-size-fits-all solutions because we know your business isn’t one-size-fits-all. Our team takes the time to understand your specific applications, production volumes, and budget constraints. Then we work with you to develop a custom solution that delivers exactly what you need.

Quality doesn’t have to mean overpaying. Our extensive experience means we can often suggest configurations that save money while actually improving performance. We’ve helped thousands of companies find that perfect balance between capability and cost, and we’re confident we can do the same for you.

The investment you’re considering represents more than just new equipment – it’s an investment in your company’s future. With our comprehensive training programs, global service network, and commitment to ongoing support, you’re not just buying a machine. You’re gaining a partner who’s invested in your success.

Don’t let budget constraints limit your potential or rush you into a decision you’ll regret. Contact Hines Bending Systems today to discuss how we can provide a custom solution that fits both your needs and your budget. With our best expertise and commitment to customer success, we’ll help you make an investment that pays dividends for years to come.