Why Your Bender is the Most Critical Tool in Roll Cage Fabrication

Tubing benders for roll cages are the backbone of automotive safety fabrication. When lives depend on structural integrity, your choice of bending equipment can mean the difference between a cage that protects and one that fails when it matters most.

Top Tubing Benders for Roll Cage Fabrication:

- CNC Tube Benders – Highest precision and repeatability for complex multi-plane bends

- Rotary Draw Benders – Best for tight radius bends with minimal deformation

- Mandrel Benders – Essential for thin-wall tubing to prevent collapse

- Hydraulic Benders – Powerful enough for thick-wall DOM and chromoly materials

Key Requirements:

- Handle 1.5″ to 2.5″ diameter tubing

- Bend DOM, chromoly, and mild steel

- Achieve tight centerline radius (CLR) ratios

- Maintain structural integrity through precise tooling

As Joel Buschman from Overkill Racing noted about his experience: “I’ve bent miles of tube with my bender and it has never let me down.” This reliability becomes critical when fabricating safety equipment that must meet strict racing organization standards like NHRA, SCCA, and FIA requirements.

The difference between amateur and professional roll cage fabrication often comes down to equipment quality. Inferior benders create weak points through tube deformation, inconsistent angles, and poor repeatability. These flaws don’t just fail tech inspection – they compromise driver safety.

Manufacturing operations managers understand that precision bending requires three elements: rigid machine construction, high-quality tooling, and expert support. When your production depends on creating consistently safe roll cages, choosing the right bending partner becomes as critical as the steel itself.

Common tubing benders for roll cages vocab:

Key Considerations When Selecting Tubing Benders for Roll Cages

Choosing the right tubing benders for roll cages isn’t just about making any bend – it’s about making bends that could save someone’s life when everything goes wrong on the track. The difference between a quality machine and a mediocre one shows up in every curve, every angle, and ultimately, in the structural integrity that keeps drivers safe.

At Hines Bending Systems, we’ve been helping fabricators make this critical decision for decades. As the #1 worldwide manufacturer of tube and pipe benders, we understand that your choice of equipment is more than an investment – it’s a commitment to safety and quality that will define your work for years to come.

When evaluating tubing benders for roll cages, five key factors separate professional-grade equipment from everything else: bending capacity, tooling quality, machine rigidity, accuracy, and repeatability. These aren’t just technical specifications on a datasheet – they’re the foundation of every safe, competition-ready roll cage that rolls out of your shop.

Our team works directly with fabricators to understand their unique needs, whether they’re building cages for weekend warriors or supplying major racing organizations. The same precision that makes our machines trusted by NASA and top government agencies ensures your roll cages meet the most demanding safety standards. For guidance on making the right choice for your operation, explore our comprehensive guide on What to Know About Buying a Metal Tube Bender for Sale.

Capacity and Material Compatibility (DOM, Chromoly, Mild Steel)

The first question every serious fabricator asks is simple: “Will this machine handle what I need to bend?” For roll cage work, you’re typically dealing with tube diameters from 1.5″ to 2.5″ with varying wall thicknesses, and three primary materials that each demand different approaches.

Mild steel might seem like the easy choice – it’s forgiving and bends without much fuss. But when you step up to DOM tubing, you’re entering territory where machine power and precision tooling become critical. DOM’s consistent wall thickness and superior strength make it a favorite for serious safety applications, but it demands a bender that won’t compromise under pressure.

Then there’s 4130 Chromoly – the material that separates the pros from the hobbyists. This high-strength alloy doesn’t just bend; it fights back with springback characteristics that can frustrate even experienced fabricators. Chromoly demands a machine with serious rigidity and the power to maintain control throughout the entire bending process.

Here’s where Hines machines shine. Our engineers have decades of experience working with these challenging materials, and our equipment is built to handle the demands of chromoly bending without breaking a sweat. The superior machine rigidity that makes our benders trusted by aerospace applications translates directly to consistent, accurate bends in the toughest materials.

Understanding material properties becomes crucial when safety is on the line. Cold Drawn Seamless (CDS) tubing offers the strength-to-weight ratio and weldability that racing organizations demand, but it requires equipment that can maintain precision under the higher forces needed for bending. Our Steel Tube Benders for Sale are specifically engineered to excel with these high-performance materials, ensuring your cages exceed safety regulations rather than just meeting them.

The Crucial Role of Dies and Tooling

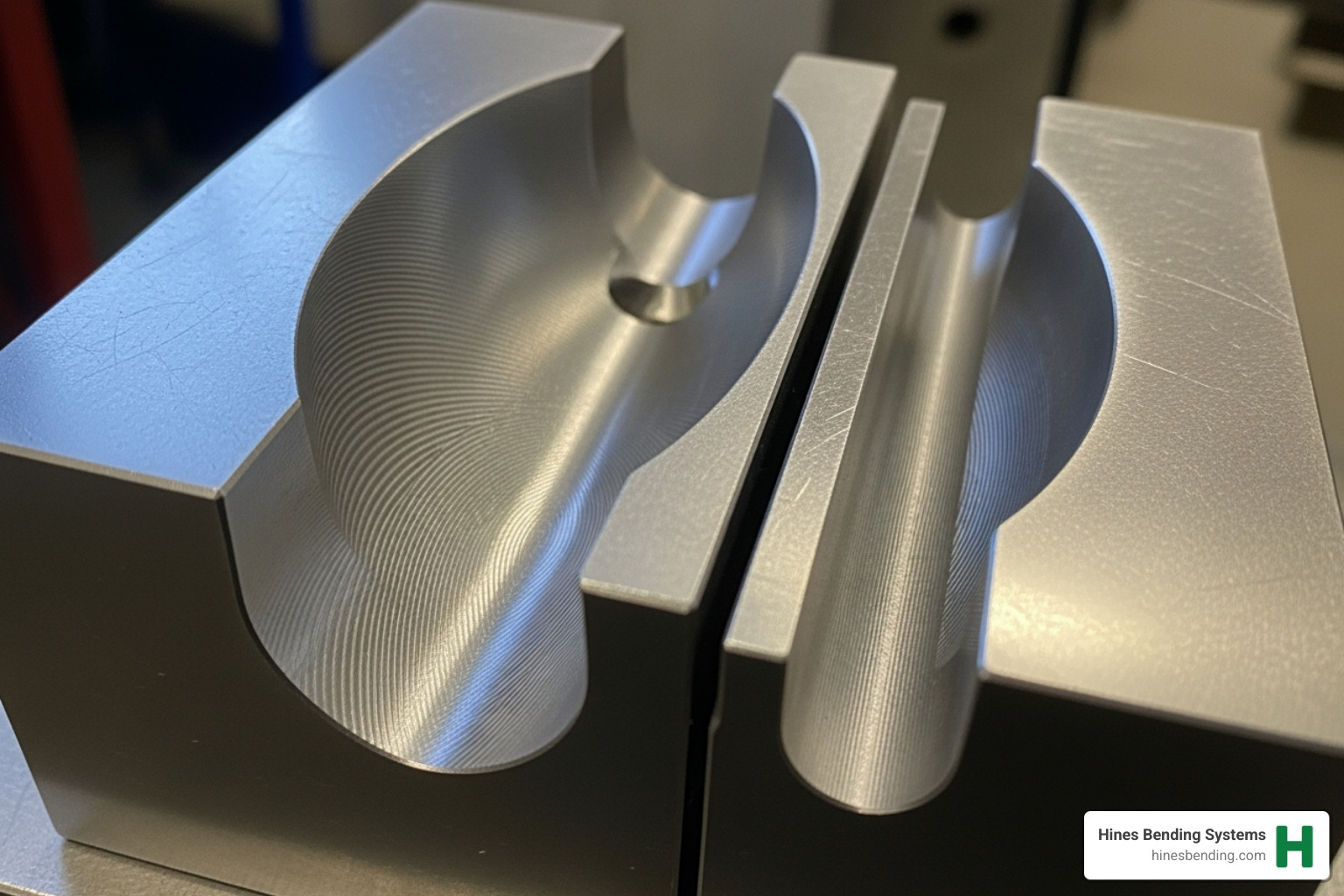

Think of your die set as the heart of your bending operation – everything else is just supporting equipment. A precision-machined die set includes the bend die, clamp die, and pressure die, all working together like a well-rehearsed team to shape your tubing without compromising its structural integrity.

The Center Line Radius (CLR) of your bend die determines how tight you can make your bends while maintaining the tube’s strength. For roll cage applications, specific CLRs aren’t just preferences – they’re often requirements that determine whether your cage passes tech inspection and, more importantly, performs when it matters most.

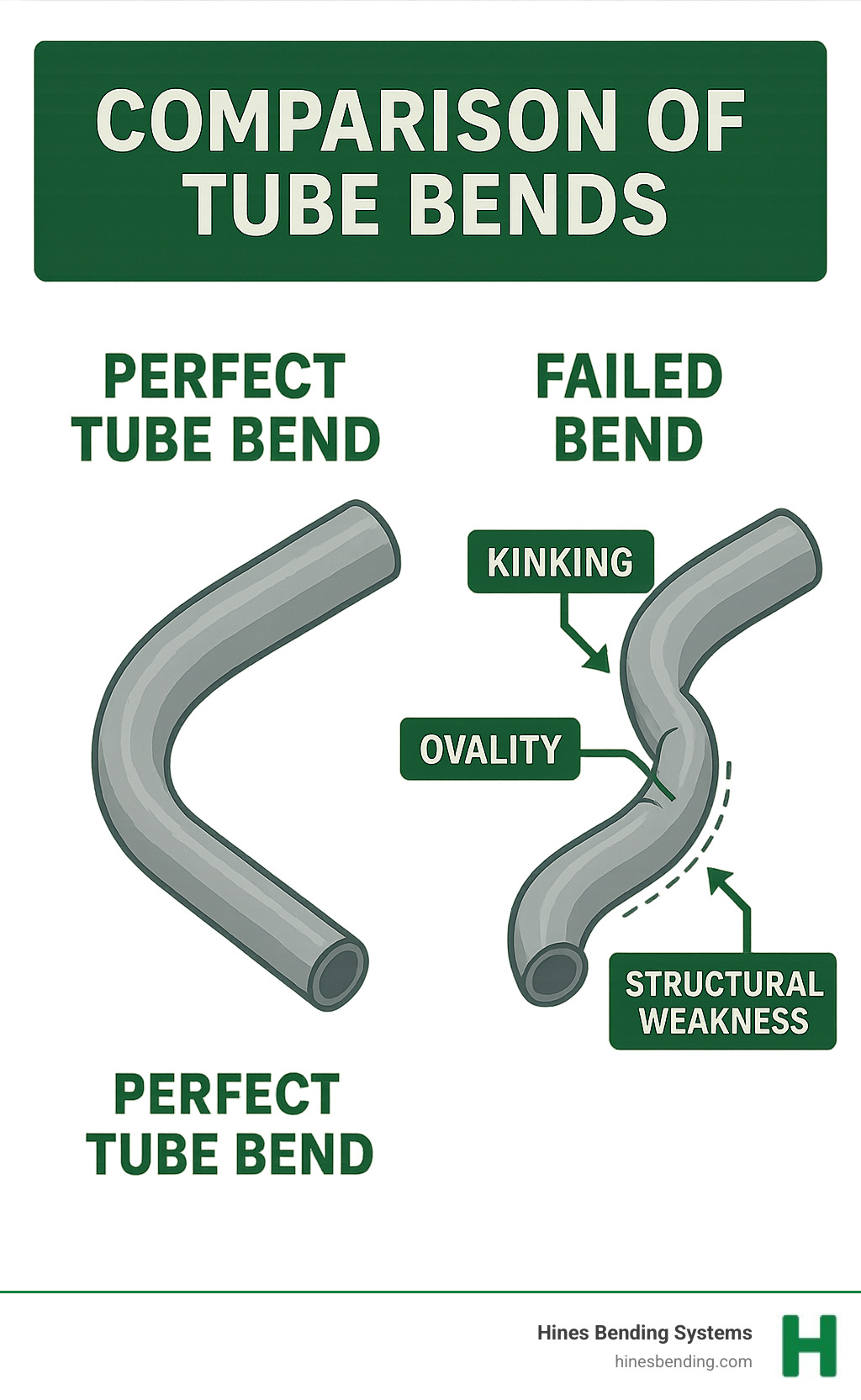

This is where the quality difference becomes obvious. Inferior dies create weak points through inconsistent contact, leading to ovality, kinking, and the kind of structural compromises that can turn a safety device into a liability. At Hines, our dies are machined to aerospace standards because we know that precision at this level translates directly to safety in your finished cage.

The investment in high-quality tooling pays dividends in every bend. Consistent contact means consistent results. Precision machining means predictable performance. And when you’re building safety equipment, predictability isn’t just nice to have – it’s essential.

Our comprehensive range of Tube and Pipe Bender Accessories ensures you have the right tools for every application. Because when lives depend on your work, “good enough” isn’t good enough.

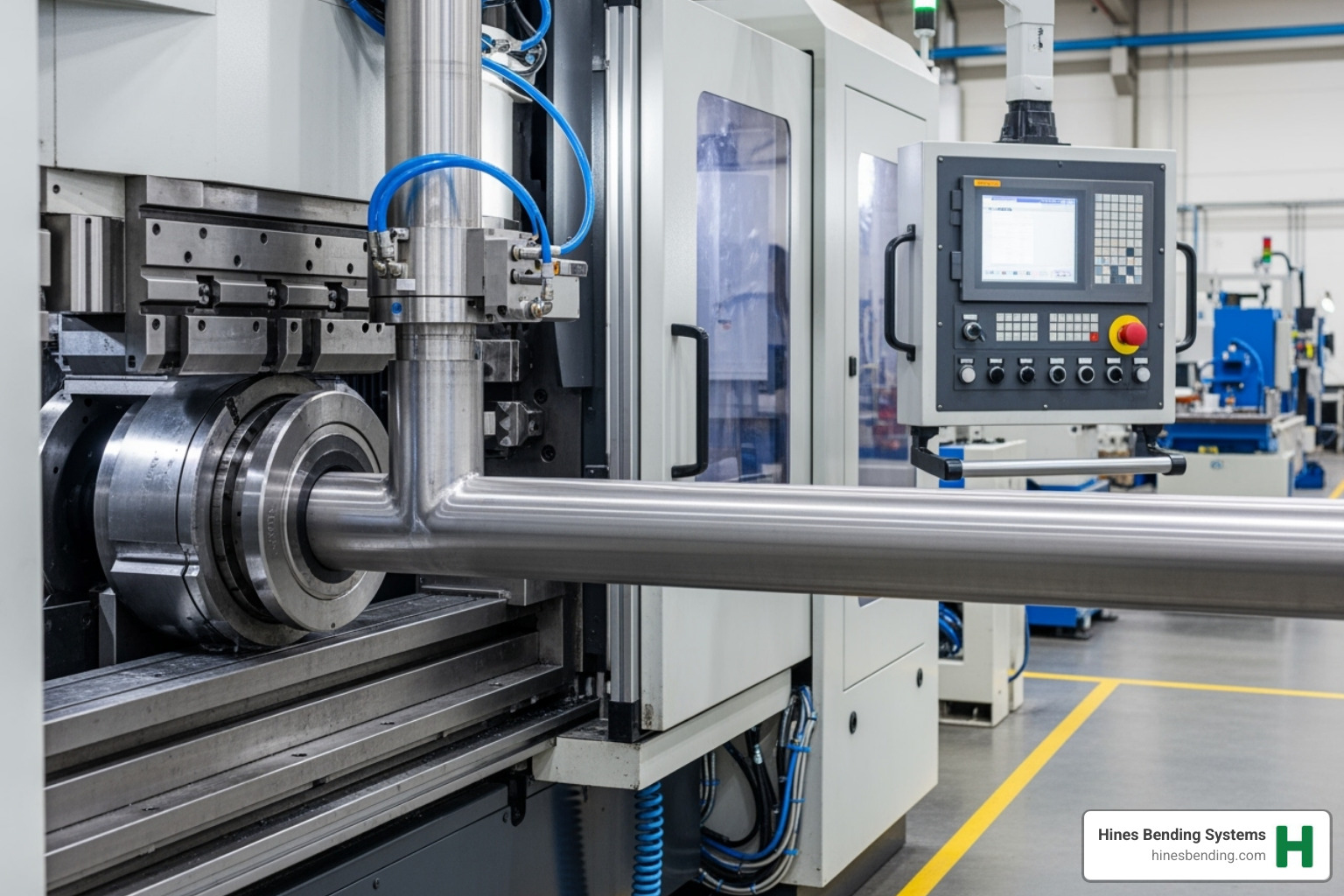

Precision, Repeatability, and the CNC Advantage

Building symmetrical cages with exact angles isn’t just about looking professional – it’s about ensuring that every structural member performs exactly as designed when forces try to crush the cage. Manual benders with degree stops might get you close, but “close” doesn’t cut it when safety is non-negotiable.

CNC benders transform roll cage fabrication from an art into a science. With programmable controls, you can specify exact bend angles, rotation, and spacing between bends, then reproduce those specifications perfectly across multiple cages. This repeatability becomes crucial when you’re building multiple cages for a racing series or need to replace damaged sections with components that fit perfectly.

The multi-plane bending capability of advanced CNC systems allows for complex geometries that would be nearly impossible to achieve consistently with manual equipment. More importantly, the ability to store hundreds of programs means you can recall proven designs instantly, eliminating the trial-and-error that wastes material and time.

Digital precision also means dramatic reductions in material waste and fabrication time. When every bend is exactly right the first time, you’re not dealing with scrap material or rework. Your efficiency increases, your costs decrease, and your reputation for quality grows.

At Hines, our Precision Pipe Bending solutions represent the pinnacle of bending technology. The same precision that makes our machines indispensable to aerospace applications ensures that your roll cages meet the most demanding specifications with unwavering consistency.

Hines Bending Systems: The Industry Leader in Roll Cage Fabrication

When you’re searching for tubing benders for roll cages, you’re not just buying a machine – you’re choosing a partner who understands that lives depend on every bend. At Hines Bending Systems, we’ve spent decades earning our reputation as the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders. This isn’t just a title we claim; it’s a position we’ve earned through relentless dedication to quality and innovation.

Here’s something that might surprise you: NASA trusts us with their bending needs. When the world’s most demanding space agency needs precision bending equipment, they turn to Hines. We supply massive agencies and companies like NASA because when failure isn’t an option, our machines deliver. If our equipment is good enough for rocket science, imagine what it can do for your roll cage fabrication.

Our global leadership isn’t accidental. We’ve installed more bending machines worldwide than anyone else, giving us best insight into what works across different industries, climates, and applications. This experience translates directly into better machines for your shop. Learn more about our industry standing at The Best Bending Machine Manufacturers.

Why Hines Bending Machines Set the Standard

What makes a Hines machine different? It starts with our uncompromising approach to quality. While others might cut corners to hit price points, we build every machine to withstand decades of demanding use. Our rigorous quality assurance process means your machine arrives ready to produce perfect bends from day one.

Innovation drives everything we do. Our engineering team continuously develops breakthrough technologies like the Dual Stack CNC Push Bender and advanced Roll Bender systems. These aren’t just fancy names – they’re solutions that address real-world fabrication challenges you face every day.

Why Induction Bending Gives You an Edge

While cold-bend technologies handle the majority of roll-cage work, many industries need to form large outside-diameter or thick-wall material that simple draw bending can’t touch. That’s where Hines’ induction benders come in. By locally heating just the section being bent and then immediately quenching and controlling the radius, our induction systems:

- Easily accommodate pipe and tube up to 36″ OD and beyond

- Maintain wall thickness with minimal thinning or ovality—even on heavy-wall material

- Produce large-sweep bends in a single smooth motion, eliminating the need for multiple weld joints

- Deliver tight dimensional tolerances with virtually no springback

The result is stronger, cleaner bends for critical applications in oil & gas, infrastructure, and architectural fabrication—capabilities that cheaper, traditional machines simply can’t match.

The superior tooling we provide works in perfect harmony with our machines. Remember how critical dies are for roll cage bending? Our precision-engineered tooling ensures every bend maintains structural integrity while meeting the tightest tolerances.

But here’s what really sets us apart: nobody in the bending machine industry has more expertise and experience than Hines. When you call with a challenging bend or unusual material requirement, you’re talking to people who’ve solved similar problems thousands of times before. This depth of knowledge becomes your competitive advantage.

Our complete line of Tube and Pipe Benders represents decades of refinement and real-world feedback from fabricators just like you.

Custom Solutions and Client Collaboration

Every shop is different, and cookie-cutter solutions rarely deliver optimal results. That’s why working directly with our clients is fundamental to how we operate. We don’t just ask what size tube you’re bending – we want to understand your complete fabrication process, your quality requirements, and your production goals.

Our team of experts brings unparalleled experience to understanding your unique project requirements. Whether you’re building single roll cages or running production lines, we analyze every aspect of your needs. Maybe you need to bend an unusual radius, work with a specific material, or integrate seamlessly with existing equipment.

Engineering custom bender solutions is where Hines truly shines. We’ve solved bending challenges that others said were impossible. Our collaborative approach means you get exactly the machine you need, not just what happens to be available. Ready to discuss your specific requirements? Contact Hines for Custom Solutions and let’s create something exceptional together.

Training, Support, and Long-Term Partnership

Buying a Hines machine is just the beginning of our relationship. We believe that comprehensive training is essential for maximizing your investment. Our experts work directly with your team, covering everything from basic operation to advanced techniques that improve both quality and efficiency.

Ongoing support means you’re never alone when challenges arise. Our customer service team understands bending machines inside and out because that’s all we do. Whether you need troubleshooting help, maintenance guidance, or advice on tackling a new project, we’re here to help.

This commitment to maximizing efficiency and safety extends throughout your machine’s lifetime. We provide resources, updates, and expert consultation that keeps your operation running smoothly. Our Tube and Pipe Bender Training programs ensure your team stays current with best practices and new techniques.

When you choose Hines, you’re not just buying equipment – you’re gaining a partner committed to your long-term success.

Advanced Bending Concepts for Flawless Roll Cages

Creating a truly flawless roll cage requires mastering advanced bending techniques that go far beyond basic tube manipulation. When you’re fabricating safety equipment that could save a driver’s life, every bend must maintain perfect structural integrity while avoiding the common defects that turn quality steel into expensive scrap.

The difference between amateur and professional roll cage work often comes down to understanding these advanced concepts. Ovality, wall thinning, and kinking aren’t just aesthetic problems – they’re structural weaknesses that can cause catastrophic failure under stress. That’s where decades of Hines expertise becomes invaluable.

At Hines, we’ve spent years perfecting these advanced techniques, working with everyone from small fabrication shops to NASA engineers. Our deep understanding of materials, tooling precision, and machine capabilities allows us to guide clients through even the most challenging bending applications. When you’re working with expensive chromoly or need to achieve tight radii without compromising strength, having the right expertise makes all the difference.

Understanding the terminology and science behind quality bending is crucial for any serious fabricator. Our comprehensive Tube and Pipe Bending Industry Terms resource provides the foundation you need to communicate effectively about your bending requirements.

The Hines Advantage in Mandrel Bending and Precision

Think of mandrel bending like supporting a garden hose while you bend it around a corner – without that internal support, the hose would kink and collapse. Mandrel bending works on this same principle, using a precisely engineered internal support system that prevents tube deformation during the bending process.

This technique becomes absolutely critical when working with thin-wall tubing or tight radii common in modern roll cage designs. The mandrel, inserted into the tube before bending, provides internal support that prevents the tube walls from collapsing inward or developing the dreaded “kink” that destroys structural integrity.

For roll cage applications, mandrel bending delivers several crucial advantages:

The outer wall maintains consistent thickness instead of stretching dangerously thin. The inner wall stays smooth without the wrinkles that create stress concentration points. The tube’s cross-section remains perfectly round, preserving its maximum strength properties. Most importantly, you achieve bends that meet strict racing organization requirements for structural integrity.

Our specialized Hines mandrel bending equipment represents the pinnacle of this technology. We’ve engineered our machines to deliver the precise control needed for safety-critical applications, ensuring that every bend maintains the full structural properties of your premium materials. When you’re investing in expensive chromoly tubing, you can’t afford to compromise with inferior bending techniques.

The precision we achieve with our mandrel bending systems isn’t just about aesthetics – it’s about creating roll cages that perform exactly as engineered when subjected to impact forces. Explore our Mandrel Tube Bender for Sale to see how we can lift your fabrication capabilities to professional levels.

Common Mistakes to Avoid When Bending Tubing for Roll Cages

Even experienced fabricators can fall into costly traps when bending tubing for roll cages. Understanding these pitfalls before they happen can save you thousands in wasted materials and countless hours of frustration.

Using inadequate equipment tops the list of expensive mistakes. We’ve seen fabricators attempt roll cage work with benders designed for exhaust pipes or simple structural work. These machines lack the rigidity and precision needed for safety-critical applications, inevitably producing bends with compromised structural integrity.

Incorrect die selection creates problems that often don’t become apparent until you’re deep into a project. Dies that don’t precisely match your tube diameter or desired centerline radius will cause deformation, no matter how carefully you operate the machine. Worn dies are equally problematic, creating inconsistent results that make symmetrical cage construction nearly impossible.

Poor material clamping might seem minor, but it leads to tube slippage during bending. This creates inconsistent angles and can damage both your expensive tubing and your bender’s tooling. Professional-grade clamps and proper setup procedures eliminate this entirely preventable problem.

Springback miscalculation catches many fabricators off guard, especially when working with high-strength materials like chromoly. All metals want to return partially to their original shape after bending. Failing to compensate for this phenomenon results in under-bent parts that won’t fit your cage design properly.

Material stretch and compression occur naturally during bending but must be controlled. The outer radius stretches while the inner radius compresses, potentially creating weak points if not properly managed through correct tooling and technique.

Racing forums like Bending Roll Cage – Help Needed are filled with fabricators struggling with these exact issues. The solution isn’t just better technique – it’s partnering with experts who understand both the science and the practical application of advanced bending concepts.

At Hines, we don’t just sell you equipment and walk away. We share the expertise gained from decades of solving complex bending challenges, ensuring that your investment in quality tubing benders for roll cages delivers the results your safety-critical applications demand.

Frequently Asked Questions about Tubing Benders for Roll Cages

When it comes to tubing benders for roll cages, we hear the same questions time and again from fabricators who understand that safety isn’t negotiable. These aren’t just technical inquiries – they’re questions from people who know that the difference between a quality bend and a catastrophic failure could mean someone’s life.

Let’s tackle the most common concerns we encounter, with answers that come from decades of experience supplying bending solutions to everyone from weekend racers to NASA.

What type of bender is best for chromoly tubing?

Here’s the thing about chromoly – it’s incredibly strong, which is exactly why you want it in your roll cage. But that strength comes with a challenge: significant springback. When you bend chromoly, it wants to return to its original shape, fighting you every step of the way.

You need a bender that’s incredibly rigid, powerful, and equipped with high-quality tooling to handle chromoly’s demanding characteristics. Anything less, and you’ll be dealing with inconsistent angles, material stress, and potentially compromised safety.

For the highest precision and repeatability, a CNC Tube Bender from Hines is your best bet. Our machines are specifically engineered to handle chromoly’s stubborn nature, ensuring you get accurate bends without compromising the material’s structural integrity. When NASA trusts us with their bending needs, you can trust us with yours.

Can I build a race-compliant roll cage with a low-quality bender?

Let’s be blunt: attempting to build a race-compliant roll cage with inferior equipment is like trying to perform surgery with a butter knife. It’s not just challenging – it’s downright dangerous.

Sanctioning bodies like the SCCA and NHRA don’t create their strict regulations for fun. These standards exist because lives depend on them. They specify everything from material types to wall thicknesses to bend quality, and for good reason.

Inferior equipment creates weak points through kinking, flattening, inconsistent angles, and material thinning. These flaws don’t just lead to failed tech inspections – they create catastrophic failure points that could collapse when a driver needs protection most.

Hines machines are engineered to meet and exceed these stringent standards. We’ve spent decades perfecting our technology because we understand that when it comes to safety equipment, “good enough” simply isn’t good enough.

How important is manufacturer support and training?

Here’s something many people don’t realize: buying a bending machine without proper support is like buying a race car without knowing how to drive. You might have the best equipment in the world, but without the knowledge to use it effectively, you’re setting yourself up for frustration and failure.

At Hines, we don’t just sell you a machine and walk away. We become your partner in success. Our comprehensive Tube and Pipe Bender Training ensures you can produce safe, accurate, and repeatable bends efficiently from day one.

Nobody in the bending machine industry has more expertise and experience than Hines. We’ve been perfecting bending technology for decades, and we’re committed to sharing that knowledge with you. Whether you’re troubleshooting an issue, optimizing your processes, or mastering advanced techniques, our expert resources and ongoing support are always available.

This level of support isn’t just valuable – it’s what distinguishes true industry leaders from companies that simply sell equipment. When you’re working on safety-critical applications like roll cages, having access to decades of expertise can make the difference between success and disaster.

Conclusion: Partnering with Hines for Uncompromised Safety and Quality

When it comes to selecting tubing benders for roll cages, you’re not just buying equipment – you’re making a decision that could literally save lives. The capacity, precision, and quality tooling we’ve discussed aren’t just nice-to-have features; they’re absolutely essential for creating roll cages that will protect drivers when everything goes wrong.

Here’s what makes this choice so critical: a roll cage is only as strong as its weakest bend. Every curve, every angle, every joint must meet exacting standards. There’s simply no room for compromise when safety is on the line.

That’s where Hines Bending Systems makes all the difference. As the #1 worldwide manufacturer of tube benders, pipe benders, and induction benders, we’ve earned our reputation through decades of delivering uncompromising quality. When NASA needs bending equipment for their missions, they turn to Hines. When racing teams need cages that will pass the strictest tech inspections, they choose Hines.

Our expertise runs deeper than anyone else in the industry. We don’t just manufacture machines; we engineer solutions. Every Hines bender is built with superior quality components and innovative technology that sets the global standard. Our Dual Stack CNC Push Bender and Roll Bender represent the cutting edge of what’s possible in tube bending technology.

But here’s what really sets us apart: we work directly with you to understand your unique project requirements. Whether you’re building street rods, race cars, or specialized fabrication projects, we’ll engineer a custom bender solution that fits your exact needs. This isn’t about selling you what we have in stock – it’s about creating what you need to succeed.

The Hines difference extends far beyond the sale. Our comprehensive training programs and ongoing support ensure you can maximize your machine’s potential from day one. With our expert resources and dedicated support team, you’re never alone in your fabrication journey.

For a task as critical as roll cage fabrication, don’t leave quality to chance. Partner with the experts who set the global standard. Explore our complete line of Tube and Pipe Benders to find the perfect, customized solution for your fabrication needs.