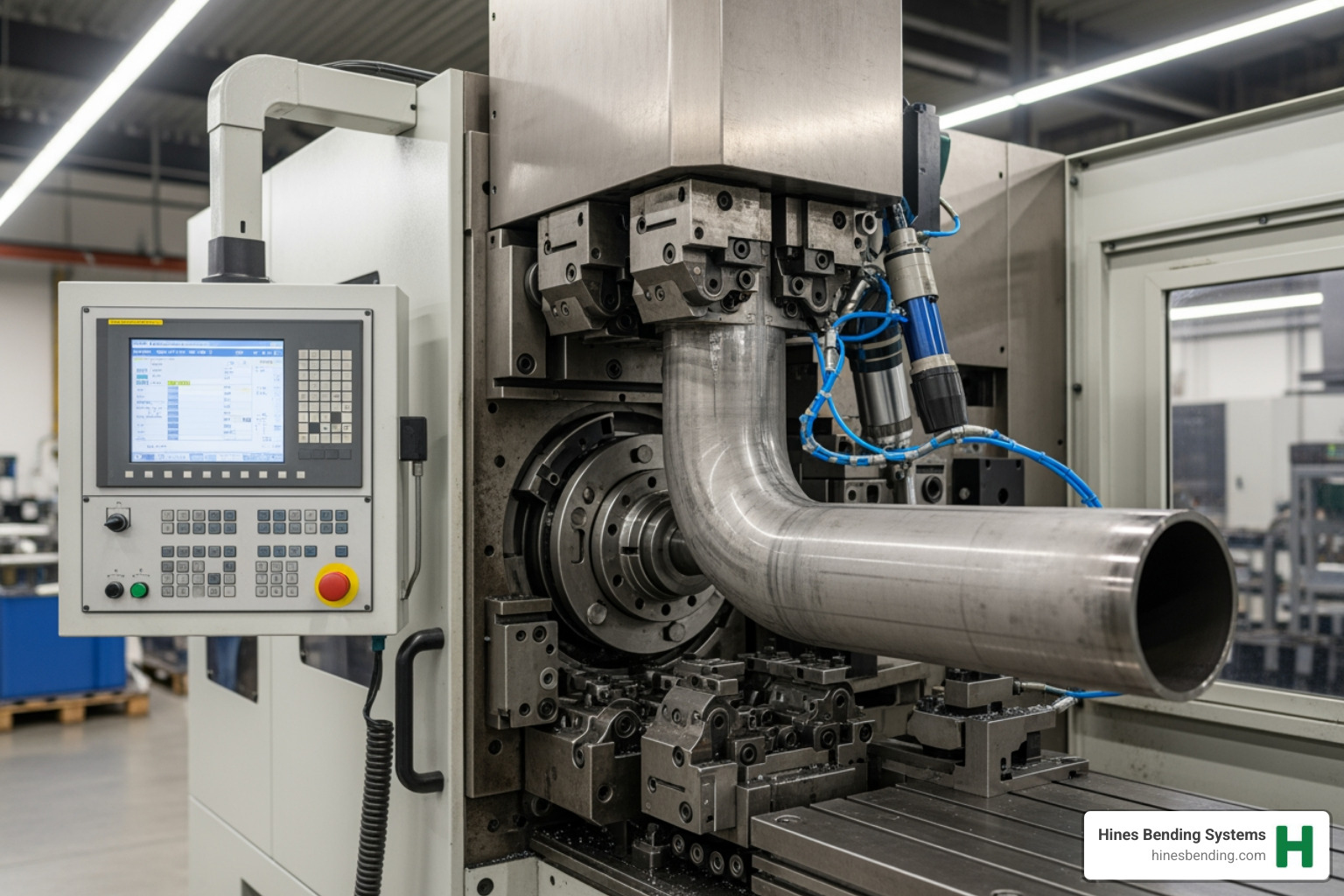

An electric nc tube bending machine is a game-changer for any manufacturing operation. It helps you achieve precise bends, reduces energy usage, and improves production capabilities.

- Precision: Achieve accurate bends every time.

- Eco-Friendly: Lower energy consumption supports sustainable goals.

- Productivity Boost: Improve production efficiency and capacity.

Hines Bending Systems leads the industry as the top worldwide manufacturer, offering the highest quality machines. Trusted by giants like NASA, Hines delivers unparalleled expertise and innovative solutions custom to your needs. Our commitment ensures precision, reliability, and support, making us the go-to choice for manufacturing experts. Whether you’re handling complex projects or seeking energy-efficient solutions, our electric NC tube bending machines are built to meet the challenge with precision and sustainability.

Understanding Electric NC Tube Bending Machines

Electric NC tube bending machines are revolutionizing the manufacturing landscape. These machines, which are numerically controlled, offer best accuracy and consistency in bending operations. Let’s explore what makes these machines a must-have for any serious production line.

Numerically Controlled Precision

At the heart of an electric NC tube bending machine is its numerical control system. This system allows operators to input exact bending specifications, ensuring each bend meets precise requirements. Whether you’re working on small or large-scale projects, the machine’s ability to replicate exact bends every time minimizes errors and waste. This precision is crucial for industries that demand high-quality standards, such as aerospace and automotive manufacturing.

Consistency in Every Bend

Consistency is key in manufacturing, and this is where electric NC tube bending machines shine. By automating the bending process, these machines ensure that every tube or pipe is bent to the exact same specifications. This level of consistency not only improves product quality but also reduces the time and cost associated with manual adjustments and rework.

Eco-Friendly Manufacturing

Sustainability is more important than ever. Electric NC tube bending machines are designed with eco-friendly manufacturing in mind. They consume significantly less energy compared to traditional bending methods, contributing to a reduction in overall energy usage. This not only helps businesses lower their carbon footprint but also reduces operational costs.

Moreover, the precision and consistency offered by these machines lead to less material waste, further enhancing their eco-friendly credentials.

Key Features of Electric NC Tube Bending Machines

Electric NC tube bending machines, especially those from Hines Bending Systems, are packed with features that make them indispensable for modern manufacturing. Let’s explore some of the standout attributes that set these machines apart and highlight why Hines is the leader in the industry.

Multi-Radius Bending

One of the most impressive capabilities of Hines’ electric NC tube bending machines is multi-radius bending. This feature allows the machine to handle complex bending tasks by accommodating multiple radii in a single setup. Whether you need a simple bend or a more intricate design, the flexibility of multi-radius bending ensures you can achieve the desired shape without needing multiple machines or setups. Hines’ expertise ensures that these machines deliver unparalleled precision and efficiency.

Fixed or Variable Radius

Flexibility is key in any manufacturing process, and Hines’ machines offer just that with their fixed or variable radius options. You can choose to use a fixed radius for consistent bends or switch to a variable radius for more complex shapes. The ability to fit up to eight tools simultaneously means you can adjust the machine to your specific needs in no time. This adaptability is crucial for industries that require diverse bending solutions without sacrificing efficiency. Hines’ commitment to custom solutions ensures that every client’s unique needs are met.

High-Quality Standards

Hines Bending Systems’ electric NC tube bending machines are designed to meet the highest quality standards. The in-process material reaction control ensures that every bend is executed with precision, resulting in high-quality appearances and minimal ovality even on small radius-to-diameter ratios. This meticulous attention to detail means you can expect perfect results from the first part, reducing waste and eliminating the need for trial and error.

Benefits of Using Electric NC Tube Bending Machines

Electric NC tube bending machines offer numerous advantages that can significantly improve your manufacturing processes. These benefits range from energy savings to increased reliability and flexibility, making them an essential tool for any production line.

Energy Savings

One of the standout benefits of electric NC tube bending machines is their ability to save energy. Unlike traditional hydraulic systems, which can be energy-intensive, these machines use electricity more efficiently. This not only reduces operational costs but also aligns with eco-friendly manufacturing practices. By choosing electric NC tube bending machines, you’re not just cutting down on energy bills—you’re also contributing to a greener planet.

Reliability

Reliability is crucial in manufacturing, and electric NC tube bending machines deliver just that. With advanced technology and precise control systems, these machines ensure consistent and accurate bends every time. This reliability reduces downtime and minimizes the risk of errors, allowing you to maintain a steady production flow. Hines Bending Systems, known for their high-quality standards, ensures that their machines are built to last, providing peace of mind and a solid return on investment.

Flexibility

Flexibility is another key advantage of using electric NC tube bending machines. These machines can handle a wide range of tube sizes and shapes, allowing you to switch between different projects with ease. The ability to adjust settings quickly means you can accommodate custom orders without extensive retooling. This adaptability is particularly valuable for businesses that need to respond swiftly to changing market demands or customer requirements.

Quick Production Changes

When it comes to manufacturing, time is money. Electric NC tube bending machines excel in making quick production changes possible. With features like automatic setup and CAD/CAM programming, these machines can be reconfigured in minutes, not hours. This rapid changeover capability reduces idle time and increases overall productivity. For companies like those served by Hines Bending Systems, this means meeting tight deadlines and maximizing output without compromising on quality.

By leveraging the energy efficiency, reliability, flexibility, and quick changeover capabilities of electric NC tube bending machines, businesses can improve their production processes and maintain a competitive edge in the market. As we explore how these machines work, you’ll see why they are a smart investment for any forward-thinking manufacturer.

How Electric NC Tube Bending Machines Work

Electric NC tube bending machines, especially those from Hines Bending Systems, are marvels of modern manufacturing. They combine CAD/CAM programming, 3D simulation, and automatic set-up to streamline the bending process and ensure precision every time. Hines Bending Systems stands out as the leader in this industry, providing unparalleled quality and expertise.

CAD/CAM Programming

Imagine designing a complex tube shape on your computer and then watching it come to life with just a click. That’s the power of CAD/CAM programming in electric NC tube bending machines from Hines. This technology allows you to design parts with exact specifications and then seamlessly translate those designs into machine instructions. It’s like turning your computer into a powerful bending assistant!

With CAD/CAM, you can store a library of designs, making it easy to find and reuse them. This not only saves time but also ensures consistency across production runs. Whether you’re an experienced engineer or new to the field, CAD/CAM makes programming so simple that anyone can become an expert. Hines’ commitment to innovation ensures that their CAD/CAM systems are always at the cutting edge.

3D Simulation

Before any metal is bent, you can visualize the entire process with 3D simulation. This feature allows you to see how the tube will bend and fit into its intended application—all in a virtual environment. It’s like having a crystal ball that shows you the future of your project!

3D simulation helps catch potential errors before they become costly mistakes. You can tweak designs, adjust angles, and see the results instantly. This not only improves accuracy but also boosts confidence in the final product. With Hines’ advanced 3D simulation, you know exactly what you’re getting before the machine even starts, ensuring the highest quality and precision.

Automatic Set-Up

Gone are the days of manual adjustments and lengthy set-up times. Electric NC tube bending machines from Hines offer automatic set-up, which means the machine prepares itself for the next job with minimal human intervention. It’s like having a self-organizing workspace that gets everything ready for you!

This feature enables quick production changes, allowing you to switch projects without losing time. Automatic set-up means less downtime and more productivity, making it ideal for businesses that need to stay agile and responsive to market demands. Hines’ machines are designed to maximize efficiency and productivity, setting them apart as the best choice in the industry.

Incorporating CAD/CAM programming, 3D simulation, and automatic set-up, electric NC tube bending machines from Hines Bending Systems provide a seamless, efficient, and precise bending process. These technologies work together to ensure that each bend is perfect, every single time. Understanding these features will show why Hines Bending Systems is the indispensable choice in modern manufacturing.

Frequently Asked Questions about Electric NC Tube Bending Machines

What is the difference between NC and CNC tube benders?

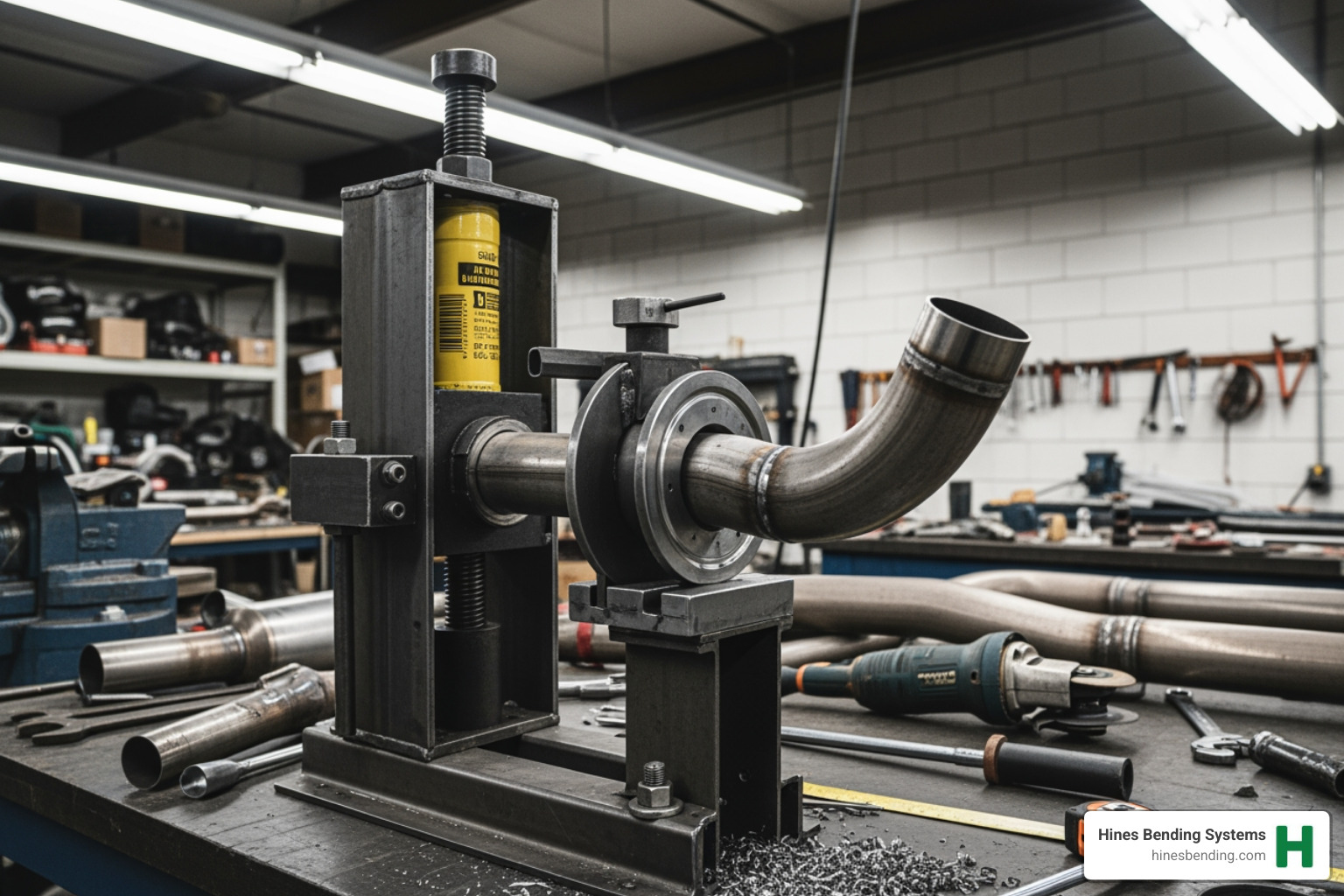

When it comes to tube bending, understanding the difference between NC (Numerically Controlled) and CNC (Computer Numerical Control) machines is crucial. NC tube benders, like those offered by Hines Bending Systems, are semi-automatic. They require the operator to manually input the degree of bend for each tube. This type of machine is excellent for projects that need precise but straightforward bends and is more cost-effective for smaller operations.

On the other hand, CNC tube benders provide more automation and are fully computerized. They can handle complex bends with multiple angles in a single setup. The choice between NC and CNC often depends on the complexity of the project and budget considerations. For those who need high precision with less manual input, CNC might be the way to go. However, for straightforward bending tasks, NC machines are more than capable.

How do electric NC tube benders save energy?

Electric NC tube benders, such as those from Hines Bending Systems, are designed with energy efficiency in mind. Unlike traditional hydraulic benders, electric models consume significantly less energy. This is because they use electric motors that only draw power when needed, reducing unnecessary energy consumption.

Furthermore, these machines often feature energy-saving modes that optimize power usage during idle times. The reduced energy consumption not only lowers operating costs but also aligns with eco-friendly manufacturing practices. By choosing an electric NC tube bender from Hines Bending Systems, you’re not only investing in quality but also contributing to a sustainable future.

Can electric NC tube benders handle complex geometries?

Yes, electric NC tube benders from Hines Bending Systems are well-equipped to handle complex geometries. Thanks to their advanced programming capabilities, these machines can bend tubes into intricate shapes with precision. The automatic set-up and 3D simulation features allow operators to visualize and adjust complex bends before execution, ensuring accuracy.

Moreover, the ability to program multiple bends into a single piece allows for the creation of sophisticated tube shapes that were once thought impossible. Whether it’s for prototyping or full-scale production, electric NC tube benders from Hines Bending Systems provide the flexibility needed to tackle challenging projects with ease.

By addressing these common questions, it’s clear that electric NC tube bending machines from Hines Bending Systems offer a blend of precision, efficiency, and sustainability. As we dig further, we’ll explore how these machines can transform your production capabilities.

Conclusion

In tube bending, finding the right partner is crucial. That’s where Hines Bending Systems comes in. As the global leader in tube, pipe, and induction bending, we deliver optimal bending solutions custom to meet your specific needs.

Our extensive expertise and experience set us apart. With the highest number of bender installations worldwide, we understand the intricacies of bending like no other. Whether you’re dealing with simple bends or complex geometries, our electric NC tube bending machines are designed to handle it all with precision and efficiency.

We take pride in our commitment to quality and innovation. Our machines are not just tools; they’re investments in your production capabilities. By choosing Hines, you’re opting for reliability, flexibility, and sustainable energy use, all wrapped in one package.

But don’t just take our word for it. Our partnership with esteemed organizations like NASA speaks volumes about our credibility and the trust our clients place in us. We work closely with each client to ensure that our solutions meet the highest standards and are customized to fit their unique requirements.

Ready to lift your production capabilities with the best in the industry? Find more about our NC bending machines and how they can transform your operations. Join us in leading the future of tube bending with best expertise and cutting-edge technology.

Hines Bending Systems has been a trusted name since 1975. Manufacturers of tube and pipe bending machines In the industry. We produce the best quality tube and pipe bend machines, and we offer both new and used models. Used tube and pipe bending machines available for sale. Call us today to speak to an expert representative who can help you select the best exhaust bending machine for your shop.