Why Smart Manufacturers Choose Pre-Owned Bending Equipment

A used pipe bending machine offers manufacturing operations managers a proven path to cost-effective production without sacrificing precision or reliability. With the secondary market showing over 200 active listings and prices ranging from $820 to $51,000, smart buyers can find quality equipment at significant savings.

Quick Guide to Used Pipe Bending Machine Shopping:

- Manual/Hydraulic Models: $15-$5,000 (perfect for small to medium production)

- CNC Systems: $15,000-$50,000+ (ideal for high-volume, precision work)

- Key Inspection Points: Hydraulic systems, electrical controls, bend accuracy, maintenance records

- Best Sources: Machinery dealers, online marketplaces, industrial auctions

- Documentation Needed: Service history, tooling inventory, operation manuals

The used equipment market has grown robust, with established brands retaining strong value. For example, a 2009 Wortelboer PBM6 still commands around $39,000, proving that quality machines hold their worth.

Why consider pre-owned over new? Three main reasons drive this decision:

- Immediate availability – no 6-12 month lead times

- Proven performance – machines with documented production history

- Budget efficiency – 40-60% savings compared to new equipment prices

However, success depends on thorough evaluation. Manufacturing operations face enough challenges without inheriting someone else’s maintenance problems. The key lies in understanding what to inspect, where to source, and how to verify a machine’s true condition.

While the secondary market offers compelling opportunities, working with experienced professionals ensures you get equipment that meets your specific bending requirements and production goals.

Simple used pipe bending machine word guide:

– industrial pipe benders

– precision tube bender

– bending machine suppliers

What Is a Used Pipe Bending Machine?

A used pipe bending machine is pre-owned equipment that shapes pipes and tubes into precise angles and curves for countless industrial applications. Think of it as the workhorse that transforms straight metal into the curved components you see everywhere—from car exhaust systems to the complex piping aboard NASA spacecraft.

The beauty of these machines lies in their versatility. Whether you’re working with thin-walled tubing for aerospace applications or heavy-duty pipes for construction projects, there’s a bending solution that fits. The key difference between pipe and tube bending comes down to application: pipes typically carry fluids and focus on flow capacity, while tubes emphasize structural strength and exact dimensions.

Understanding the science behind bending helps explain why quality matters so much. Scientific research on bending force reveals that successful bending requires precise control over material stress. Too little force and you get incomplete bends. Too much and you risk buckling, wrinkling, or dangerous wall thinning that compromises structural integrity.

This is where Hines Bending Systems’ expertise becomes invaluable. With more bender installations worldwide than any other manufacturer, we understand exactly how different materials behave under bending stress—knowledge that helps our clients choose the right used equipment for their specific needs.

Main Types of used pipe bending machine

Manual lever benders represent the entry point into pipe bending, typically available used for under $300. These hand-operated tools work perfectly for electrical conduit and basic plumbing modifications. While simple, they require proper technique to achieve consistent results.

Hydraulic ram systems dominate the used equipment market between $1,000 and $5,000. These machines harness hydraulic pressure to generate consistent bending force, making them ideal for medium-production requirements. Popular 12-ton and 2-ton hydraulic models frequently appear in equipment listings, offering reliable performance when properly maintained.

Electric servo-driven units bring precision control through advanced motor systems, typically ranging from $3,000 to $15,000 used. These machines excel when repeatability matters most, delivering faster cycle times and consistent accuracy.

CNC multi-axis systems represent the premium category, commanding $15,000 to $50,000+ in the used market. These computer-controlled powerhouses perform complex bending sequences with minimal operator intervention. Features often include programmable sequences, automatic tool changes, and integrated quality control—capabilities that Hines Bending Systems pioneered in the industry.

How industries deploy a used pipe bending machine

Automotive manufacturers drive enormous demand for used bending equipment, shaping everything from exhaust systems to chassis components. The tight packaging constraints in modern vehicles require precise bending that meets both performance and space requirements.

HVAC contractors frequently invest in used hydraulic and manual benders for custom ductwork fabrication. The ability to bend pipes on-site provides flexibility and reduces material waste significantly.

Construction projects use used pipe bending machines for structural applications, handrails, and utility installations. The portability of smaller used units makes them perfect for job-site work where fabrication shop access is limited.

Shipbuilding operations often source used heavy-duty benders for hull piping and structural components. The marine environment demands corrosion-resistant materials that require specialized bending techniques to maintain material properties.

Aerospace manufacturing represents perhaps the most demanding application, where even used equipment must meet extraordinary quality standards. Companies like NASA trust Hines Bending Systems precisely because we understand these critical requirements. The cost savings of properly certified used machines can be substantial while maintaining the precision aerospace applications demand.

At Hines Bending Systems, we’ve seen every type of bending challenge across these industries. Our expertise helps customers identify not just any used pipe bending machine, but the right machine for their specific application and production goals.

Advantages & Key Considerations Before You Buy

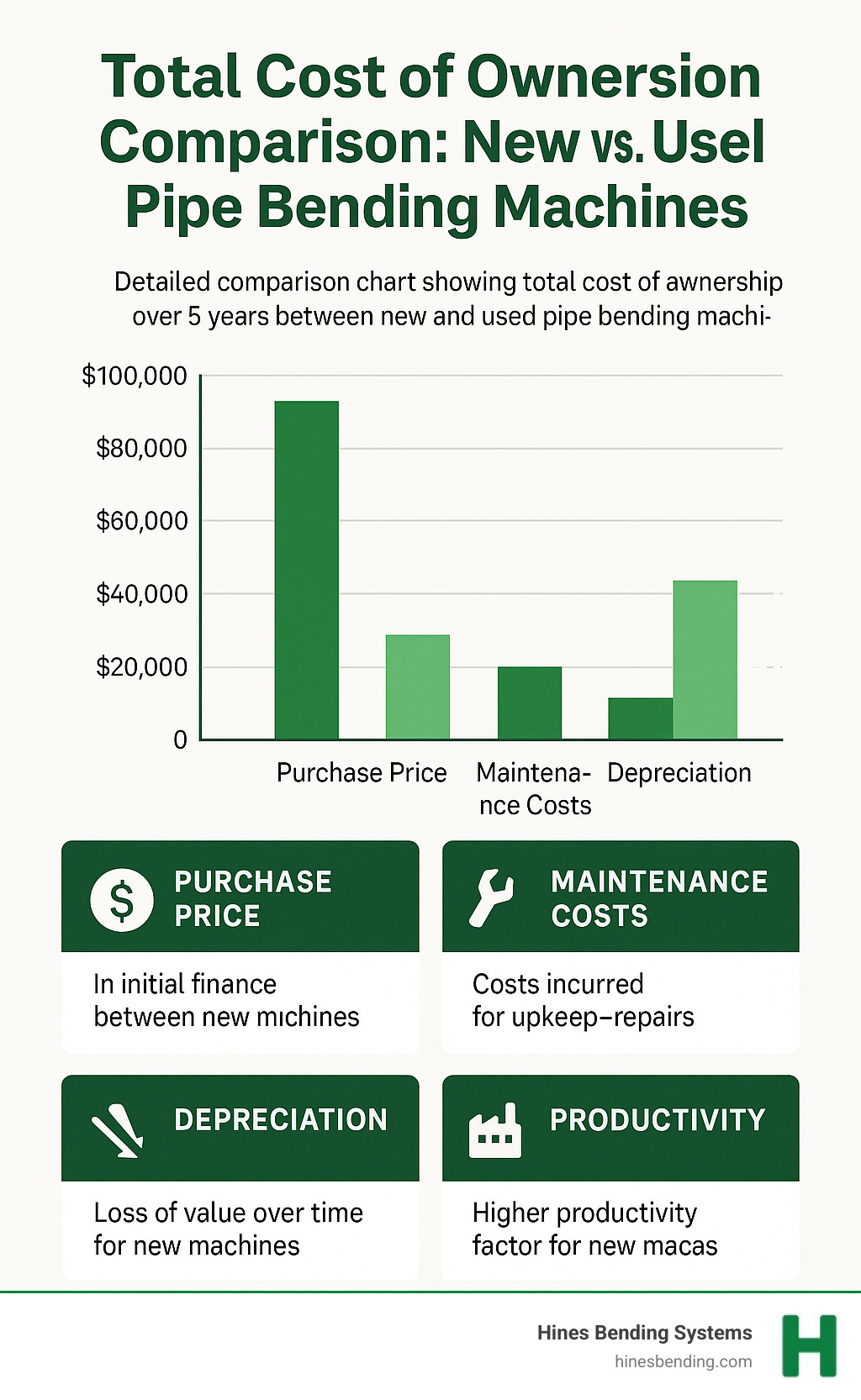

Let’s be honest about the numbers – a used pipe bending machine typically costs 40-60% less than new equipment. That’s not just pocket change; we’re talking about savings of $20,000 to $100,000+ that you can invest in better tooling, operator training, or facility improvements.

The immediate availability factor often seals the deal for many manufacturers. While new equipment orders can stretch 6-12 months, you can often inspect, purchase, and install a quality used machine within weeks. When production demands don’t wait, this timeline advantage becomes invaluable.

Depreciation patterns actually work in your favor when buying used. Well-maintained machines from established manufacturers hold their value remarkably well. That 2009 Wortelboer PBM6 still commanding $39,000 proves that quality equipment doesn’t just disappear in value – it maintains worth through proven performance.

However, tooling compatibility can make or break your investment. If your existing die sets and mandrels fit the used machine, you’ve just saved thousands more. This compatibility factor often determines whether a particular used machine makes financial sense for your operation.

Service history documentation separates the gems from the headaches. Complete maintenance records, regular service intervals, and documented repairs provide the confidence you need for future reliability. Think of it as a machine’s medical records – you want to see a clean bill of health.

Benefits of choosing a used pipe bending machine

The budget-friendly acquisition advantage goes beyond the sticker price. Those substantial savings free up capital for other critical investments in your operation. Instead of stretching your budget thin on new equipment, you can allocate funds to improved tooling, comprehensive operator training, or facility improvements that boost overall productivity.

Quick delivery eliminates the painful waiting game. Production schedules don’t accommodate 6-12 month lead times, and emergency replacements certainly can’t wait. Used machines often ship within days or weeks, keeping your operations moving forward.

Proven performance offers something new machines can’t – a documented track record. These machines have already worked through their initial bugs and established reliable operating parameters.

Inspection checklist for a used pipe bending machine

Start your visual wear assessment by examining the critical components that take the most abuse. Ram cylinders, die holders, and frame structures should show normal wear patterns, not excessive damage, cracking, or amateur repairs that could compromise safety or performance.

Bend test procedures provide the ultimate proof of capability. Request sample bends using your specific materials and dimensions. Check for wall thinning, ovality, and surface finish quality. If the machine can’t produce acceptable parts during testing, it won’t magically improve in your shop.

Hydraulic system evaluation requires checking fluid condition, pressure capabilities, and seal integrity. Clean fluid and tight seals indicate proper maintenance, while leaky hydraulics suggest expensive repairs ahead.

Electrical system inspection becomes critical for CNC and servo-driven machines. Verify that control systems function properly, motors operate smoothly, and safety interlocks work as designed.

Software verification ensures the machine handles your specific bending requirements. Check programming options, data storage capabilities, and compatibility with your existing CAD systems.

Maintenance log review tells the real story of how the machine was cared for. Well-documented maintenance suggests responsible ownership and helps predict future service requirements.

Risk mitigation & warranties

Hidden damage represents your biggest risk when buying used equipment. Structural cracks, worn ways, or damaged control systems may not show up during a quick inspection but can require costly repairs later. Take time for thorough evaluation or bring in an expert.

Obsolete controls create long-term headaches. Machines with discontinued control systems face parts availability issues and limited technical support. Research parts availability and technical support options before committing to any purchase.

Spare parts availability varies dramatically between manufacturers and machine ages. Popular brands typically maintain better parts support, while specialized or discontinued models may leave you searching for components.

Certified refurbishers offer a middle ground between used and new equipment. These specialists rebuild used machines to near-new condition with warranties and support programs. While more expensive than straight used purchases, they provide additional peace of mind.

At Hines Bending Systems, we understand the complexities of equipment decisions. Our expertise in bending technology – proven through installations worldwide and trusted by agencies like NASA – helps manufacturers make informed choices about their bending equipment needs.

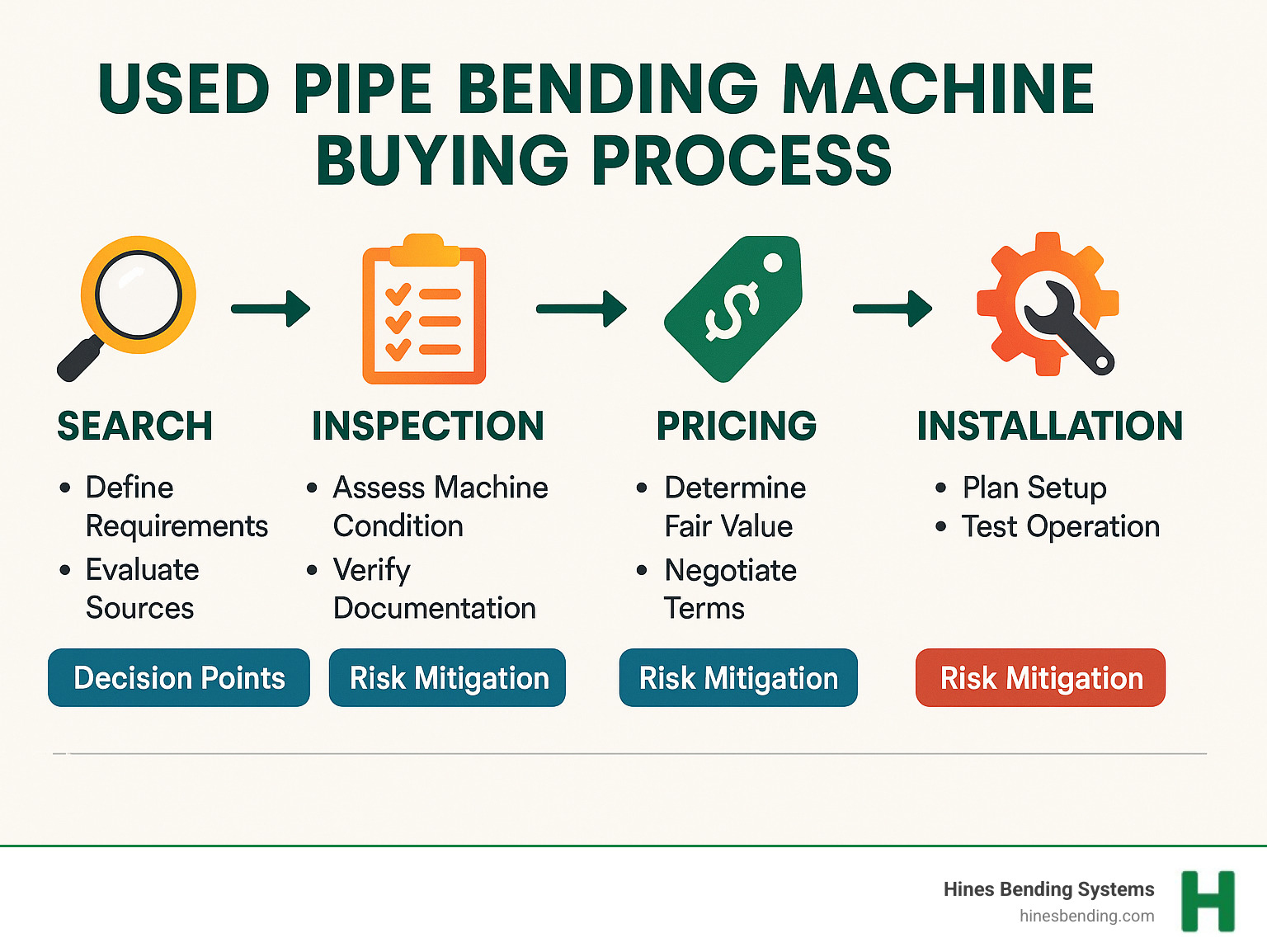

Where to Find & Evaluate Your Next used pipe bending machine

Finding the right used pipe bending machine requires knowing where to look and how to separate quality equipment from potential headaches. The secondary market has evolved dramatically, with digital platforms now dominating what was once a handshake-and-cash business.

Online marketplaces have revolutionized used equipment sales, making it easier than ever to compare options across different regions and price points. However, this convenience comes with new challenges – you can’t kick the tires or hear the machine run from behind a computer screen.

Professional machinery dealers offer the most reliable path for serious buyers. These specialists stake their reputation on equipment quality and typically perform basic inspections before listing machines. While you’ll pay slightly more than private sales, the added confidence often justifies the premium.

Industrial auctions create opportunities for significant savings, but they’re not for the faint-hearted. You’ll need cash ready and quick decision-making skills. The environment limits inspection time, and there’s rarely opportunity to test equipment under power.

Direct seller transactions through classified platforms can yield the best prices, but require more buyer diligence. These deals often involve small shops upgrading equipment or businesses closing operations.

Online sources & listings for used pipe bending machine

Machineryline stands out for its comprehensive international listings and detailed filtering system. You can search by capacity, year, location, and price range, with current listings spanning machines from 1976 to 2024. The platform’s strength lies in its professional presentation and detailed specifications.

Kijiji provides excellent access to local markets, with over 60 listings in Ontario alone showing prices from basic hand tools to industrial models reaching $26,200. The platform’s real value comes from enabling direct communication with sellers and opportunities for in-person inspection.

Machinio focuses specifically on industrial equipment with professional-grade listings and established dealer networks. Many listings feature certified dealers who offer refurbishment services and limited warranties.

While these platforms offer extensive options, we always recommend consulting with bending experts before making significant equipment investments. Our Used Pipe Bender For Sale resource provides additional guidance, though at Hines Bending Systems, our decades of experience help clients determine whether used equipment truly meets their long-term production goals.

In-person inspection & on-site testing of a used pipe bending machine

Nothing replaces running equipment under power for revealing true machine condition. Listen carefully for unusual noises, observe smooth operation cycles, and verify all functions respond correctly. Hydraulic systems should operate quietly without excessive vibration or erratic movement.

Bend radius accuracy testing requires bringing sample materials and measuring equipment. Request multiple test bends using your specific pipe dimensions and materials. Check for consistency across repeated cycles – variations often indicate worn tooling or mechanical issues.

Tool change procedures reveal important details about machine versatility and operator skill requirements. Complex setups may require extensive training or significantly impact production efficiency. Simple, intuitive tool changes generally indicate better machine design.

Noise level assessment affects both workplace safety and long-term operating costs. Excessive noise often signals worn bearings, inadequate lubrication, or mechanical problems that will require attention.

Even the best used pipe bending machine represents someone else’s solution to their specific needs. What worked perfectly for their application might not align with your production requirements, material specifications, or quality standards. This is where Hines Bending Systems’ expertise becomes invaluable – we’ve installed more bending systems worldwide than anyone else and understand how different applications stress equipment in unique ways.

Pricing, Financing & Logistics

Let’s talk numbers – because understanding the financial landscape of used pipe bending machine purchases helps you make smart decisions for your operation.

The secondary market shows clear pricing patterns that can guide your budget planning. Hand benders and manual tools represent the entry point, typically selling for under $300. You’ll find simple conduit benders available for as little as $15-$50, though these serve specialized applications rather than production work.

Mid-range hydraulic systems occupy the sweet spot for many manufacturers, commanding $1,000-$5,000 depending on capacity and condition. Those popular twelve-ton hydraulic benders we mentioned earlier? They fall right into this range and offer excellent value for medium-production applications.

CNC and programmable systems require more serious investment, ranging from $15,000-$50,000+. Some high-end units exceed $100,000, but these machines justify their cost through precision, automation, and production capacity that can transform your operation.

Current market data reveals over 200 active listings with this spread, giving buyers plenty of options across all price ranges. However, the cheapest option isn’t always the best value – especially when production demands require reliability and precision.

Typical price ranges for used pipe bending machine models

Entry-level manual benders under $300 serve hobbyists and light commercial applications perfectly. These tools make sense for small businesses tackling specialized applications like greenhouse construction or basic metalworking where volume doesn’t justify larger equipment.

Hydraulic production machines in the $1,000-$5,000 range offer substantial capacity increases over manual tools. These workhorses handle medium-production requirements and accommodate larger pipe diameters that manual tools simply can’t manage.

CNC systems starting around $15,000 provide the automation and precision that high-volume production demands. Premium used CNC benders can exceed $50,000, but they offer capabilities approaching new machine performance – without the new machine price tag.

The key is matching your budget to your actual production needs, not your wishful thinking about future growth. Better to buy the right machine for today’s requirements than struggle with inadequate equipment or overextend financially.

Financing and leasing options

Traditional bank loans provide straightforward financing for creditworthy buyers, typically offering 3-7 year terms with competitive interest rates for established businesses.

Dealer financing programs offer convenience and may include extended warranties or service packages. These programs sometimes provide more flexible terms than traditional lenders, especially for buyers with unique circumstances.

Section 179 tax benefits allow immediate deduction of equipment purchases up to annual limits. This tax advantage can significantly reduce the effective cost of used equipment purchases – essentially letting Uncle Sam help fund your productivity improvements.

Operating leases provide monthly payments with potential purchase options at lease end. This structure preserves capital while providing access to needed equipment, though total costs typically exceed direct purchase over time.

Shipping, installation & training essentials

Rigging quotes should come from certified machinery movers familiar with industrial equipment. Proper rigging prevents damage during transport and ensures safe installation – cutting corners here can turn a good deal into an expensive disaster.

Foundation requirements vary significantly by machine size and type. Hydraulic machines may require reinforced concrete foundations to handle bending forces and vibration.

Power supply specifications must match your facility capabilities. Three-phase power requirements and voltage specifications need verification before installation. Nothing’s more frustrating than having your new machine arrive only to find your electrical system can’t handle it.

Operator training becomes critical for safe and productive operation. Even experienced operators benefit from machine-specific training to maximize productivity and prevent damage. The investment in proper training pays dividends in reduced downtime and better results.

While the used equipment market offers compelling opportunities, the complexity of purchasing, financing, and installing industrial bending equipment benefits from expert guidance. At Hines Bending Systems, we’ve helped countless manufacturers steer these decisions – whether they’re buying used equipment or investing in new solutions. Our experience with installations worldwide means we understand the challenges you’ll face and can provide insights that prevent costly mistakes.

Frequently Asked Questions about Used Pipe Bending Machines

How do I know a used pipe bending machine fits my pipe diameter and bend radius?

The compatibility question keeps many buyers up at night, and rightfully so. Getting stuck with a used pipe bending machine that can’t handle your specific requirements is an expensive mistake.

Pipe diameter compatibility starts with understanding the machine’s throat depth and die capacity. Most machines clearly specify their working range – you’ll commonly find used machines handling pipes from 0.375 inches up to 2.48 inches, though larger capacity machines are available.

Bend radius capabilities vary dramatically between machine types. Manual benders typically lock you into fixed radius options determined by the die sets, while CNC systems offer variable radius control that adapts to your specific needs. The key is verifying the machine can achieve your tightest bend radius with your exact pipe material and wall thickness.

Here’s where things get tricky: die availability for ongoing production. Popular machine brands typically maintain robust die inventories, but specialized or discontinued models might leave you hunting for tooling. Factor both die costs and long-term availability into your purchase decision – sometimes a slightly more expensive machine with better tooling support saves money over time.

At Hines Bending Systems, we’ve seen countless situations where buyers focused solely on machine price without considering their complete bending requirements. Our expertise helps customers avoid these costly oversights by matching equipment capabilities to actual production needs.

What documentation should accompany a used pipe bending machine purchase?

Walking into a used pipe bending machine purchase without proper documentation is like buying a car without knowing its maintenance history. You might get lucky, but you’re gambling with your production schedule.

Operation manuals provide your foundation for safe, productive operation. Original manuals are gold, but quality reproductions or digital copies can work for basic operation. Without proper operating procedures, even experienced operators risk damaging the machine or producing substandard bends.

Maintenance records tell the real story of how the machine was treated. Look for regular service intervals, component replacements, and documentation of any major repairs. Machines with spotty maintenance histories often hide expensive surprises that surface after purchase.

Complete tooling inventory should include all die sets, mandrels, and specialized fixtures. Missing tooling can add thousands to your actual purchase cost. Get a detailed list and verify everything is present before finalizing the deal.

Electrical schematics become critical for future troubleshooting and maintenance. CNC machines particularly require complete electrical documentation for service support. Without these diagrams, simple repairs can become expensive service calls.

Software and programming information enables you to fully use the machine’s capabilities. Backup copies of programs and software licenses ensure you won’t face unexpected downtime or licensing issues.

Our experience at Hines Bending Systems shows that well-documented machines typically reflect responsible ownership and predict better long-term reliability. We always recommend thorough documentation review before any equipment purchase.

Are spare parts still available for older control systems?

This question strikes at the heart of used pipe bending machine ownership concerns. Nothing kills productivity like a machine down for parts that no longer exist.

Parts availability varies dramatically by manufacturer and control system age. Established manufacturers typically maintain better long-term parts support than smaller or discontinued brands. However, even major manufacturers eventually discontinue support for older systems.

Control system manufacturers often provide retrofit options when original parts become unavailable. These upgrades can actually improve machine capabilities while solving parts availability issues. The investment in a control retrofit often extends machine life by decades.

Third-party suppliers sometimes fill gaps when original manufacturers stop supporting older systems. These sources may offer cost-effective alternatives to original parts, though quality and compatibility require careful verification.

Specialized repair services can rebuild obsolete components when new parts aren’t available. Circuit board repair and component replacement services extend older system life, though turnaround times may be longer than stocking new parts.

Before committing to any machine with older control systems, research parts availability and potential upgrade paths. Factor these considerations into your total cost of ownership calculations.

At Hines Bending Systems, we understand the challenges of maintaining older equipment. Our decades of industry experience help customers evaluate whether used equipment makes sense for their specific situation, or whether investing in new, fully-supported systems provides better long-term value. With our track record of supplying organizations like NASA, we know the importance of reliable, supportable equipment for critical applications.

Conclusion

The used pipe bending machine market presents smart manufacturers with genuine opportunities to expand their capabilities while keeping costs manageable. With potential savings of 40-60% and immediate availability, the secondary market deserves serious consideration for many operations.

However, success in buying used equipment isn’t just about finding the lowest price. It requires careful evaluation, realistic budgeting, and most importantly, expert guidance to avoid expensive mistakes down the road.

At Hines Bending Systems, we’ve spent decades helping manufacturers make smart equipment decisions. As the world’s #1 manufacturer of tube benders, pipe benders, and induction benders, we understand that every bending challenge is unique. Our machines have earned the trust of organizations like NASA and major manufacturers worldwide—not by accident, but through consistent quality and performance.

Whether you’re exploring used equipment options or considering new solutions, our team brings best industry expertise to help you make the right choice. We don’t just sell machines; we work closely with clients to develop custom bending solutions that solve real production challenges while maximizing both productivity and quality.

Nobody in the bending industry has more experience helping manufacturers succeed. Our commitment extends far beyond the initial equipment purchase. We provide comprehensive training, ongoing support, and continuing education that transforms your team’s capabilities and improves your operation’s efficiency.

When you work with Hines Bending Systems, you’re partnering with industry leaders who genuinely care about your success. We take time to understand your specific requirements and deliver solutions that work reliably for years to come.

Ready to explore your bending equipment options? Visit our More info about used CNC bending machines resource or contact our experts directly. We’re here to help you make the best decision for your operation.

Stay connected with the latest industry insights and bending solutions: